Ultrahigh Carbon Nanotube Volume Fraction Effects on Micromechanical Quasi-Static & Dynamic Properties of Poly(Urethane-Urea) Filled Nanocomposites †

Abstract

1. Introduction

2. Methods

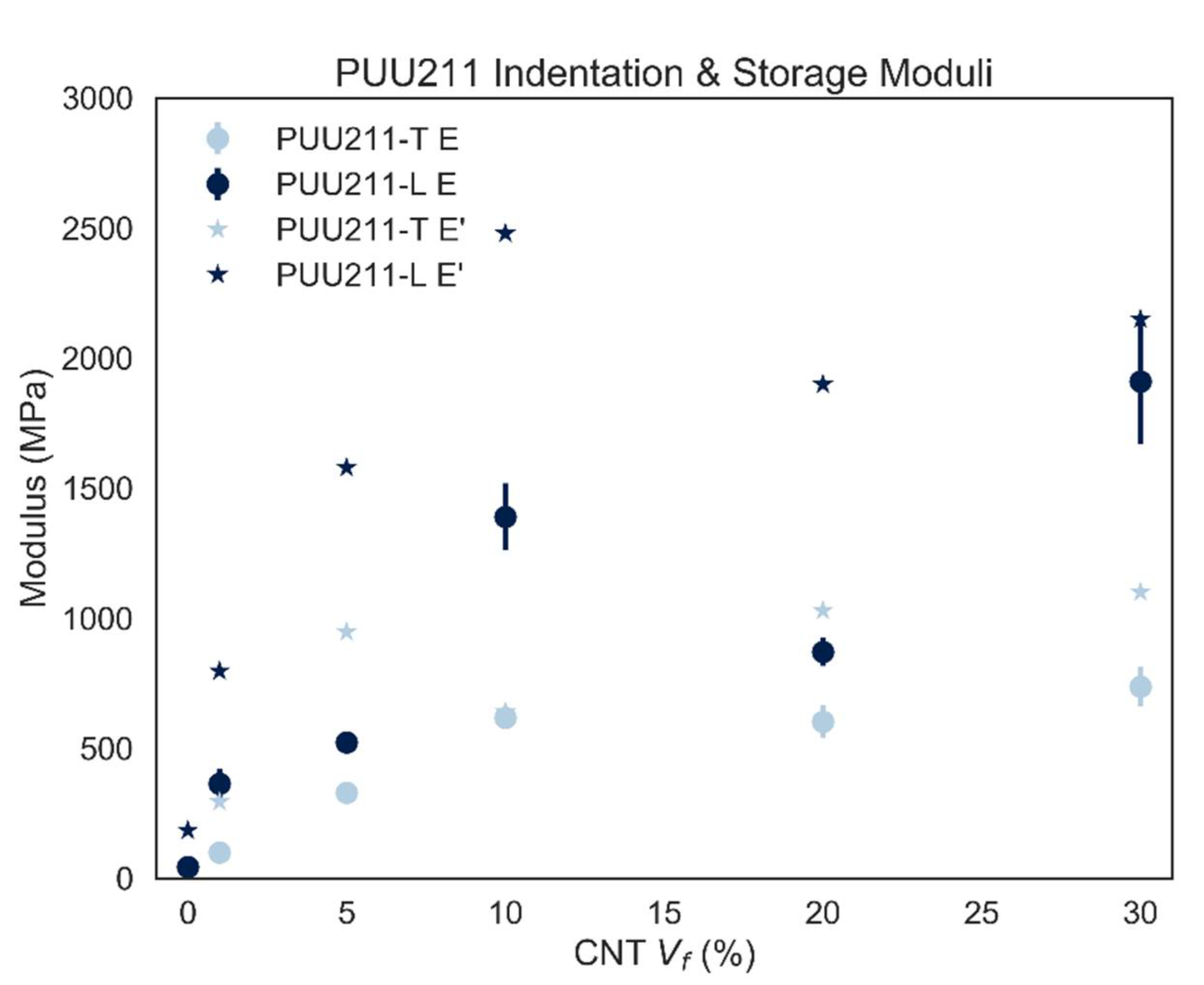

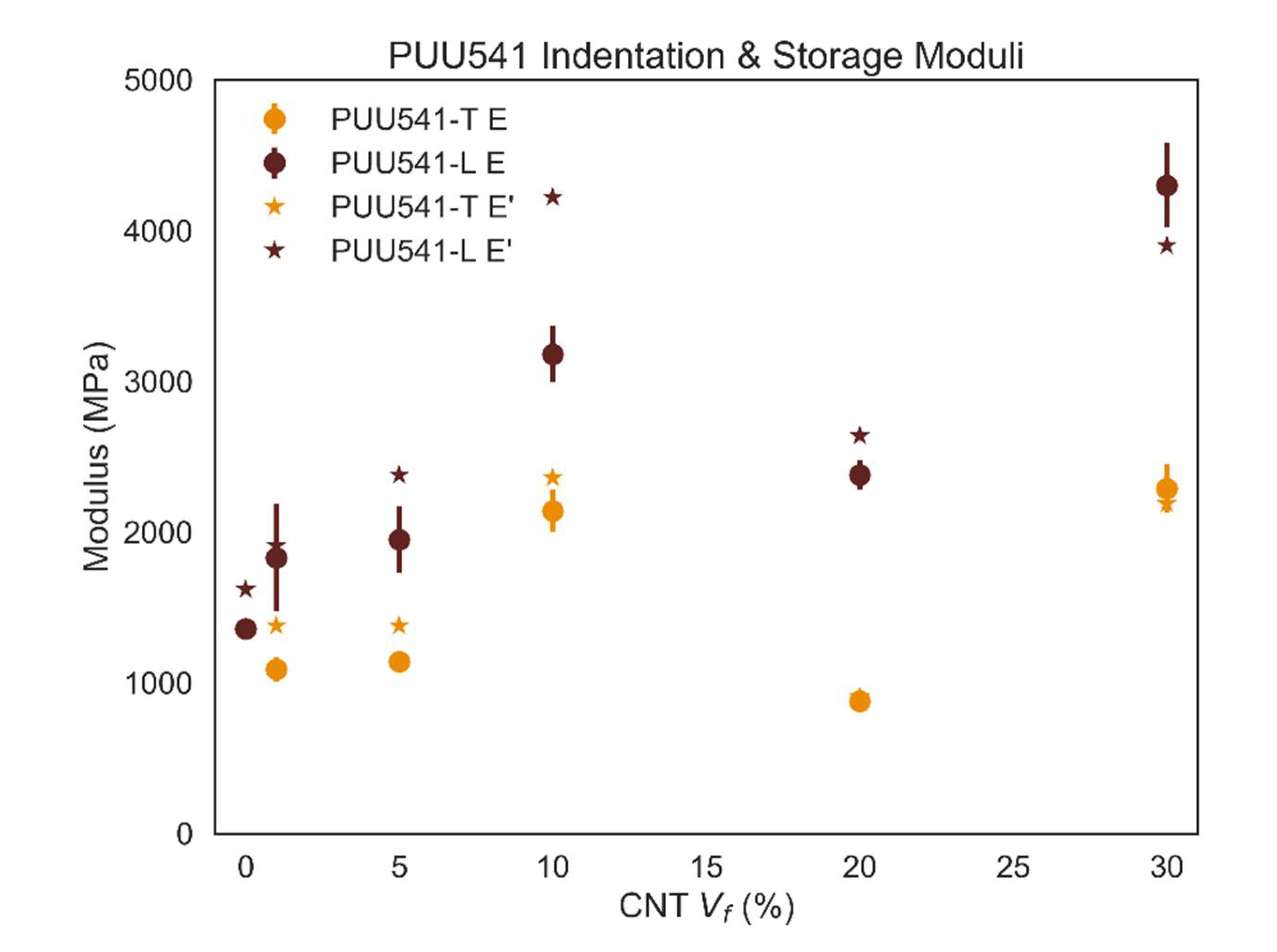

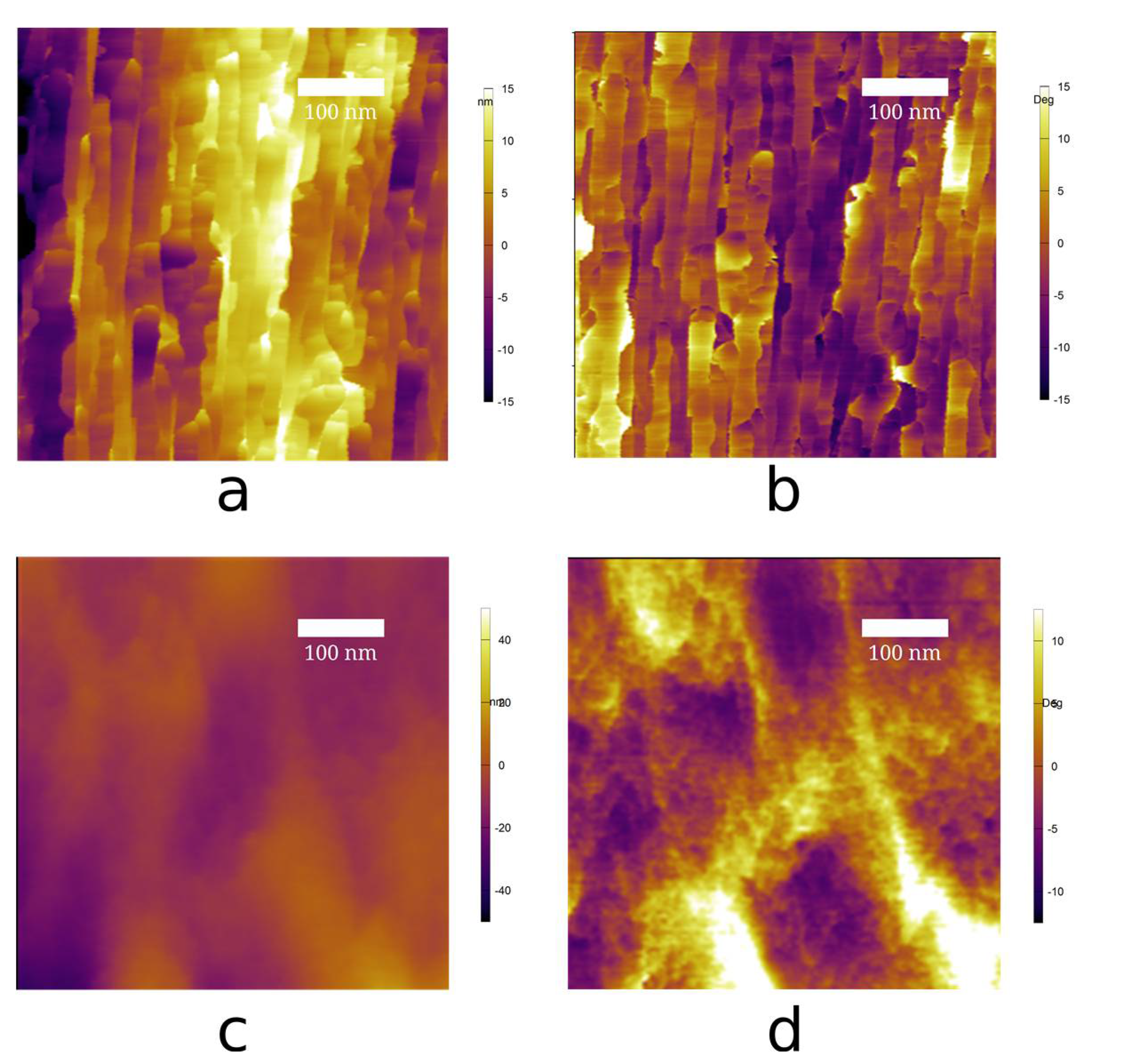

3. Results & Discussion

4. Conclusions

Author Contributions

Acknowledgments

References

- Yamamoto, N.; Hart, A.J.; Garcia, E.J.; Wicks, S.S.; Duong, H.M.; Slocum, A.H.; Wardle, B.L. High-yield growth and morphology control of aligned carbon nanotubes on ceramic fibers for multifunctional enhancement of structural composites. Carbon N. Y. 2009, 47, 551–560. [Google Scholar] [CrossRef]

- Li, R.; Lachman, N.; Florin, P.; Wagner, H.D.; Wardle, B.L. Hierarchical carbon nanotube carbon fiber unidirectional composites with preserved tensile and interfacial properties. Compos. Sci. Technol. 2015, 117, 139–145. [Google Scholar] [CrossRef]

- Wang, T.L.; Yu, C.C.; Yang, C.H.; Shieh, Y.T.; Tsai, Y.Z.; Wang, N.F. Preparation, characterization, and properties of polyurethane-grafted multiwalled carbon nanotubes and derived polyurethane nanocomposites. J. Nanomater. 2011, 2011, 7. [Google Scholar] [CrossRef][Green Version]

- Xu, M.; Zhang, T.; Gu, B.; Wu, J.; Chen, Q. Synthesis and Properties of Novel Polyurethane—Urea/Multiwalled Carbon Nanotube Composites. Macromolecules 2006, 39, 3540–3545. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, B.; Gao, Z.; Chen, C.; Zhao, S.; Qin, Y. Functionalization of multiwalled carbon nanotubes with uniform polyurea coatings by molecular layer deposition. Carbon N. Y. 2015, 82, 470–478. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Manas-Zloczower, I. Understanding phase separation and morphology in thermoplastic polyurethanes nanocomposites. Polymer 2016, 90, 256–263. [Google Scholar] [CrossRef]

- Wu, H.L.; Wang, C.H.; Ma, C.C.M.; Chiu, Y.C.; Chiang, M.T.; Chiang, C.L. Preparations and properties of maleic acid and maleic anhydride functionalized multiwall carbon nanotube/poly(urea urethane) nanocomposites. Compos. Sci. Technol. 2007, 67, 1854–1860. [Google Scholar] [CrossRef]

- Patton, S.T.; Frasca, A.J.; Hu, J.; Varshney, V.; Phillips, B.S.; Roy, A.K.; Voevodin, A.A. Multiphysics characterization of multi-walled carbon nanotube thermoplastic polyurethane polymer nanocomposites during compression. Carbon N. Y. 2016, 98, 638–648. [Google Scholar] [CrossRef]

- Fernández-d’Arlas, B.; Khan, U.; Rueda, L.; Coleman, J.N.; Mondragon, I.; Corcuera, M.A.; Eceiza, A. Influence of hard segment content and nature on polyurethane/multiwalled carbon nanotube composites. Compos. Sci. Technol. 2011, 71, 1030–1038. [Google Scholar] [CrossRef]

- Wardle, B.L.; Saito, D.S.; García, E.J.; Hart, A.J.; De Villoria, R.G.; Verploegen, E.A. Fabrication and characterization of ultrahigh-volume-fraction aligned carbon nanotube-polymer composites. Adv. Mater. 2008, 20, 2707–2714. [Google Scholar] [CrossRef] [PubMed]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W. Stress–strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Chantawansri, T.L.; Sliozberg, Y.R.; Andzelm, J.W.; Hsieh, A.J. Coarse-grained modeling of model poly(urethane urea)s: Microstructure and interface aspects. Polymer 2012, 53, 4512–4524. [Google Scholar] [CrossRef]

- Strawhecker, K.E.; Hsieh, A.J.; Chantawansri, T.L.; Kalcioglu, Z.I.; Van Vliet, K.J. Influence of microstructure on micro-/nano-mechanical measurements of select model transparent poly(urethane urea) elastomers. Polymer 2013, 54, 901–908. [Google Scholar] [CrossRef]

- Hsieh, A.J.; Orlicki, J.A.; Beyer, R.L. Molecular Design of Novel Poly (Urethane-Urea) Hybrids as Helmet Pads for Ballistic and Blast Trauma Mitigation; ARL Technical Reports; Army Research Laboratory: Aberdeen Proving Ground, MD, USA, 2105. [Google Scholar]

- Primeaux, D.J. Polyurea vs. In Polyurethane & Polyurethane/Polyurea: What’s the Difference? In Proceedings of the Polyurea Linings Annual Conference, Polyurea Development Assocaition (PDA), Tampa, FL, USA, 2–4 March 2004. [Google Scholar]

- Kantheti, S.; Gaddam, R.R.; Narayan, R.; Raju, K.V.S.N. Hyperbranched polyol decorated carbon nanotube by click chemistry for functional polyurethane urea hybrid composites. RSC Adv. 2014, 4, 24420–24427. [Google Scholar] [CrossRef]

- Gair, J.L.; Lambeth, R.H.; Cole, D.P.; Lidston, D.L.; Hsieh, A.J.; Bruck, H.A.; Bundy; Wardle, B.L. Tunable Poly(Urethane-Urea) Based Aligned Carbon-Nanotube Polymer Nanocomposites. In Proceedings of the 21 st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Gair, J.L.; Lambeth, R.H.; Cole, D.P.; Lidston, D.L.; Stein, I.Y.; Kalfon-Cohen, E.; Hsieh, A.J.; Bruck, H.A.; Bundy, M.L.; Wardle, B.L. Strong Process-Structure Interaction in Stoveable Pol(Urethane-Urea) Aligned Carbon Nanotube Nanocomposites. Compos. Sci. Technol. 2018. submitted. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gair, Jr., J.L.; Lidston, D.L.; Cole, D.P.; Lambeth, R.H.; Hsieh, A.J.; Bruck, H.A.; Hall, A.J.; Bundy, M.L.; Wardle, B.L. Ultrahigh Carbon Nanotube Volume Fraction Effects on Micromechanical Quasi-Static & Dynamic Properties of Poly(Urethane-Urea) Filled Nanocomposites. Proceedings 2018, 2, 398. https://doi.org/10.3390/ICEM18-05228

Gair, Jr. JL, Lidston DL, Cole DP, Lambeth RH, Hsieh AJ, Bruck HA, Hall AJ, Bundy ML, Wardle BL. Ultrahigh Carbon Nanotube Volume Fraction Effects on Micromechanical Quasi-Static & Dynamic Properties of Poly(Urethane-Urea) Filled Nanocomposites. Proceedings. 2018; 2(8):398. https://doi.org/10.3390/ICEM18-05228

Chicago/Turabian StyleGair, Jr., Jeffrey L., Dale L. Lidston, Daniel P. Cole, Robert H. Lambeth, Alex J. Hsieh, Hugh A. Bruck, Asha J. Hall, Mark L. Bundy, and Brian L. Wardle. 2018. "Ultrahigh Carbon Nanotube Volume Fraction Effects on Micromechanical Quasi-Static & Dynamic Properties of Poly(Urethane-Urea) Filled Nanocomposites" Proceedings 2, no. 8: 398. https://doi.org/10.3390/ICEM18-05228

APA StyleGair, Jr., J. L., Lidston, D. L., Cole, D. P., Lambeth, R. H., Hsieh, A. J., Bruck, H. A., Hall, A. J., Bundy, M. L., & Wardle, B. L. (2018). Ultrahigh Carbon Nanotube Volume Fraction Effects on Micromechanical Quasi-Static & Dynamic Properties of Poly(Urethane-Urea) Filled Nanocomposites. Proceedings, 2(8), 398. https://doi.org/10.3390/ICEM18-05228