Performance Analysis of Single Glazed Solar PVT Air Collector in the Climatic Condition of NE India †

Abstract

:1. Introduction

2. Methodology

- ⮚

- Heat transfer process is one dimensional.

- ⮚

- The heat capacity of PVT collector system is negligible.

- ⮚

- The system is in quasi-steady state.

- ⮚

- The ohmic and recombination losses in the solar cell are negligible.

2.1. Energy Analysis

2.2. Exergy Analysis

3. Model Analysis

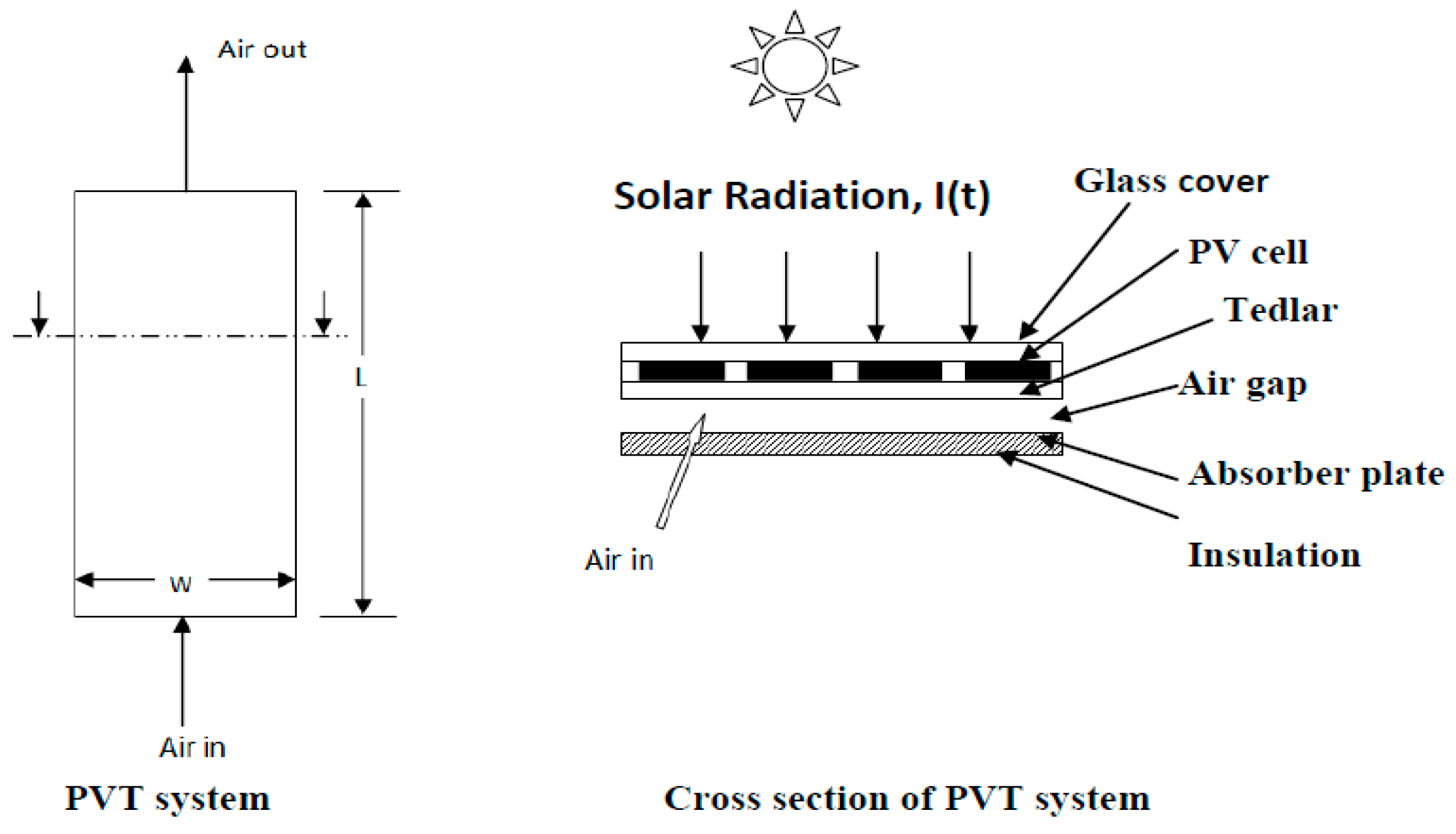

3.1. Physical Model of PVT System

3.2. Location of the Study

4. Analysis

- (i)

- (ii)

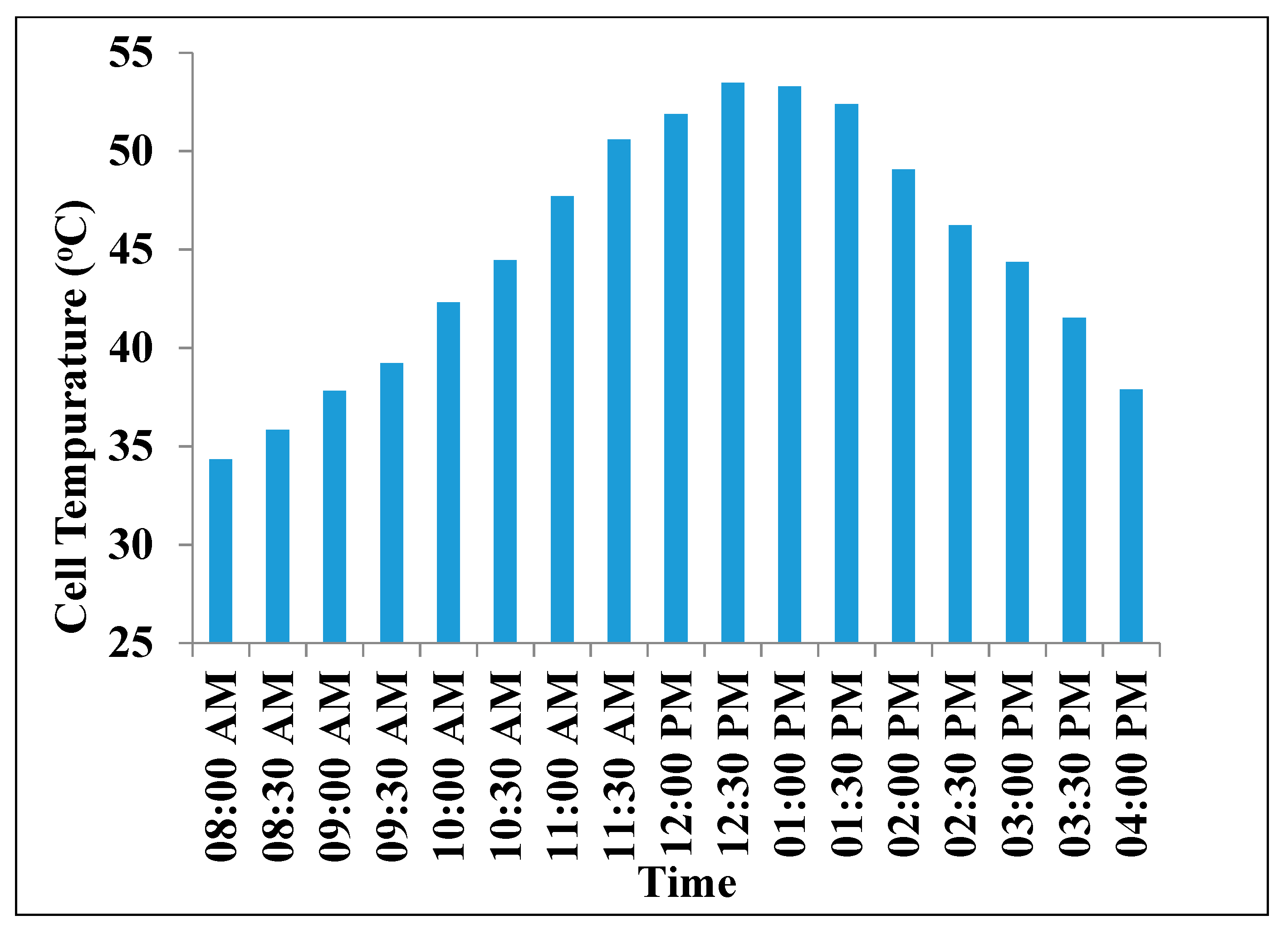

- The PV cell temperature is obtained by inserting the climatic data and the back surface temperature of PV cell in Equation (1).

- (iii)

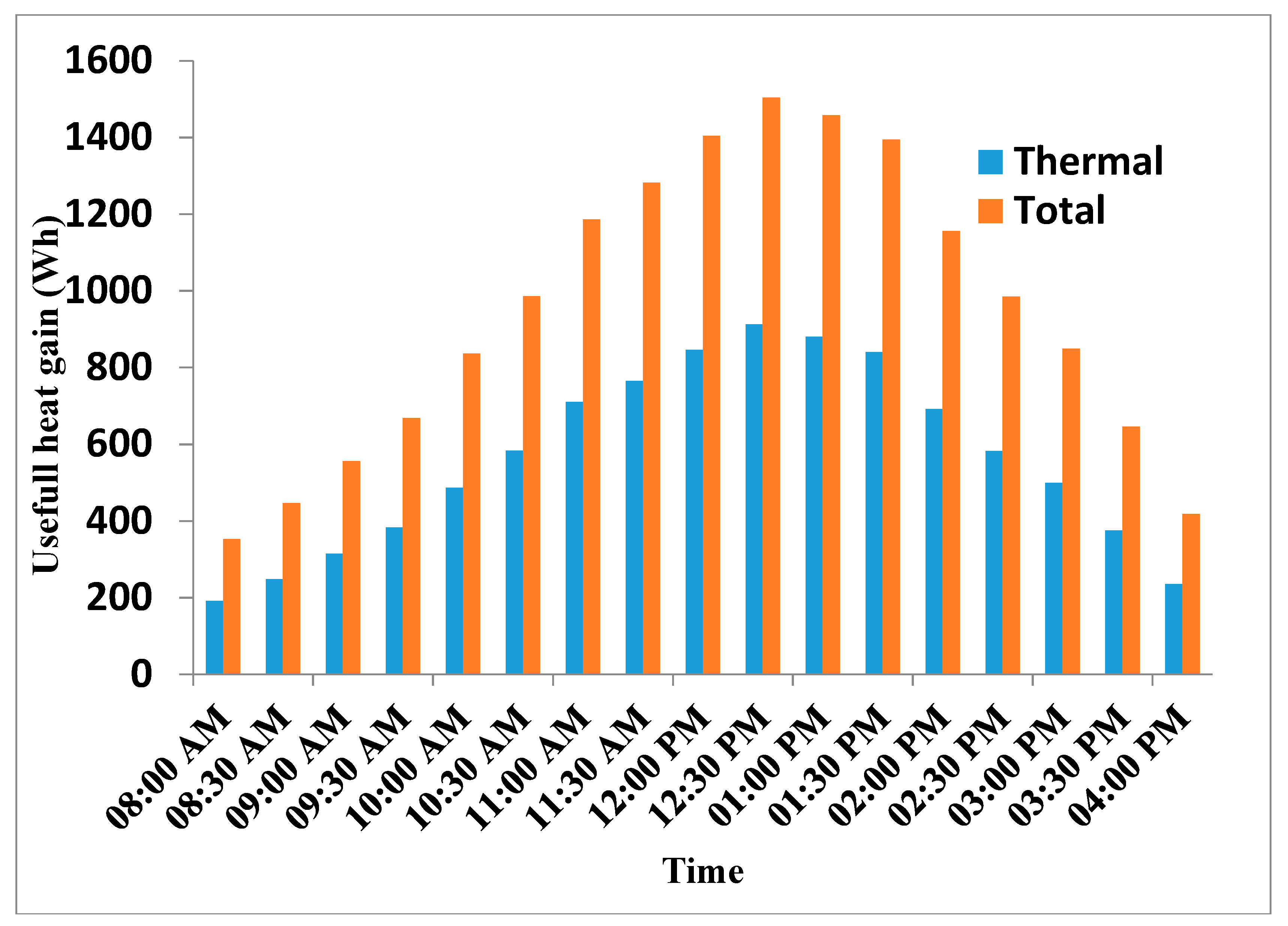

- The magnitude of the useful heat gain is obtained by inserting the inlet fluid temperature and the climatic data in Equation (4).

- (iv)

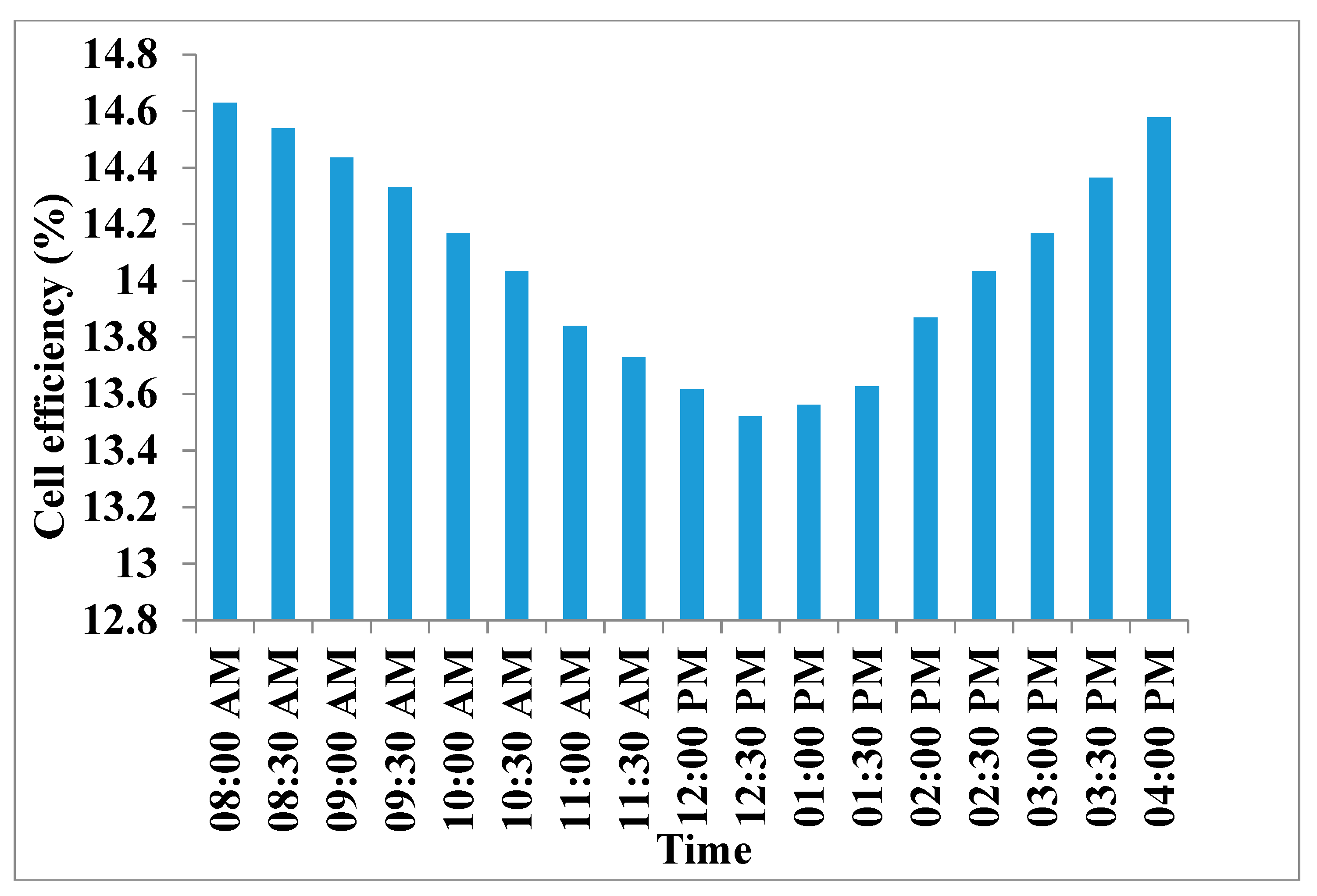

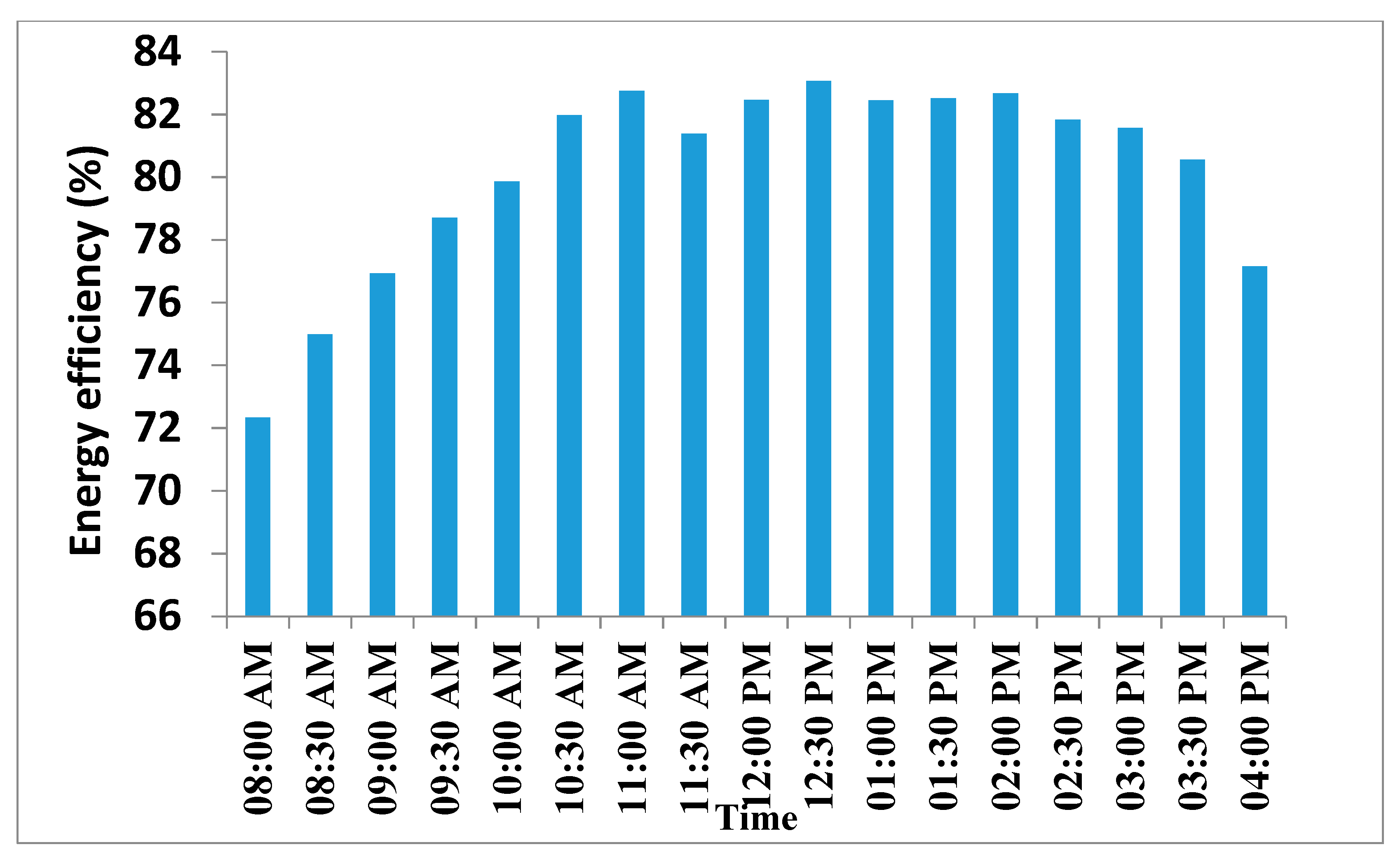

- The temperature dependent electrical efficiency is obtained by using the climatic data and the conversion efficiency of the PV cell () in Equation (5).

- (v)

- The instantaneous thermal efficiency is obtained by using the useful heat gain , the design data and the climatic data in Equation (7).

- (vi)

- The exergy inlet is obtained by using the climatic data in Equation (11).

- (vii)

- The exergy outlet is obtained by using the climatic data and the overall useful heat gain and electrical exergy in Equation (12).

- (viii)

- Finally the exergy efficiency is obtained by using the exergy inlet and exergy outlet in Equation (13).

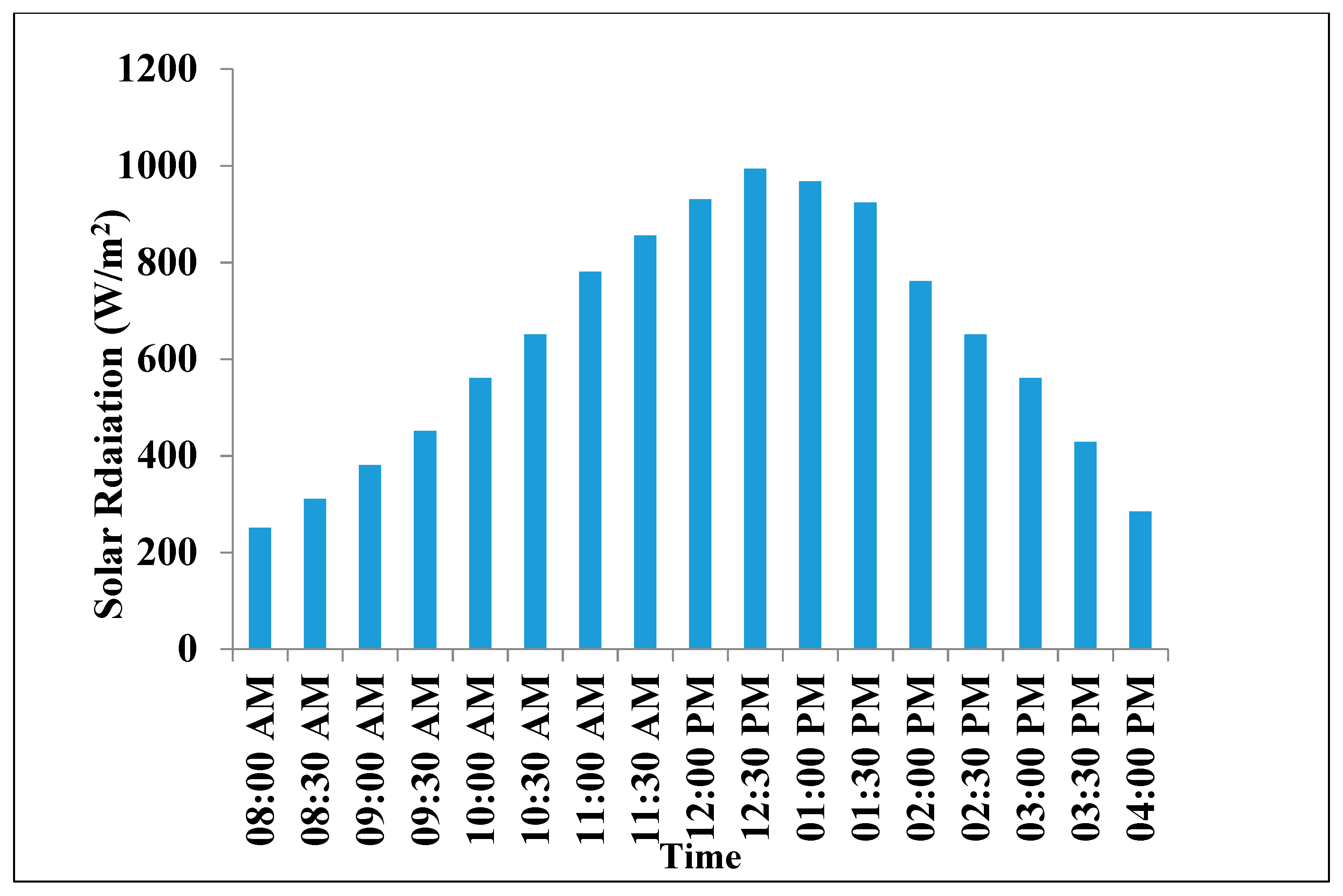

5. Results and Discussions

6. Conclusions

Acknowledgments

Abbreviations

| A | Area of module (m2) |

| w | Width of module (m) |

| Cf | Specific heat of air (J/kg K) |

| FR | Heat removal factor |

| hp1 | Penalty factor due to tedlar of PV module |

| hp2 | Penalty factor due to glass of PV module |

| hT | Convective heat transfer coefficient from the tedlar back surface to the working fluid, i.e., air (W/m2K) |

| L | Length of module (m) |

| LT | Thermodynamic loss (kW·h) |

| mf | Air mass flow rate (kg/s) |

| Qu | Useful heat (W) |

| T | Temperature (K) |

| U | Overall heat transfer coefficient (W/m2 K) |

| UI | Estimation of internal uncertainty |

| UT | Convective heat transfer coefficient through the tedlar (W/m2K) |

| Ub | Overall heat transfer coefficient from flowing fluid to ambient (W/m2 K) |

| Utc,a | Overall heat transfer coefficient between solar cell to ambient through glass cover (W/m2 K) |

| Greek letters | |

| Absorptivity | |

| Product of effective absorptivity and transmittivity | |

| Packing factor | |

| Temperature coefficient of efficiency (1/K) | |

| Transmittivity | |

| Efficiency of solar cell at standard test condition (%) | |

| Temperature dependent efficiency (%) | |

| Density (kg/m3) | |

| Subscripts | |

| a | Ambient |

| bs | Base |

| c | Solar cell |

| eff | Effective |

| f | Fluid (air) |

| fi | Inlet fluid |

| fo | Outgoing fluid |

| g | Glass |

| s | Sun |

| T | Tedlar |

| tc | Tedlar to cell |

References

- Sahota, L.; Tiwari, G.N. Review on series connected photovoltaic thermal (PVT) systems: Analytical and experimental studies. Sol. Energy 2017, 150, 96–127. [Google Scholar] [CrossRef]

- Bhargava, A.K.; Garg, H.P.; Agrawal, R.K. Study of a hybrid solar system-solar air heater combined with solar cells. Energy Convers. Manag. 1991, 31, 471–479. [Google Scholar] [CrossRef]

- Sopian, K.; Yigit, K.S.; Liu, H.T.; Kakaç, S.; Veziroglu, T.N. Performance analysis of photovoltaic thermal air heaters. Energy Convers. Manag. 1996, 37, 1657–1670. [Google Scholar] [CrossRef]

- Garg, H.P.; Adhikari, R.S. Conventional hybrid photovoltaic/thermal (PV/T) air heating collectors: Steady-state simulation. Renew. Energy 1997, 11, 363–385. [Google Scholar] [CrossRef]

- Hegazy, A.A. Comparative study of the performances of four photovoltaic/thermal solar air collectors. Energy Convers. Manag. 2000, 41, 861–881. [Google Scholar] [CrossRef]

- Othman, M.Y.H.; Ruslan, H.; Sopian, K.; Jin, G.L. Performance study of photovoltaic-thermal (PV/T) solar collector with del-grooved absorber plate. Sains Malays. 2009, 38, 537–541. [Google Scholar]

- Kim, J.H.; Kim, J.T. Comparison of Electrical and Thermal Performances of Glazed and Unglazed PVT Collectors. Int. J. Photoenergy 2012. [Google Scholar] [CrossRef]

- Tonui, J.K.; Tripanagnostopoulos, Y. Air-cooled PVT solar collectors with low-cost performance improvements. Sol. Energy 2007, 81, 498–511. [Google Scholar] [CrossRef]

- Raman, V.; Tiwari, G.N. Life cycle cost analysis of HPVT air collector under different Indian climatic conditions. Energy Policy 2008, 36, 603–611. [Google Scholar] [CrossRef]

- Dubey, S.; Sandhu, G.S.; Tiwari, G.N. Analytical expression for electrical efficiency of PV/T hybrid air collector. Appl. Energy 2009, 86, 697–705. [Google Scholar] [CrossRef]

- Farshchimonfared, M.; Bilbao, J.I.; Sproul, A.B. Full optimisation and sensitivity analysis of a photovoltaic—Thermal (PV/T) air system linked to a typical residential building. Sol. Energy 2016, 136, 15–22. [Google Scholar] [CrossRef]

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A.; Adeli, M.M. An improved thermal and electrical model for a solar photovoltaic thermal (PV/T) air collector. Appl. Energy 2010, 87, 2328–2339. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, A. Experimental validation of micro-channel solar cell thermal tile. Sol. Energy 2011, 85, 3046–3056. [Google Scholar] [CrossRef]

- Hussain, F.; Othman, M.Y.H.; Yatim, B.; Ruslan, H.; Sopian, K.; Anuar, Z.; Khairuddin, S. An improved design of photovoltaic/thermal solar collector. Sol. Energy 2015, 122, 885–891. [Google Scholar] [CrossRef]

- Khelifa, A.; Touafek, K.; BenMoussa, H.; Tabet, I.; Bencheikh, H.; Haloui, H. Analysis of a hybrid solar collector photovoltaic thermal (PVT). Energy Procedia 2015, 74, 835–843. [Google Scholar] [CrossRef]

- Yang, T.; Athienitis, A.K. Experimental investigation of a two-inlet air-based building integrated photovoltaic/thermal (BIPV/T) system. Appl. Energy 2015, 159, 70–79. [Google Scholar] [CrossRef]

- Pauly, L.; Rekha, L.; Vazhappilly, C.V.; Melvinraj, C.R. Numerical Simulation for Solar Hybrid Photovoltaic Thermal Air Collector. Procedia Technol. 2016, 24, 513–522. [Google Scholar]

- Mojumder, J.C.; Chong, W.T.; Ong, H.W.; Leong, K.Y.; Mamoon, A.A. An experimental investigation on performance analysis of air type photovoltaic thermal collector system integrated with cooling fins design. Energy Build. 2016, 130, 272–285. [Google Scholar] [CrossRef]

- Dimri, N.; Tiwari, A.; Tiwari, G.N. Thermal modelling of semitransparent photovoltaic thermal (PVT) with thermoelectric cooler (TEC) collector. Energy Convers. Manag. 2017, 146, 68–77. [Google Scholar] [CrossRef]

- Ooshaksaraei, P.; Sopian, K.; Zaidi, S.H.; Zulkifli, R. Performance of four air-based photovoltaic thermal collectors configurations with bifacial solar cells. Renew. Energy 2017, 102, 279–293. [Google Scholar] [CrossRef]

- Slimani, M.; Amirat, M.; Kurucz, I.; Bahria, S.; Hamidat, A.; Chaouch, W.B. A detailed thermal-electrical model of three photovoltaic/thermal (PV/T) hybrid air collectors and photovoltaic (PV) module: Comparative study under Algiers climatic conditions. Energy Convers. Manag. 2017, 133, 458–476. [Google Scholar] [CrossRef]

- Kamthania, D.; Nayak, S.; Tiwari, G.N. Energy and exergy analysis of a hybrid photovoltaic thermal double pass air collector. Appl. Sol. Energy 2011, 47, 199–206. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, A. Overall energy, exergy, and carbon credit analysis by different types of hybrid photovoltaic thermal air collectors. Energy Convers. Manag. 2013, 65, 628–636. [Google Scholar] [CrossRef]

- Dubey, S.; Tiwari, G.N. Energy and exergy analysis of different configuration of flat plate collectors connected in series. Int. J. Energy Res. 2009, 32, 1362–1372. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, G.N. Exergoeconomic analysis of glazed hybrid photovoltaic thermal module air collector. Sol. Energy 2012, 86, 2826–2838. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, A. Energy and exergy analysis of hybrid micro-channel photovoltaic thermal module. Sol. Energy 2011, 85, 356–370. [Google Scholar] [CrossRef]

- Bahrehmand, D.; Ameri, M.; Gholampour, M. Energy and exergy analysis of different solar air collector systems with forced convection. Renew. Energy 2015, 83, 1119–1130. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| (m2) | 0.61 | 0.375 | |

| w (m) | 0.54 | 0.965 | |

| (J/kgK) | 1012 | (W/mK) | 66 |

| (°C) | 25 | (W/mK) | 11.4 |

| 0.9 | (W/mK) | 9.72 | |

| 0.0045 | (W/mK) | 5.62 | |

| 1 | (W/mK) | 11.4 | |

| 0.15 | 0.95 | ||

| 0.95 | 0.95 | ||

| (kg/s) | 0.0108 | 0.5 | |

| (W/mK) | 1.1 | FR | 0.90 |

| (m) | 0.003 | (W/mK) | 10.3 |

| (W/mK) | 4.03 | L (m) | 1.12 |

| (W/mK) | 2.94 | (W/mK) | 9.83 |

| Parameters | Value |

|---|---|

| (°C) | 25 |

| (W/m·K) | 10.3 |

| Ts (K) | 5778 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, B.; Rezaie, B.; Jha, P.; Gupta, R. Performance Analysis of Single Glazed Solar PVT Air Collector in the Climatic Condition of NE India. Proceedings 2018, 2, 171. https://doi.org/10.3390/ecea-4-05021

Das B, Rezaie B, Jha P, Gupta R. Performance Analysis of Single Glazed Solar PVT Air Collector in the Climatic Condition of NE India. Proceedings. 2018; 2(4):171. https://doi.org/10.3390/ecea-4-05021

Chicago/Turabian StyleDas, Biplab, Behnaz Rezaie, Prabhakar Jha, and Rajat Gupta. 2018. "Performance Analysis of Single Glazed Solar PVT Air Collector in the Climatic Condition of NE India" Proceedings 2, no. 4: 171. https://doi.org/10.3390/ecea-4-05021

APA StyleDas, B., Rezaie, B., Jha, P., & Gupta, R. (2018). Performance Analysis of Single Glazed Solar PVT Air Collector in the Climatic Condition of NE India. Proceedings, 2(4), 171. https://doi.org/10.3390/ecea-4-05021