The Alignment Method for Linear Scale Projection Lithography Based on CCD Image Analysis †

Abstract

:1. Introduction

2. Method

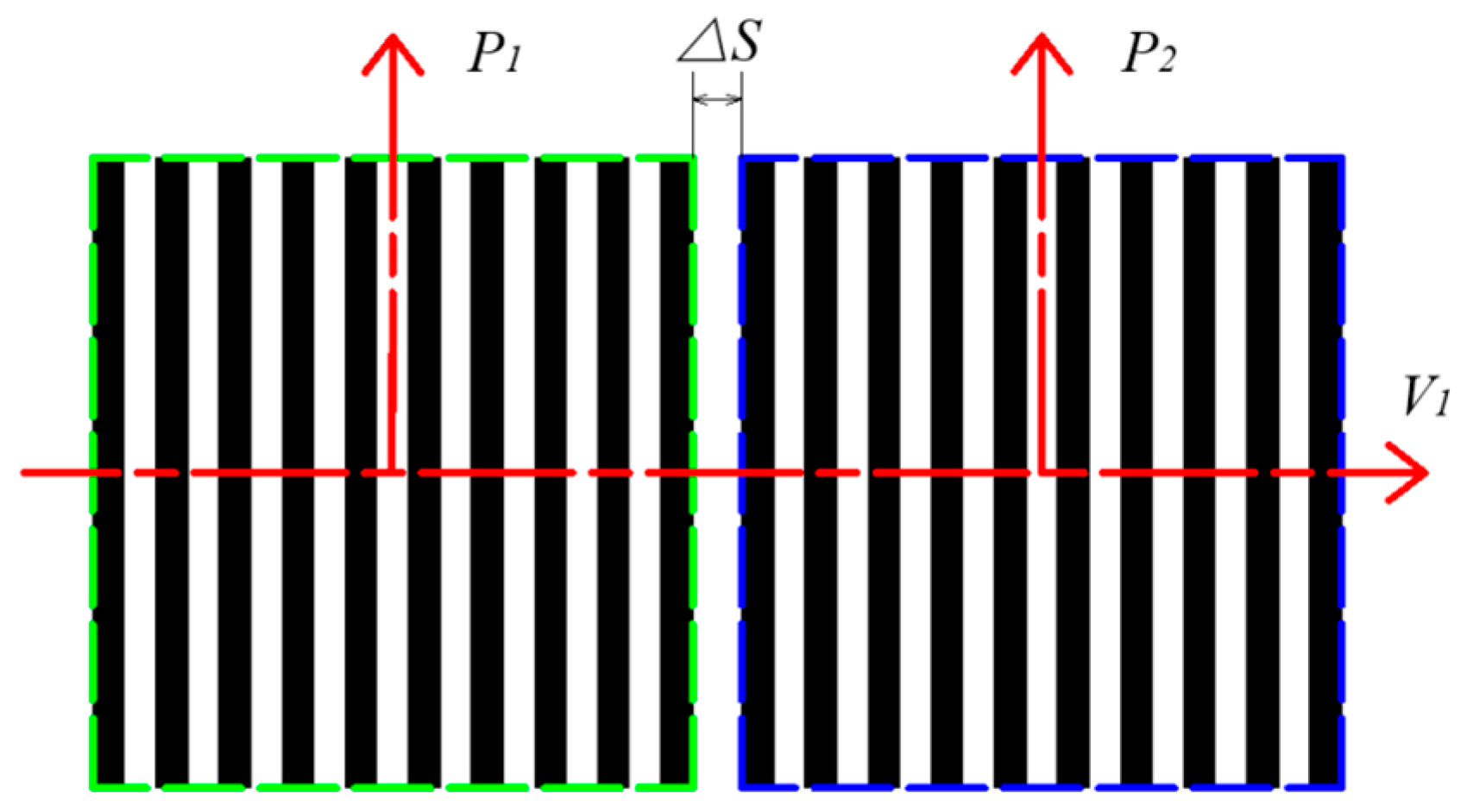

2.1. Principle for Accuracy Alignment

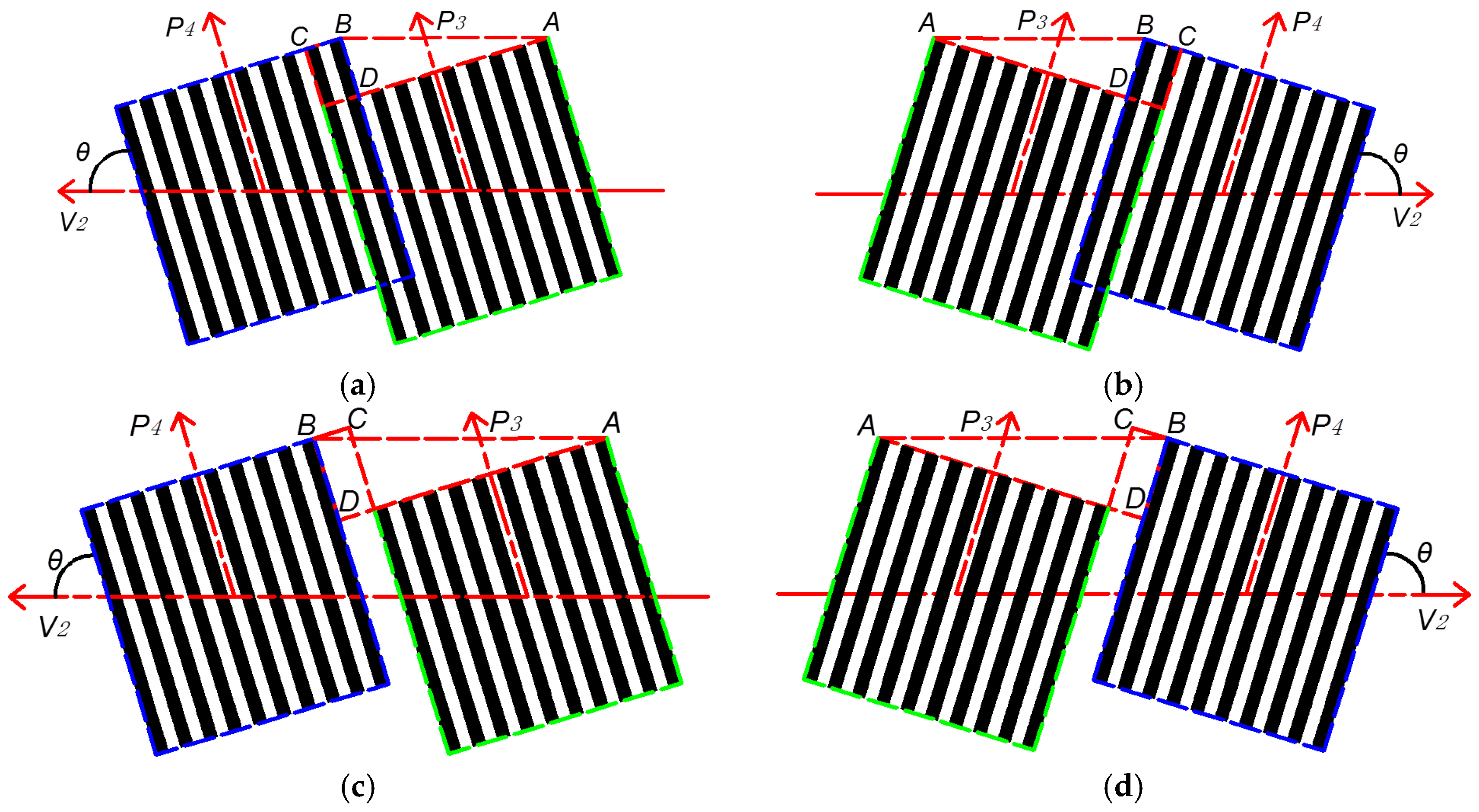

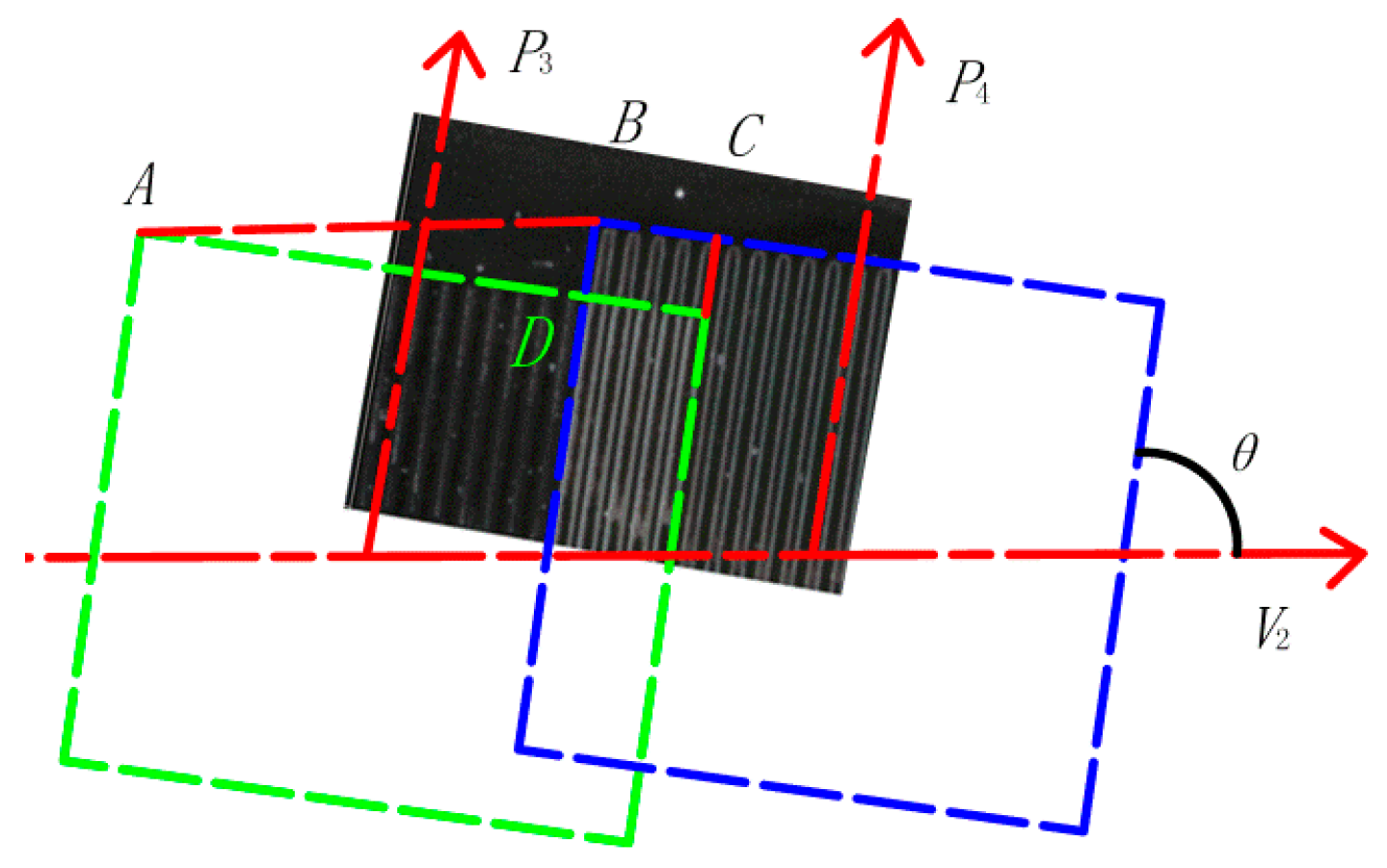

2.2. Tilt Mask Alignment

2.3. Rotation Mask Alignment

3. Alignment Experiments

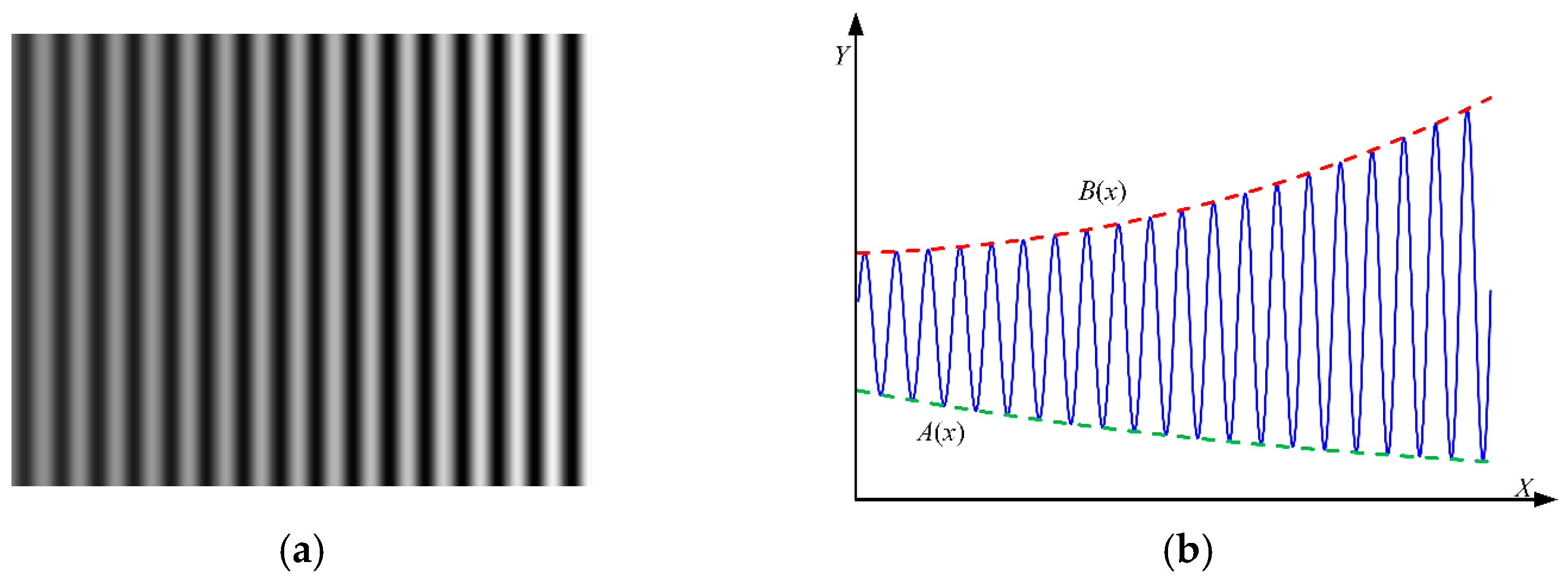

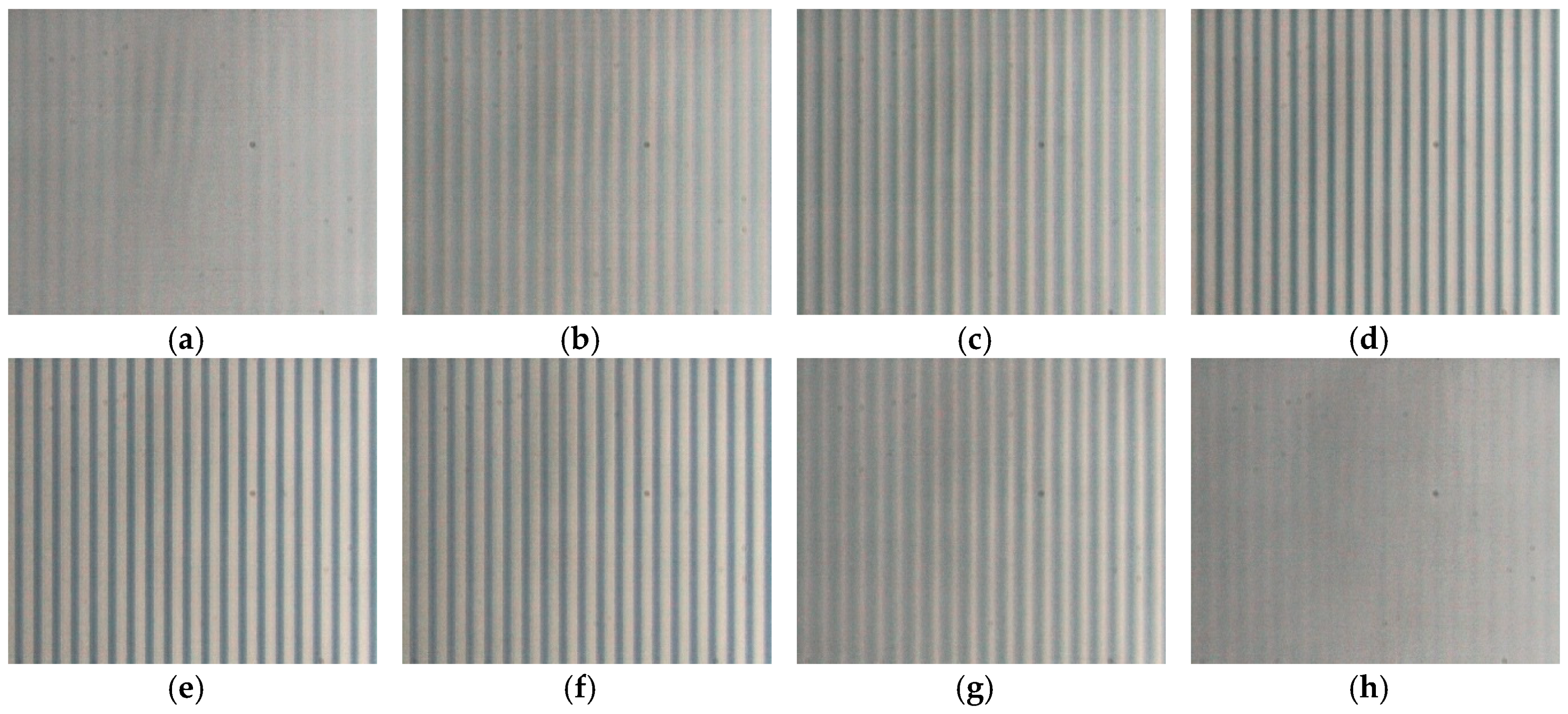

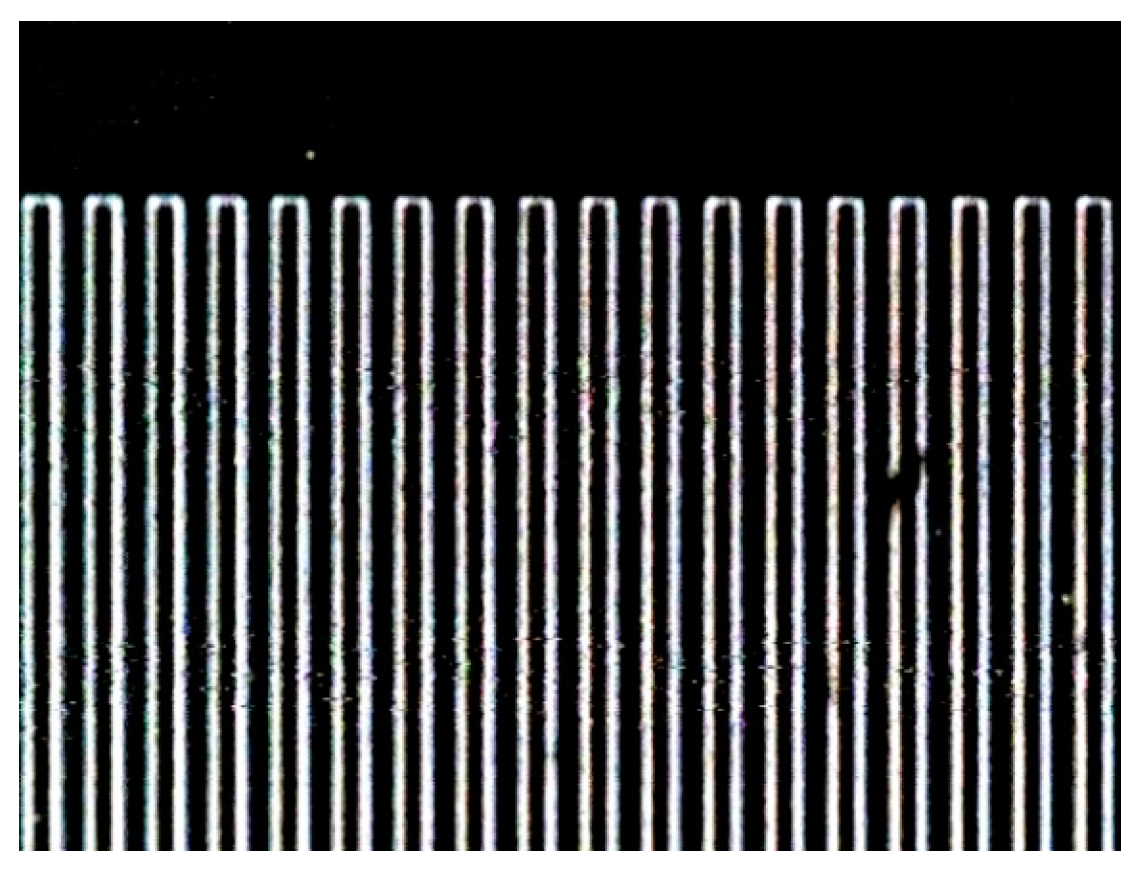

3.1. Align the Focal Plane Based on CCD Image

3.2. Align Tilt Mask with Laser Interferometer

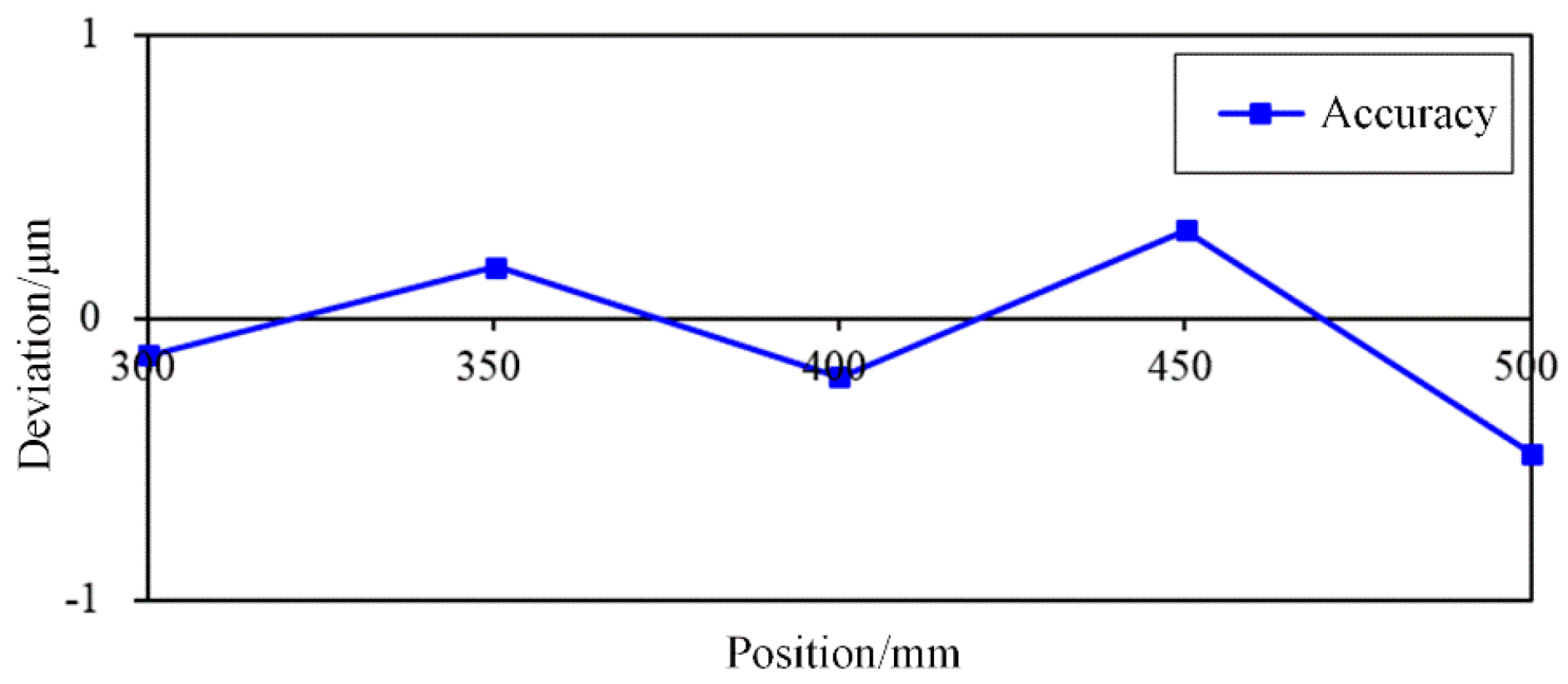

3.3. Influence of Alignment Error on Lithography Accuracy

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Di, C.; Zhu, J.; Yan, W.; Hu, S. A modified alignment method based on four-quadrant-grating moiré for proximity lithography. Opt. Lasers Eng. 2014, 125, 4868–4872. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, S.; Zhou, P.; Yu, J. Experimental study of Talbot imaging moiré-based lithography alignment method. Opt. Lasers Eng. 2014, 58, 54–59. [Google Scholar] [CrossRef]

- Li, N.; Wu, W.; Chou, S.Y. Sub-20-nm Alignment in nanoimprint lithography using moiré fringe. Nano Lett. 2006, 6, 2626–2629. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Ding, Y.; Tian, H.; Li, X.; Li, X.m.; Liu, H. Digital moiré fringe measurement method for alignment in imprint lithography. Opt. Laser Technol. 2012, 44, 446–451. [Google Scholar] [CrossRef]

- Miyashiro, R.; Fukagawa, Y. Optimization of alignment in semiconductor lithography equipment. Precis. Eng. 2009, 33, 327–332. [Google Scholar] [CrossRef]

- Farrow, R.C.; Liddle, J.A.; Berger, S.D.; Huggins, H.A.; Kraus, J.S.; Camarda, R.M.; Tarascon, R.G.; Jurgensen, C.W.; Kola, R.R.; Fetter, L. Marks for alignment and registration in projection electron lithography. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. 1993, 11, 240–246. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, Y.; Dong, L.; Su, X.; Tian, Z.; Fang, C.; Wei, Y.; Ye, T. New alignment mark design structures for higher diffraction order wafer quality enhancement. SPIE Adv. Lithogr. 2017, 10145, 101452C. [Google Scholar] [CrossRef]

- Lee, C.W.; Kim, S.W. An ultraprecision stage for alignment of wafers in advanced microlithography. Precis. Eng. 1997, 21, 113–122. [Google Scholar] [CrossRef]

- Sreenivasan, S.V. Thermally controlled alignment for wafer-scale lithography. J. Micro/Nanolithogr. MEMS MOEMS 2013, 12, 031109. [Google Scholar] [CrossRef]

- Terasawa, T. Novel alignment technique for 0.1-μm lithography using the wafer rear surface and canceling tilt effect. Opt. Eng. 1993, 32, 2344–2349. [Google Scholar]

- Qian, Q.; Zang, D.D. A modified sharpness-evaluation function of image based on sobel. Comput. Digit. Eng. 2015, 10, 1865–1870. [Google Scholar]

- Ren, D.; Zhao, H.; Zhang, C.; Yuan, D.; Xi, J.; Zhu, X.; Ban, X.; Dong, L.; Gu, Y.; Jiang, C. Multi-repeated projection lithography for high precision linear scale based on average homogenization effect. Sensors 2016, 16, 538. [Google Scholar] [CrossRef] [PubMed]

| a | b | c | d | e | f | g | h | |

|---|---|---|---|---|---|---|---|---|

| 6.41 | 6.85 | 7.19 | 7.80 | 7.95 | 7.64 | 7.20 | 6.39 | |

| 0.01 | 0.29 | 0.51 | 0.91 | 1.00 | 0.80 | 0.52 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, D.; Xi, J.; Li, Z.; Li, B.; Zhao, Z.; Zhao, H.; Cui, L.; Xu, H. The Alignment Method for Linear Scale Projection Lithography Based on CCD Image Analysis. Proceedings 2018, 2, 101. https://doi.org/10.3390/ecsa-4-04936

Ren D, Xi J, Li Z, Li B, Zhao Z, Zhao H, Cui L, Xu H. The Alignment Method for Linear Scale Projection Lithography Based on CCD Image Analysis. Proceedings. 2018; 2(3):101. https://doi.org/10.3390/ecsa-4-04936

Chicago/Turabian StyleRen, Dongxu, Jianpu Xi, Zhengfeng Li, Bin Li, Zexiang Zhao, Huiying Zhao, Lujun Cui, and Hang Xu. 2018. "The Alignment Method for Linear Scale Projection Lithography Based on CCD Image Analysis" Proceedings 2, no. 3: 101. https://doi.org/10.3390/ecsa-4-04936

APA StyleRen, D., Xi, J., Li, Z., Li, B., Zhao, Z., Zhao, H., Cui, L., & Xu, H. (2018). The Alignment Method for Linear Scale Projection Lithography Based on CCD Image Analysis. Proceedings, 2(3), 101. https://doi.org/10.3390/ecsa-4-04936