Abstract

The city of Arnhem is known for its trolley busses, which operates in a network of over-head grid lines, leading to zero local emission. However, extending the driving range of the trolley busses beyond the over-head grid network is technically challenging and economically demanding due to the infrastructure requirements. This led to their participation in EUREGIO project e-Bus 2020 IMC. The aim of the project is to develop, design and optimize a hybrid driveline for trolley busses using an additional traction battery. Using the over-head grid network for In Motion Charging (IMC), eliminates the need for a separate charging infrastructure needed for regular electric busses. This paper presents a backward quasi-static modeling approach to estimate the battery capacity for the required range extension. The viability of the battery is verified using a scenario analysis.

1. Introduction

In the search for clean, quiet, comfortable and efficient means of transportation, trolley busses provide a realistic solution which use electricity from the over-head grid network. However, the infrastructure requires an over-head grid network, limiting the deployment of trolley busses through an urban area. This led the city of Arnhem (also known as “Trolley City”) to participate in the EUREGIO project e-Bus 2020 IMC. This research project focuses on In Motion Charging (IMC) of battery-hybrid trolley busses, creating the opportunity of operating the trolley busses outside the over-head grid network without expanding the infrastructure. The primary objective of the project is to extend the driving range of existing trolley busses by approx. 10 km by using a traction battery. One of the challenges, besides the power transfer over the trolley glider, is the balance between the battery capacity and the operational constraints (such as drive cycle, load cycle, weather conditions, etc.) of the trolley bus. Therefore, an assessment of the battery capacity related to the operational constraints is necessary, leading to the following main research question of this paper:

“What size of the battery is needed to make IMC a viable solution for trolley busses on certain bus routes in Arnhem?”

2. Backward Quasi-Static Modelling

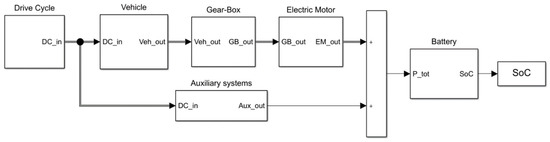

Modelling and simulation are widely used methods to investigate, design, control and optimize drivelines. Backward quasi-static modelling (BQM) is the most commonly adapted approach for modelling drivelines when optimization and sizing is concerned [1,2]. Therefore, BQM is selected as an approach to answer the above research question. An overview of the BQM model of the trolley bus with battery is presented in Figure 1, which is developed in Matlab/Simulink using QSS toolbox [3] tuned to the trolley bus driveline.

Figure 1.

Overview of BQM model of the trolley bus.

It may be observed from the Figure 1, the driveline of the existing trolley bus is modelled using five systems, namely, drive cycle, vehicle, gear-box, electric motor and auxiliary systems. The drive cycle is the main input (such as velocity, acceleration, number of passengers during the trip, cabin and ambient temperature, slope of the road, time and distance travelled during the trip), as represented by DC_in. The vehicle system models the road resistances (such as aerodynamic, rolling and gradient resistance) and estimates the wheel torque, wheel rotational speed and wheel rotational acceleration using drive cycle input, as represented by Veh_out. The gear-box system models a single gear reduction mechanical transmission and estimates the electric motor torque and its rotational speed using gear ratio, gear-box efficiency, rotational inertia, its idling losses and vehicle input (i.e., wheel torque, wheel rotational speed and acceleration), as represented by GB_out.

The electric motor system models the power supplied to the motor in traction mode (i.e., during positive acceleration) and recuperated in regeneration mode (i.e., during negative acceleration) using motor torque, motor rotational speed and motor efficiency map, as represented by EM_out. The efficiency map is generated using the motor specifications provided by the vehicle manufacturer (Hess AG) and efficiency maps of electric motors with similar characteristics [4]. HVAC (heating, ventilation and air-conditioning) is second source which consumes significant energy and is modelled using heat balance method [5] in auxiliary systems together with miscellaneous components. The miscellaneous components include ignition, internal lightings, dashboard, headlights, wipers, infotainment, etc. and are modelled using fixed rated power demand and their on/off signal. Aux_out represents the power consumed by HVAC and miscellaneous components.

3. Battery Sizing

The capacity of the battery is the key component of the proposed hybrid electric driveline of trolley busses enabling the driving range outside the over-head grid network. In order to determine the required capacity of the battery, to cover required 10 km as aforementioned in Section 1, the foremost requirement is to know the energy demand of the trolley busses. Therefore, real-time measurements were performed on one of the trolley bus in Arnhem city and subsequently, energy demand of the trolley bus is determined, as presented in Table 1. The measurement data is also used for validating the BQM model and subsequent predicted energy demand of the trolley bus is presented in Table 1.

Table 1.

Energy demand of the trolley bus.

It may be observed that BQM model overestimates the energy demand (with regard to traction and regeneration) by approx. 10% compared to measurements while considering the same auxiliary consumption. Two primary limitations were encountered during the validation process; first due to the deficiency of the measurement data (i.e., no GPS data, no signals corresponding to the auxiliary systems) and second due to the uncertainty of the parameters and motor efficiency map used for BQM model to represent the target trolley bus. However, un-modelled losses and measurement error may also be the contributing factor, therefore, further investigation is required for validation of the BQM model.

The capacity of the battery is estimated for required driving range (viz. 10 km) using Equation (1), by considering three following factors:

- Batteries degrade over their lifetime, therefore, a factor of 20% is assumed.

- Batteries are operated and controlled within a range of state of charge (SoC), therefore, SoC range of 70% is assumed.

- The overall efficiency of battery during discharging is assumed as 85%, which depends on various factors such as charging/discharging current, temperature, terminal voltage, etc.

By using Equation (1), it can be concluded that the required capacity of the battery is 30 kWh to fulfil the primary objective (i.e., to extend the driving range of trolley busses by 10 km).

To analyze the viability of the battery, a scenario is created using approx. 10 km long section from the measurement data and corresponding gradient profile is estimated using google maps. The trolley bus is assumed to be driving with its full capacity (i.e., 110 passengers). A constant opposing average (annually) wind velocity of 15 km/h [6] is also considered within the scenario. The battery model in BQM is parameterized using a Lithium Titanate (LTO) battery. It is selected based on the battery of hybrid electric busses operating in the city of Esslingen (Germany), using IMC technology [7]. The open circuit voltage of the battery is assumed similar to the over-head grid voltage (approx. 675–725 [V]) in city of Arnhem.

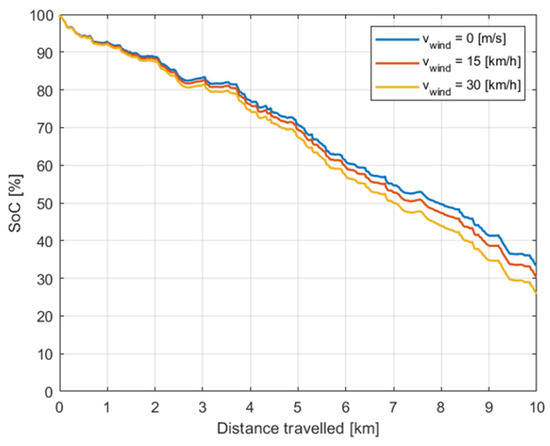

The state of charge (SoC) of the battery with respect to travelled distance is presented in Figure 2. It may be observed that the SoC of the battery reaches approx. 30% for above described scenario. However, wind velocity may reach approx. 30 km/h and higher on a certain day in city of Arnhem, therefore, influence of wind velocity on the battery SoC is also presented in Figure 2, indicating the further decrease in SoC as expected.

Figure 2.

State of charge of the battery vs. distance travelled.

4. Conclusions

This paper presents a backward quasi-static modelling approach to estimate the size of battery for new battery-hybrid trolley busses. Due to present limitations, the BQM model is only partially validated using the measurement data. However, using the energy demand for the existing trolley bus, the required capacity of battery is estimated as approx. 30 [kWh] for desired driving range of 10 km. The viability of battery is analyzed using a scenario analysis, which indicates the estimated capacity to be sufficient, considering BQM overestimates the energy requirement by approx. 10%. The next step is to perform another set of measurement on the existing trolley bus such that the BQM model can be validated more accurately and can be used for further analysis.

Acknowledgments

This research has been funded by INTERREG V A Deutschland-Nederland in the project: E-bus 2020: In Motion Charging—“Productinnovaties voor trolley-accubussen”. The project consortium is: Vossloh-Kiepe (lead partner), Municipality of Arnhem and Renkum, Hogeschool van Arnhem en Nijmegen (HAN), I+ME Actia GmbH, Braunschweig (Braunschweig, Kreisfreie Stadt, D), Friedrich Hippe GmbH), Hagen (Osnabrück, Landkreis): Venema-tech, Fransen Technical Services, Bordbuster, and Hermes.

References

- Hofman, T.; Leeuwan, D.; Steinbuch, M. Analysis of modelling and simulation methodologies for vehicular propulsion systems. Int. J. Powertrains 2011, 1, 117–136. [Google Scholar] [CrossRef]

- Guzzella, L.; Amstutz, A. CAE tools for quasi-static modelling and optimization of hybrid powertrains. IEEE Trans. Veh. Technol. 1999, 48, 1762–1769. [Google Scholar] [CrossRef]

- Guzzella, L.; Amstutz, A. The QSS Toolbox Manual; Institute fur Mess and Regeltechnik, ETH Zurich: Zurich, Switzerland, 2005. [Google Scholar]

- LCM-160-6, Elinta Motors. Available online: http://www.elintamotors.com/datasheets/LCM-160.pdf (accessed on 5 July 2018).

- Fayazbakhsh, M.A.; Bahrami, M. Comprehensive Modeling of Vehicle Air Conditioning Loads Using Heat Balance Method; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Current Results. Available online: https://www.currentresults.com/Weather/Netherlands/wind-speed-annual.php (accessed on 9 July 2018).

- Articulated Electric Bus with In Motion Charging (IMC), Esslingen. Vossloh Kiepe. Available online: https://platformduurzaamovenspoor.nl/.../factsheet_esslingen_articulated_imc_electric_bus_825_e.pdf (accessed on 12 July 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).