Abstract

The present research shows a fractographic analysis, using a scanning electron microscope (SEM), based in previous experimental tests of the delamination under mode I fatigue loading for two aeronautical quality composite materials at different test temperatures (90, 20 and −60 °C) in order to analyze the matrix and temperature influence (flight conditions). The materials employed are composed of two different epoxy matrixes and the same unidirectional carbon fiber reinforcement. This study suggests a variable behavior depending on the temperature and the type of matrix used.

1. Introduction

The engineering applications of polymer composite materials have been increased notably in recent years, especially in applications that are weight-critical. Therefore, it is essential to study the failure mechanisms that limit the use of this type of materials, being the interlaminar fracture (or delamination) one of the main failure mechanisms in fiber reinforced composite materials (FRC). This type of failure is induced by interlaminar and shear stresses that occur due to various factors such as: effects of free edges, structural discontinuities, disturbances located during the manufacturing process or in working conditions, such as impact, variations in humidity or temperature and mechanisms of internal failure such as cracking of the matrix [1,2].

Certain loading scenarios, such as the structure of an airplane during the flight, can lead to delamination growth if some pre-existing delamination exists in the structural component, which can in turn lead to structural failure. One of the most common is failure due to fatigue (cyclic loading), which has been researched by several authors using numerical analysis [3,4,5] and experimental analysis [6], though not to a great extent due to the complexity involved in carrying out the tests. This is especially the case when considering the effect of environmental conditions such as humidity or temperature on mechanical behaviour [7].

Fractographic analysis is the key to understanding the fracture mechanisms since it provides a new point of view of the physical processes by which composites are damaged and fail. Compared with isotropic materials the fractographic analysis of composites still needs to be matured with respect to the influence of certain factors such as environmental conditions or cyclic loads. However, fractography is proving to be a powerful and reliable tool for composites engineering and is a vital technique for the overall development of composite structures [8,9].

2. Materials and Methods

In the present research a fractographic analysis was carried out in order to analyze the type of matrix and the temperature behavior under Mode I fatigue loading of different composites tested previously in other studies [10,11,12].

Two types of materials were employed to carry out this research: one composed of a 3501-6 epoxy resin prepreg reinforced with AS4 unidirectional carbon fiber and the other composed of a 8552 epoxy resin prepreg, modified in order to increase its toughness and the same fiber reinforced.

To characterize delamination under mode I fatigue loading Double Cantilever Beam (DCB) specimens were used according to the standard ASTM 6115-97 [13]. The test equipment employed was made up of a servo-hydraulic MTS testing machine provided with a 1 kN load cell controlled by a computer using the original software. Tests were carried out using different temperatures in order to simulate flight conditions: 90 °C, 20 °C (room temperature) and −60 °C. A thermal chamber was coupled to the testing machine to carry out the low temperature tests (using nitrogen bottles to achieve low temperature tests). In order to facilitate visual monitoring of the progress of delamination, a video-camera focused on the graduated edge and connected to a monitor, was used to observe the advance of the crack. This solution was necessary because it was not possible in the tests carried out inside the thermal chamber to observe the crack growth with a microscope as shown in the standard. Table 1 shows the energy release rate threshold values (Gth) obtained from the experimental procedure during the crack propagation.

Table 1.

Gth (J/m2) values obtained from the experimental analysis [12].

As it can be observed at the Gth values obtained, a noticiable influence of the temperature and the type of matrix was observed during fatigue crack propagation. In general, the material with the modified epoxy matrix presents a greater resistance to delamination under dynamic solicitation for all the temperatures analysed. Regarding the influence of temperature can be seen as the values of fracture toughness decrease with the decrease in temperature for both materials.

In order to assist the interpretation of the experimental results an analysis of the damage micromechanisms was carried out. For this purpose, a fractographic study was performed using a Scanning Electron Microscope (SEM) on samples obtained from the previously tested specimens at the different test conditions.

3. Fractographic Analysis

In order to analyse fracture micromechanisms, samples were extracted at the edge of the insert (in order to analyze the initiation of the crack) and in the central area of the specimens (to analyze the propagation of delamination). However, the initiation was observed to be strongly related to the manufacturing process of the material being outside the scope of the object of the present research. Crack propagation zone is notable influenced by the main micromechanisms in the interlaminar fracture: formation of fiber bridges, in isolated fibers or bundles of fibers, and that causes fiber breakage; formation of the fracture surface of the main crack; formation of lateral cracks and plastic deformation and/or formation of microcracks in the matrix between fibers.

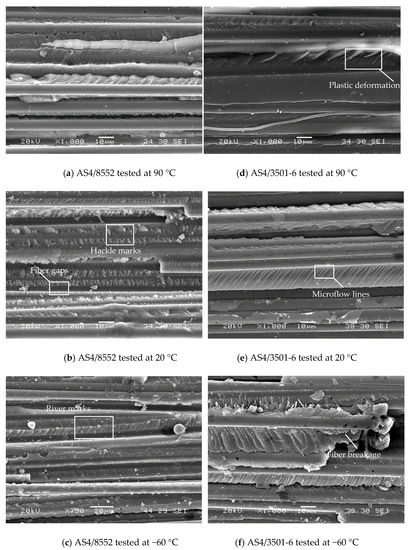

Figure 1 shows some of the pictures obtained from the materials analyzed at the temperatures under study.

Figure 1.

Micrographs obtained from the fractographic analysis for both materials at the different test temperature conditions (1000×).

The micrographs obtained show different morphologies typical of mode I fracture. In general, under mode I loading the fibers were separated by fairly flat-sided valleys and the so-called ‘‘river markings’’ were generally observed, which indicate a plastic behavior of the matrix [14]. As the temperature decreases these markings gradually give way to a brittle aspect of the matrix. In tests at high temperatures, an increase in the ductility of the matrix can be observed with increasing temperature, a feature that is appreciated by the deformation observed in the matrix itself and the amount of resin adhered to the fibers on the fracture surfaces of the tested specimens.

4. Conclusions

In general, the analyzed composites show more brittle behavior at low temperatures and an increase in the ductility of the matrix when the temperature increases. However, it can be observed that the influence of the temperature is more significant for the material with the non modified epoxy matrix.

During fatigue tests at high temperatures the ductility of the matrix increases, leading to higher resistance to delamination during the dynamic propagation procedure.

As regards the fractographic analysis of the fracture surfaces, it may be concluded that, in addition to the observed typical morphologies of mode I fracture, the analyzed micrographs have a relationship with the results obtained during the experimental procedure.

References

- Hojo, M.; Kageyama, K.; Tanaka, K. Prestandardization study on mode I interlaminar fracture toughness test for CFRP in Japan. Composites 1995, 26, 243–255. [Google Scholar] [CrossRef]

- Rizov, V.I. Fracture in composites—An overview (Part I). J. Theor. Appl. Mech. 2012, 42, 3–42. [Google Scholar] [CrossRef][Green Version]

- Turón, A.; Costa, J.; Camanho, P.P.; Dávila, C.G. Simulation of delamination in composites under high cycle fatigue. Compos. Part A 2007, 38, 2270–2282. [Google Scholar] [CrossRef]

- Shivakumar, K.; Chen, H.; Abali, F. A total fatigue life model for mode I delaminated composites laminates. Int. J. Fatigue 2005, 28, 179–184. [Google Scholar] [CrossRef]

- De Moura, M.F.; Campilho, R.D.; Amaro, A.M.; Reis, P.N. Interlaminar and intralaminar fracture characterization of composites under mode I loading. Compos. Struct. 2010, 92, 144–149. [Google Scholar] [CrossRef]

- Maillet, I.; Michel, L.; Rico, G.; Fressinet, M.; Gourinat, Y. A new test methodology based on structural resonance for mode I fatigue delamination growth in an unidirectional composite. Compos. Struct. 2013, 97, 353–362. [Google Scholar] [CrossRef]

- Kalarikkal, S.G.; Sankar, B.V.; Ifju, P.G. Effect of cryogenic temperature on the fracture toughness of graphite/epoxy composites. J. Eng. Technol. 2006, 128, 151–157. [Google Scholar] [CrossRef]

- Greenhalgh, E.S.; Hiley, M.J. Fractography of polymer composites: Current status and future issues. In Proceedings of the 13th European Conference on Composite Materials (ECCM13), Stockholm, Sweden, 2–5 June 2008. [Google Scholar]

- Jollivet, T.; Greenhalgh, E.S. Fractography, a powerful tool for identifying and understanding fatigue in composite materials Procedia. Eng. 2015, 133, 171. [Google Scholar] [CrossRef][Green Version]

- Coronado, P.; Argüelles, A.; Viña, J.; Viña, I. Influence of low temperatures on the phenomenon of delamination of mode I fracture in carbon-fibre/epoxy composites under fatigue loading. Compos. Struct. 2014, 112, 188–193. [Google Scholar] [CrossRef]

- Coronado, P.; Argüelles, A.; Viña, J.; Mollón, V.; Viña, I. Influence of temperature on a carbon–fibre epoxy composite subjected to static and fatigue loading under mode-I delamination. Int. J. Solids Struct. 2012, 49, 2934–2940. [Google Scholar] [CrossRef]

- Coronado, P. Influencia del Tipo de Matriz y de la Temperatura en el Fenómeno de Deslaminación a Fractura, en Materiales Compuestos, Sometidos a Solicitación Estática y Dinámica en Modo I. Master’s Thesis, Universidad de Oviedo, Oviedo, Spain, 2014. [Google Scholar]

- ASTM D 6115-97; Standard Test Method for Mode I Fatigue Delamination Growth Onset of Unidirectional Fiber-Reinforced Polymer Matrix Composites. American Society for Testing and Materials: West Conshohocken, PA, USA, 1997.

- Mollón, V.; Bonhomme, J.; Viña, J.; Argüelles, A.; Canteli, A.F. Influence of the principal stresses on delamination fracture mechanisms and associated morphology for different loading modes in carbon/epoxy composites. Int. J. Damage Mech. 2011, 20, 963–978. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).