Mineral Processing Technologies for the Remediation of Soils Polluted by Trace Elements †

Abstract

:1. Introduction

- Isolation/landfill transportation: Conceptually cannot be categorized as remediation procedures, since they do not remove the pollutants from the soil or change its physicochemical characteristics.

- Solidification/stabilization: Solidification encapsulates the waste to form a solid material. Stabilization converts the contaminants into less soluble, mobile, or toxic forms.

- Pollutant removal: This group of technologies can be divided, in its turn, in:

- ○

- Physicochemical: They remove, extract or transform the pollutant via physicochemical procedures.

- ○

- Thermal methods: They warm the contaminant up to high temperatures in order to destroy or immobilize it.

- ○

- Biological methods: They use the activity of living organisms (plants, fungus and bacteria) to degrade or accumulate the contaminants.

2. Experiments

- Soils and sediments polluted by As and other heavy metals in the surroundings of the Los Rueldos abandoned mine (Asturias, Spain) [3].

- Soils and sediments polluted by As, Hg and other heavy metals in the surroundings of the former La Soterraña mine and metallurgical plant (Asturias, Spain) [4].

- Soils polluted by pyrite ashes from the former fertilizers plant of Nitrastur (Asturias, Spain) [5].

- Soils by Pb and other heavy metals from different environments affected by the mining and metallurgical activities in the Linares mining district (Andalucía, Spain) [6].

3. Results

3.1. Protocol

- I.

- Representative samples obtention. Soil are extremely heterogenous so this steep is key for the rest of process.

- I.

- II. General pedological study: The recommended parameters include: Texture, structure, density, field capability, total nitrogen, organic matter, C/N, pH, electrical conductivity, total carbonates, extractable bases (Na, K, Ca, Mg) and effective cation exchange capacity (sum of cations + exchangeable Al).

- I.

- III. Grain size characterization: The granulometric fractionation (<63; 63–125; 125–500; 500–2000; 2000–4000 µm) should be obtained by wet sieving in order to improve classification efficiency which might be hindered by the presence of clays. The end of these fractions would not only be the obtention of the granulometric curve, but samples supply to further chemical analysis and mineralogical observations.

- I.

- IV. Study of chemical parameters: This steep would include an exhaustive study of the typology, evolution and origins of the pollutants present in the site. The characterization would encompass the determination of metal concentrations, sequential extraction, chemical speciation, etc.

- I.

- V. Mineralogical study: Predominant mineral species could be determined in soils by X-Ray diffractometry. Additionally, petrographic microscope and scanning electron microscope observations would aid in mineral species determination (sulphides, oxides, etc.) and liberation degree assessment.

- I.

- VI. Physical separation feasibility assessment: Apart from the previous, a complete mineral processing feasibility study would be required. This would include:

- -

- Milling study: Although milling previous to soil washing makes the process expensive, it is for this precise reason that Bond mill tests should be performed if this process is suspected to be necessary for the separation process.

- -

- Classification: Direct classification with screens and trommels, as well as indirect by sedimentation and hydrodynamic classification with hydrocyclones.

- -

- Gravimetric study: Its aim is to determine, for each size fraction, the feasibility of density separation. It is carried out through heavy liquid separation (HLS) or direct use of density separators: shaking tables, spirals, jigs, multigravimetric separators (MGSs), etc.

- -

- Magnetic susceptibility study: Each grain size fraction could be subjected to magnetic susceptibility determinations in order to assess the magnetic separation feasibility. Alternatively and complementary direct tests with dry-/wet- and high/low- magnetic separators are advisable.

- -

- Pilot scale tests: In accordance with the previous tests, a complete lab plant should be constructed so the results could later be scaled-up to the industrial plant.

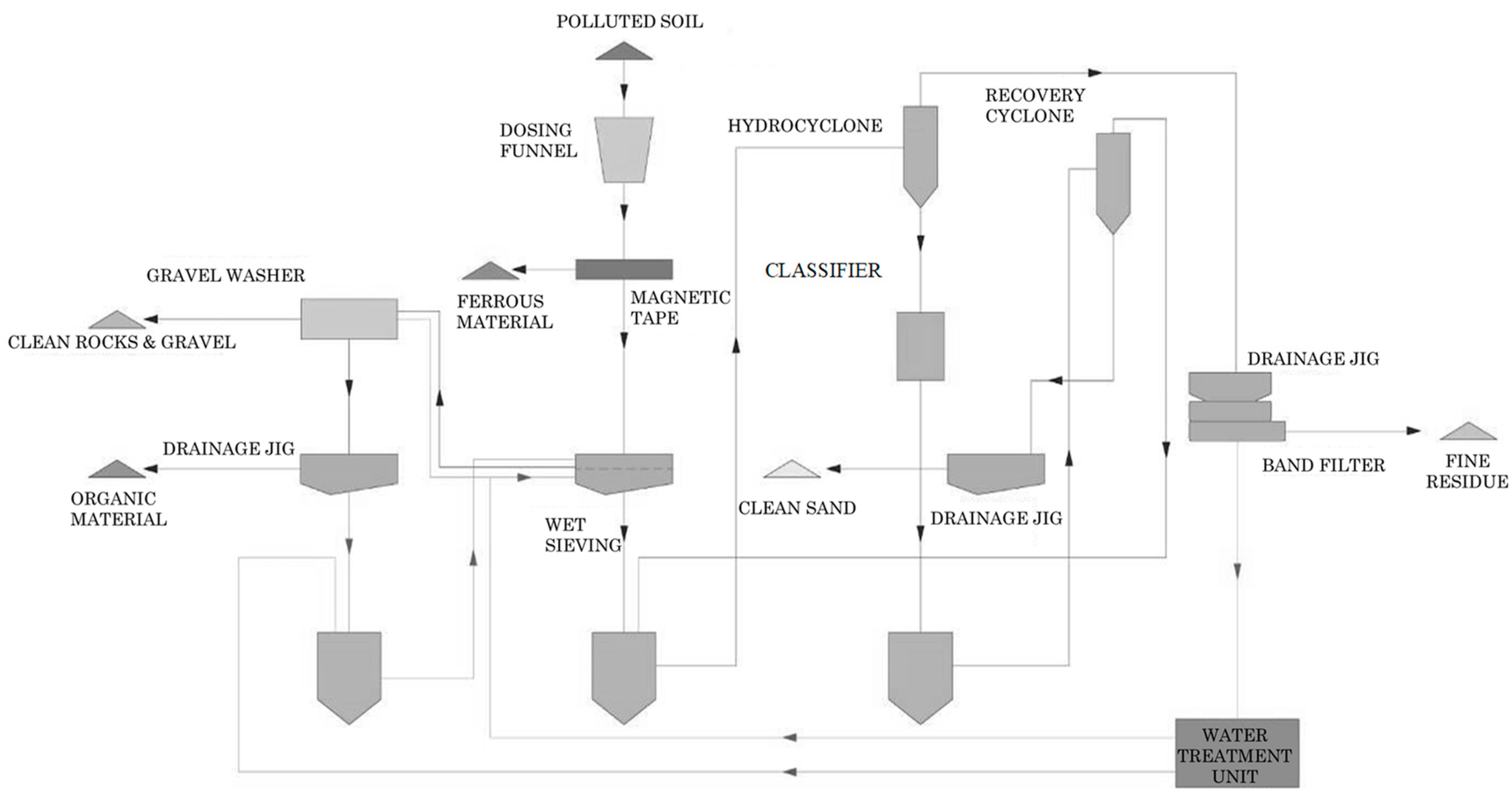

3.2. Treatment Example

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sharma, H.D.; Reddy, K.R. Geoenvironmental Engineering: Site Remediation, Waste Containment, and Emerging Waste Management Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Dermont, G.; Bergeron, M.; Mercier, G.; Richer-Laflèche, M. Soil washing for metal removal: A review of physical/chemical technologies and field applications. J. Hazard. Mater. 2008, 152, 1–31. [Google Scholar] [CrossRef] [PubMed]

- González-Coto, F.; Sierra, C.; Villa, R.; Menéndez-Aguado, J.M.; Gallego, J.R. Textural distribution of arsenic and heavy metals in soils affected by abandoned mining works: Consequences for soil washing. In Proceedings of the 8th International Scientific Conference on Modern Management of Mine Producing, Geology and Environmental Protection, SGEM, Varna, Bulgaria, 16–20 June 2008; pp. 2349–2354. [Google Scholar]

- Sierra, C.; Menéndez-Aguado, J.M.; Afif, E.; Carrero, M.; Gallego, J.R. Feasibility study on the use of soil washing to remediate the As-Hg contamination at an ancient mining and metallurgy area. J. Hazard. Mater. 2011, 196, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Boente, C.; Sierra, C.; Rodríguez-Valdés, E.; Menéndez-Aguado, J.M.; Gallego, J.R. Soil washing optimization by means of attributive analysis: Case study for the removal of potentially toxic elements from soil contaminated with pyrite ash. J. Clean. Prod. 2017, 142, 2693–2699. [Google Scholar] [CrossRef]

- Sierra, C.; Martínez, J.; Menéndez-Aguado, J.M.; Afif, E.; Gallego, J.R. High intensity magnetic separation for the clean-up of a site polluted by lead metallurgy. J. Hazard. Mater. 2013, 248–249, 194–201. [Google Scholar] [CrossRef] [PubMed]

- Boente, C.; Sierra, C.; Martínez-Blanco, D.; Menéndez-Aguado, J.M.; Gallego, J.R. Nanoscale zero-valent iron-assisted soil washing for the removal of potentially toxic elements. J. Hazard. Mater. 2017, 350, 55–65. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boente, C.; Sierra, C.; Rodríguez-Valdés, E.; Baragaño, D.; Gallego, J.L.R.; Aguado, J.M.M. Mineral Processing Technologies for the Remediation of Soils Polluted by Trace Elements. Proceedings 2018, 2, 1458. https://doi.org/10.3390/proceedings2231458

Boente C, Sierra C, Rodríguez-Valdés E, Baragaño D, Gallego JLR, Aguado JMM. Mineral Processing Technologies for the Remediation of Soils Polluted by Trace Elements. Proceedings. 2018; 2(23):1458. https://doi.org/10.3390/proceedings2231458

Chicago/Turabian StyleBoente, Carlos, Carlos Sierra, Eduardo Rodríguez-Valdés, Diego Baragaño, José Luis Rodríguez Gallego, and Juan María Menéndez Aguado. 2018. "Mineral Processing Technologies for the Remediation of Soils Polluted by Trace Elements" Proceedings 2, no. 23: 1458. https://doi.org/10.3390/proceedings2231458

APA StyleBoente, C., Sierra, C., Rodríguez-Valdés, E., Baragaño, D., Gallego, J. L. R., & Aguado, J. M. M. (2018). Mineral Processing Technologies for the Remediation of Soils Polluted by Trace Elements. Proceedings, 2(23), 1458. https://doi.org/10.3390/proceedings2231458