The Effect of Mixing Technique and Prolonged Mixing Time on Strength Characteristics of Concrete †

Abstract

:1. Introduction

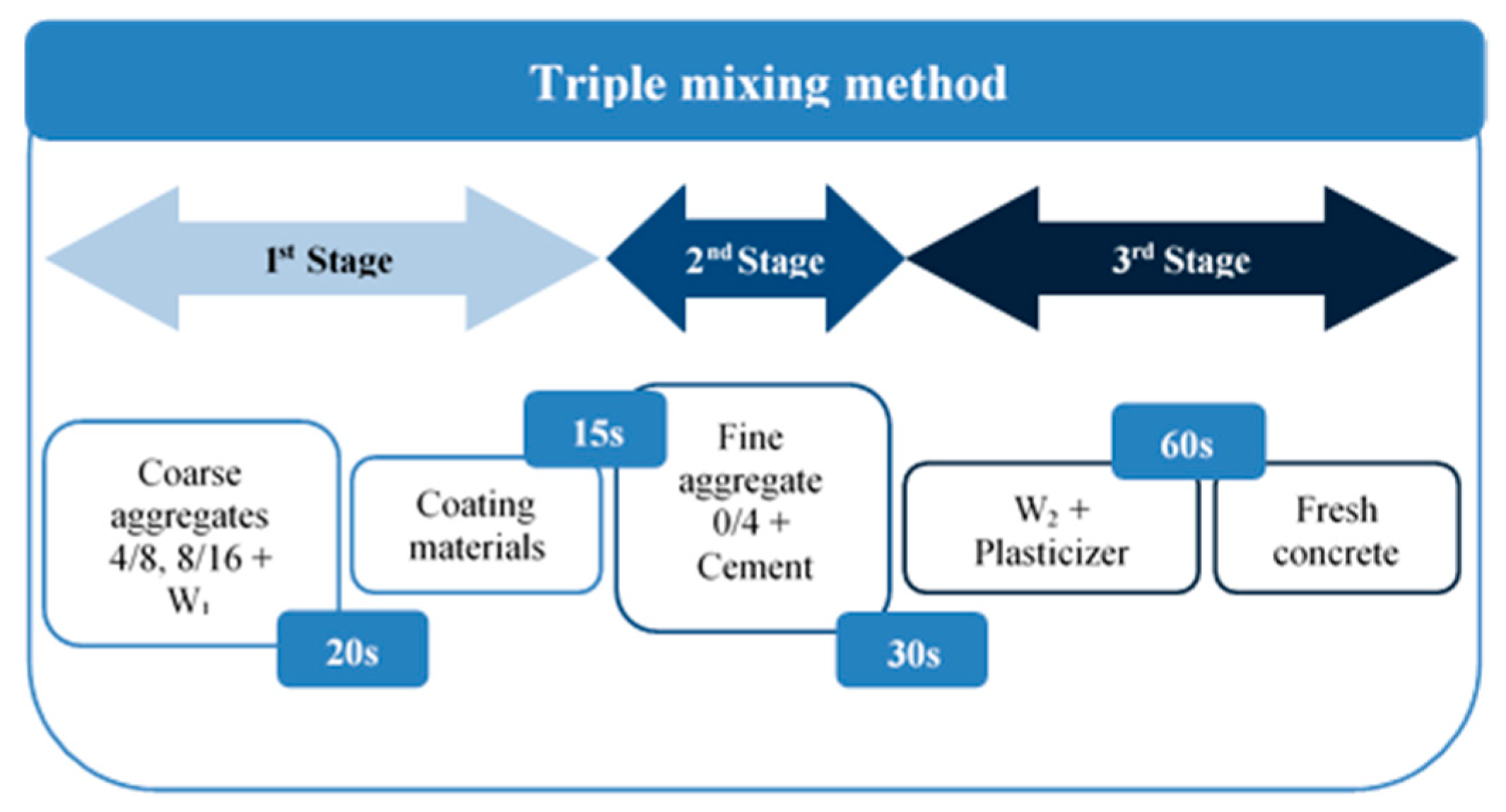

2. Methods and Materials

3. Results and Discussion

3.1. Analysis of Change in Results in Terms of Mixing Technique

3.2. Analysis of Change in Results in Terms of Mixing Time

4. Conclusions

- Triple mixing brings improvement of compressive strength for samples RCACEM and NAFA; the improvement in tensile splitting strength was detected for all samples, excepting sample RCAFA.

- Prolonged mixing time brought both the positive and negative changes in strength characteristics however the worst difference between initial mixing (0′) and 90′ minutes of mixing was only 8.4% for compressive strength (NM-NACEM) and 8.5% for tensile splitting strength (NM-NAFA). Effect on strengths obtained from 3M is generally better.

- When focused on impact of prolonged mixing time, the RCA-based mixtures seem to be more favorable, as they retain the initial strength values better.

Acknowledgments

References

- Kuosa, H. Reuse of Recycled Aggregates and Other C&D Wastes; VIT Technical Research Centre: Espoo, Finland, 2012; pp. 1–71. [Google Scholar]

- Kubissa, W.; Jaskulski, R.; Koper, A.; Szpetulski, J. Properties of Concretes with Natural Aggregate Improved by RCA Addition. Procedia Eng. 2015, 108, 30–38. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Urban, K.; Sicakova, A. Impact of specific mixing method on the properties of concrete with BFS aggregate. SGEM 2016 Conf. Proc. 2016, 4, 49–56. [Google Scholar]

- Junak, J.; Sicakova, A. Concrete Containing Recycled Concrete Aggregate with Modified Surface. Procedia Eng. 2017, 180, 1284–1291. [Google Scholar] [CrossRef]

- Lee, S.-H.; Hong, K.-N.; Park, J.-K.; Ko, J. Influence of Aggregate Coated with Modified Sulfur on the Properties of Cement Concrete. Materials 2014, 7, 4739–4754. [Google Scholar] [CrossRef] [PubMed]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Urban, K.; Sicakova, A. The technological aspect of specific mixing technology and its influence on strength properties of concrete. Improv. Effic. Constr. MMC Technol. Proc. Sci. Pap. 2017 2017, 95–102. [Google Scholar]

- Urban, K.; Sicakova, A. The influence of kind of coating additive on the compressive strength of RCA-based concrete prepared by triple-mixing method. IOP Conf. Ser. Earth Environ. Sci. 2017, 92, 1–5. [Google Scholar] [CrossRef]

| Sample | Increase/Decrease in Strength Characteristics NM/3M [%] | |||||

|---|---|---|---|---|---|---|

| Compressive Strength | Tensile Splitting Strength | |||||

| Mixing Time | ||||||

| 0′ | 45′ | 90′ | 0′ | 45′ | 90′ | |

| RCACEM | +48.6 | +26.5 | +23.8 | +2.6 | +22.2 | +10.8 |

| RCAFA | −19.5 | −17.5 | −16.5 | −12.5 | −9.5 | -5.4 |

| NACEM | −13.8 | −13.3 | −11.5 | +4.2 | +4.2 | +6.7 |

| NAFA | +1.3 | +5.8 | +19.5 | +2.1 | +2.2 | +4.7 |

| Sample | Increase/Decrease in Strength Characteristics 0′/90′ [%] | ||||

|---|---|---|---|---|---|

| Compressive Strength | Tensile Splitting Strength | Sample | Compressive Strength | Tensile Splitting Strength | |

| 3-RCACEM | -6.0 | +2.5 | 3-NACEM | −5.9 | −4.0 |

| 3-RCAFA | +9.4 | 0.0 | 3-NAFA | +9.2 | −6.0 |

| NM-RCACEM | +13.0 | −5.1 | NM-NACEM | −8.4 | −6.2 |

| NM-RCAFA | +5.5 | −7.5 | NM-NAFA | −7.4 | −8.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urban, K.; Sicakova, A. The Effect of Mixing Technique and Prolonged Mixing Time on Strength Characteristics of Concrete. Proceedings 2018, 2, 1290. https://doi.org/10.3390/proceedings2201290

Urban K, Sicakova A. The Effect of Mixing Technique and Prolonged Mixing Time on Strength Characteristics of Concrete. Proceedings. 2018; 2(20):1290. https://doi.org/10.3390/proceedings2201290

Chicago/Turabian StyleUrban, Karol, and Alena Sicakova. 2018. "The Effect of Mixing Technique and Prolonged Mixing Time on Strength Characteristics of Concrete" Proceedings 2, no. 20: 1290. https://doi.org/10.3390/proceedings2201290

APA StyleUrban, K., & Sicakova, A. (2018). The Effect of Mixing Technique and Prolonged Mixing Time on Strength Characteristics of Concrete. Proceedings, 2(20), 1290. https://doi.org/10.3390/proceedings2201290