Abstract

This paper presents a new way of dealing with drinkable water shortness all over the world. The developed devices’ functionality is based on the well-known and established SODIS (SOlar DISinfection) method. The whole device, Scipio—Scientific Purification Indicator, is designed in a way, that it is self-powered by solar cells and can be placed inside a bottle in order to provide best measurements. The device is capable of communicate via Bluetooth with other devices. Thus, an observation or control of the correct application of the SODIS method can be established. The paradigm shift we offer in terms of development aid not to simply help the people but to empower them to care for themselves. It is a very important that everyone can purify their own drinking water without the need of subsequent supplies.

1. Introduction

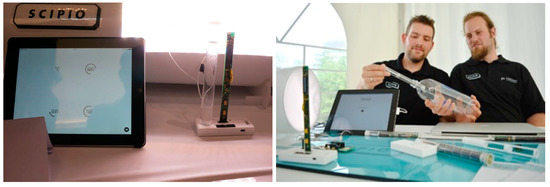

Scipio is an innovative tool that helps indicate whether water is drinkable (Figure 1). In developing countries, water is often disinfected through the SODIS method, which uses the germ-killing effect of UV radiation present in sunlight [1,2,3,4]. By simply filling a standard PET plastic bottle with water and placing it in direct sunlight for six hours, the water should be safe to drink! [5,6] Scipio confirms whether it is drinkable by measuring: inclination, temperature, UV intensity, sunlight intensity, environmental medium.

Figure 1.

Fully assembled Scipio device.

The SODIS Method requires an exposure duration of at least 6 h in direct sunlight. Problems can occur if the sky is cloudy or if the bottle is shadowed, and thus the exposure duration dramatically increases. Scipio can be submerged in PET bottles of water, where it measures the intensity and duration of exposure to UV radiation as well as the temperature of the water. Based on these measured key factors, optical signals indicate the progress of decontamination. The complete device is a stand-alone system powered by a solar-cell. During the development, a special focus was put on low power consumption, simple application, low costs and high reliability. The focus of the Scipio project is charity. We aim to resolve the significant worldwide problem of water quality assurance. Communication with Scipio is possible via the display, touch panel and wireless link. In order to improve the usability especially for children and analphabets we developed a full-custom smartphone and tablet app. The main objective of this app is that the whole process can be remotely protocoled and monitored. This enables people to let the bottle unobserved while exposed to the sun and do their daily work without risking poor water quality. Another advantage is that the teaching of the correct disinfection process is made easy and does not need the monitoring of an instructor. Moreover, the user gets a direct feedback whether the method is applied in the right way.

2. Sodis Method

As mentioned Scipio is designed to support the “Solar Water Disinfection” (SODIS) method which is extensively described in [1]. In the following, a short overview of the method is given. Solar disinfection uses the UV radiation contained in sunlight to purify the water by killing all of the pathogens therein. The possibility to use solar radiation for water disinfection was first discovered in 1984 and was subject to extensive laboratory studies in the 1990s by Eawag. The SODIS-method was designed as a standard procedure to enable an easy-to-use application of solar disinfection. Today, the SODIS method is promoted worldwide by various projects. There are many advantages of the SODIS method which have been proven in field studies. The method is effective in inactivating bacteria and viruses, very easy to understand and very low cost since only PET bottles are needed. No external energy source is needed as it is the case for boiling water for disinfection. Additionally, the taste is not changed due to chemical additives like chlorination. However, the method also presents some difficulties for the user. A correct application of the method is crucial for a successful disinfection of the water. First of all, the bottle used for the method has to be transparent regarding UV-radiation and should not be too badly scratched. Yet another problem is the turbidity of the water, which might prolong the required exposure time or render the disinfection impossible altogether. During the complete process, the bottles should be exposed to direct sunlight. It is also stated that there is a lack of a visual indicator for when the water is disinfected, which would also give the method a more technical appeal [1]. Under ideal conditions the disinfection is finished after a shorter time which could also be measured by such an indicator. The developed indicator Scipio can solve these problems. Scipio is submerged into the water in the PET bottle. During the complete process of solar disinfection, all important parameters such as intensity and duration of UV-radiation and temperature are measured and visual feedback can be given to the user about the progress of the disinfection. By using pictograms, the used can also be guided through the complete process of the SODIS method to ensure a correct and thus successful application (Figure 2).

Figure 2.

Scipio enhanced application of the SODIS method.

3. Technical Overview

The Scipio device consists of several functional units. Mainly, UV sensor, daylight sensor, temperature sensor for SODIS measurements. For environmental feedback a gyroscope and a capacitance change sensor are used. User interaction is established via a memory LCD and Bluetooth. Other Scipio parts are the microcontroller, the solar power supply, and a connector to plug in the capacitive sensor pad or the programming/debug adapter.

In order to be able to guarantee a constant energy supply when the insolation changes, the energy from the solar cell is collected by an energy harvester and fed into large intermediate buffers (capacitors), which can continue to supply energy for a sufficient time in the event that the solar cells do not receive any incident sunlight. The harvester then switches between the two energy sources. Since the voltages of the solar cells and the capacitors can fluctuate, depending on the load, the supply voltage of the individual functional units is safeguarded by means of a linear controller.

At the heart of Scipio is a powerful microcontroller with an ARM core. What is important here, however, is that the energy consumption remains low, something which is guaranteed by the built-in microcontroller. This carries out all the necessary computations and controls a display which incorporates various pictograms to indicate the how far the disinfection has progressed; these pictograms also help to guide the user through the whole procedure of the SODIS method. Various sensors must be incorporated in order for Scipio to be able to guide the user through the complete cycle of the SODIS method. First, it is important to ascertain whether Scipio is immersed in water. Only when this is the case is the subsequent measuring procedure started. Several capacitive sensors are used for this, and the change in capacity helps the microcontroller to ascertain whether Scipio is immersed in water or not. As soon as it is, the procedure to lead the user through the method can begin. In order to be able to ascertain whether the bottle has been shaken up correctly, and to be able to assess the orientation of the bottle in the sun, there is an acceleration sensor. Scipio also offers the possibility of finding out whether the bottle used is suitable for this purpose. This is done by measuring the daylight with a corresponding sensor and measuring the UV intensity. The values are essential for the decision-making process as to whether the water is potable. The measured values for the UV intensity come from four UV sensors, two mounted on each side of the printed circuit board.

In addition to the sensors and active components already mentioned, Scipio also has an RF link which can be used in the course of the development to transmit measurement data directly from the bottle. Furthermore, this makes it possible to adapt various reference values afterwards or to communicate any errors to the outside. This is particularly important because Scipio is designed for long-term use. The feature allows central facilities such as aid agencies to transmit new findings about the SODIS method directly to the stick or to quickly diagnose any problems.

4. Firmware

The firmware is written in two languages: the low-level peripheral interface is implemented in C whereas the application and Bluetooth interconnection is written in object-oriented C++ programming language. “Threads” and thread control is implemented using a very simple round robin scheduler and is highly efficient when it comes to execution speed and code size. During one program cycle every process is executed once and looks for urgent data to be processed. In average Scipio is in deep standby mode for 90% of the time which reduces the power consumption drastically.

- Main functionality: if this thread is not blocked by the second one, it runs a state machine every cycle and starts collecting available data from the sensors. Once all samples have been collected they are processed by the subsequent state machine for finding a decision. Depending on the decision the display is updated.

- Plausibility tests: this thread samples the accelerometer as well as the touch sensing unit. The touch sensing unit is used to measure a relative change in the capacitance and is able to decide whether the stick is placed in a water-filled bottle. Using the accelerometer, the position of the stick is calculated. If both conditions are met, this thread will unblock the main functionality thread. It also encloses power monitoring.

- Communication thread: this process handles communication requests and if the Ipad app is connected, it continuously transmits data samples via Bluetooth and takes advantages of the Bluetooth low Energy (BLE) protocol stack embedded in the NRF8001 System-on-a-Chip. A low-energy profile is used to transfer data.

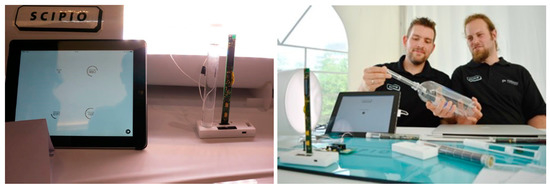

This thread also transmits a simple message containing all sensor data via a serial connection the connected development PC. This feature is used for debugging purposes only. When the memory display made by Sharp was included into the project there were no resources available, so the display driver including draw functionality and frame synchronization was implemented from scratch. As already mentioned all measurements can be displayed via the Bluetooth link in an ipad app (Figure 3). In addition to that demonstrator was designed to power the Scipio with LED for test and debugging purposes.

Figure 3.

Measuremnt data within the tablet app and Communication of the Scipio device with the app running on the ipad.

5. Conclusions

In this paper, we present a new type of device to indicator whether water is purified. The Scipio is designed for low power purposes and is fully autonomous in terms of energy. It is capable of measuring all crucial parameters for a correct application if the SODIS method. Furthermore, a demonstrator has been built to show full functionality of the developed device.

Acknowledgment

We would like to thank all our supporters on our way to the completed and fully functional device.

References

- Rainey, R.C.; Harding, A.K. Acceptability of solar disinfection of drinking water treatment in Kathmandu Valley, Nepal. Int. J. Environ. Health Res. 2005, 15, 361–372. [Google Scholar] [CrossRef]

- Rainey, R.C. Drinking water quality and solar disinfection: Effectiveness in peri-urban households in Nepal. J. Water Health 2005, 3, 239–248. [Google Scholar] [CrossRef]

- United Nations. The Millennium Development Goals Report 2012; United Nations: New York, NY, USA, 2012. [Google Scholar]

- World Health Organization. Water for Life: Making It Happen: [WHO/UNICEF Joint Monitoring Programme for Water Supply and Sanitation]; World Health Organization: Geneva, Switzerland, 2005. [Google Scholar]

- McGuigan, K.G.; Conroy, R.M.; Mosler, H.J.; Du Preez, M.; Ubomba-Jaswa, E.; Fernandez-Ibañez, P. Solar water disinfection (SODIS): A review from bench-top to roof-top. J. Hazard. Mater. 2012, 235–236, 29–46. [Google Scholar] [CrossRef]

- Sommer, B.; Marino, A.; Solarte, Y.; Salas, M.L.; Dierolf, C.; Valiente, C.; Mora, D.; Rechsteiner, R.; Setter, P.; Wirojanagud, W.; et al. SODIS—An emerging water treatment process. AQUA(OXFORD) 1997, 46, 127–137. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).