Novel Methodology Based on Thick Film Gas Sensors to Monitor the Hydraulic Oil Ageing †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hydraulic Test Bench

2.2. Gas Chomatographic Analysis

2.3. Laboratory MOX Sensors System

3. Results and Discussion

3.1. Hydraulic Test Bench

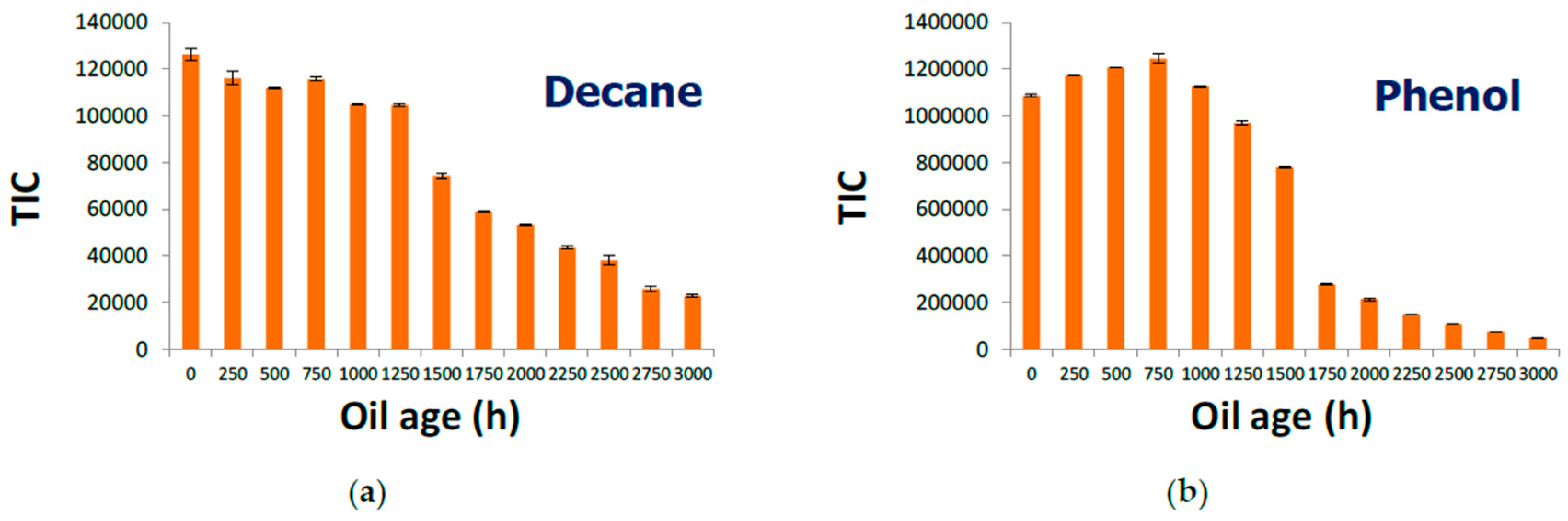

3.2. Gas Chomatographic Analysis

3.3. Laboratory MOX Sensors System–Oil Ageing Characterization

Author Contributions

Conflicts of Interest

References

- Mujahid, A.; Dickert, F.L. Monitoring automotive oil degradation: Analytical tools and onboard sensing technologies. Anal. Bioanal. Chem. 2012, 404, 1197–1209. [Google Scholar] [CrossRef] [PubMed]

- Zebing, M.; Zhao, J.; Xuan, W.; Wang, W.; Luo, J.; Xie, J. Distilling determination of water content in hydraulic oil with a ZnO/glass surface acoustic wave device. Microsyst. Technol. 2017, 23, 1841–1845. [Google Scholar] [CrossRef]

- Sepcic, K.; Josowicz, M.; Janata, J.; Selby, T. Diagnosis of used engine oil based on gas phase analysis. Analyst 2004, 129, 1070–1075. [Google Scholar] [CrossRef]

- Capone, S.; Zuppa, M.; Presicce, D.S.; Francioso, L.; Casino, F.; Siciliano, P. Metal oxide gas sensor array for the detection of diesel fuel in engine oil. Sens. Actuators B Chem. 2008, 131, 125–133. [Google Scholar] [CrossRef]

- Carotta, M.C.; Fioravanti, A.; Gherardi, S.; Malagù, C.; Sacerdoti, M.; Ghiotti, G.; Morandi, S. (Ti,Sn) solid solutions as functional materials for gas sensing. Sens. Actuators B Chem. 2014, 194, 195–205. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fioravanti, A.; Bonanno, A.; Carotta, M.C.; Massarotti, G.P.; Morandi, S.; Riboni, N.; Bianchi, F. Novel Methodology Based on Thick Film Gas Sensors to Monitor the Hydraulic Oil Ageing. Proceedings 2018, 2, 944. https://doi.org/10.3390/proceedings2130944

Fioravanti A, Bonanno A, Carotta MC, Massarotti GP, Morandi S, Riboni N, Bianchi F. Novel Methodology Based on Thick Film Gas Sensors to Monitor the Hydraulic Oil Ageing. Proceedings. 2018; 2(13):944. https://doi.org/10.3390/proceedings2130944

Chicago/Turabian StyleFioravanti, Ambra, Antonino Bonanno, Maria Cristina Carotta, Giorgio Paolo Massarotti, Sara Morandi, Nicolò Riboni, and Federica Bianchi. 2018. "Novel Methodology Based on Thick Film Gas Sensors to Monitor the Hydraulic Oil Ageing" Proceedings 2, no. 13: 944. https://doi.org/10.3390/proceedings2130944

APA StyleFioravanti, A., Bonanno, A., Carotta, M. C., Massarotti, G. P., Morandi, S., Riboni, N., & Bianchi, F. (2018). Novel Methodology Based on Thick Film Gas Sensors to Monitor the Hydraulic Oil Ageing. Proceedings, 2(13), 944. https://doi.org/10.3390/proceedings2130944