Gas Detection Using LMR-Based Optical Fiber Sensors †

Abstract

1. Introduction

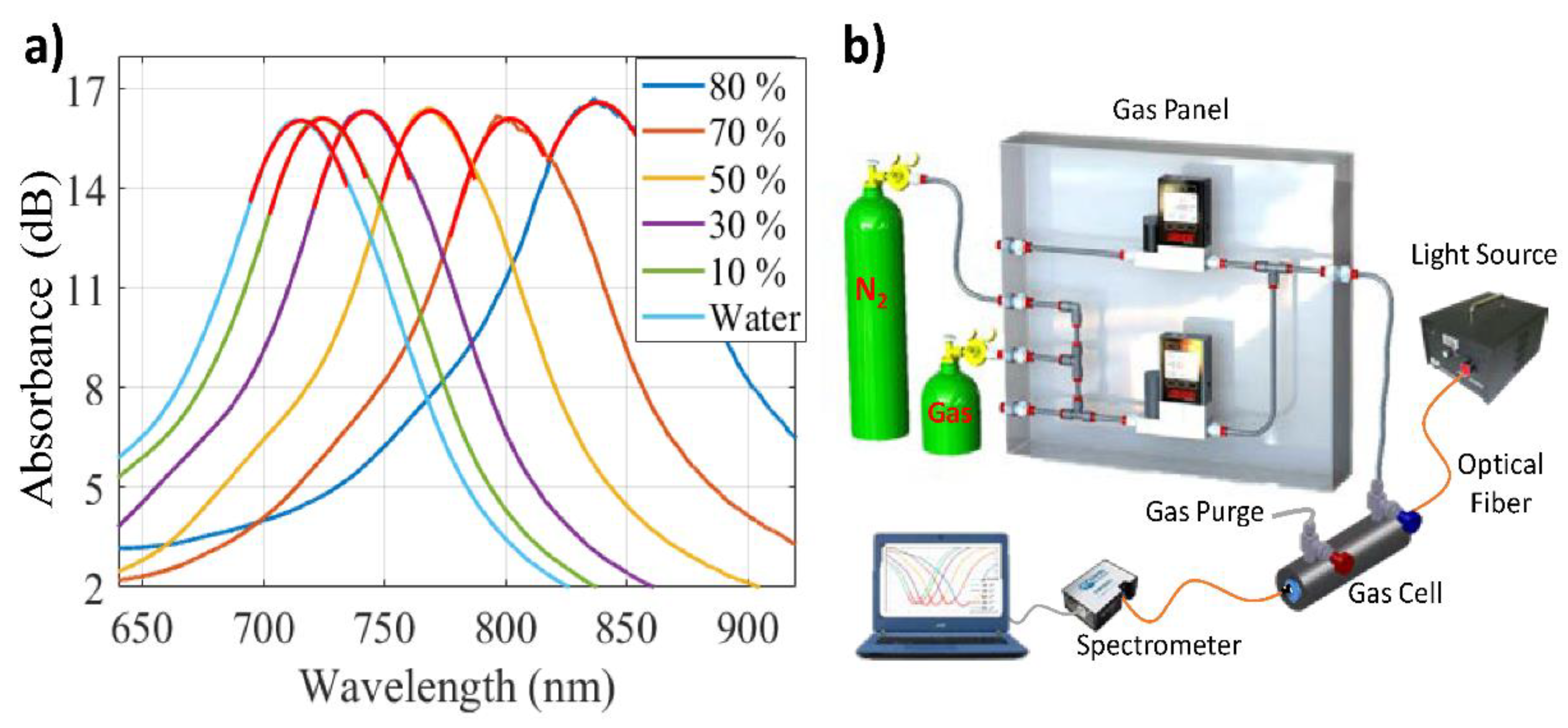

2. Materials and Methods

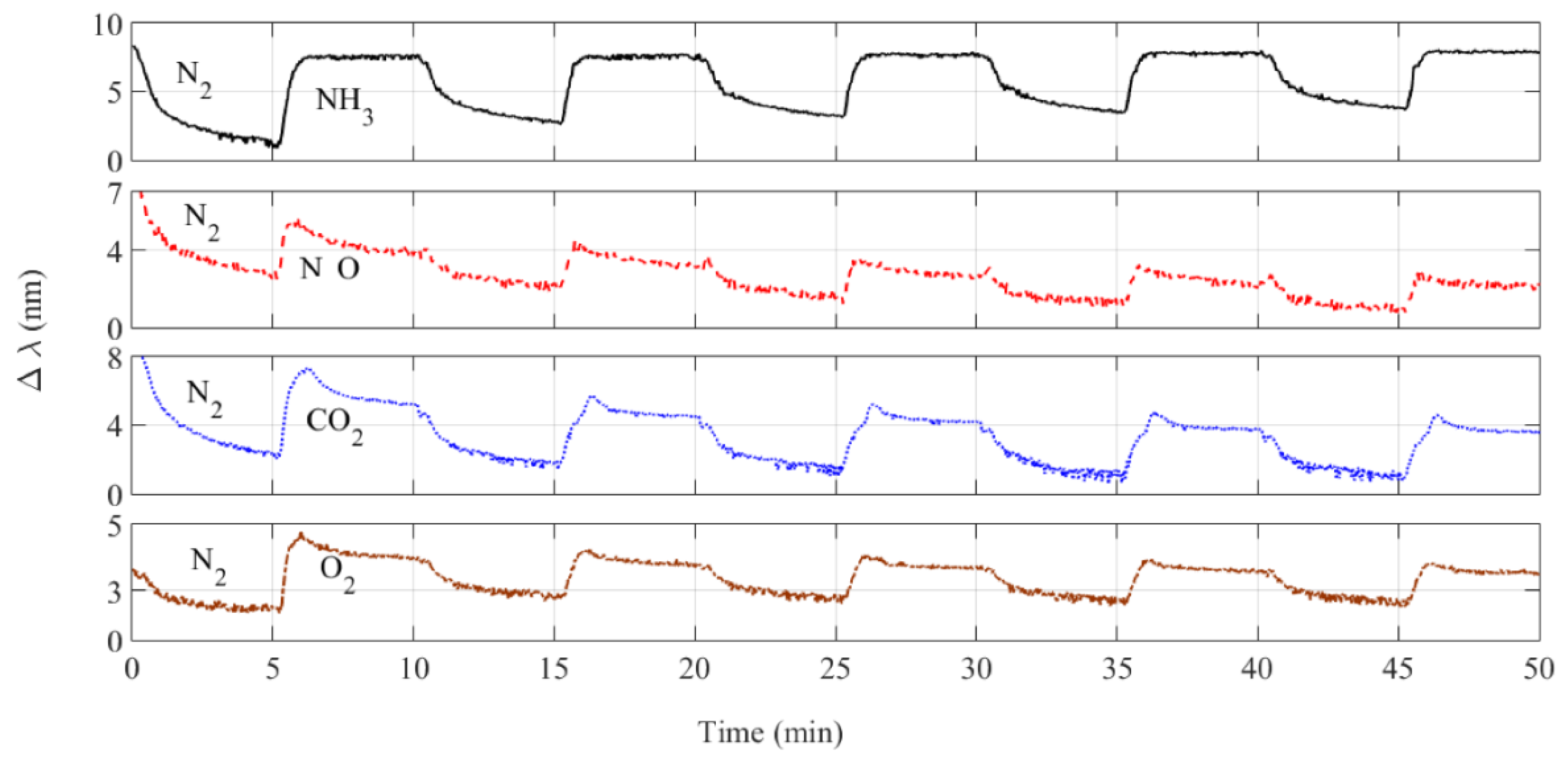

3. Results and Discussions

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef] [PubMed]

- Del Villar, I.; Arregui, F.J.; Zamarreño, C.R.; Corres, J.M.; Bariain, C.; Goicoechea, J.; Elosua, C.; Hernaez, M.; Rivero, P.J.; Socorro, A.B.; et al. Optical sensors based on lossy-mode resonances. Sens. Actuators B Chem. 2017, 240, 174–185. [Google Scholar] [CrossRef]

- Das, S.; Jayaraman, V. SnO2: A comprehensive review on structures and gas sensors. Prog. Mater. Sci. 2014, 66, 112–255. [Google Scholar] [CrossRef]

- Sanchez, P.; Zamarreño, C.R.; Hernaez, M.; Matias, I.R.; Arregui, F.J. Optical fiber refractometers based on Lossy Mode Resonances by means of SnO2 sputtered coatings. Sens. Actuators B Chem. 2014, 202, 154–159. [Google Scholar] [CrossRef]

- Arregui, F.J.; del Villar, I.; Zamarreño, C.R.; Zubiate, P.; Matias, I.R. Giant sensitivity of optical fiber sensors by means of lossy mode resonance. Sens. Actuators B Chem. 2016, 232, 660–665. [Google Scholar] [CrossRef]

- Ozcariz, A.; Zamarreño, C.R.; Zubiate, P.; Arregui, F.J. Is there a frontier in sensitivity with Lossy mode resonance (LMR) based refractometers? Sci. Rep. 2017, 7, 10280. [Google Scholar] [CrossRef] [PubMed]

- Preiß, E.M.; Rogge, T.; Krauß, A.; Seidel, H. Gas Sensing by SnO2 Thin Films Prepared by Large- area Pulsed Laser Deposition. Procedia Eng. 2015, 120, 88–91. [Google Scholar] [CrossRef][Green Version]

- Cao, W.; Duan, Y. Optical fiber-based evanescent ammonia sensor. Sens. Actuators B Chem. 2005, 110, 252–259. [Google Scholar] [CrossRef]

- Huang, Y.; Wieck, L.; Tao, S. Development and evaluation of optical fiber NH3 sensors for application in air quality monitoring. Atmos. Environ. 2013, 66, 1–7. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dreyer, U.J.; Ozcariz, A.; Ascorbe, J.; Zubiate, P.; Vitoria, I.; Martelli, C.; Da Silva, J.C.C.; Zamarreño, C.R. Gas Detection Using LMR-Based Optical Fiber Sensors. Proceedings 2018, 2, 890. https://doi.org/10.3390/proceedings2130890

Dreyer UJ, Ozcariz A, Ascorbe J, Zubiate P, Vitoria I, Martelli C, Da Silva JCC, Zamarreño CR. Gas Detection Using LMR-Based Optical Fiber Sensors. Proceedings. 2018; 2(13):890. https://doi.org/10.3390/proceedings2130890

Chicago/Turabian StyleDreyer, Uilian José, Aritz Ozcariz, Joaquín Ascorbe, Pablo Zubiate, Ignacio Vitoria, Cicero Martelli, Jean Carlos Cardozo Da Silva, and Carlos Ruiz Zamarreño. 2018. "Gas Detection Using LMR-Based Optical Fiber Sensors" Proceedings 2, no. 13: 890. https://doi.org/10.3390/proceedings2130890

APA StyleDreyer, U. J., Ozcariz, A., Ascorbe, J., Zubiate, P., Vitoria, I., Martelli, C., Da Silva, J. C. C., & Zamarreño, C. R. (2018). Gas Detection Using LMR-Based Optical Fiber Sensors. Proceedings, 2(13), 890. https://doi.org/10.3390/proceedings2130890