Efficient Self-Heating in Nanowire Sensors: Prospects for Very-Low Power †

Abstract

1. Introduction

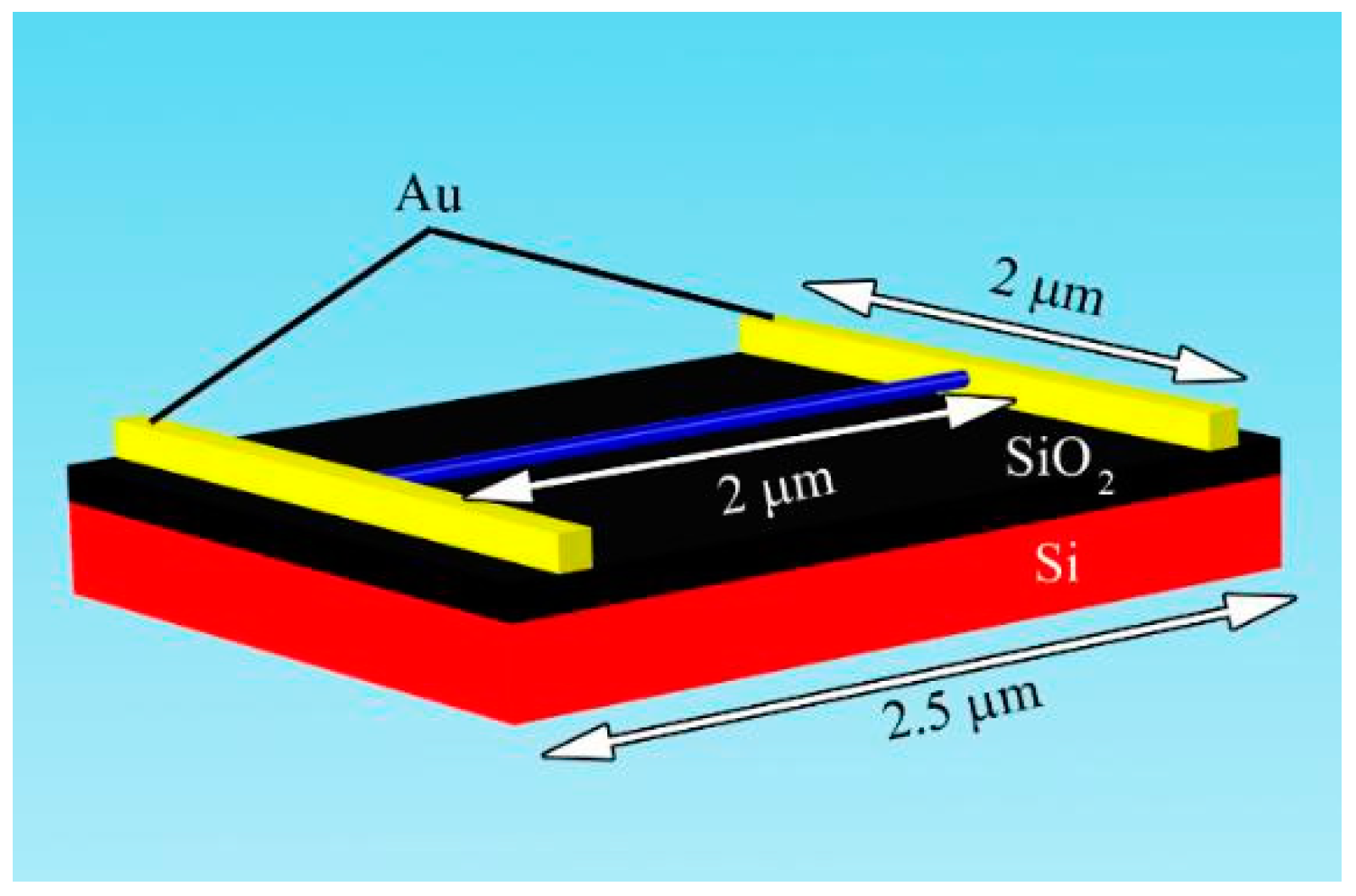

2. Materials Shape and Dimensions

3. Electrical Transport Properties

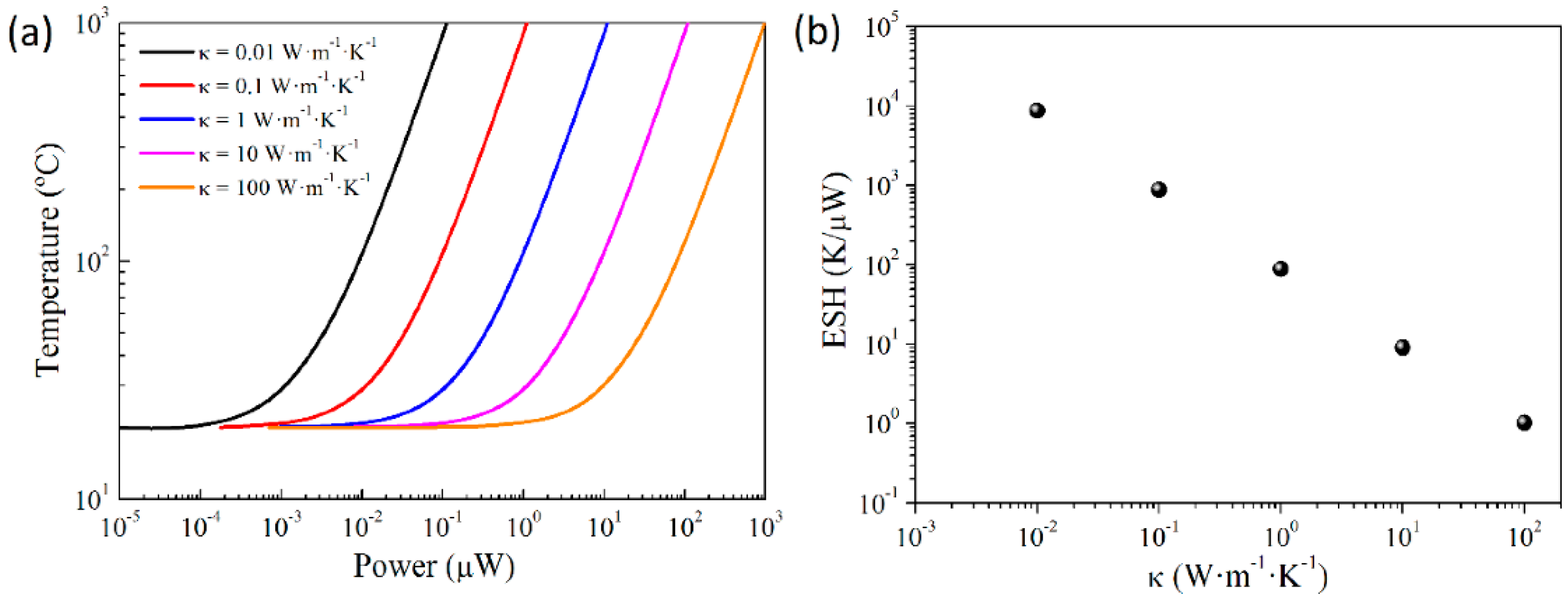

4. Heat Transport Properties

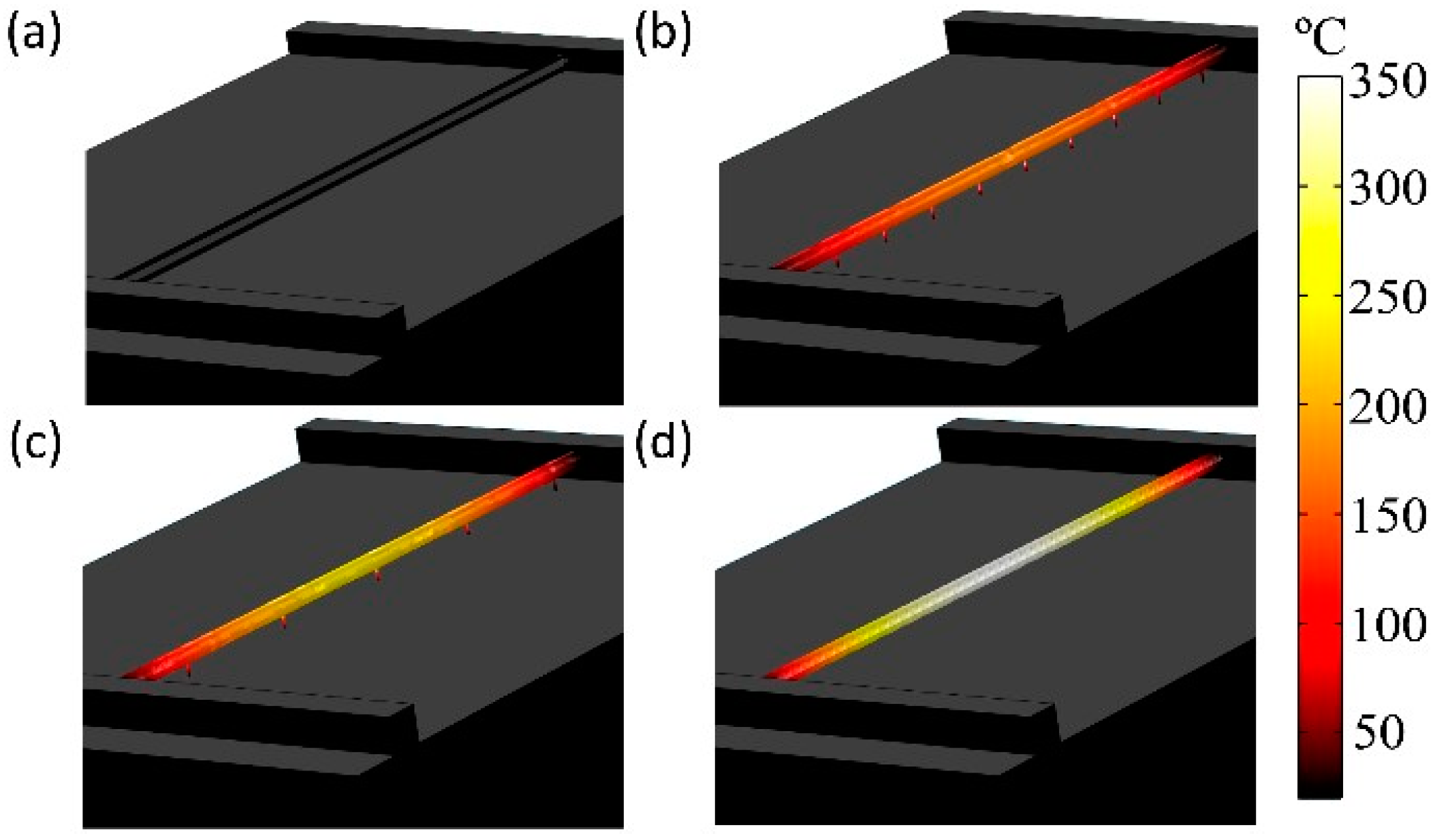

5. Thermal Loses With the Substrate

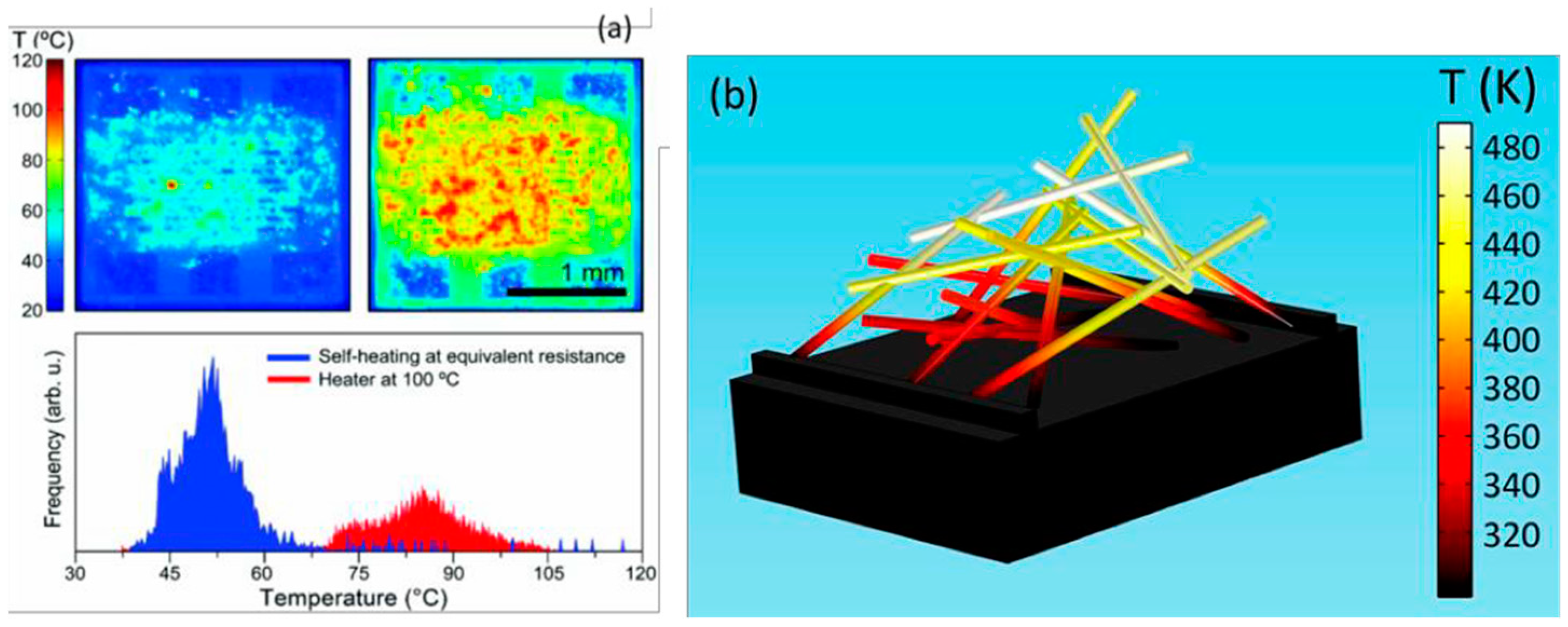

6. Multiple Nanowires

7. Recommendations for an Efficient Self-Heating

- i.

- For obvious reasons, the cross-section dimensions of the wires are crucial, as the temperature is inversely proportional to the square of the characteristic width of the nanoparticle (e.g., radius in the case of a cylindrical nanowire).

- ii.

- In terms of materials properties, thermal conductivity is the determining factor for an efficient self-heating. Confinement effects at the nanoscale can modify the thermal conductivity in the direction of improving the efficiency.

- iii.

- The electrical properties (i.e., electrical conductivity or resistivity) are not the key factors to achieve efficient self-heating, but they are accountable for the conditions in which the electrical power should be applied.

- iv.

- Thermal loses with all elements in contact with the self-heated material (usually, substrate and electrical contacts) are greatly detrimental for the efficiency. While some thermal insulation is needed, just a few nanometers might be enough to dramatically reduce these thermal losses.

- v.

- Multiple-wire configuration may help to create the suitable thermal insulation conditions, facilitating device integration, but opening new challenges in device reproducibility.

- vi.

- The coupling between sensing effects and temperature effects on the nanowire resistance affects the amount of power being dissipated. This effect does not compromise the ability to increase the temperature of the material, but limits the accuracy in controlling the actual temperature reached in self-heating mode.

8. Conclusions

Author Contributions

Acknowledgments

References

- de Silva, C.W. Sensors and Actuators: Engineering System Instrumentation, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Semancik, S.; Cavicchi, R. Kinetically Controlled Chemical Sensing Using Micromachined Structures. Acc. Chem. Res. 1998, 31, 279–287. [Google Scholar] [CrossRef]

- Semancik, S.; Cavicchi, R.E.; Wheeler, M.C.; Tiffany, J.E.; Poirier, G.E.; Walton, R.M.; Suehle, J.S.; Panchapakesan, B.; DeVoe, D.L. Microhotplate platforms for chemical sensor research. Sens. Actuators B Chem. 2001, 77, 579–591. [Google Scholar] [CrossRef]

- Graf, M.; Barrettino, D.; Baltes, H.P.; Hierlemann, A. CMOS Hotplate Chemical Microsensors; Springer-Verlag: Berlin, Germany, 2007. [Google Scholar]

- Elmi, I.; Zampolli, S.; Cozzani, E.; Mancarella, F.; Cardinali, G.C. Development of ultra-low-power consumption MOX sensors with ppb-level VOC detection capabilities for emerging applications. Sens. Actuators B Chem. 2008, 135, 342–351. [Google Scholar] [CrossRef]

- Giberti, A.; Guidi, V.; Vincenzi, D. A study of heat distribution and dissipation in a micromachined chemoresistive gas sensor. Sens. Actuators B Chem. 2011, 153, 409–414. [Google Scholar] [CrossRef]

- Taguchi, N. Gas-Detecting Device. U.S. Patent 3,631,436, 1971. [Google Scholar]

- Briand, D.; Krauss, A.; Van der Schoot, B.; Weimar, U.; Barsan, N.; Göpel, W.; De Rooij, N.F. Design and fabrication of high-temperature micro-hotplates for drop-coated gas sensors. Sens. Actuators B Chem. 2000, 68, 223–233. [Google Scholar] [CrossRef]

- Puigcorbé, J.; Vogel, D.; Michel, B.; Vila, A.; Gracia, I.; Cane, C.; Morante, J.R. Thermal and mechanical analysis of micromachined gas sensors. J. Micromech. Microeng. 2003, 13, 548–556. [Google Scholar] [CrossRef]

- Iwaki, T.; Covington, J.A.; Gardner, J.W.; Udrea, F.; Blackman, C.S.; Parkin, I.P. SQI-CMOS heaters for gas sensors. IEEE Sens. 2006, 1–3, 460–463. [Google Scholar]

- Vallejos, S.; Grácia, I.; Chmela, O.; Figueras, E.; Hubálek, J.; Cané, C. Chemoresistive micromachined gas sensors based on functionalized metal oxide nanowires: Performance and reliability. Sens. Actuators B. Chem. 2016, 235, 525–534. [Google Scholar] [CrossRef]

- Chikkadi, K.; Muoth, M.; Maiwald, V.; Roman, C.; Hierold, C. Ultra-low power operation of self-heated, suspended carbon nanotube gas sensors. Appl. Phys. Lett. 2013, 103, 223109. [Google Scholar] [CrossRef]

- Kim, Y.D.; Kim, H.; Cho, Y.; Ryoo, J.H.; Park, C.H.; Kim, P.; Kim, Y.S.; Lee, S.; Li, Y.; Park, S.N.; Yoo, Y.S. Bright visible light emission from grapheme. Nat. Nanotechnol. 2015, 10, 1–7. [Google Scholar] [CrossRef]

- COMSOL AB COMSOL Multiphysics® v. 5.2. 2017. Available online: https://www.comsol.com/ (accessed on 1 December 2018).

- Earle, M.D. The electrical conductivity of titanium dioxide. Phys. Rev. 1942, 61, 56–62. [Google Scholar] [CrossRef]

- Comini, E.; Guidi, V.; Malagu, C.; Martinelli, G.; Pan, Z.; Sberveglieri, G.; Wang, Z.L. Electrical Properties of Tin Dioxide Two-Dimensional Nanostructures. J. Phys. Chem. B 2004, 108, 1882–1887. [Google Scholar] [CrossRef]

- Sakurai, M.; Wang, Y.G.; Uemura, T.; Aono, M. Electrical properties of individual ZnO nanowires. Nanotechnology 2009, 20, 155203. [Google Scholar] [CrossRef]

- Fàbrega, C.; Hernández-Ramírez, F.; Prades, J.D.; Jiménez-Díaz, R.; Andreu, T.; Morante, J.R. On the photoconduction properties of low resistivity TiO2 nanotubes. Nanotechnology 2010, 21, 445703. [Google Scholar] [CrossRef]

- Žagar, K.; Fàbrega, C.; Hernandez-Ramirez, F.; Prades, J.D.; Morante, J.R.; Rečnik, A.; Čeh, M. Insight into the structural, electrical and photoresponse properties of individual Fe: SrTiO3 nanotubes. Mater. Chem. Phys. 2013, 141, 9–13. [Google Scholar] [CrossRef]

- Turkes, P.; Pluntke, C.; Helbig, R. Thermal conductivity of SnO2 single crystals. J. Phys. C Solid State Phys. 1980, 13, 4941–4951. [Google Scholar] [CrossRef]

- Shi, L.; Hao, Q.; Yu, C.; Mingo, N.; Kong, X.; Wang, Z.L. Thermal conductivities of individual tin dioxide nanobelts. Appl. Phys. Lett. 2004, 84, 2638–2640. [Google Scholar] [CrossRef]

- Özgür, Ü.; Gu, X.; Chevtchenko, S.; Spradlin, J.; Cho, S.J.; Morkoc, H.; Pollak, F.H.; Everitt, H.O.; Nemeth, B.; Nause, J.E. Thermal conductivity of bulk ZnO after different thermal treatments. J. Electron. Mater. 2006, 35, 550–555. [Google Scholar] [CrossRef]

- Im, J.S.; Kim, S.J.; Kang, P.H.; Lee, Y.S. The improved electrical conductivity of carbon nanofibers by fluorinated MWCNTs. J. Ind. Eng. Chem. 2009, 15, 699–702. [Google Scholar] [CrossRef]

- Mahanta, N.K.; Abramson, A.R.; Lake, M.L.; Burton, D.J.; Chang, J.C.; Mayer, H.K.; Ravine, J.L. Thermal conductivity of carbon nanofiber mats. Carbon 2010, 48, 4457–4465. [Google Scholar] [CrossRef]

- Salehi, A. A highly sensitive self heated SnO2 carbon monoxide sensor. Sens. Actuators B Chem. 2003, 96, 88–93. [Google Scholar] [CrossRef]

- Afshar, M.; Preiß, E.M.; Sauerwald, T.; Rodner, M.; Feili, D.; Straub, M.; König, K.; Schütze, A.; Seidel, H. Indium-tin-oxide single-nanowire gas sensor fabricated via laser writing and subsequent etching. Sens. Actuators B Chem. 2015, 215, 525–535. [Google Scholar] [CrossRef]

- Vasileska, D.; Raleva, K.; Hossain, A.; Goodnick, S.M. Current progress in modeling self-heating effects in FD SOI devices and nanowire transistors. J. Comput. Electron. 2012, 11, 238–248. [Google Scholar] [CrossRef]

- Hunley, D.P.; Johnson, S.L.; Flores, R.L.; Sundararajan, A.; Strachan, D.R. Analytical model for self-heating in nanowire geometries. J. Appl. Phys. 2013, 113, 234306. [Google Scholar] [CrossRef]

- Pala, M.G.; Cresti, A. Increase of self-heating effects in nanodevices induced by surface roughness: A full-quantum study. J. Appl. Phys. 2015, 117, 084313. [Google Scholar] [CrossRef]

- Vasileska, D.; Hossain, A.; Raleva, K.; Goodnick, S.M. The role of the source and drain contacts on self-heating effect in nanowire transistors. J. Comput. Electron. 2010, 9, 180–186. [Google Scholar] [CrossRef]

- Rhyner, R.; Luisier, M. Influence of thermal losses at the gate contact of Si nanowire transistors: A phenomenological treatment in quantum transport theory. Appl. Phys. Lett. 2017, 110, 103508. [Google Scholar] [CrossRef]

- Zhu, L.F.; She, J.C.; Luo, J.Y.; Deng, S.Z.; Chen, J.; Ji, X.W.; Xu, N.S. Self-heated hydrogen gas sensors based on Pt-coated W18O49 nanowire networks with high sensitivity, good selectivity and low power consumption. Sens. Actuators B Chem. 2011, 153, 354–360. [Google Scholar] [CrossRef]

- Chinh, N.D.; van Toan, N.; van Quang, V.; van Duy, N.; Hoa, N.D.; van Hieu, N. Comparative NO2 gas-sensing performance of the self-heated individual, multiple and networked SnO2 nanowire sensors fabricated by a simple process. Sens. Actuators B Chem. 2014, 201, 7–12. [Google Scholar] [CrossRef]

- Guilera, J.; Fàbrega, C.; Casals, O.; Hernández-Ramírez, F.; Wang, S.; Mathur, S.; Udrea, F.; De Luca, A.; Ali, S.Z.; Romano-Rodríguez, A.; Prades, J.D. Facile integration of ordered nanowires in functional devices. Sens. Actuators B Chem. 2015, 221, 104–112. [Google Scholar] [CrossRef]

- Monereo, O.; Casals, O.; Prades, J.D.; Cirera, A. A Low-cost Approach to Low-power Gas Sensors Based on Self-Heating Effects in Large Arrays of Nanostructures. Procedia Eng. 2015, 120, 787–790. [Google Scholar] [CrossRef][Green Version]

- Monereo, O.; Prades, J.D.; Cirera, A. Self-heating effects in large arrangements of randomly oriented carbon nanofibers: Application to gas sensors. Sens. Actuators B Chem. 2015, 211, 489–497. [Google Scholar] [CrossRef]

- Monereo, O.; Casals, O.; Prades, J.D.; Cirera, A. Self-heating in pulsed mode for signal quality improvement: Application to carbon nanostructures-based sensors. Sens. Actuators B Chem. 2016, 226, 254–265. [Google Scholar] [CrossRef]

- Monereo, O.; Illera, S.; Varea, A.; Schmidt, M.; Sauerwald, T.; Schütze, A.; Cirera, A.; Prades, J.D. Localized self-heating in large arrays of 1D nanostructures. Nanoscale 2016, 8, 5082–5088. [Google Scholar] [CrossRef]

- Tan, H.M.; Manh Hung, C.; Ngoc, T.M.; Nguyen, H.; Duc Hoa, N.; Van Duy, N.; Hieu, N.V. Novel Self-Heated Gas Sensors Using on-Chip Networked Nanowires with Ultralow Power Consumption. ACS Appl. Mater. Interfaces 2017, 9, 6153–6162. [Google Scholar] [CrossRef]

- Fàbrega, C.; Casals, O.; Hernández-Ramírez, F.; Prades, J.D. A review on efficient self-heating in nanowire sensors: Prospects for very-low devices. Sens. Actuators B Chem. 2018, 256, 797–811. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fàbrega, C.; Casals, O.; Prades, J.D. Efficient Self-Heating in Nanowire Sensors: Prospects for Very-Low Power. Proceedings 2018, 2, 829. https://doi.org/10.3390/proceedings2130829

Fàbrega C, Casals O, Prades JD. Efficient Self-Heating in Nanowire Sensors: Prospects for Very-Low Power. Proceedings. 2018; 2(13):829. https://doi.org/10.3390/proceedings2130829

Chicago/Turabian StyleFàbrega, Cristian, Olga Casals, and Joan Daniel Prades. 2018. "Efficient Self-Heating in Nanowire Sensors: Prospects for Very-Low Power" Proceedings 2, no. 13: 829. https://doi.org/10.3390/proceedings2130829

APA StyleFàbrega, C., Casals, O., & Prades, J. D. (2018). Efficient Self-Heating in Nanowire Sensors: Prospects for Very-Low Power. Proceedings, 2(13), 829. https://doi.org/10.3390/proceedings2130829