Abstract

This paper reports a calorimetric micro-sensor designed for aerodynamic applications. Measuring both the amplitude and the sign of the wall shear stress at small length-scale and high frequencies, the micro-sensor is particularly suited for flow separation detection and flow control. The micro-sensor was calibrated in static and dynamic in a turbulent boundary layer wind tunnel. Several micro-sensors were embedded in various configurations for measuring the shear stress and detecting flow separation. Specially, one was embedded inside an actuator slot for in situ measurements and twelve, associated with miniaturized electronics, were implemented on a flap model for active flow control experiments.

1. Introduction

Flow control consists in manipulating free stream or wall bounded flows to produce favourable changes in the flow state [1]. Such technique can decrease drag, prevent separation, delay laminar-turbulent transition, reduce noise, and enhance mixing… This is thereby a solution for both safety and ecological issues concerning the world of transportation, as the main objectives in research on future vehicles deals with the reduction of fuel consumption and CO2 or toxic NOx gases emission. Flow control strategies are divided into two categories: passive flow control and active flow control, depending on the device nature. Active flow control is most powerful as it can be modulated according to sensors readings on the flow state. Efforts are therefore made in order to realize power saving actuators and accurate small easy-integrated and robust sensors. Focusing on sensors technology, microelectromechanical system (MEMS) based sensors present the advantage of reduced size and high sensibility.

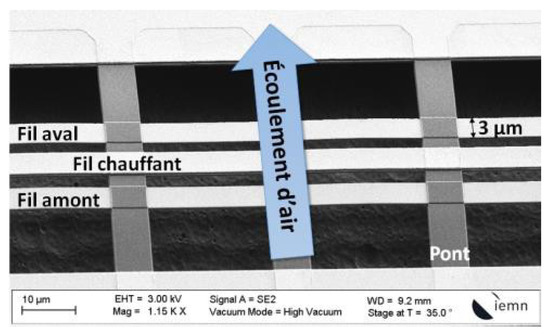

On previous studies, we presented a high temperature gradient calorimetric micro-sensor designed for flow control applications in [2,3,4]. This micro-sensor (Figure 1) works as a thermal anemometer with a heated wire, which is maintained at constant temperature by adapting the heating current to the flow velocity. Two micro-wires-based temperature detectors placed on both sides of the heater provide the flow direction information. This flat surface mounted micro-sensor measure the wall shear stress. This quantity is proportional to the velocity gradient at the wall and its knowledge plays a key role in complex flow phenomena such as separation. The micro-sensor was calibrated with wall shear stress between −2.4 Pa and +2.4 Pa, exhibiting a traditional polynomial behaviour [2,3]. It has been tested in non-classic flow configurations: at the trailing edge of an airfoil model to detect separation [4] and downstream a 2D square obstacle with massive recirculation bubble [3]. In this paper, we present the advances made with the micro-sensor integration in complex environments. In the first part, the micro-sensor was integrated inside the slot of a macroscopic jet actuator, for in situ velocity measurements. The application aimed here is the actuator control using non-intrusive measurements. In the second part, twelve micro-sensors were embedded into an airfoil model designed for flow separation control experiments.

Figure 1.

Scanning Electron Microscopy Image of the calorimetric micro-sensor [4].

2. In Situ Measurements of a Jet Actuator Using the Calorimetric Micro-Sensor

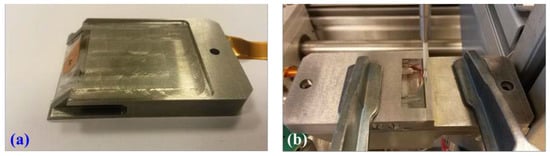

The calorimetric micro-sensor has been integrated in an actuator slot. The actuator is composed of a cavity with an active valve on one side and closed by a cap open to the exterior with a 30 mm × 10 mm × 0.5 mm inclined slot. The hood is removable and can be dissembled into two parts, enabling the integration of the micro-sensor on one half (Figure 2a). The assembled actuator is characterized on a purpose-built bench. A hot-wire probe is positioned near the slot for velocity measurements near the jet exit (Figure 2b).

Figure 2.

(a) Micro-sensor integrated in the actuator hood (b) Full assembled actuator with integrated micro-sensor on the testing bench.

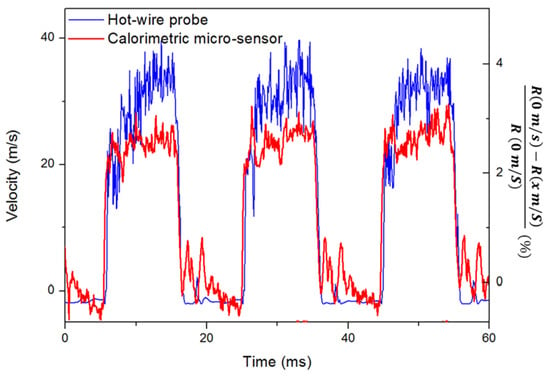

The actuator can work as a pulsed jet with air pressure supply and voltage command of the valve. On Figure 3, the actuator is controlled using a square wave voltage signal to close and open the valve at a frequency of 50 Hz. The air pressure supply is 1 bar. The output velocity measured with the hot-wire (left axis) presents peaks up to 40 m/s. The resulting response of the MEMS sensor (right axis) is in phase with the hot-wire response and presents peaks up to 3% of resistance variation.

Figure 3.

Micro-sensor and hot-wire responses for pulsed blowing at 50 Hz actuation frequency.

3. Active Flow Control on a Flap Model Using an Array of Twelve Calorimetric Micro-Sensors

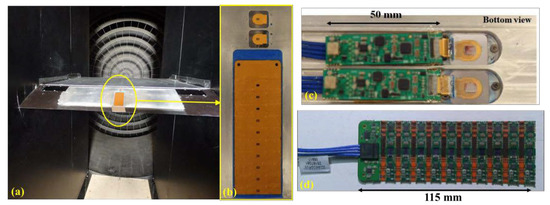

Twelve calorimetric micro-sensors have been implemented in an airplane flap model. The model was mounted on a large wind tunnel with flow velocities going up to 70 m/s. The model is composed of a 1 m long flat plate and a 22 cm long cord flap (Figure 4a). The flap is equipped with Festo® MHE2 pulsed jet valves distributed along the leading edge. The micro-sensors have been implement in the middle of the flap, along the cord, with two micro-sensors in single packaging near the leading edge and a flexible strip reuniting ten micro-sensors reaching the trailing edge (Figure 4b). Being flexible, the strip matches the flap camber. The two single packaging micro-sensors are coupled with miniaturized constant temperature electronics (Figure 4c) implemented in the model. For the ten micro-sensors implemented in the flexible strip, a common miniaturized electronics has been designed and produced.

Figure 4.

(a) Flap model equipped with twelve calorimetric micro-sensor placed along the cord (b) Zoom on the micro-sensors: two single micro-sensors and a flexible strip with 10 micro-sensors (c) Miniaturized electronics of the single sensors (d) Miniaturized electronics of the flexible strips.

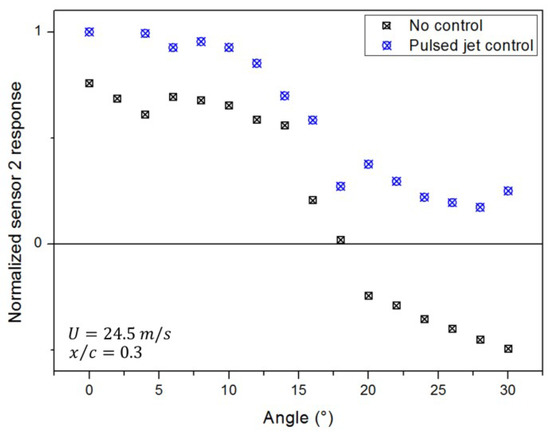

Active flow control experiments have been performed to control the flow separation naturally occurring on the flap when the angle of attack (AOA) is increased. Figure 5 compares the measurements obtained without active control (black square symbols) and with pulsed jet control (blue circles). The calorimetric measurements enables to detect the negative shear stress resulting from the natural flow separation. For the micro-sensor 2 located in x/c = 0.3, the flow separation naturally occurs for an angle of 17°. With pulsed jet control, the shear stress remains positive even for 30° of angle of attack. The actuators achieve to control separation and the micro-sensors successfully detect the flow change.

Figure 5.

Control of separation: (a) normalized time-averaged response of the micro-sensor at x/c = 0.3 without and with active control (b) Dynamic response for an angle of attack (AOA) of 2° (attached flow), 30° (separated flow) and 30° with pulsed jets.

4. Conclusions

This paper presented two aerodynamic applications performed using calorimetric micro-sensors previously developed. One micro-sensor was integrated inside a macroscopic actuator slot. The actuator has been used in pulsed blowing mode. The micro-sensor successfully provided in situ measurements of the actuator jet flow with high sensitivity in constant current mode. The second experiment consisted in implementing twelve micro-sensors in a flap model and running flow control experiments. Natural flow separation along the flap cord was detected using the calorimetric measurements of the micro-sensors. The micro-sensors detected the effect of the active flow control to prevent flow separation. These experiments contributed to increasing the maturity of the devices and ensuring its robustness for aerodynamic applications.

Acknowledgments

The French National Research Agency (ANR) in the framework of the ANR ASTRID “CAMELOTT” Project funded this work. It was supported by the regional platform CONTRAERO in the framework of the CPER ELSAT 2020 Project, co-financed by the European Regional Development Fund, the French State and the Hauts de France Region. The authors also thank RENATECH, the French national nanofabrication network, and the ONERA Specific Devices and Models unit, which provided the design and fabrication of the test models.

References

- MacMynowski, D.G.; Williams, D. Flow Control Terminology. Fundam. Appl. Mod. Flow Control 2009, 59–71. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Claudel, J.; Gerbedoen, J.-C.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. High temperature gradient micro-sensor for wall shear stress and flow direction measurements. Appl. Phys. Lett. 2016, 109, 241905. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. High temperature gradient calorimetric wall shear stress micro-sensor for flow separation detection. Sens. Actuators Phys. 2017, 266, 232–241. [Google Scholar] [CrossRef]

- Ghouila-Houri, C.; Gallas, Q.; Garnier, E.; Merlen, A.; Viard, R.; Talbi, A.; Pernod, P. Wall Shear Stress Calorimetric Micro-Sensor Designed for Flow Separation Detection and Active Flow Control. Proceedings 2017, 1, 376. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).