Enhancing the Sensitivity of SMS Fiber Sensors by the Use of High Refractive Index Coatings †

Abstract

:1. Introduction

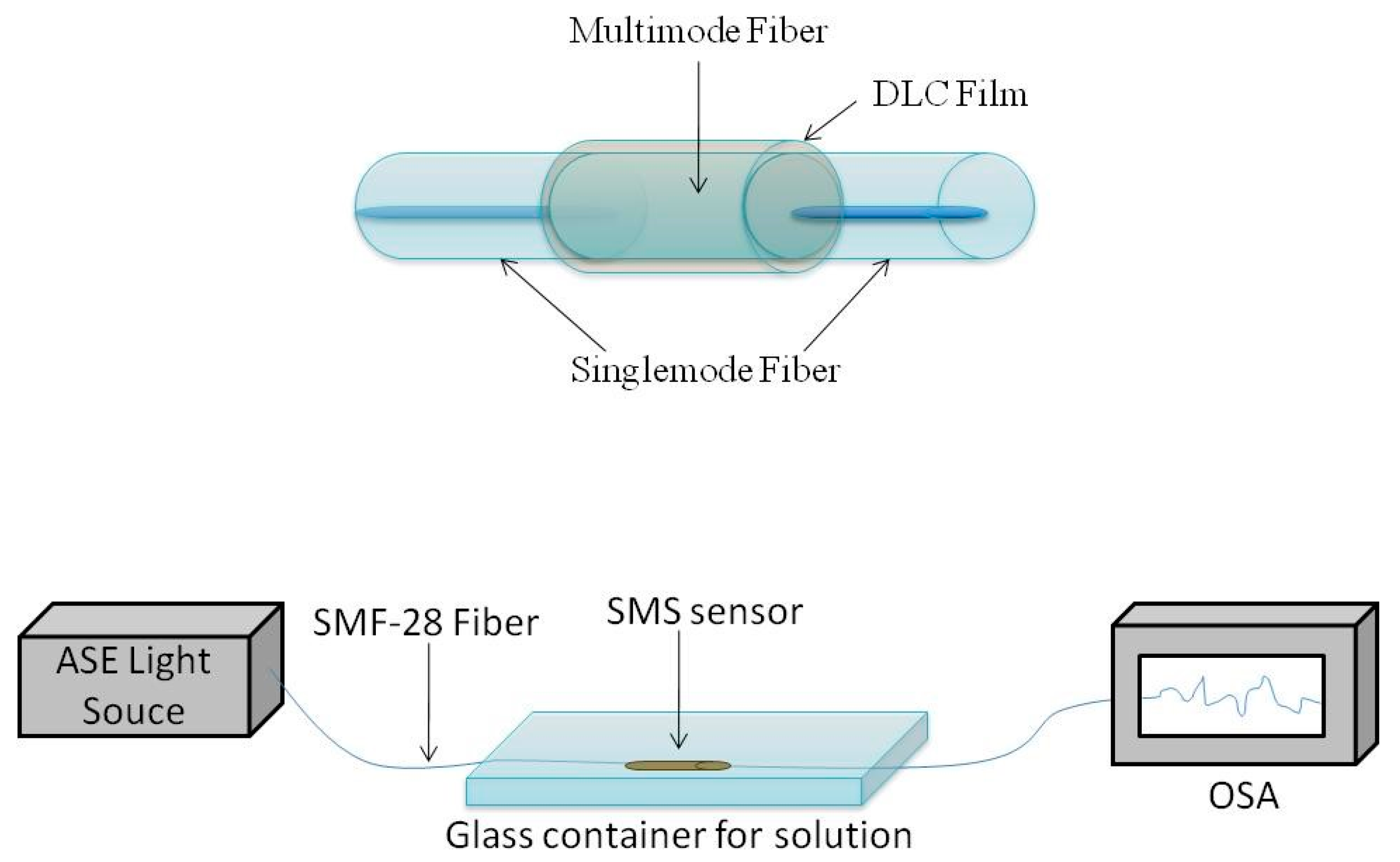

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Soldano, L.B.; Pennings, E.C.M. Optical multi-mode interference devices based on self-imaging: Principles and applications. J. Light. Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef]

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. High sensitivity SMS fiber structure based refractometer—Analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef] [PubMed]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Homola, J.; Sinclair, S.Y.; Günter, G. Surface plasmon resonance sensors. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Iadicicco, A.; Cusano, A.; Campopiano, S.; Cutolo, A.; Giordano, M. Thinned fiber Bragg gratings as refractive índex sensors. IEEE Sens. J. 2005, 5, 1288–1295. [Google Scholar] [CrossRef]

- Smietana, M.; Szmidt, J.; Korwin-Pawlowski, M.L.; Bock, W.J.; Grabarczyk, J. Application of diamond-like carbon films in optical fibre sensors based on long period gratings. Diam. Relat. Mater. 2007, 16, 1374–1377. [Google Scholar] [CrossRef]

- Bhatia, P.; Gupta, B.D. Surface-plasmon-resonance-based fiber-optic refractive index sensor: Sensitivity enhancement. Appl. Opt. 2011, 50, 2032–2036. [Google Scholar] [CrossRef] [PubMed]

- Constantini, D.M.; Muller, C.A.P.; Vasiliev, S.A.; Limberger, H.G.; Salathe, R.P. Tunable loss filter based on metal coated long-period fibre grating. IEEE Photonics Technol. Lett. 1999, 11, 1458–1460. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. 2002, 37, 129–281. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vette, T.; Burns, G.; Bellini, R.; Camargo, S.S., Jr.; Borges, C.V.S.; Rente, B.; Grattan, K.; Martinez, M.A.G. Enhancing the Sensitivity of SMS Fiber Sensors by the Use of High Refractive Index Coatings. Proceedings 2018, 2, 1106. https://doi.org/10.3390/proceedings2131106

Vette T, Burns G, Bellini R, Camargo SS Jr., Borges CVS, Rente B, Grattan K, Martinez MAG. Enhancing the Sensitivity of SMS Fiber Sensors by the Use of High Refractive Index Coatings. Proceedings. 2018; 2(13):1106. https://doi.org/10.3390/proceedings2131106

Chicago/Turabian StyleVette, Thulio, Gustavo Burns, Renato Bellini, Sergio S. Camargo, Jr., Carolina V. S. Borges, Bruno Rente, Kenneth Grattan, and Maria A. G. Martinez. 2018. "Enhancing the Sensitivity of SMS Fiber Sensors by the Use of High Refractive Index Coatings" Proceedings 2, no. 13: 1106. https://doi.org/10.3390/proceedings2131106

APA StyleVette, T., Burns, G., Bellini, R., Camargo, S. S., Jr., Borges, C. V. S., Rente, B., Grattan, K., & Martinez, M. A. G. (2018). Enhancing the Sensitivity of SMS Fiber Sensors by the Use of High Refractive Index Coatings. Proceedings, 2(13), 1106. https://doi.org/10.3390/proceedings2131106