Flatness Improvement of Double-Sided Magnetic Film for Narrow Gap Electromagnetic Energy Harvester †

Abstract

:1. Introduction

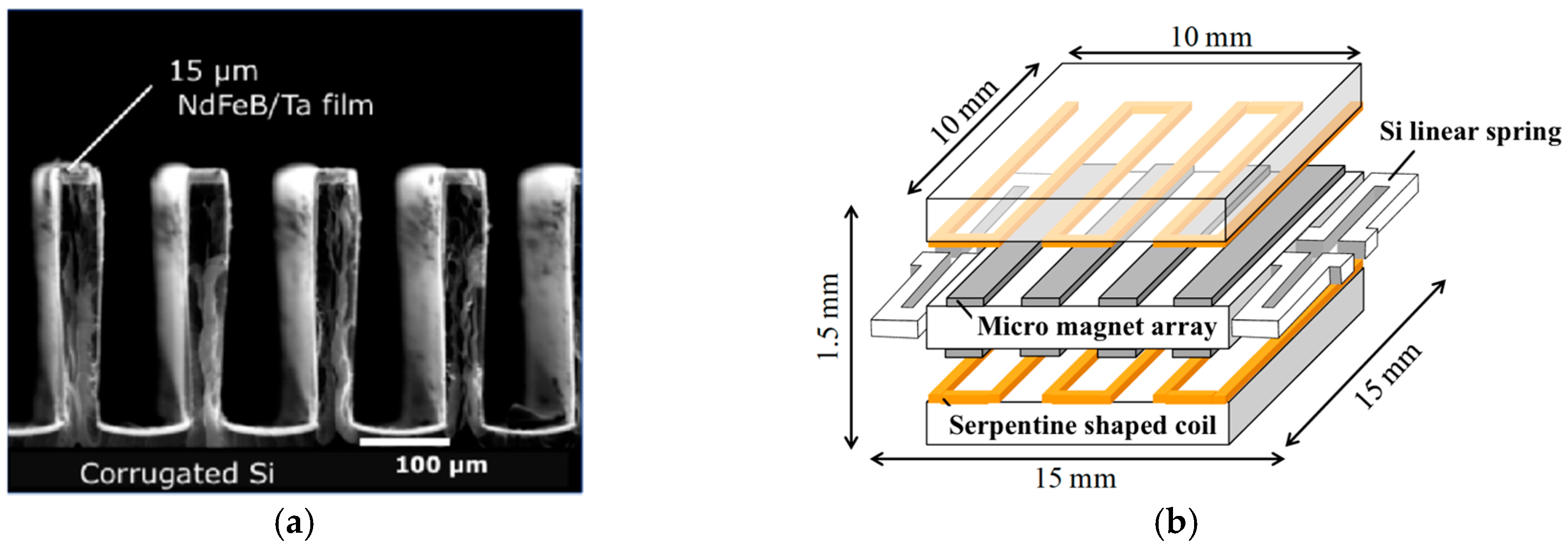

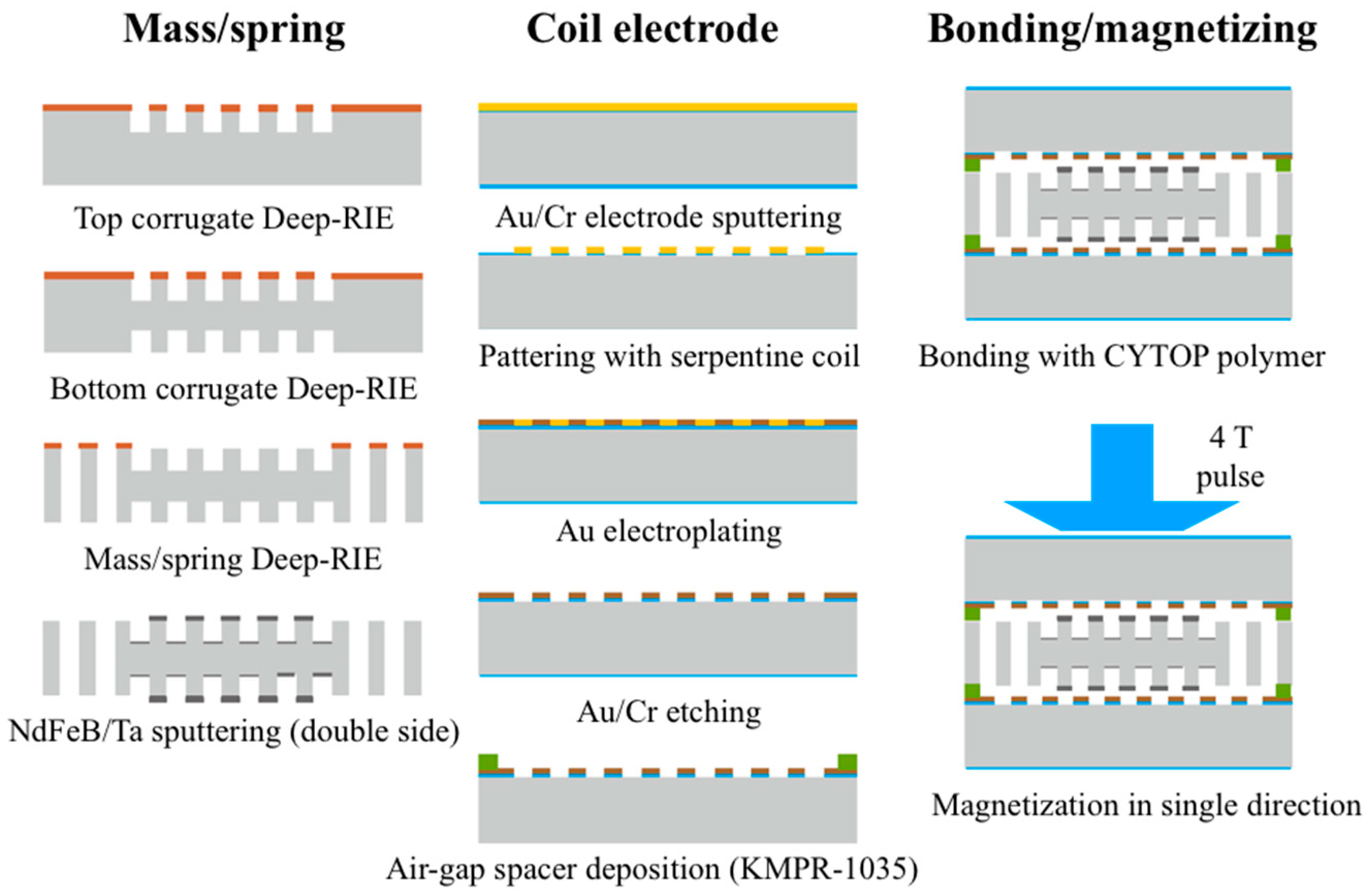

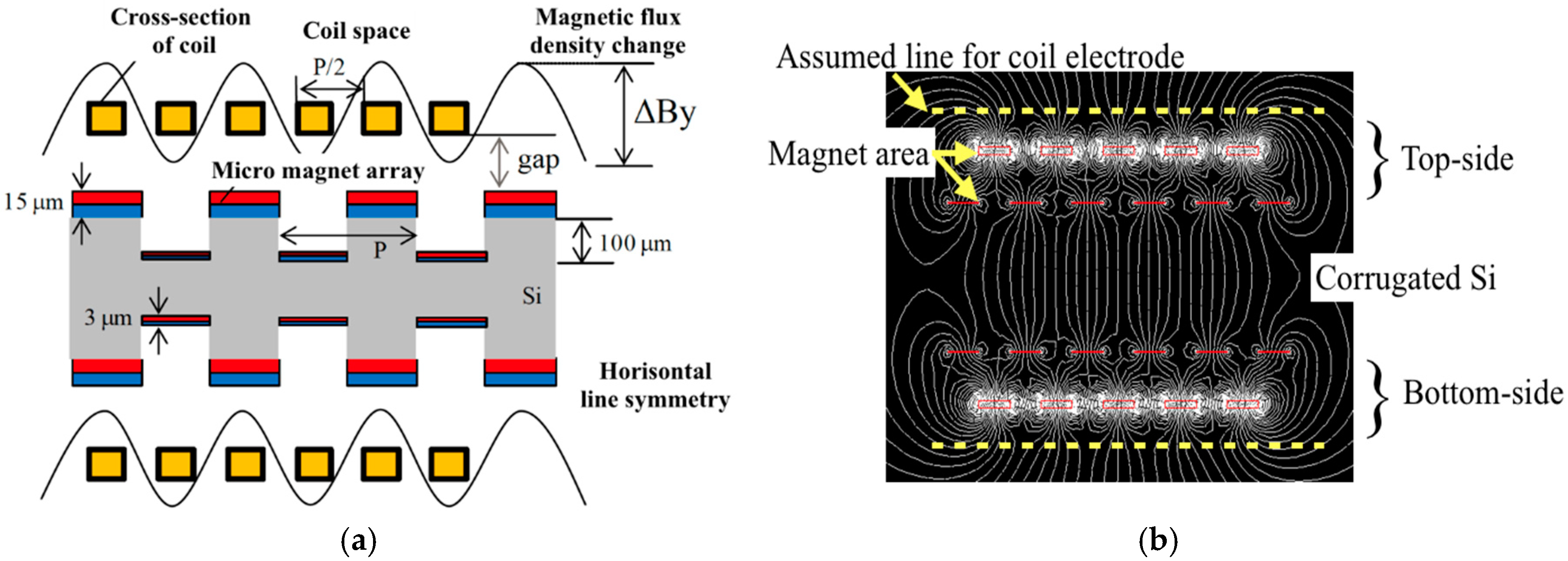

2. Double-Sided NdFeB EMG VEH

3. Harvesting Evaluation from Flatness Improved Structure

4. Conclusions

Acknowledgments

References

- Shaikh, F.K.; Zeadallyc, S. Energy harvesting in wireless sensor networks. J. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Iannacci, J. Microsystem based Energy Harvesting (EH-MEMS): Powering pervasivity of the Internet of Things (IoT)—A review with focus on mechanical vibrations. J. King Saud Univ. 2017. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Q.; Zhao, L.; Shkel, A.; Tang, Y.; Kim, E.S. Stackable Dual-Layer Coil Based on Wafer-Level Transfer Technique for Electromagnetic Energy Harvester. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems, Shanghai, China, 24–28 January 2016; pp. 1264–1267. [Google Scholar]

- Yamaguchi, K.; Fujita, T.; Kanda, K.; Maenaka, K. Optimal Design of Electromagnetic Harvester with Sputtered Thin NdFeB/Ta Film and Considering Lorentz Force. IEEJ Trans. Sens. Micromach. 2016, 136, 72–76. [Google Scholar] [CrossRef]

- Uehara, M. Microstructure and permanent magnet properties of a perpendicular anisotropic NdFeB/Ta multilayered thin film prepared by magnetron sputtering. J. Magn. Magn. Mater. 2004, 284, 281–286. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Tanaka, Y.; Fujita, T.; Takehira, N.; Sonoda, K.; Kanda, K.; Maenaka, K. Optimization and Experiment of Electromagnetic Energy Harvester by Using NdFeB Sputtered on High aspect-ratio Corrugated Si. J. Phys. Conf. Ser. 2014, 557, 012056. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujita, T.; Yoshii, S.; Nakanishi, R.; Kanda, K.; Maenaka, K. Flatness Improvement of Double-Sided Magnetic Film for Narrow Gap Electromagnetic Energy Harvester. Proceedings 2018, 2, 1043. https://doi.org/10.3390/proceedings2131043

Fujita T, Yoshii S, Nakanishi R, Kanda K, Maenaka K. Flatness Improvement of Double-Sided Magnetic Film for Narrow Gap Electromagnetic Energy Harvester. Proceedings. 2018; 2(13):1043. https://doi.org/10.3390/proceedings2131043

Chicago/Turabian StyleFujita, Takayuki, Shinichi Yoshii, Ryosuke Nakanishi, Kensuke Kanda, and Kazusuke Maenaka. 2018. "Flatness Improvement of Double-Sided Magnetic Film for Narrow Gap Electromagnetic Energy Harvester" Proceedings 2, no. 13: 1043. https://doi.org/10.3390/proceedings2131043

APA StyleFujita, T., Yoshii, S., Nakanishi, R., Kanda, K., & Maenaka, K. (2018). Flatness Improvement of Double-Sided Magnetic Film for Narrow Gap Electromagnetic Energy Harvester. Proceedings, 2(13), 1043. https://doi.org/10.3390/proceedings2131043