Abstract

To realize an actual in-situ Laser-Induced Incandescence (LII) sensor system for measurements in an exhaust pipe of a combustion engine, suitable components for such an application were chosen, integrated in a first prototype and tested. Key components for the proposed LII system are a super-compact high-power DPSS laser (CTR HiPoLas®) as excitation source, fast KETEK silicon photomultipliers (SiPM) as detectors and a specially designed optical measurement setup. Using a defined aerosol from a soot generator (Jing 5201 miniCAST), signals were collected at different laser energies and soot concentrations. By comparing the recorded behaviour with the literature, the incandescence effect could be reliably identified as the true source of the signal. Further long-term tests at an AVL engine testbed were performed.

1. Introduction

Laser-Induced Incandescence (LII) is a promising and widely known technology in science for studying soot in flames and aerosols and particles of other materials [1]. Its capability to measure different aerosol parameters simultaneously with high accuracies, and it ability to meet legally mandated limits, makes it of high interest for measuring soot concentrations in automotive exhausts [2]. Given by the fast nature of the LII process, single measurements are very short (few 100 ns). Thus, transient events, like fast changes in engine load and the thereby occurring short and high soot emissions, can be resolved with high accuracy. The limits to this are set by the repetition rate of the laser and the dynamics of the detectors and electronics used. LII is stimulated by a short, some ns long, laser pulse with an energy density of about 3–4 mJ/mm². While laser systems capable of producing this kind of pulses with a high frequency are nowadays commercially available, such laser systems are usually big, bulky devices that have to be operated under controlled conditions and maintained with care. CTR developed a super-compact laser measuring just a few cm that is capable of producing pulses suitable for LII excitation. Furthermore, having initially been developed as a laser spark plug, and tested recently for use as a laser ignition system (LIS) for the main and upper stage engines of ESA’s Ariane 6 launch vehicle, this device is very robust and easy in operation [3].

Stimulated particle incandescence lasts for a few 100 ns and requires very sensitive and fast detectors for light detection. The usual choice are photo multiplier tubes (PMTs), which are suitably sensitive and fast, but hard to integrate into an in-situ field setup. However, recent developments made silicon photo multipliers (SiPMs) available at very low costs, which are highly robust against vibrations and show even better dynamic range. Around these major components, an optical setup within a measurement cell was designed and optimized for collection of LII signals. This setup was then used for extensive investigations into the capability of performing neat LII, with a view to the realization of a highly compact in-situ LII system applicable directly at an automotive exhaust pipe.

While appearing very simple—shoot a high-power laser on particles and detect their glowing—LII measurements are based on several interlinked, complex and fast processes. In general, four thermal transport processes must be considered [4,5]: absorption, radiation, sublimation and convection. The particles absorb the incoming laser pulse according to their material properties, are heated and emit blackbody radiation. This radiation release of thermal energy is the contribution we measure as “LII signal”. The main transport process of heat is convection, sublimation occurs mostly during the illumination with the laser pulse and shortly after [6]. So, the measured decay in the LII signal mainly depends on a combination of radiation and convection, whereby convection is the dominant process [4]. For analysis of these signals, these processes have to be modelled well and consider the dependencies on particle size and material [1,2,4,5,6,7]. The realization of any LII sensor system thus requires careful preparation and data analysis. Yet, since the behaviour of the LII signal in dependency of laser fluence, particle size and mass concentration is unique, it is possible to reliably differentiate the LII signal from e.g., light scattering of the laser excitation and thus survey the quality of the LII experiment.

2. Materials and Methods

2.1. Experimental Setup

The main components of the setup are (i) a super-compact high-power diode pumped solid state (DPSS) laser, (ii) fast and compact SiPMs, and (iii) as specially designed measurement cell.

The laser source (CTR HiPoLas®, CTR AG (Villach/St. Magdalen, Austria), A) is a radially diode-pumped, monolithic solid-state Nd:YAG laser, which emits pulses at 1064 nm at an adjustable repetition rate with a spot size of about 8 mm2. Originally developed for use as a laser spark plug, it is very robust and compact—the laser head of the latest generation (gen. 5) only measures 50 × 50 × 30 mm³. Auxiliary equipment, including a water cooler and the laser driver electronics in a control box with an interlock, can be flexibly connected and thus deployed away from the harsh conditions of e.g., an automotive engine, or its exhaust line. For the experiments presented here, a HiPoLas generation (gen.) 3 was used, experiments using a latest generation 5 laser head are ongoing and results will be presented at the 2018 Eurosensors conference. The gen. 3 HiPoLas is capable of a continuous repetition rate up to 3 Hz with 6 ns/20 mJ pulses. The gen. 5 laser was adjusted to LII specifications and emits 30 mJ pulses with a continuous repetition rate up to 5 Hz.

SiPMs, very sensitive solid-state photodetectors, were selected for various reasons. Firstly, SiPMs are available at low prices, compared to photo multiplying tubes (PMT), similarly sensitive and significantly more robust. In particular, the threshold for radiation damage for SiPMs is high, the temperature influence is comparably low, and they are completely insensitive to vibrations. A SiPM detector is an array of hundreds to thousands of micro avalanche photodiodes (APD) operated in Geiger-mode [8]. Each APD is capable of single photon detection, but needs to recover after an event. The “recovery-time” of the SiPMs used here was 15 ns, which provides good dynamics for the detection of LII signals. For this study, “custom array” sensor modules consisting of 4 SiPMs with 3 × 3 mm2 SiPM arrays each (KETEK PM 3315, 15 µm micro-cell size; KETEK GmbH (Munich, Germany), D) were used.

The signals were read out without pre-amplification. For data collection in this proof-of-concept setup, a PICO PicoScope 6000 USB oscilloscope was used that provides a continuous sampling rate of up to 1 GHz.

2.2. Experimental Methods

The main topic of the measurements was to assure that the initiated and detected process is indeed neat LII. As mentioned in the introduction, LII signals are the result of the complex interplay of different processes, which create a unique signal behaviour. To validate this, in a first step the detectors were carefully shielded from the laser beam, using a combination of optical bandpass and band filters, a closed housing, and pieces of a laser safety curtain in such a way, that no signal is detected without a specimen inside the measurement cell. Next, the measurement cell was challenged with defined aerosol particles from a miniCAST 5201 (Jing Ltd. (Schiller Park, IL, USA), CH) and the laser fluence varied using a variable beam splitter, whereby the second beam was measured with a power meter. Since the total laser power is constant, the measurement of one beam defines also the power of the second. The measured dependency of the detected signal to the laser fluence was then compared to literature, to check if the slope follows the characteristic LII behaviour [2].

Following the initial proof-of-principle phase, the setup was expanded (i) to comprise four SiPMs, operated at different gains to cover a wider dynamic range and (ii) a sampling system for automotive exhaust gases, supplied by AVL (AVL List GmbH (Graz, Austria), A), and encased in a black box to warrant class 1 laser safety. This setup was then installed to an AVL engine testbed for long-term measurements on actual exhausts. At the engine testbed, the LII was continuously operated with optimal settings at 1 Hz, as defined from the feasibility stage, for 10 h straight. An AVL MicroSoot Sensor (MSS) was used as reference device throughout the measurements.

3. Results and Discussion

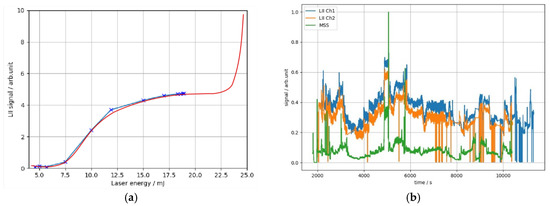

A detailed examination of the signal behaviour, are shown in Figure 1a, proved (i) that the incandescence signals are clearly distinguishable from scattered laser light and (ii) show the typical characteristics of neat LII signals. Rising laser fluence heats the particles at the interaction volume to higher temperatures, causing the dominant heat transport process to change since they scale differently with particle size and temperature [2,4,9]. This effect is non-linear, while scattered light would scale linearly with particle size and laser fluence [10]. The actual measured signals follow this LII behaviour [2] very well. So, since the data in Figure 1a is in good compliance with the theoretical behaviour, one can be quite sure that the measured signals originate from LII. The pulse energies of the gen. 3 laser we used are not fully sufficient for a stabile LII system, since the plateau regime is not reached. But the fundamental feasibility of realising an in-situ LII probe was thereby proven. This opens a vision to replace the previously used extractive cells and large-scale laser sources by compact, field-operable components, creating an approach for a true in-situ particle sensor.

Figure 1.

Measurement data collected with our LII system (a) a qualitative comparison of the LII signal at different laser energies with results from [2]; (b) raw data from the measurements on the engine testbed, with an AVL MSS as reference, showing an excellent qualitative correlation.

In Figure 1b the LII data is qualitatively compared against the PM measurements obtained from the AVL MSS (MSS data was scaled down, so the transient behaviour can be compared directly). While quantitatively there is no linear dependency, nor a correlation that could be easily established, they follow the same event changes in soot concentration. In general, it can be said that the LII signal follows the MSS very well, and all load changes were accurately captured.

4. Conclusions

A LII system was realized using components suitable for an in-situ probe. Measurements with defined soot from a MiniCAST soot generator and subsequent comparison of the signal behaviour with LII literature and theory proved the gained signals to be LII in nature. Further long-term measurement at an engine testbed on exhaust gases proved the basic feasibility of an in-situ probe. Still, due to the challenging analysis of LII signals, realising an actual sensor capable of providing quantitative data that is back-traceable to standard methods will require further R&D efforts into signal processing, as well as into deeper systems integration.

The results presented here were gained from experiments using a generation 3 HiPoLas and shall be considered as preliminary. Experiments using a generation 5 HiPoLas which was adjusted for LII are ongoing, results will be presented at the 2018 Eurosensors conference.

References

- Wal, R.L.V.; Ticich, T.M.; West, J.R. Laser-induced incandescence applied to metal nanostructures. Appl. Opt. 1999, 38, 5867–5879. [Google Scholar]

- Wainner, R.; Seitzman, J. Soot diagnostics using laser-induced incandescence in flames and exhaust flows. In Proceedings of the 37th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 11–14 January 1999. [Google Scholar]

- Peach, M. Austrian Researchers to Adapt Laser Ignition for Rockets. Available online: http://optics.org/news/6/11/12 (accessed on 18 June 2018).

- Bladh, H.; Johnsson, J.; Bengtsson, P.E. On the dependence of the laser-induced incandescence (LII) signal on soot volume fraction for variations in particle size. Appl. Phys. B Lasers Opt. 2008, 90, 109–125. [Google Scholar] [CrossRef]

- Snelling, D.R.; Smallwood, G.J.; Gülder, Ö.L. Soot Volume Fraction Characterization Using the Laser-Induced Incandescence Detection Method. In Proceedings of the 10th International Symposium on Applications of Laser Techniques to Fluid Mechanics, Lisbon, Portugal, 10–13 July 2000; pp. 1–16. [Google Scholar]

- Michelsen, H.A.; Liu, F.; Kock, B.F.; Bladh, H.; Boiarciuc, A.; Charwath, M.; Dreier, T.; Hadef, R.; Hofmann, M.; Reimann, J.; et al. Modeling laser-induced incandescence of soot: A summary and comparison of LII models. Appl. Phys. B Lasers Opt. 2007, 87, 503–521. [Google Scholar] [CrossRef]

- Wal, R.L.V.; Ticich, T.M.; Stephens, A.B. Can soot primary particle size be determined using laser-induced incandescence? Combust. Flame 1999, 116, 291–296. [Google Scholar]

- Dinu, N. Silicon photomultipliers (SiPM). In Photodetectors: Materials, Devices and Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 255–294. [Google Scholar]

- Mewes, B.; Seitzman, J.M. Soot volume fraction and particle size measurements with laser-induced incandescence. Appl. Opt. 1997, 36, 709–717. [Google Scholar] [CrossRef] [PubMed]

- Ogendal, L. Light Scattering Demystified Theory and Practice; University of Copenhagen: København, Denmark, 2013. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).