1. Introduction

Industrial wastewater is characterized by high COD concentrations, very low to high BOD/COD, TSS, salinity, color, etc. In addition, since flow rates and concentrations vary continuously, it is very difficult to develop a universal treatment method for all types of industrial wastewater. In most cases where biological treatment could be applied, a pre-treatment or post-treatment step is necessary to reduce the high pollutant loads or to refine the treated water before its final disposal [

1]. For this purpose, several physical or chemical methods or advanced oxidation processes have been developed, mainly to pre-treat wastewater before it enters the biological treatment step.

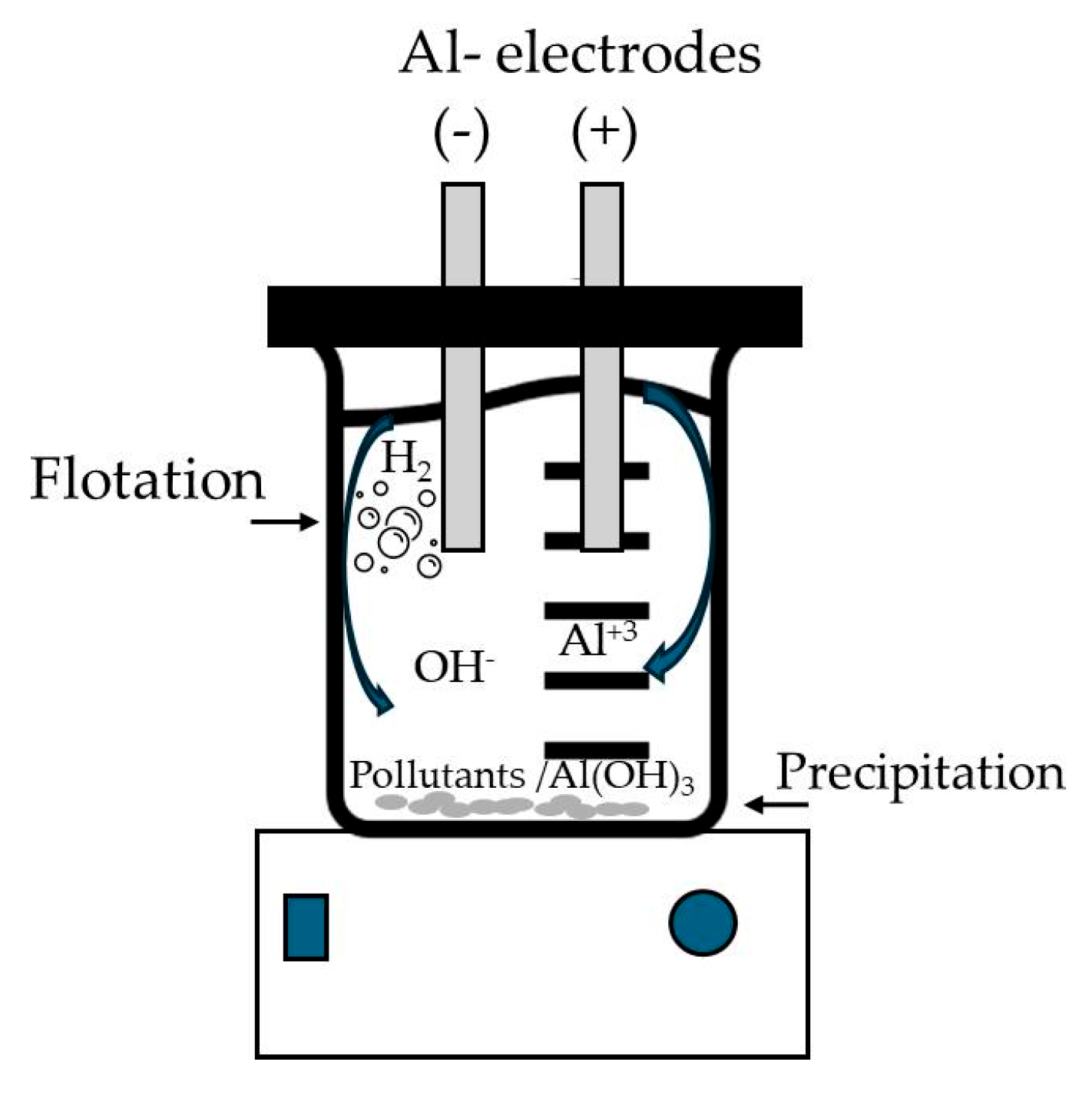

Electrocoagulation (EC) is a well-known and widely examined method. Two electrodes are used as an anode and cathode, mainly aluminum or iron. The anode slowly dissolves, releasing metal cations into the wastewater. The electrolysis of water takes place at the cathode, producing hydroxyl anions and hydrogen gas [

2]. The metal hydroxide formed results in electrocoagulation, which is the precipitation of all suspended solids, while the hydrogen gas results in electroflotation, which is the flotation of all light flocs on the surface of the reactor [

3].

However, it is not a widely applicable method because shortly after its development it was replaced by chemical coagulation due to the high price of electricity [

4]. In recent years, electrocoagulation has been revived and there is a lot of research going on to increase the efficiency of the method and to reduce the cost of applied electricity and metal electrode dissolution. Moreover, several parameters such as the type of metallic electrodes, electrode surface area, electrode spacing, applied current density, conductivity, reactor design, and gas productivity determine process efficiency and operating costs. All these parameters importance differ, depending on the wastewater type and its physicochemical characteristics [

5].

The present study evaluated the efficiency of electrocoagulation–flotation technology as a pre-treatment method for the management of strongly colored wastewater with suspended solids and a high chemical oxygen demand (COD). Specifically, wastewater samples were collected from a brewery, dairy, winery, and marine oil refinery. Laboratory-scale reactors were designed and printed using a 3D printer, while pilot-scale reactors were used to validate the laboratory-scale results under industrial conditions. All tests use draw wastewater, aluminum electrodes, and renewable energy for power generation.

2. Materials and Methods

Laboratory experiments were performed in glass or 3D-printed reactors with a 100–1000 mL working volume, as shown in

Figure 1. Aluminum plates were used as both the anode and cathode while direct current was used for the process. The distance between the electrodes was kept at 5 mm, while the current density varied between 3 and 10 mA/cm

2. The number of electrodes also varied to achieve high hydrogen production and to increase the capacity of electroflotation, which is a much faster process than electrocoagulation. Experimental runs lasted from 10 to 60 min, resulting in low energy and metal consumption. Samples were selected at different time intervals (5, 10, 15, 20, 30, 40, 60 min) and the COD concentration was measured according to standard methods [

6]. All the experiments were conducted in Environmental Systems Laboratory of the Chemical Engineering Department of the University of Patras, in collaboration with WATERA S.A. The electrocoagulation reactors were developed for the pretreatment of industrial wastewater.

3. Results and Discussion

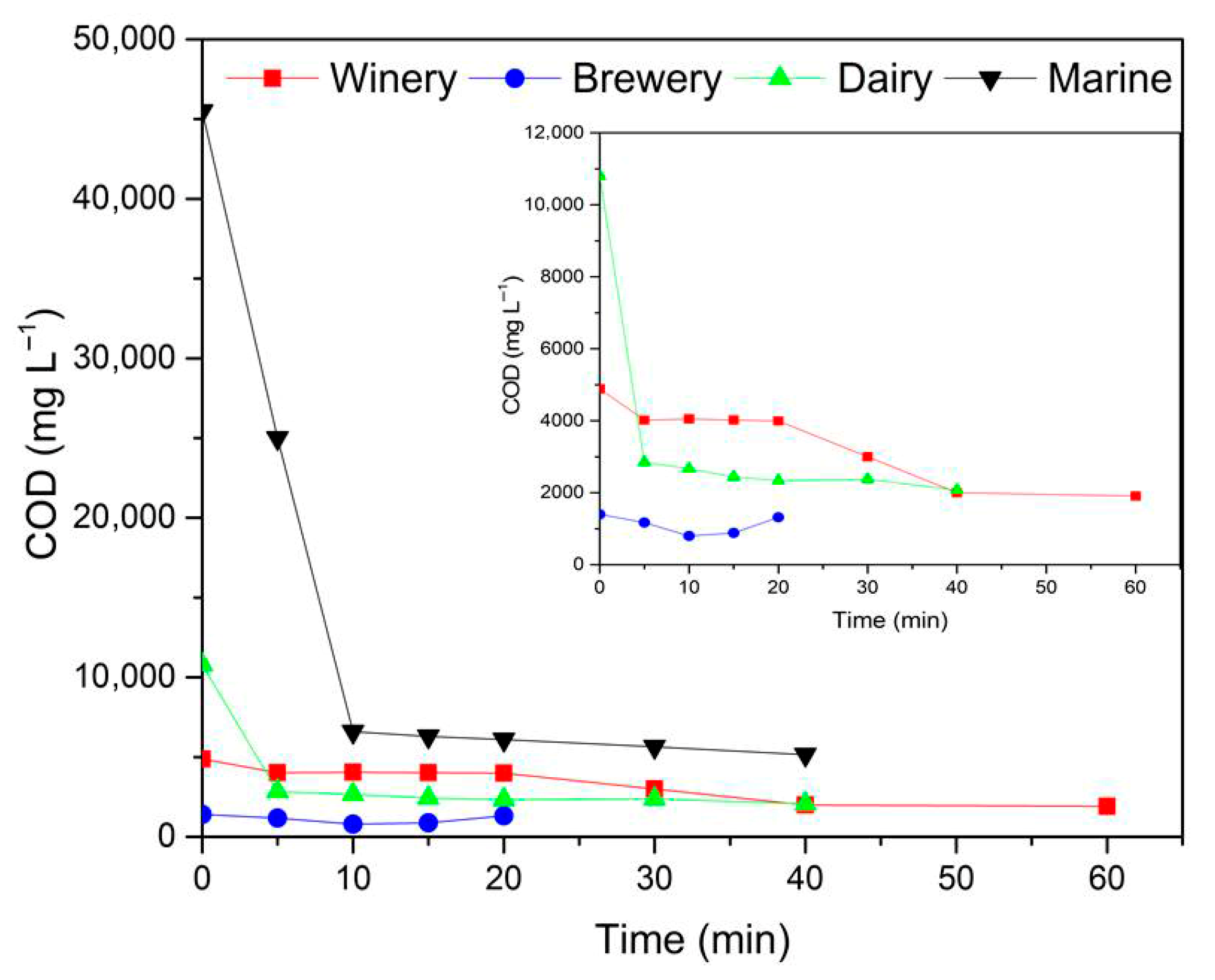

The EC–flotation method’s efficiency for decreasing COD in the winery, brewery, diary, and marine oil wastewater samples was evaluated. As can be seen in

Figure 2, in all cases the COD keeps decreasing as retention time increases, despite the fluctuations each wastewater sample presents.

Specifically, for the marine oils that had the highest examined initial COD concentration (exceeded the 45,500 mg L−1), 40 min of treatment was necessary to obtain 88.6% removal, reaching the final concentration of approximately 5000 mg L−1. A similar pattern was observed for the dairy wastewater, where a steep decrease was gained within the first 5 min of treatment, noting a decrease up to 75%, while the maximum removal of 80% was obtained after the 30 min of treatment, reaching a final concentration of ~2000 mg L−1 from 10,800 mg L−1.

On the contrary, the brewery wastewater had the minimum examined initial COD, close to 1500 mg L

−1, where 10 to 15 min was found to be adequate for the process and a 60% COD decrease was achieved. The behavior of the winery wastewater was slightly different, since 60 min of treatment was demanded to decrease the COD from approximately 5000 mg L

−1 to 1900 mg L

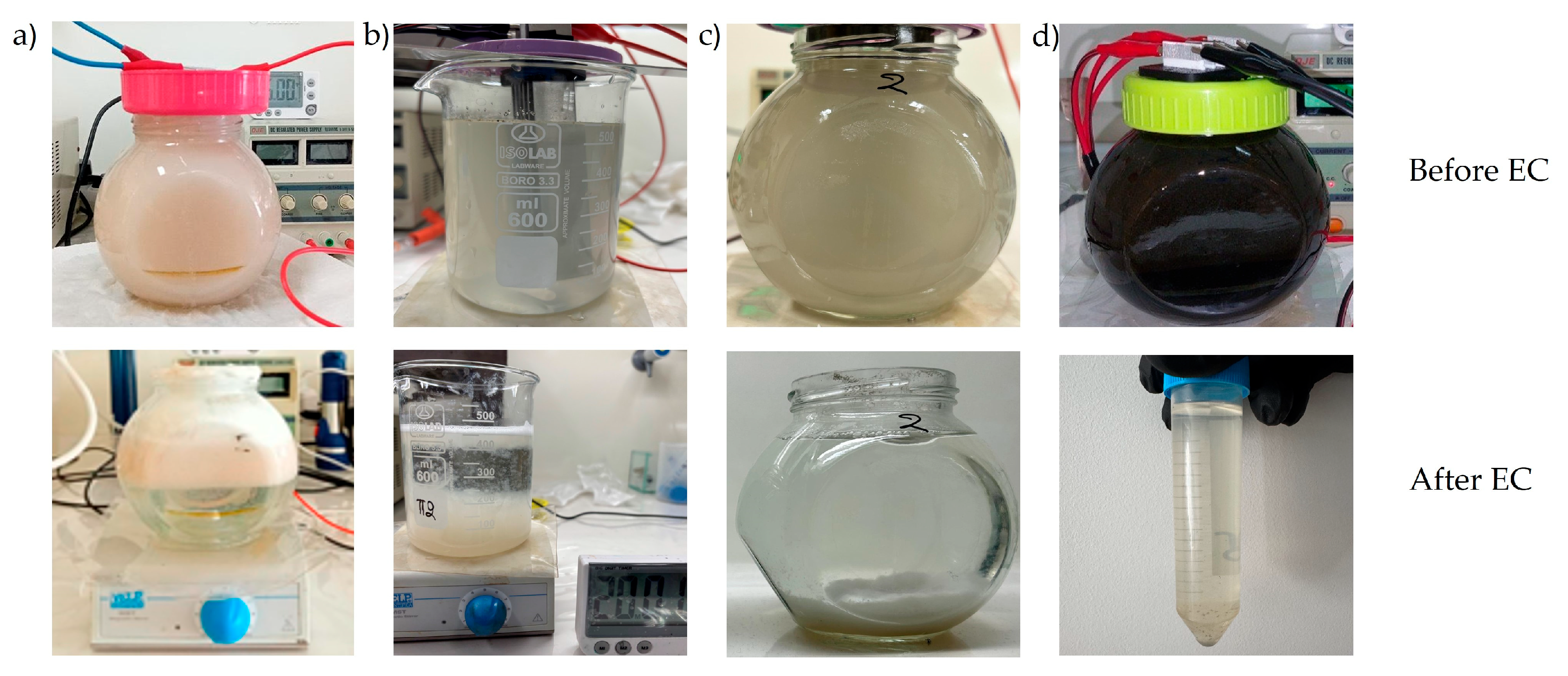

−1 with a much slower pace of removal, probably due to the higher dissolved organic load that these samples may contain. Nevertheless, all of the wastewater samples at the end of their treatment presented TSSs removal ranging from 90 to 95%, and color removal from 70 to 90%, as can be observed in

Figure 3.

Overall, the EC process effectively reduced COD levels in all four types of wastewater, with the most significant reductions occurring within the first 10–20 min of treatment. Marine oils and dairy wastewater initially exhibited the highest COD concentrations and showed a steep decline, though it stabilized at a higher residual level compared to the others. The brewery wastewater demonstrated the most rapid and complete COD reduction, reaching negligible levels early in the process. The winery wastewater presented slower but steady COD reductions over time, reaching its maximum at 60 min. These results highlight the efficacy of the examined method, and emphasize the variability in treatment performance based on wastewater characteristics.

4. Conclusions

The capacity of the electrocoagulation (EC)–electroflotation method for chemical oxygen demand (COD) reduction was evaluated in four different types of industrial- wastewater: winery, brewery, dairy, and marine oil refinery effluents. The results demonstrated the method’s high effectiveness and adaptability across wastewater with diverse organic loads and characteristics. Concerning the COD reduction, all wastewater types demonstrated total suspended solids (TSSs) removal efficiencies of 90–95%, and color removal in the range of 70–90%.

Overall, the electrocoagulation–flotation method proved to be an effective and adaptable treatment approach across various high-strength wastewaters, with the most significant COD reductions typically occurring within the first 10–20 min of treatment. These findings emphasize the influence of wastewater composition on treatment dynamics and highlight the potential of EC as a versatile pretreatment or standalone option in industrial wastewater management.

Author Contributions

Conceptualization, methodology, supervision, writing—original draft preparation, project administration, validation, resources, D.V.V.; writing—original draft preparation, formal analysis, data curation, validation, C.V.L.; methodology, data curation, visualization, M.G., M.K., S.K. and M.M.; methodology, investigation, resources, A.I.; methodology, investigation, resources A.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within this article.

Conflicts of Interest

Authors Athanasios Iliopoulos and Alexandros Zolotas were employed by the company Watera Hellas. The remaining authors declare that the research was conducted in the absence of any commercial or financial relation-ships that could be construed as a potential conflict of interest.

References

- Al-Ajmi, F.; Al-Marri, M.; Almomani, F.; AlNouss, A. A Comprehensive Review of Advanced Treatment Technologies for the Enhanced Reuse of Produced Water. Water 2024, 16, 3306. [Google Scholar] [CrossRef]

- Song, P.; Yang, Z.; Zeng, G.; Yang, X.; Xu, H.; Wang, L.; Xu, R.; Xiong, W.; Ahmad, K. Electrocoagulation Treatment of Arsenic in Wastewaters: A Comprehensive Review. Chem. Eng. J. 2017, 317, 707–725. [Google Scholar] [CrossRef]

- Hakizimana, J.N.; Gourich, B.; Chafi, M.; Stiriba, Y.; Vial, C.; Drogui, P.; Naja, J. Electrocoagulation Process in Water Treatment: A Review of Electrocoagulation Modeling Approaches. Desalination 2017, 404, 1–21. [Google Scholar] [CrossRef]

- Islam, S.M.D.U. Electrocoagulation (EC) Technology for Wastewater Treatment and Pollutants Removal. Sustain. Water Resour. Manag. 2019, 5, 359–380. [Google Scholar] [CrossRef]

- Zampeta, C.; Mastrantonaki, M.; Katsaouni, N.; Frontistis, Z.; Koutsoukos, P.G.; Vayenas, D.V. Treatment of Printing Ink Wastewater Using a Continuous Flow Electrocoagulation Reactor. J. Environ. Manag. 2022, 314, 115033. [Google Scholar] [CrossRef] [PubMed]

- Baird, R.B.; Eaton, A.D.; Rice, E.W. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; The American Journal of Public Health: Washington, DC, USA, 2017. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).