1. Introduction

Cassava is a crucial staple crop in many developing regions, essential for food security and income for smallholder farmers [

1]. It serves multiple purposes, such as a famine-reserve crop, rural staple, urban convenience food, industrial raw material, cash crop, and foreign exchange source. Processing cassava into various products boosts the economies of tropical nations, with Nigeria seeing increased output due to such processing. However, the lack of modern drying technology in rural areas leads to inconsistent drying, lower product quality, and higher post-harvest losses, hindering the production of value-added cassava products [

2].

Cassava roots are versatile, used for human consumption, livestock feed, and industrial products such as starch and flour. Cassava faces post-harvest challenges, despite low production costs; hence, efficient post-harvest processing is crucial for converting raw cassava into consumable or industrial products such as flour, starch, and chips [

3]. Reliable technologies are essential for making cassava processing profitable, reducing losses and enhancing food security and economic sustainability. The processing phase includes peeling, washing, cutting, drying, and milling, all of which impact the final product’s quality [

3]. High-quality cassava flour (HQCF) can stimulate rural industrialization, elevate market value, and improve farmers’ earnings and livelihoods. HQCF is versatile, suitable for household use, pastries, urban convenience foods, and industrial products like textiles, plywood, paper, and packaged foods. It can also be blended with wheat flour for making bread, biscuits, cookies, and pies [

4].

Drying cassava roots is crucial for producing high-quality products for industrial and human use, but small-scale farmers often struggle with the costs of fossil fuel-powered and solar dryers [

5]. Traditional drying methods are labor intensive, time consuming, and susceptible to weather, crop damage, and quality loss due to insect infestation. There is a critical need for affordable, eco-friendly drying technology accessible to rural farmers. Biomass-based drying presents a viable solution, reducing post-harvest losses and improving cassava product quality through controlled heat processes.

Biomass plays a crucial role in rural areas, providing around 90% of energy needs, primarily for cooking, and biomass waste can also generate electricity and heat in the food industry [

6]. Various biomass sources like wood, charcoal, sawdust, and agricultural residues such as maize cobs, coconut shells, and rice husks are suitable for biomass gasification [

7]. Mishra [

8] developed a prototype drying system with energy storage using solar and biomass energy for drying potatoes and chayote. Muhammad et al. [

9] designed a biomass dryer with coconut shells and an IoT-based monitoring system to optimize drying processes for various materials, including cassava chips. Biomass has proven effective as a heat source in drying trials for plantain, cashew nuts, tomatoes, okra, peppers, copra, and peanuts in laboratory or prototype settings [

10,

11].

Large-scale biomass dryers for cassava drying are primarily manufactured in countries such as China and Brazil. Companies like Zhengzhou Taida Drying Equipment Co., Ltd., and Shanghai Yongxian Machinery Manufacturing Company specialize in commercial biomass dryers, including the Osa cassava dreg dryer [

12]. However, research on locally designed biomass heat-driven cabinet dryers for large-scale cassava drying to produce high-quality cassava flour (HQCF) is very limited, especially in developing countries like Nigeria. Locally developed biomass heat-generated cabinet dryers offer a cost-effective, culturally relevant, and sustainable solution. They empower local communities, promote economic growth, minimize environmental impact, and are easier to maintain compared to imported dryers.

The biomass-fueled dryer for cassava drying offers a promising solution to rural challenges, combining innovative design with locally available biomass as a renewable energy source. This research aims to explore the feasibility and practicality of this dryer. It focuses on designing, developing, and evaluating the performance of a biomass-fueled dryer tailored for cassava drying. This is a sustainable solution which addresses environmental issues while providing efficient drying capabilities in rural areas.

2. Materials and Methods

2.1. Description of the Biomass-Fueled Cabinet Dryer

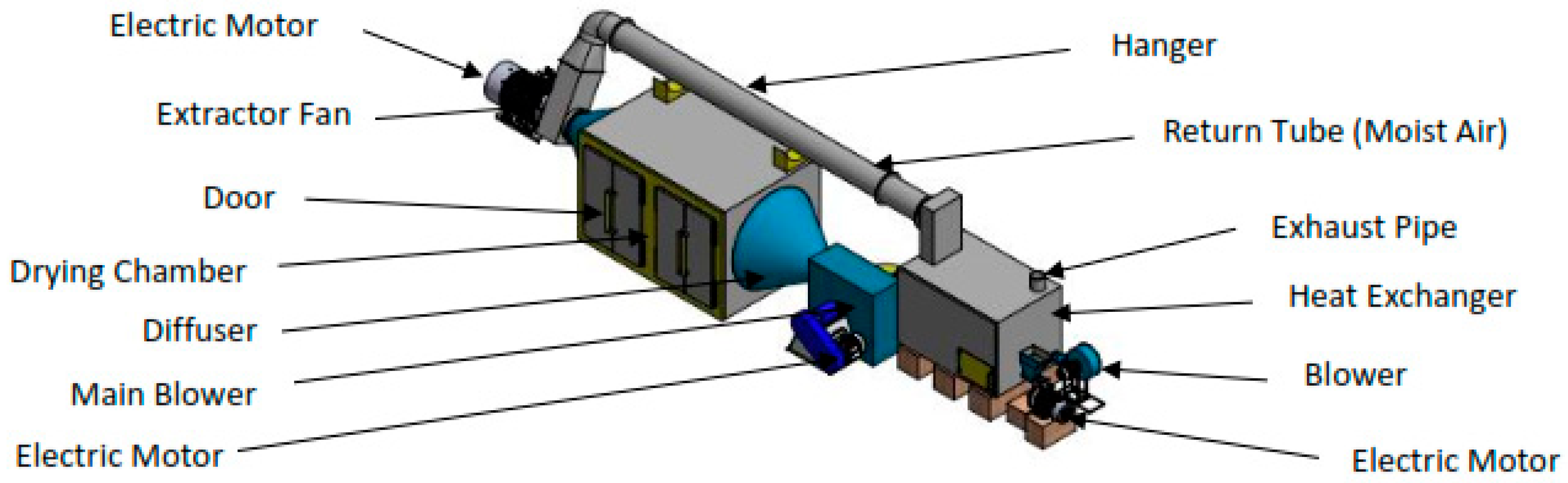

The biomass-fueled cabinet dryer comprises a heat exchanger, main blower, and drying chamber (

Figure 1). The heat exchanger is where biomass combustion occurs to generate heat for the drying process. The drying chamber contains two racks, each with 10 drying trays, totaling 20 trays. The main blower draws hot air from the heat exchanger and channels it through a diffuser, ensuring even heat distribution in the drying chamber. The drying process employs conduction, convection, and radiation for effective heat transfer. Conductive heat transfer occurs through the walls of the heat exchanger, while convective heat transfer facilitates heat distribution through hot gases and forced airflow, thereby ensuring uniform moisture removal. Radiative heat exchange enhances evaporation, while effective thermal management—via airflow control, combustion efficiency, and temperature distribution—facilitates the production of high-quality cassava flour with reduced energy waste. The dryer takes about 30 min to reach a steady state, with the drying chamber temperature ranging from 90 to 115 °C. This dryer was installed at the cassava processing center at the Open-Door International System in Akileye, located 12 km off Owode–Idiroko road via Ota, Ogun State, Nigeria. The biomass-fueled cabinet dryer is as shown in

Figure 1.

2.2. Materials

The materials and components for the dryer’s fabrication were sourced locally to minimize environmental impact, maximize economic benefits, and ensure accessibility for smallholder farmers. Materials were chosen based on their ability to withstand heat, vibration, humid air fatigue, and stress during operation without failure. Aluminum and stainless steel were selected for sections in direct contact with cassava mash to prevent corrosion, contamination, and to resist the toxic nature of cassava. Mild steel and medium carbon steel, known for their robustness and ductility, were used for the dryer’s construction. The materials used for the dryer evaluation included palm kernel shells, wet cassava mash, plastic containers, a weighing scale, a moisture meter, a digital hygrometer, a digital anemometer, temperature probe, a stopwatch, and fuel (diesel) to power the generator.

2.3. Methods

2.3.1. Design Analysis of the Biomass-Fueled Cabinet Dryer

Drying Chamber: The volume of the drying chamber was determined using the relationship described by Adzimah and Seckley [

13], as shown in Equation (1).

where

l,

b, and

h were the length (2.5 m), breadth (1.4 m), and height (2.7 m) of the drying chamber. Therefore, the volume of the drying chamber was 9.45 m

3. The dimension of the drying tray were 1.20 m, 1.00 m, and 0.03 m in terms of length, breadth, and height, respectively.

Hopper: The hopper is the device through which biomass materials are fed into the combustion chamber for heat generation in the heat exchanger. The volume (V

h) of the hopper was determined as described by Imanogor [

14] using Equation (2).

where A is the hopper’s top side, B its bottom, H its height, and L its length.

Screw auger: Beneath the hopper is the cylindrical trough which house the screw auger for conveyance of the biomass materials into the combustion chamber. The pitch (Pa), diameter (Ø

xa), and capacity of the screw auger (Q

m) were computed using the relationship given by David and Micheal [

15] as shown in Equations (3)–(5).

where Ø

ia and Ø

xa were the auger’s internal diameter (m) and external diameter (m), v

a was the screw auger’s downward flow velocity of material (ms

−1), x

a was the distance along the length of the auger (m), ꞷ

a was the auger’s angular velocity (rpm), c was the clearance between the trough and the screw auger, s was the specific mass of the palm kernel shell (Nm

−3), and i was the degree of screw‘s trough filling (%).

Selection of the Blower: The blower horsepower was 3.86 Hp, which was determined using the relationship as described by Adzimah and Seckley [

13], as shown in Equation (6)

where an air flow rate of 3843.44 cfm, a static pressure of 5.4 inches of water were determined based on the dimension of the drying chamber, and a fan efficiency of 80% was selected because most industrial blowers have an efficiency range of 70–85%, as reported by Adzimah and Seckley [

13]. Therefore, a centrifugal fan with electric motor of 5 Hp, which draws heat from the heat exchanger for effective heat distribution within the drying chamber, was selected.

Design of Shaft

Selection of pulleys: Equation (7) expresses the relationship between the blower shaft with the shaft of electric motor based on speed ratio in accordance with the procedures of [

16].

where N

1 and N

2 are the speeds of the electric motor (driver) and the blower shaft (rpm) (driven), Ø

1 and Ø

2 are the diameters of the driver pulley (mm) and the pulley driving the blower shaft (mm). A similar procedure was followed to determine the pulley specifications for the screw auger.

Selection of the Machine Belts: Using the dryer power rating and standard V-belts according to IS: 2494–1974, Khurmi, R. S. and Gupta [

16], a V-belt of class A type and class B type were chosen for the screw auger and the blower shaft, respectively. Equations (8) and (9) were used to determine the center distance, C, of the pulleys and the length of the belt (L

b) according to [

16].

Belt tensions: the belt tensions on the tight and slack sides of the belt drive (T

1 and T

2) for the screw auger and that of the main blower were determined as described by Harikumar [

17] using Equations (10)–(13).

where µ is the frictional coefficient of belt running on a pulley, ∂ is the belt groove angle in radian, V

b is the belt velocity, and P

1 is the power transmission of the belt drive which is a function of the power rating of the electric motor. According to Khurmi and Gupta [

16], the shaft’s design was based on the shaft’s fluctuating torque, bending moment, and shearing force. Equation (14) was used to calculate the shaft’s diameter (d

s).

where S

s is the shaft constant, K

b is the combined shock and fatigue factor applied to the bending moment, K

t is the combined shock and fatigue factor applied to the torsional moment, M

b1 is the screw auger shaft’s resultant bending moment (Nm), and M

t1 is the screw auger shaft’s resultant torsional moment.

2.4. Dryer Fabrication

The isometric drawing of the dryer, which served as a reference during its fabrication, is presented in

Figure 2. Shafts were machined from rods, while angle iron and pipes were used as a framework. Material specifications were used to procure the necessary components. Fasteners, including bolts, nuts, and sturdy welds, were used. There were no crevices or fractures to be found because the welding and finishing were carried out properly to keep bacteria from growing in the crevices of the walls. Arc welding was used to assemble the components, and welds were filled, ground, and polished with the correct filler materials. Bolts and nuts were used to join various components while studs were strategically placed to provide proper tension and torque. Electric motors were selected and installed. The dryer was insulated with 100 mm thick fiber glass. Stainless steel was used to fabricate the drying trays and racks. All necessary adjustments and changes were made before the dryer was put to test.

2.5. Energy Required for Drying

The energy required for drying was determined using the procedures of Famurewa et al. [

18], as shown in Equation (15)

where

H is the energy required for drying,

M is the mass of cassava mash per batch (150 kg),

C is the specific heat capacity of cassava mash (1.445 kJ/kg k),

Δθ is the change in temperature (80 °C),

Mc is the mass of moisture to be removed (65 kg),

t is the time of drying (2 h), and

L is the latent heat of vaporization of water (2256 kJ/kg).

Quantity of Palm Kernels That Will Produce the Required Energy

Equation (16), in accordance with Famurewa et al. [

18], was used to calculate the amount of palm kernel shell required to produce 163,980 kJ of heat required for drying 150 kg of cassava mash. Palm kernel shells have a calorific value of 23,604.71 kJ/kg. As a result, 6.95 kg of palm kernel was needed.

2.6. Evaluation of the Cabinet Dryer

Cassava processing: Cassava roots were harvested, peeled, and grated using a mechanical cassava grater (500 kg/h, Nigerian made). The grated mash was pressed to form a cake, which was then pulverized. The weight and moisture content of the granulated mash were recorded. The initial weights of palm kernel shells, ambient conditions (humidity and temperature), and the time for loading the dryer were noted. The experiment was conducted in triplicates using a three-point loading mass per tray (2 kg, 3 kg, and 4 kg) with the average value determined. The cabinet dryer operated at a blower motor speed of 800 rpm with a varying mass of cassava mash (40 kg, 60 kg, and 80 kg) per batch. Air velocity, humidity, and temperature were monitored every 10 min. Each experiment was replicated three times. The dried flour was milled, weighed, and packaged.

Tools and equipment: The equipment used included a digital electronic weighing scale (Model A-12_300 kg capacity, manufactured in Shenzhen, China) for weighing wet cassava mash and dried flour, a digital anemometer (Model MS6252B, PEAKMETER, manufactured in Shenzhen, China) for air velocity measurement, a thermocouple thermometer (Model SD-947, REED instruments; manufactured in Taipei, Taiwan) for drying air and outlet air temperature measurement, and a digital hygrometer (Model TP49, ThermoPro; manufactured in Hongkong, SAR) for air humidity measurement. The moisture content of wet cassava mash was assessed using a wood moisture meter (Model MD-2G, OMICRON; manufactured in Ambala Cantt, Haryana, India) and confirmed via oven drying method. The process duration was tracked with a stopwatch. The dryer stabilized at 50 °C, over 30 min before loading the wet cake.

2.7. Thermal Analysis of the Dryer

Drying Rate: The drying rate was computed using the relationship given by Saravanan et al. [

6], as shown in Equation (17).

where R

d is drying rate (kg/s);

Mi is the initial mass of the sample before drying (kg);

Md is the final mass of the sample after drying; and

t is the drying time (s).

Drying Chamber Efficiency: The drying chamber’s efficiency was calculated according to Saravanan et al. [

6], as shown in Equation (18).

where

ηd is drying chamber efficiency;

T1 is the drying chamber inlet temperature (°C);

T2 is the drying chamber outlet temperature (°C); and

Ta is the ambient temperature (°C).

Heating Energy: The drying was assessed as a two-step process to estimate how much energy was utilized to evaporate water from the mash. Thus, the sensible heating and evaporation process were evaluated as described by Rajvir et al. [

19] using Equations (19) to (21), respectively.

where

Cp is the specific heat capacity of water (kJ/kg K);

Mw is the mass of water removed after drying (kg); T

1 is the drying chamber inlet temperature (

°C); the

Ta is the ambient temperature (

°C); and Q

s is the sensible heating energy (kJ).

The second stage is the evaporation of moisture from the product and the heat required is given as follows:

where

hg is the enthalpy of water as a vapor (kJ/kg) and

hf is the enthalpy of water as a liquid (kJ/kg) at the drying temperature obtained from the steam table; and Q

l is the evaporating heating energy (kJ). Therefore, the total heat requirement (Q

t) was determined using Equation (21)

Biomass System/Overall Efficiency: This is the combustion efficiency of the heat source which was determined according to Rajvir et al. [

19] using Equation (22).

where

ηs is the overall efficiency;

L is the latent heat of vaporization (2260 kJ/kg);

Mi is the initial mass of sample before drying (kg);

Md is the final mass of sample after drying (kg);

FC is the fuel consumption per batch;

CV is the calorific value of palm kernel shells (23,605 kJ/kg).

2.8. Statistical Analysis

The data were analyzed using SPSS version 6.0 software. A one-way ANOVA with a completely randomized design was utilized to assess the impact of loading mass on parameters including the drying efficiency, heating energy, and moisture content of cassava flour.

4. Discussion

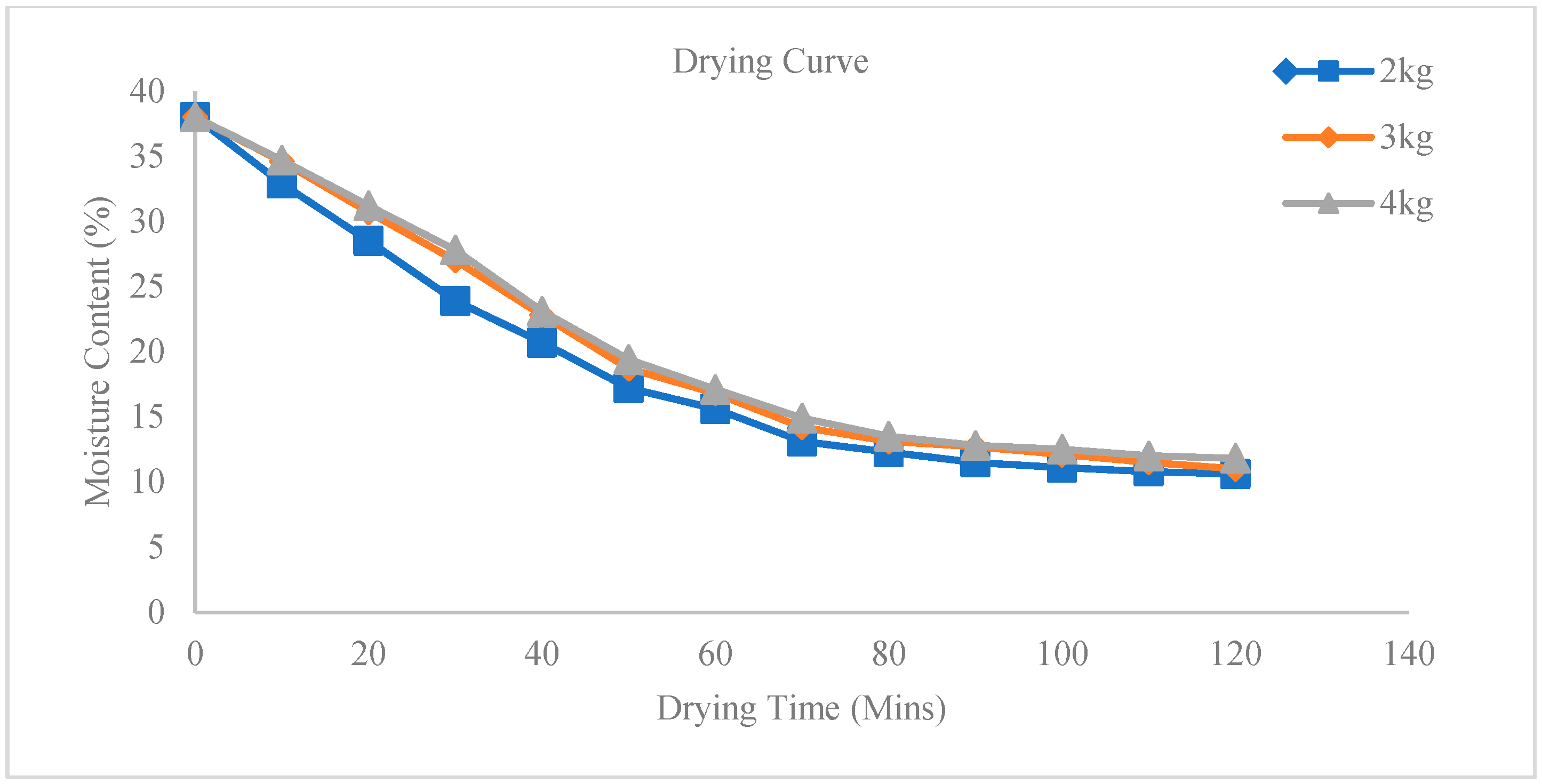

The moisture content steadily decreases throughout the drying process until reaching equilibrium moisture content across all the loading masses. This drying behavior is consistent with findings from previous study on plantain and potato [

18]. The final moisture content of the dried samples under varying loading masses meets the Nigerian standards for high-quality cassava flour (HQCF). This highlights the cabinet dryer’s effectiveness in producing high-quality cassava flour with a suitable shelf life. Similar drying results have been reported in various studies focusing on biological materials processed in biomass heat-driven dryers. For instance, Godwin et al. [

11] observed moisture content reductions from 87.6% to 17.3% (wb) for okra and from 90% to 15.3% (wb) for pepper. Likewise, Saravanan et al. [

6] noted a reduction in cashew nut moisture content from 9% to 4% (wb).

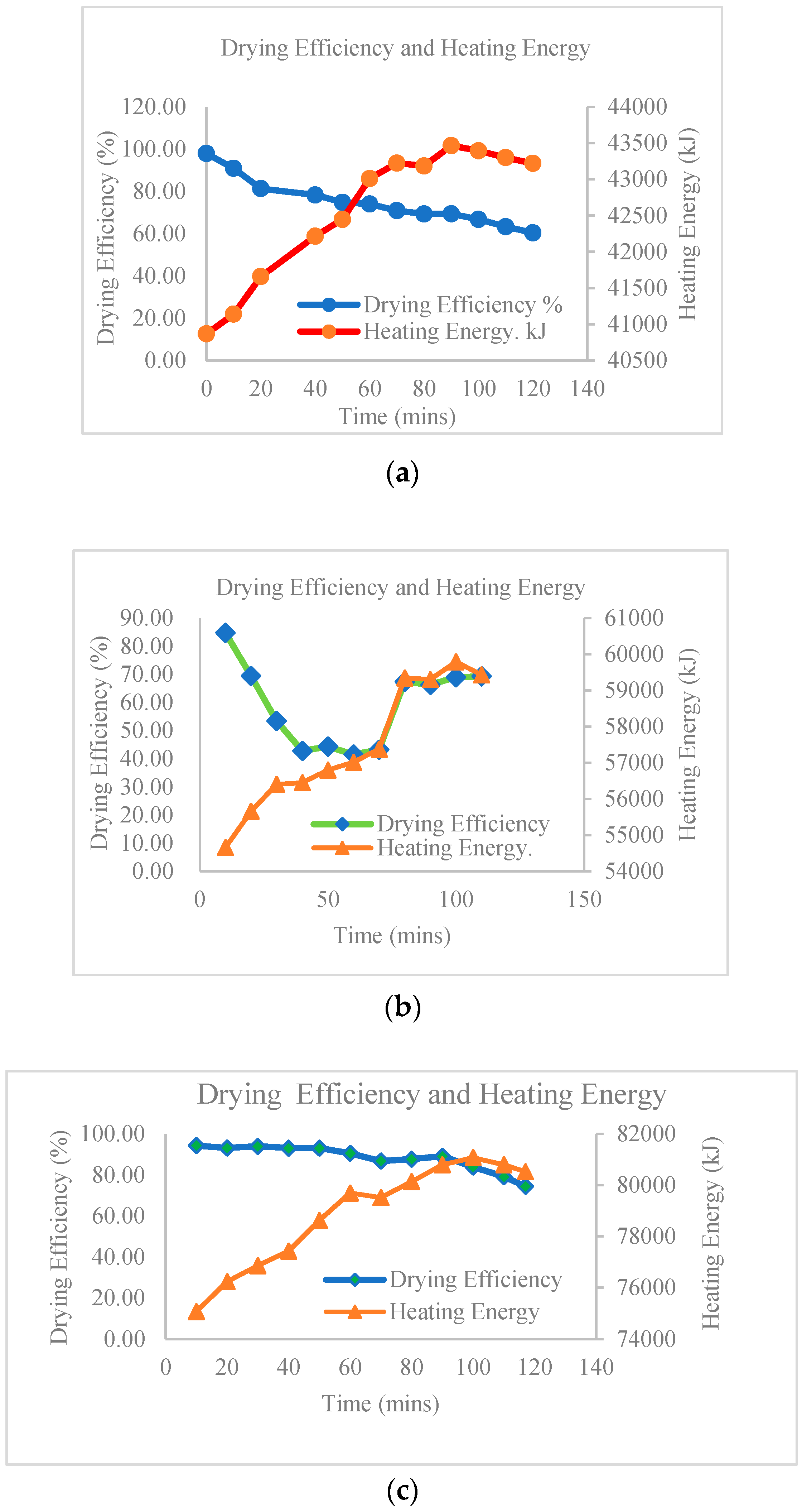

Furthermore, the study evaluates the drying efficiency across different material capacities, recording efficiencies of 74.77%, 59.22%, and 88.24% for material capacities of 40 kg, 60 kg, and 80 kg, respectively. This highlights the dryer’s capability to handle varying loads effectively, showcasing its versatility. The performance of this dryer compares favorably with drying results reported in previous studies on biomass heat-driven dryers and conventional dryers. For instance, a biomass cabinet dryer achieved an 89.67% drying efficiency for plantain in Famurewa et al.’s study [

18], an industrial fruit and vegetable dryer attained an 84% drying efficiency for tomato in Ehiem et al.’s study [

10], and a bio-material cabinet dryer recorded an average drying efficiency of 79% for okra, pepper, and groundnut [

11]. Also, the drying efficiency of 50.4% was recorded in a natural convection grain dryer for paddy and other cereals as reported by Mohapatra et al. [

20], while Bukola and Ayoola [

21] reported a drying efficiency of 85.4% in a mixed-mode solar dryer for yam chips. In addition, Adamade and Olaoye [

22] reported drying efficiency of an electrically operated dryer, which ranged from 65.71 to 84.60% for Iru Woro and 65.60–84.87% for Iru Pete, respectively,

Moreover, Saravanan et al. [

6] reported drying efficiencies ranging from 25% to 35%, averaging 30%, for a biomass dryer used for cashew nuts, attributing the lower efficiency to the inherent nature of the product. Sawant et al. [

23] reported a drying efficiency of 25.20% for copra (a coconut derivative) in a waste-fired dryer, acknowledging its relatively lower efficiency. Drying efficiency is influenced by factors such as drying time, local environmental conditions, and the design of the drying system. The reduction in moisture content and the drying efficiencies recorded in the developed dryer suggest that the designed biomass-fueled cabinet dryer could serve as a practical solution for cassava flour production in rural communities.

The conventional drying of cassava using electrical energy or fossil fuel as input is a highly energy-intensive operation; hence, biomass drying could be one of the viable options for reducing the energy cost for cassava drying. Therefore, the biomass dryer is one of the suitable drying systems in rural areas where biomass is abundantly available. The comparative advantage of biomass dryer is that it can be effectively used during nights and even on rainy days without additional energy from other sources.

Furthermore, the study also highlights biomass efficiencies of 3.0%, 3.5%, and 4.0%. These values are significantly lower than those found in similar study on biomass dryers for cashew nut drying, which range from 4% to 16%, with the average value of 9.5% [

6]. The biomass efficiencies recorded in the dryer indicate that the combustion efficiency within the drying chamber is limited. Hence, there is a need to expand the drying chamber to increase capacity and enhance heat transfer from the heat exchanger. In addition, a dehumidifier could be incorporated for the recirculation of the drying air to enhance the dryer efficiency. Despite these relatively modest biomass efficiencies, the overall drying efficiency underscores the dryer’s effectiveness in achieving its primary objective.

This research focuses on designing, assessing, and analyzing the thermodynamic performance of a biomass-powered cabinet dryer for cassava processing. It evaluates moisture reduction, energy efficiency, and product quality, comparing the dryer to solar and electric alternatives to highlight its advantages and disadvantages. Although the study is limited to small-scale cassava drying, it provides useful insights for farmers, agro-processors, and policymakers looking for sustainable drying methods with possible applicability in other agricultural products. The study offers valuable insights into the performance of the biomass heat-generated cabinet dryer while emphasizing the importance of tailored technological solutions for addressing rural challenges. This approach underscores a holistic perspective that integrates socio-economic and environmental considerations into technology implementation in rural settings. By leveraging locally available materials and addressing the specific needs of the target community, the biomass heat-generated cabinet dryer proves to be a practical and efficient solution for cassava flour production in rural areas. This approach aligns with the overarching principles of sustainable and context-specific technology development.

The study provides useful insights; nonetheless, it has limitations, including the effects of biomass fuel variability, combustion efficiency, and environmental conditions on drying uniformity. It may also neglect long-term maintenance expenses, emissions, and difficulties in scaling for industrial application, as the emphasis is predominantly on small- to medium-scale drying. Moreover, elements such as air recirculation remain inadequately examined, potentially augmenting drying efficiency.

5. Conclusions

This study illustrates how a biomass-fueled dryer enhances cassava-drying processes compared to traditional methods, emphasizing its efficiency, controllability, and adaptability to varying conditions and loads. By utilizing locally available biomass as a renewable energy source, the dryer promotes sustainability and resilience in agricultural ecosystems. Despite its lower biomass efficiency, the dryer effectively reduces moisture levels, making it viable for small- and medium-scale farmers and enhancing economic opportunities through increased cassava processing for income generation. The use of locally sourced materials meets engineering standards, facilitating technology transfer and adoption in resource-limited settings. The dryer supports economic growth, environmental sustainability, and improved livelihoods for smallholder farmers, contributing to the comprehensive development of rural communities. Future research should prioritize improving biomass efficiency, the incorporation of dehumidifier for air recirculation, scalability, and operational ease to ensure widespread adoption across diverse rural contexts.