1. Introduction

Nigeria is a prominent rice producer in Africa with a substantial installed capacity of over 3 million metric tons for rice milling each year [

1,

2]. This capacity encompasses both large-scale integrated rice mills and smaller mills spread throughout the country [

2]. The smaller mills, often operated by local entrepreneurs or cooperatives, are dispersed across different regions such as the North-West, North-Central, and South-East and serve the local markets and communities [

3]. Consequently, these mills play a significant role in ensuring food security and boosting the economy. They contribute substantially to rice consumption in Nigeria and generate employment opportunities along the value chains. By reducing reliance on rice imports, which exposes the country to external factors such as market fluctuations, currency exchange rates, and trade disruptions, domestic rice milling enhances food security and price stability [

4,

5]. Furthermore, local rice milling helps to stabilize the rice supply within the country by reducing transportation costs and logistical challenges associated with importing rice from distant locations [

6]. This not only saves foreign reserves but also ensures a consistent supply of rice, particularly during global food crises or trade disruptions. Moreover, rice milling operations not only support local rice farmers by providing a reliable market for their produce but also create employment opportunities across different stages of the supply chain, thereby alleviating poverty, stimulating economic growth, and fostering rural development in agricultural regions [

7].

Despite the crucial role of domestic rice milling in ensuring food security and economic stability, rice milling in Sub-Saharan Africa (SSA) heavily relies on water availability and favorable weather conditions [

8,

9]. Local millers often lack access to modern rice milling technologies, leading to a dependence on water for various stages of the milling process, including cleaning, soaking, and parboiling [

10,

11]. In regions with irregular or unreliable water availability due to seasonal variations in rainfall or inadequate irrigation infrastructure, small millers may face challenges in maintaining consistent milling operations [

5]. Water scarcity can disrupt production schedules, cause delays in processing activities, and reduce milling capacity, resulting in decreased productivity and income for mill owners. In low-lying and flood-prone areas, excessive rainfall can lead to flooding, which can damage rice milling factories, causing waterlogging, soil erosion, and harm to milling facilities, machinery, and storage structures [

12,

13]. This disrupts milling operations, necessitates costly repairs, and leads to downtime for small-scale millers, impacting their profitability and competitiveness in the market [

14].

Furthermore, high air humidity levels and moisture content during rainy seasons can worsen the growth of mold and spoilage of rice grains during storage and processing [

15]. Small-scale rice millers may encounter difficulties in mitigating the risks of grain deterioration and quality degradation caused by fungal contamination, resulting in product losses, rejection by buyers, and damage to reputation [

16]. The challenges of managing moisture-related issues in rice milling are further complicated by inadequate drying facilities and poor ventilation in storage areas. Moreover, the reliability of electricity supply for small-scale rice mills can be affected by extreme weather conditions, such as power outages during storms or damage to electrical infrastructure. This can lead small millers to rely on grid electricity, diesel generators, or other energy sources for their milling operations as any interruptions or fluctuations in energy supply can result in increased production costs, decreased efficiency, and hinder the overall profitability of rice milling enterprises [

17].

In addition to the above, difficulties faced by small-size millers in addressing the overreliance of domestic milling on WWrP is due to a lack of adequate infrastructure for rice milling, including milling facilities, storage facilities, transportation networks, and power supply [

17,

18]. The absence of modern milling equipment and technology also hampers the efficiency and competitiveness of domestic rice milling operations. Additionally, small-scale rice millers often have limited access to credit and financial services, which constrains their ability to invest in modern milling equipment, infrastructure upgrades, and working capital [

19]. This limits their capacity to expand their operations, improve productivity, and compete with larger-scale producers. Furthermore, the lack of skilled personnel and technical expertise in rice milling techniques, equipment maintenance, and quality control poses a significant challenge to domestic rice millers [

18]. This affects their ability to optimize their milling processes, adhere to quality standards, and meet consumer preferences [

20]. As a result, inadequate market access and competition arise, with domestic rice being outcompeted by imported rice that may be subsidized and offered at lower prices [

1]. Inadequate market access, trade barriers, and lack of government support for domestic rice promotion further exacerbate the challenges faced by local millers in competing with imported rice.

In spite of the significant adverse impacts of WWrPs on domestic rice milling, there is limited documentation on the efforts made by indigenous millers in the region to adapt and build the resilience of their rice milling processes and operations to these pressures and continue to supply the majority of rice consumed across Nigeria. These efforts are referred to here as endogenous adaptation strategies. These are locally developed strategies based on indigenous knowledge, social structures, and cultural institutions [

13,

21,

22]. These practices enable local actors and communities to manage or mitigate the impacts of climate change. Key characteristics of endogenous adaptation are that they are deeply rooted in local culture and shaped not by external influences but by the socioeconomic, political, and environmental conditions unique to each community [

13,

22]. Thus, given the importance of such practices to managing and moderating the impacts of climate change, this study aims to document the exposure and sensitivity of rice millers to WWrPs in Benue State, Nigeria. It also seeks to examine the current endogenous adaptation strategies used by rice millers in response to WWrPs and identify potential entry points for policy interventions to enhance the resilience of rice milling in Benue State.

2. Methodology

This section provides an overview of the study area, including the criteria for selecting data collection sites. It also describes the data collection process, highlighting the sampling techniques and procedures used for conducting interviews and workshops. Finally, it outlines the methods used for data analysis and the presentation of results.

2.1. Study Area

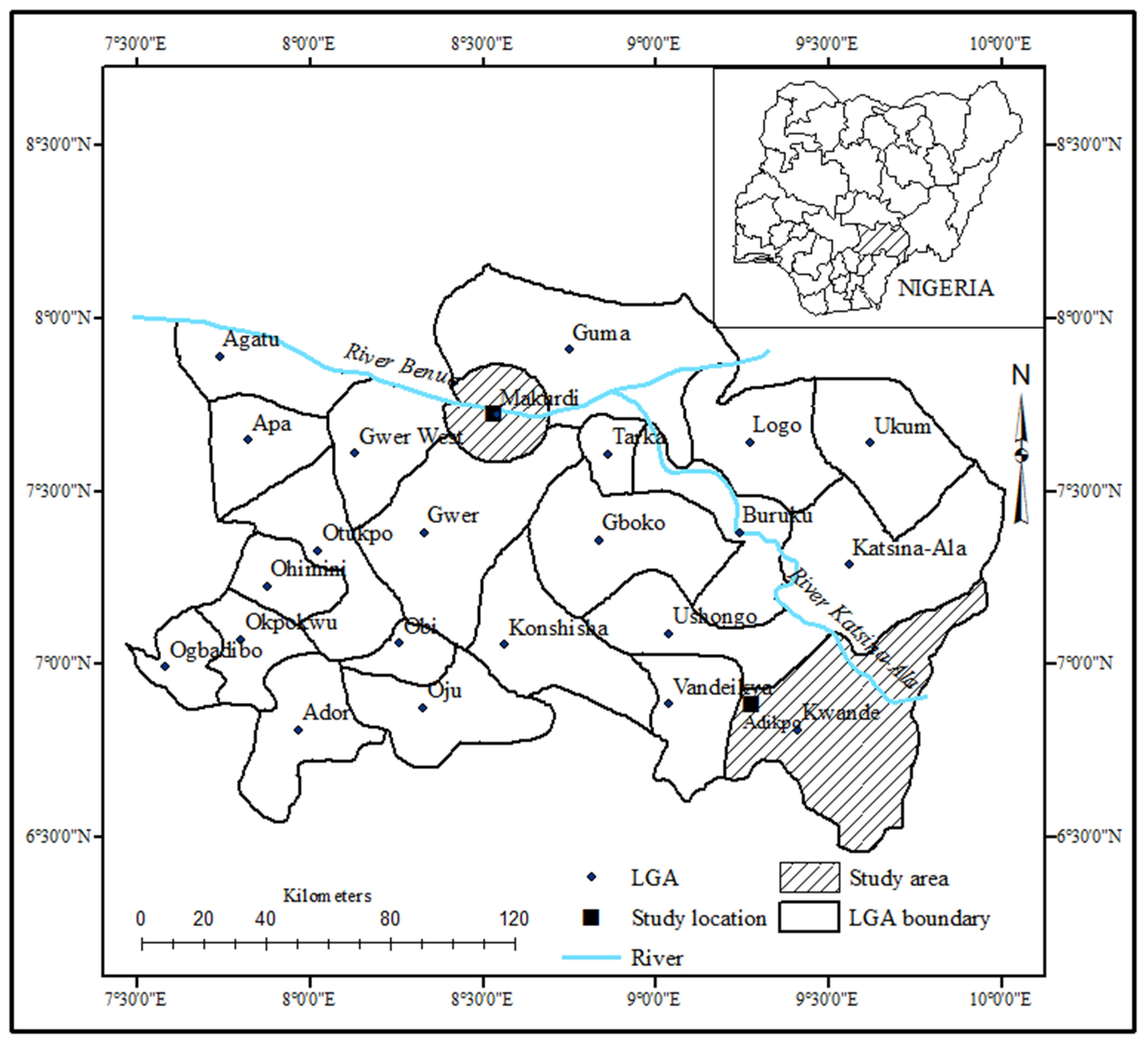

The study was carried out in Benue State, commonly known as the “Food Basket of the Nation” [

23]. This state is situated in the North-Central geopolitical zone of Nigeria, between latitude 7°47′ N and 10°0′ N, as well as longitude 6°25′ E and 9°30′ E (

Figure 1). It shares its boundaries with Nasarawa State to the north, Taraba State to the east, Cross River State to the southeast, Enugu State to the south, Ebonyi State to the southwest, and Kogi State to the west. Makurdi is the capital city of Benue State, where agriculture forms the backbone of the state’s economy, encompassing the production of a diverse range of fruits, grains, and tuber crops. The state is known for its significant rice cultivation originating from the six primary rice production and processing belts or clusters, namely Lower Benue River Basin (Makurdi), Gboko, Katsina-Ala, Utukpo, Ukum, and Adikpo [

24]. These collectively contribute to the state’s substantial rice production output, playing a pivotal role in fulfilling local demand and making a notable contribution to the broader agricultural sector in Nigeria.

2.2. Data Collection

To account for the current exposures and adaptation responses of the miller to WWrP, a qualitative strategy that draws from a combination of participatory tools, including participants’ observations, semi-structured interviews, and workshops, were used in two rice processing and milling clusters: Makurdi in the West and Adikpo in the North. These locations were purposefully chosen due to their contrasting geographical and political characteristics, as well as the presence of different types of rice mills, ranging from large-scale integrated mills to smaller ones.

A total of 21 face-to-face semi-structured interviews (10 in Adikpo and 11 in Makurdi) to obtain a comprehensive insight into the issue being studied. Although the sample size appears small, it is considered representative, as it reflects the characteristics of rice millers in the two study locations. In Adikpo, Kwande, 10 participants (22%) were selected from 45 active rice milling houses, while in Makurdi, 11 participants (64.7%) were chosen from a total of 17 milling houses. The interviews, each lasting 1 hour and 30 minutes or longer, were initially conducted between February and July 2017, with additional interviews added in August 2019. In addition, 2 workshops involving 14 rice millers (7 in Makurdi and 7 in Adikpo) were conducted to complement and validate the interviews in the respective locations. This approach engages participants in practical exercises and activities, enhancing the co-creation process while generating qualitative insights into endogenous adaptive practices and identifying entry points to reduce millers’ exposure to water-related pressures [

25].

Given the complexity of exploring endogenous adaptation practices, the small sample size allows for a more in-depth examination and meaningful engagement with each participant. This enables researchers to uncover rich qualitative data that larger samples might overlook (see also, [

26]). Thus, with participants’ consent, both the interviews and workshops were recorded using an Olympus Digital Voice Recorder VN-741PC. Additionally, two research assistants took notes, which provided a foundation for analyzing the interviews and workshops in the later stages of the research.

Moreover, due to the millers’ skepticism and reluctance to grant interviews to individuals they perceive as outsiders, such as government officials or representatives of organizations whom they feel have been unsupportive or have made unfulfilled promises of loans and safety nets to improve their milling quality but failed to deliver, a snowball sampling was implemented to overcome this challenge and address the issue of distrust. This involved having a leader introduce the interviewer to the next miller, and this process continued until all interviews were completed, reaching the saturation point where responses became consistently similar, and repetition was no longer necessary. Although rice processing activities typically fluctuate seasonally (within a year), the exposure, sensitivity, and adaptive practices are influenced by barriers and enabling factors that develop over a more extended period.

Consequently, data and information about rice millers’ vulnerability (i.e., exposure, sensitivity, and adaptive strategies) to WWrPs, such as the types of pressure and impacts currently being experienced, as well as the strategies employed to manage or mitigate these impacts on rice milling processes and activities, were collected. Accordingly, during the interviews, rice millers were invited to share their experiences with exposure, sensitivity, and adaptation to WWrPs, particularly extreme events, and to describe how they had responded to these challenges over the past 5–10 years (refer to

Figure 2 and

Table 1 for the summary of data generated from the interviews).

2.3. Data Analysis

With the help of two research assistants, both native speakers of Tiv, one holding an MSc in English Language and the other an MSc in Geography, the researcher, who also has a good command of Tiv, translated the audio recordings of the interviews and workshop sessions from Tiv to English. The translations were then stored as Microsoft Word documents. To minimize bias during the transcription of interview data, verbatim translation was used to avoid “cleaning up” grammar, paraphrasing, or adding interpretation. Additionally, collaboration with two research assistants who are native speakers helped ensure accurate transcription and translation. In addition, peer debriefing sessions were conducted after each transcription to check for potential bias or misrepresentation. During this process, the field and workshop notes were utilized to supplement the audio recordings.

A computer-assisted NVivo 11 (QSR International, 17; [

27]) was used during the analysis. The transcripts of the interviews were imported into the software and files were created to organize the data. Codes were generated progressively and refined or merged by selecting text and assigning it to nodes or themes. An inductive thematic and content analysis was conducted to identify code frequencies [

28,

29]. This involved counting how often specific codes appeared, particularly by noting how many participants in a set of interviews mentioned or alluded to a given issue or concept. Percentages were then calculated based on these frequencies. The utilization of content and inductive thematic analyses allowed for the identification of emerging themes, patterns, and the hiding and underlying insights within the qualitative data [

30].

To ensure validity, the findings from the analysis of interview data were cross-checked against the workshop analysis results. If both methods produced similar outcomes, it could be inferred that the findings are robust. However, if there were disparities between the two results, the reasons behind such discrepancies were provided. Finally, the results obtained from the analysis are presented through charts or graphics and tables.

3. Results

The section presents the results on the types of WWrPs that rice millers are exposed and sensitive to and the endogenous strategies employed in response to the pressures.

3.1. Exposure and Sensitivity of Rice Millers to WWrPs in Benue State

The results of the analysis of data on millers’ exposure and sensitivity to WWrPs are presented in

Figure 2. Results showed that rice millers encountered frequent flooding of rice mills, water shortages, limited sunshine hours during peak rainy seasons, and extreme dryness caused by harmattan winds in the dry season (

Figure 2).

A number of millers shared their experiences regarding these pressures, which are highlighted in

Figure 2. According to the millers, flooding has posed a significant challenge in the region of Makurdi. In this particular area, both the Wurukum and Wadata rice mills are located on the banks of River Benue, allowing them to fulfill the water requirements during the rice parboiling and milling. Nevertheless, this location of the two mills makes them prone to frequent flooding, often disrupting key milling activities such as soaking, parboiling, and drying. This location also makes the two mills vulnerable to frequent flooding, which often disrupts milling activities, such as soaking, parboiling, and drying. These disruptions can go on for days, weeks, or even months, especially during the heavy rainfall period in August and September.

In contrast to Makurdi, scarcity of water was identified by millers in Adikpo as one of the challenges frequently encountered in the mills. The rice mills in these locations are strategically situated near water sources to ensure convenient access during the milling processes. Nevertheless, during the peak of the dry season, typically in March and April, these water sources tend to dry up, leading to greater challenges, including raising the costs of rice milling during this time. Since millers have no other options, they are forced to buy water from vendors, often at a high cost.

Another ongoing challenge for rice millers across the two study sites is the inconsistent duration of sunshine, caused by seasonal fluctuations and irregularities in weather and climate patterns. Firewood is the primary energy source for milling, but during the rainy season’s peak (August and September), frequent cloud cover and reduced sunlight make drying difficult. This lack of adequate sunshine complicates the drying of parboiled rice to the desired moisture content, leading to a higher likelihood of grain shattering or preventing the complete removal of the chaff during the dehusking process (i.e., a process where the milling machines remove the chaff from the rice grains).

In contrast to the challenges posed by limited sunshine hours due to wet conditions, millers in all the study locations highlight excessive dryness during the harmattan season (i.e., between December and January) as a significant issue for milling. According to the millers, this period is characterized by strong dry winds leading to quicker drying. Consequently, firewood tends to become excessively dry and burns at a faster rate than intended. Additionally, the wind during steaming and parboiling often blows out the fire, leading to improperly parboiled rice. In addition, rice dried during this time becomes overly dry, making it susceptible to splitting into smaller pieces during dehusking.

3.2. Adaptation of Millers to WWrPs

This section explores the endogenous adaptation strategies rice millers use to cope with WWrPs.

Table 1 presents a summary of the current adaptive practices adopted by millers in both locations to address the challenges posed by WWrPs. These strategies are classified into various types: tactical (i.e., short-term), reactive (e.g., implemented after pressure arises), strategic (i.e., long-term), anticipatory, or preventive (e.g., applied proactively before pressures occur).

In Makurdi (

Table 1), for instance, when faced with frequent flooding, rice millers commonly employ the strategy of temporarily closing their mills and relocating to safer areas. While this practice helps them avoid total damage from the floods, it also places significant pressure on their income throughout the flooding period when all operations are suspended. Furthermore, the millers noted other challenging situations, such as extended scarcity of unmilled rice or severe milling machine malfunction, which includes difficulties in accessing necessary spare parts, for which temporary closure of milling activities is often the best approach (

Table 1).

Furthermore, when millers encounter changes in sunshine duration caused by overcast weather or extreme dryness resulting from the harmattan wind, they are often prompted to respond by altering their rice drying methods. During the peak of the rainy season, spanning August to September, most millers change their usual drying method to drying the rice in thin layers of about a 7–10 cm bed depth, allowing for easy circulation of air and efficient heat penetration resulting from limited sunlight. As reported by the millers (

Table 1), this process ensures that the rice’s moisture content is reduced to appropriate levels for milling, preventing spoilage, and discoloration. In contrast, during the harmattan season, typically between December and January, the dry and intense winds cause the rice’s moisture content to fall below the recommended 12–14% required for high-quality milling [

24]. To address this, millers dry the rice in thick layers or clusters above the usual 7–10 cm bed depth, limiting air circulation and sunlight exposure to minimize shattering during milling.

In addition to altering the drying method, millers also adjust the quantity of rice milled during times of intense rainfall when hours of sunlight are reduced. As highlighted in

Table 1, by reducing the amount of rice milled to a manageable level, they can minimize losses from improper handling and maintain the quality of the milled rice. Although this reduction in supply during heavy rainfall causes a temporary shock in the market, leading to increased prices, it is short-lived.

Additionally, millers often adopt a rotational system for drying parboiled rice (

Table 1). This approach is necessary because during wet weather, the time needed to adequately dry the rice, which is critical for achieving high-quality milling, significantly increases. As a result, the available drying slabs or pavements become insufficient for the heightened drying demands, forcing millers to resort to drying rice in unsuitable locations, such as roadsides, to avoid spoilage. Unfortunately, this practice compromises the quality of the rice, often introducing broken stone fragments into the milled product. To address these issues, a coordinated approach is implemented, allowing only a limited number of millers to dry parboiled rice at a time while others wait their turn, thereby reducing these challenges.

Furthermore, due to the lack of nearby major rivers in Adikpo, rice millers often depend on well water as an alternative source. According to the millers (

Table 1), this practice is especially common between January and May, when water scarcity is more pronounced. However, during extended dry periods, particularly when rainfall is delayed, many hand wells dry up, worsening the problem. In these cases, some millers report having to travel long distances to collect water from larger streams and rivers.

4. Discussion

This study was carried out to increase understanding of how the rice millers in Benue State, Nigeria are adapting to WWrPs. Accordingly, the findings revealed that rice milling is currently exposed and sensitive to prolonged periods of wet conditions, high moisture content, excessive dryness, and water scarcity. These put pressure on the local rice milling sector in Benue State, resulting in poor milling quality and loss of competitiveness of local rice in the market and ultimately its profitability. To respond to these pressures, thereby building resilience to keep producing and to continue to supply the end-use market in the face of these pressures, rice millers have implemented various practices. These include temporarily relocating rice mills, rotating drying shifts, managing the quantity and frequency of rice parboiled during flooding, digging wells, and modifying drying methods. These results are in agreement with those of 5, 8, 9, 12, 13, and 24, which demonstrate that the entire rice value chain’s activities and processes (e.g., rice production, processing, and milling and marketing and distribution) are vulnerable to multiple climatic and economic pressures. Thus, enhancing the capacity of rice millers to adapt to these pressures requires investments in modern technology, capacity building of millers to use modern technology, and access to soft loans [

17,

18] to invest in demand-lifting strategies, including advertisement and branding to reverse urban biases toward locally milled rice and its market outcompetition [

14,

20,

31,

32].

The results of this study also highlight that the differences in adaptation strategies between the two study sites (i.e., Makurdi and Adikpo) may be influenced by factors such as the severity and frequency of environmental pressures, availability of resources, access to infrastructure, and socioeconomic considerations. This demonstrates the ability of the rice millers to innovate and adjust their practices to mitigate the impacts of climate variability [

9]. While the adoption of strategic anticipatory measures (such as digging hand wells to address water scarcity) indicates forward-looking planning and proactive management of risks, the domination of tactical reactive strategies, such as temporary closure, relocation during flooding, and changing drying techniques in response to limited sunshine or excessive dryness, used by rice millers to address immediate threats shows that more effort is needed to address long-term pressures.

These findings demonstrate that the widespread adoption of endogenous adaptation practices in the study sites is largely driven by the small scale of rice milling operations and the low-income status of most millers, which limits their ability to attract investment [

8,

21,

22]. While such adaptation measures help manage exposure to water-related pressures in the short term, their long-term effectiveness is constrained by a lack of technological advancement [

5,

8,

32].

The findings also underscore the importance of context-specific adaptation planning and the need for targeted interventions to strengthen the resilience of rice milling communities across different locations. Policymakers and stakeholders can leverage these insights to design tailored adaptation strategies that address maladaptive outcomes of endogenous adaptation measures and enhance the adaptive capacity of rice millers to cope with water-related pressures, ultimately promoting more sustainable livelihoods [

33].

4.1. Potential Entry Points to Reduce WWrPs and Enhance Resilience

This study highlights three key opportunities for reducing WWrPs and enhancing the resilience of locally milled rice to maintain its supply to the end market. These include upgrading rice milling technologies and infrastructure, adopting more proactive and long-term adaptive approaches, and implementing collective strategies for adaptation [

9,

14].

4.1.1. Upgrading Rice Milling Technologies and Infrastructure

Investment in modern milling machinery such as advanced rice hullers, polishers, driers, graders, and sorters can significantly improve the efficiency and quality of rice processing. These machines enable milling activities and processes during unfavorable weather conditions (e.g., limited sunshine to dry parboiled rice) and help reduce processing time, minimize grain breakage, and ensure higher milling yields. In addition, upgrading rice milling technologies and infrastructure to mechanized rice milling processes can help to streamline operations and reduce dependence on manual labor. This involves providing access to affordable mechanization technologies such as rice threshers, milling machines, and drying equipment. This view is shared by a number of previous studies [

9,

11,

14,

34,

35].

4.1.2. Adoption of More Proactive and Long-Term Adaptive Practices

Similar to the above point, proactive measures such as proper drying with the use of modern driers and storage techniques can help minimize post-milling losses associated with mold growth, insect infestation, and moisture-related damage. This ensures that a higher percentage of the milled rice reaches the end-user market in good condition, thereby reducing economic losses for millers, traders, and consumers [

5,

8]. Furthermore, long-term adaptive practices enable rice millers to anticipate and respond effectively to various challenges and risks, such as fluctuations in market prices, changes in consumer preferences, and environmental factors like climate change. By diversifying their operations, investing in innovation, and building resilient supply chains, millers can mitigate risks and maintain business continuity even in uncertain conditions [

9].

4.1.3. Implementation of Collective Adaptive Strategies

The implementation of collective adaptive strategies empowers rice millers to collaboratively address WWrPs; by working together, sharing knowledge and resources, and embracing innovative solutions, millers can adapt to changing environmental conditions and contribute to the resilience and prosperity of their communities. In particular, collective action allows rice millers to pool resources and access climate finance, insurance schemes, and risk-sharing/reduction mechanisms or measures that provide financial support in the event of weather-related losses or damage to crops and infrastructure. This may involve the construction of communal flood barriers, the rehabilitation of drainage systems, and the establishment of early warning and evacuation systems to mitigate the impacts of floods and storms on rice production and milling operations [

5,

36]. By participating in collective risk-pooling arrangements and leveraging their collective bargaining power, millers can learn from the system, reduce their vulnerability to weather-related shocks, and build their resilience, as well as ensure more sustainable livelihoods for themselves and their communities [

33].

5. Conclusions

This study demonstrates that adapting rice milling to weather and climate-related pressures is key to building the resilience of the rice value chains (RVCs) in Sub-Saharan Africa in the face of pressures to respond to growing demands for high-quality milled rice. The findings highlight the significance of local adaptation strategies used by rice millers in addressing WWrPs, showcasing their capacity to innovate and modify their methods to reduce the effects of climate variability. As effective adaptation requires a combination of tactical reactive responses to immediate threats and strategic anticipatory measures to prepare for future challenges, the use of both types of adaptation strategies indicates a proactive approach to managing risks and building resilience.

Policymakers and stakeholders can use these insights to design targeted interventions and support mechanisms to enhance the adaptive capacity of rice millers, such as improving access to water resources, providing training on adaptive practices, and investing in climate-resilient infrastructure. Consequently, further research could explore the effectiveness and efficiency of different adaptation strategies, assess their socioeconomic implications, and identify barriers to their adoption to inform more tailored and context-specific interventions.