A Spray Processed Polymer-Based High Temperature Organic/Metal Thermocouple for Embedding in Organic Coatings of Steel Substrates †

Abstract

:1. Introduction

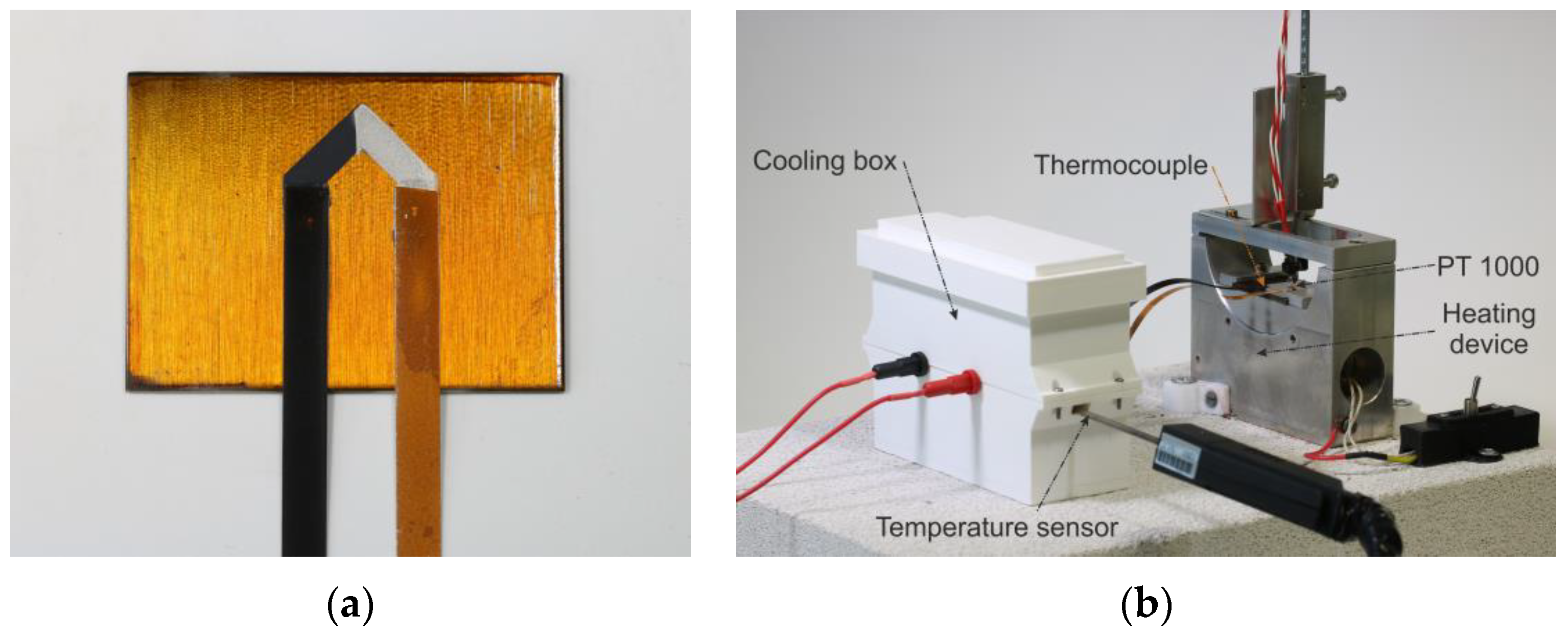

2. Materials and Methods

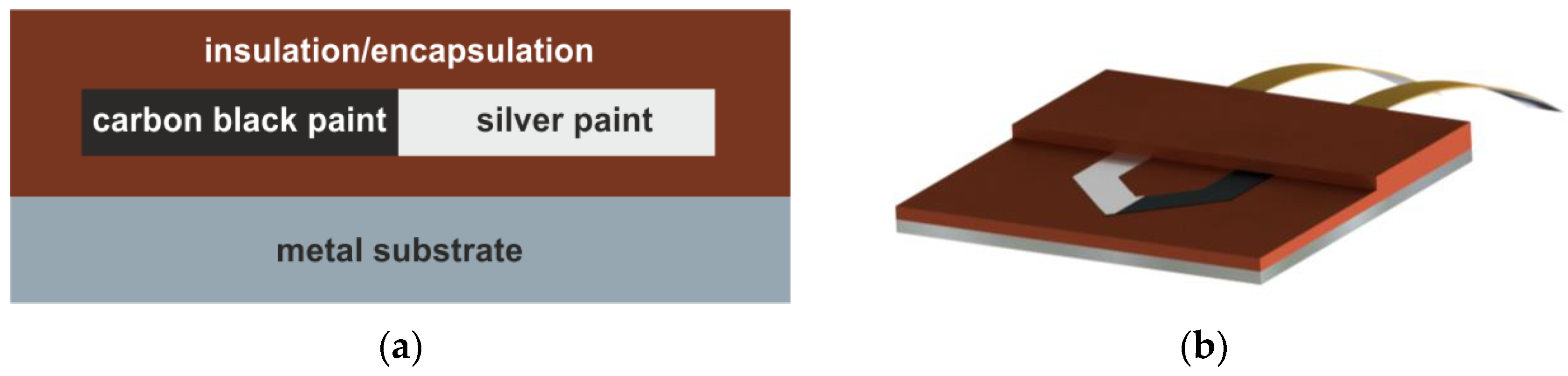

2.1. Sensor Architecture

2.2. Paint Preparation and Processing

3. Measurement and Results

4. Discussion and Conclusions

Acknowledgments

Conflicts of Interest

References

- Zou, H.; Rowe, D.M.; Williams, S.G.K. Peltier effect in a co-evaporated Sb2Te3(P)-Bi2Te3(N) thin film thermocouple. Thin Solid Films 2002, 408, 270–274. [Google Scholar] [CrossRef]

- Castaño, E.; Revuelto, E.; Martín, M.C.; García-Alonso, A.; Gracia, F.J. Metallic thin-film thermocouple for thermoelectric microgenerators. Sens. Actuators A Phys. 1997, 60, 65–67. [Google Scholar] [CrossRef]

- Farré, R.; Montserrat, J.M.; Rotger, M.; Ballester, E.; Navajas, D. Accuracy of thermistors and thermocouples as flow-measuring devices for detecting hypopnoeas. Eur. Respir. J. 1998, 11, 179–182. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Hong, H.P.; Lee, C.J.; Park, C.W.; Min, N.K. Microfabrication and characterization of spray-coated single-wall carbon nanotube film strain gauges. Nanotechnology 2011, 22, 455301. [Google Scholar] [CrossRef] [PubMed]

- Jaworska, E.; Schmidt, M.; Scarpa, G.; Maksymiuk, K.; Michalska, A. Spray-coated all-solid-state potentiometric sensors. Analyst 2014, 139, 6010–6015. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zhou, N.; Han, S.; Lin, H.; Buchholz, D.B.; Yu, J.; Chang, R.P.H.; Marks, T.J.; Facchetti, A. Flexible spray-coated TIPS-pentacene organic thin-film transistors as ammonia gas sensors. J. Mater. Chem. C 2013, 107, 666–677. [Google Scholar] [CrossRef]

- Dole, M.; Wunderlich, B. Melting points and heats of fusion of polymers and copolymers. Die Makromol. Chem. 1959, 34, 29–49. [Google Scholar] [CrossRef]

- Heichal, Y.; Chandra, S.; Bordatchev, E. A fast-response thin film thermocouple to measure rapid surface temperature changes. Exp. Therm. Fluid Sci. 2005, 30, 153–159. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knoll, M.; Offenzeller, C.; Jakoby, B.; Hilber, W. A Spray Processed Polymer-Based High Temperature Organic/Metal Thermocouple for Embedding in Organic Coatings of Steel Substrates. Proceedings 2017, 1, 611. https://doi.org/10.3390/proceedings1040611

Knoll M, Offenzeller C, Jakoby B, Hilber W. A Spray Processed Polymer-Based High Temperature Organic/Metal Thermocouple for Embedding in Organic Coatings of Steel Substrates. Proceedings. 2017; 1(4):611. https://doi.org/10.3390/proceedings1040611

Chicago/Turabian StyleKnoll, Marcel, Christina Offenzeller, Bernhard Jakoby, and Wolfgang Hilber. 2017. "A Spray Processed Polymer-Based High Temperature Organic/Metal Thermocouple for Embedding in Organic Coatings of Steel Substrates" Proceedings 1, no. 4: 611. https://doi.org/10.3390/proceedings1040611

APA StyleKnoll, M., Offenzeller, C., Jakoby, B., & Hilber, W. (2017). A Spray Processed Polymer-Based High Temperature Organic/Metal Thermocouple for Embedding in Organic Coatings of Steel Substrates. Proceedings, 1(4), 611. https://doi.org/10.3390/proceedings1040611