Inkjet 3D Printed Miniature Water Turbine Energy Harvester-Flow Meter for Distributed Measurement Systems †

Abstract

:1. Introduction

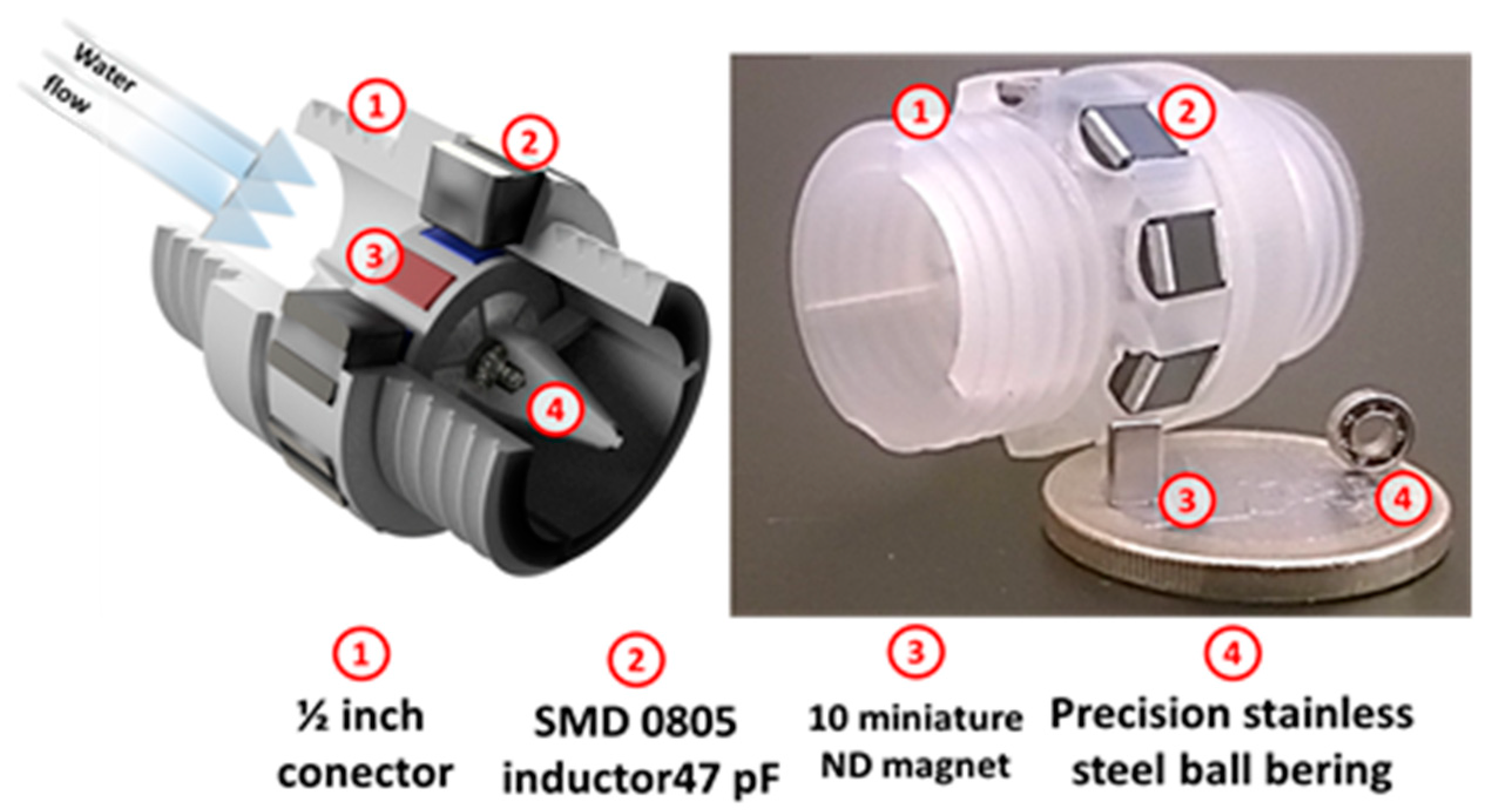

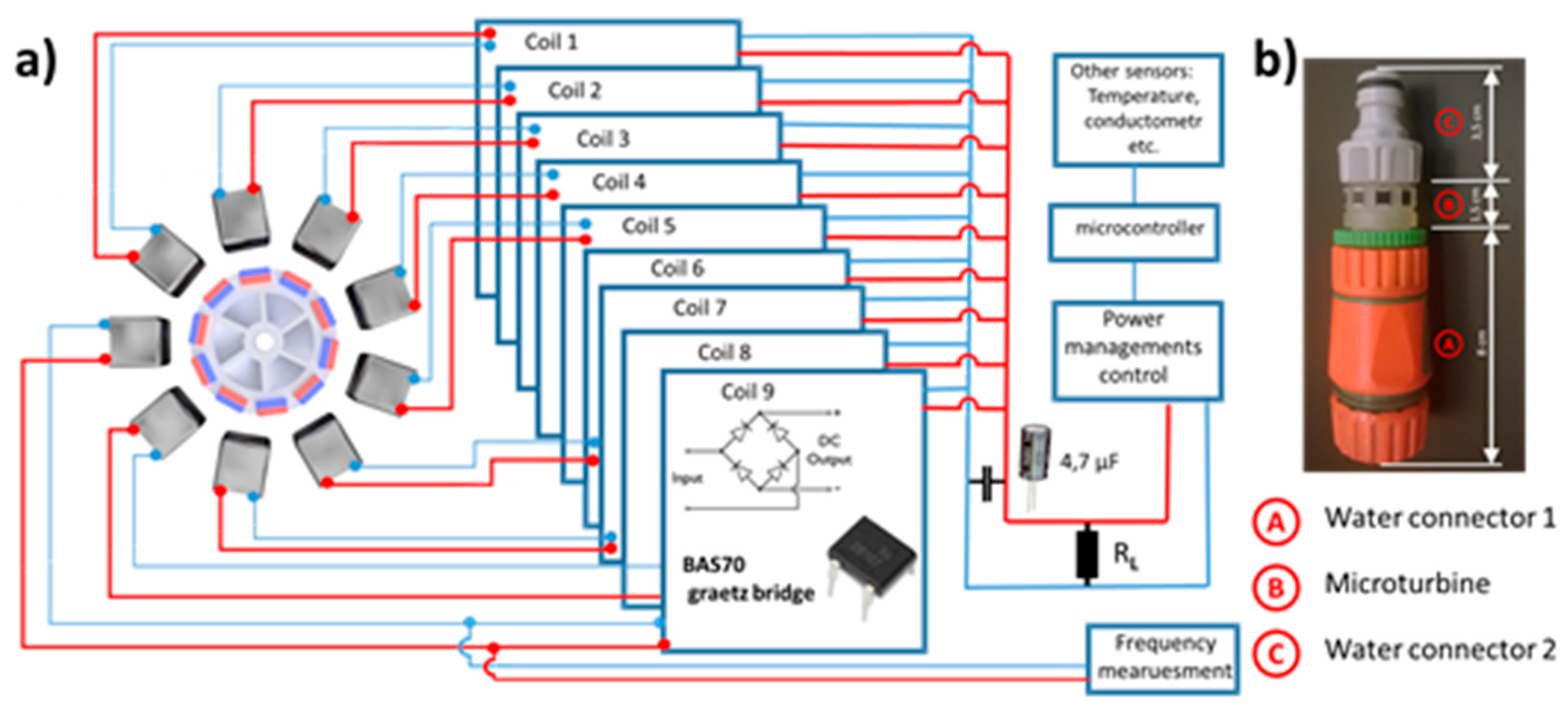

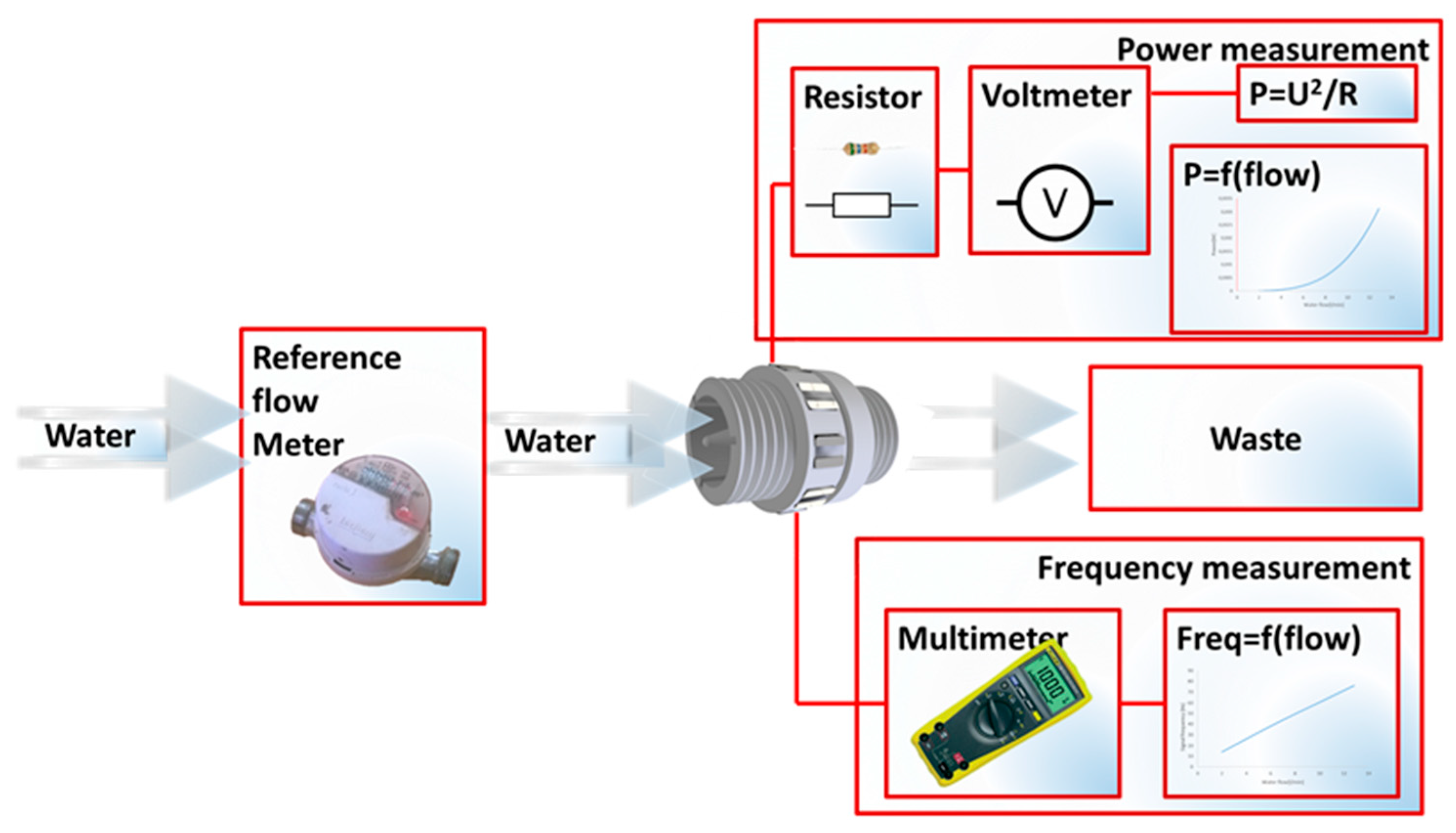

2. Material and Methods

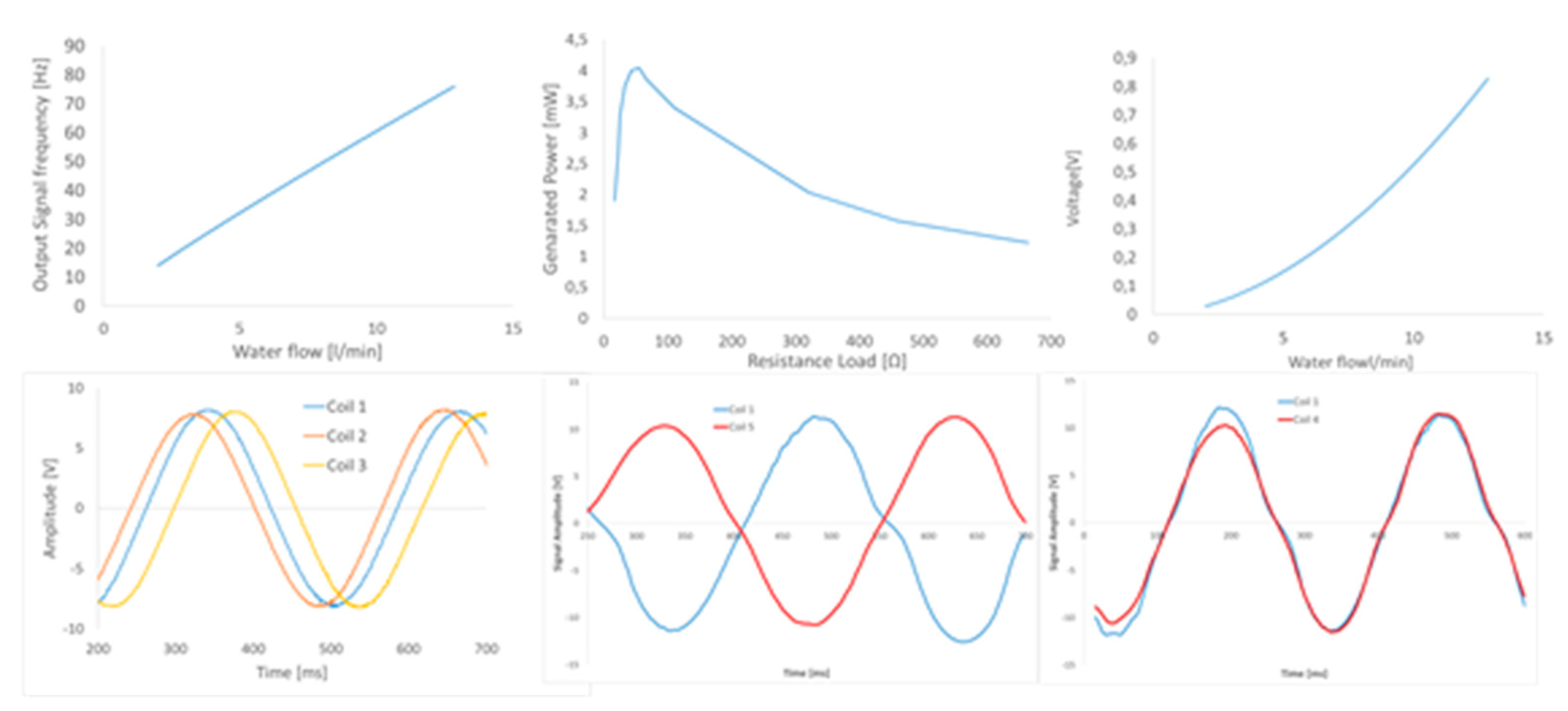

3. Results

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Waldbaur, A.; Rapp, H.; Länge, K.; Rapp, B.E. Let there be chip—Towards rapid prototyping of microfluidic devices: One-step manufacturing processes. Anal. Methods 2011, 3, 2681. [Google Scholar] [CrossRef]

- Walczak, R.; Adamski, K. Inkjet 3D printing of microfluidic structures—On the selection of the printer towards printing your own microfluidic chips. J. Micromech. Microeng. 2015, 28. [Google Scholar] [CrossRef]

- Walczak, R.; Adamski, K.; Lizanets, D. Inkjet 3D printed check microvalve. J. Micromech. Microeng. 2017, 24. [Google Scholar] [CrossRef]

- Boisseau, S.; Duret, A.-B.; Perez, M.; Jallas, E.; Jallas, E. Water flow energy harvesters for autonomous flowmeters. J. Phys.: Conf. Ser. 2016, 773. [Google Scholar] [CrossRef]

- Hoffmann, D.; Willmann, A.; Göpfert, R.; Becker, P.; Folkmer, B.; Manoli, Y. Energy harvesting from fluid flow in water pipelines for smart metering applications. J. Phys.: Conf. Ser. 2013, 476. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamski, K.; Adamski, J.; Dziuban, J.A.; Walczak, R. Inkjet 3D Printed Miniature Water Turbine Energy Harvester-Flow Meter for Distributed Measurement Systems. Proceedings 2017, 1, 578. https://doi.org/10.3390/proceedings1040578

Adamski K, Adamski J, Dziuban JA, Walczak R. Inkjet 3D Printed Miniature Water Turbine Energy Harvester-Flow Meter for Distributed Measurement Systems. Proceedings. 2017; 1(4):578. https://doi.org/10.3390/proceedings1040578

Chicago/Turabian StyleAdamski, Krzysztof, Jarosław Adamski, Jan A. Dziuban, and Rafał Walczak. 2017. "Inkjet 3D Printed Miniature Water Turbine Energy Harvester-Flow Meter for Distributed Measurement Systems" Proceedings 1, no. 4: 578. https://doi.org/10.3390/proceedings1040578

APA StyleAdamski, K., Adamski, J., Dziuban, J. A., & Walczak, R. (2017). Inkjet 3D Printed Miniature Water Turbine Energy Harvester-Flow Meter for Distributed Measurement Systems. Proceedings, 1(4), 578. https://doi.org/10.3390/proceedings1040578