Modelling and Characterisation of Droplet Generation and Trapping in Cell Analytical Two-Phase Microfluidic System †

Abstract

:1. Introduction

2. Materials and Methods

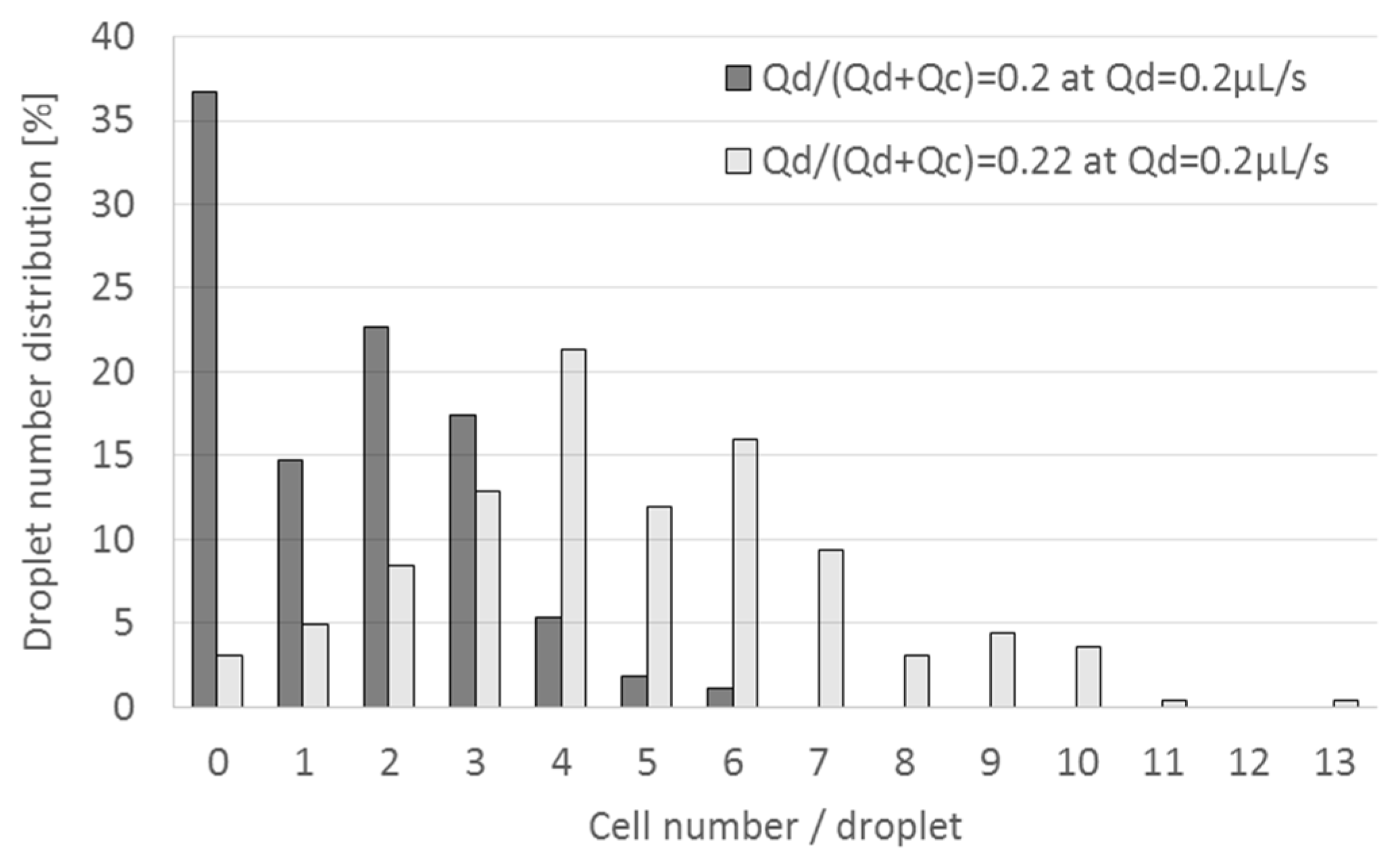

3. Results

4. Conclusions

Acknowledgments

Conflicts of Interest

Reference

- Wingki, L.; Walker, L.M.; Anna, S.L. Role of Geometry and Fluid Properties in Droplet and Thread Formation Processes in Planar Flow Focusing. Phys. Fluids 2009, 21, 032103. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, A.B.; Holczer, E.; Hakkel, O.; Tóth, E.L.; Iván, K.; Fürjes, P. Modelling and Characterisation of Droplet Generation and Trapping in Cell Analytical Two-Phase Microfluidic System. Proceedings 2017, 1, 526. https://doi.org/10.3390/proceedings1040526

Tóth AB, Holczer E, Hakkel O, Tóth EL, Iván K, Fürjes P. Modelling and Characterisation of Droplet Generation and Trapping in Cell Analytical Two-Phase Microfluidic System. Proceedings. 2017; 1(4):526. https://doi.org/10.3390/proceedings1040526

Chicago/Turabian StyleTóth, Anna B., Eszter Holczer, Orsolya Hakkel, Eszter L. Tóth, Kristóf Iván, and Péter Fürjes. 2017. "Modelling and Characterisation of Droplet Generation and Trapping in Cell Analytical Two-Phase Microfluidic System" Proceedings 1, no. 4: 526. https://doi.org/10.3390/proceedings1040526

APA StyleTóth, A. B., Holczer, E., Hakkel, O., Tóth, E. L., Iván, K., & Fürjes, P. (2017). Modelling and Characterisation of Droplet Generation and Trapping in Cell Analytical Two-Phase Microfluidic System. Proceedings, 1(4), 526. https://doi.org/10.3390/proceedings1040526