1. Introduction

Bacterial infections are a public health problem for the next decades, in particular due to the emergence of multi resistant bacteria. One of main challenges in microbiological quality control and in public health is to rapidly and simultaneously count and identify bacteria present in an environment by developing powerful and reliable means detection. Although standard microbiological methods of cell culture and plating are confirmative to identify bacterial strains, it often takes several days to complete the processes. The development of bacteria sensors that enable low cost detection method, direct and sensitive quantification of bacteria is of high interest.

The recent advances in micro- and nano-fabrication technologies of nano-objects (nanowires, nanotubes…), compatible with CMOS (Complementary Metal Oxide Semiconductor) silicon technology, provide unique advantages for developing sensors in several respects. In particular, silicon nanowires (SiNWs) are potential functional probes due to their unique physical properties. Their one dimensional structure offers the smallest confinement for an electron transport along the longitudinal direction, their large surface area promotes interaction between the target cells and nanomaterials and improves the sensitivity. The benefits taking advantage of this smaller scale approach are: (a) the possibility of mass production and reduced unit costs, (b) the use of sample volumes in the range of nanolitres or less, which also implies the reduced costs of reagents, (c) micro-fluidics facilities improve mixing rates and mass transport, (d) the possibility of shortened analysis time. Many groups have reported on SiNWs based sensors, using nanowires as sensitive units for chemical or biochemical (DNA hybridization) detection [

1,

2], gas [

3,

4], or mechanical sensors [

5], but few works report on bacteria detection using SiNWs as sensitive units.

However, there is up to now no demonstration of a versatile sensor that fulfils the promise of a reliable small sized cost effective sensor based on nanowires. Indeed, there are many different materials, devices and functionalization techniques demonstrated in the literature but many of these solutions have severe issues when they are used to integrate them into a sensor. The main hurdle is the conflict between the requirement of a low-cost technology and the technological difficulty of fabricating the nanowire-based sensing element which presently requires expensive lithography equipment such as e-beam [

2] or complex processing such as the spacer transfer technique [

6] into a thin SOI substrate. However, nanowires fabrication based on self-assembly method [

7] is a promising alternative technique, free of high cost lithography tools, compatible with integration of silicon nanowires fabrication in CMOS technology.

In this context, the strategy of our work is to develop low cost fabrication technology of SiNWs based pathogen bacterial sensors, with SiNWs synthesized by self-assembly method used as sensitive units, compatible with the following requirements: (i) high sensitivity and a low detection limit; (ii) a real-time analysis; and (iii) portability and ease-of-use for on-site monitoring.

2. Materials and Methods

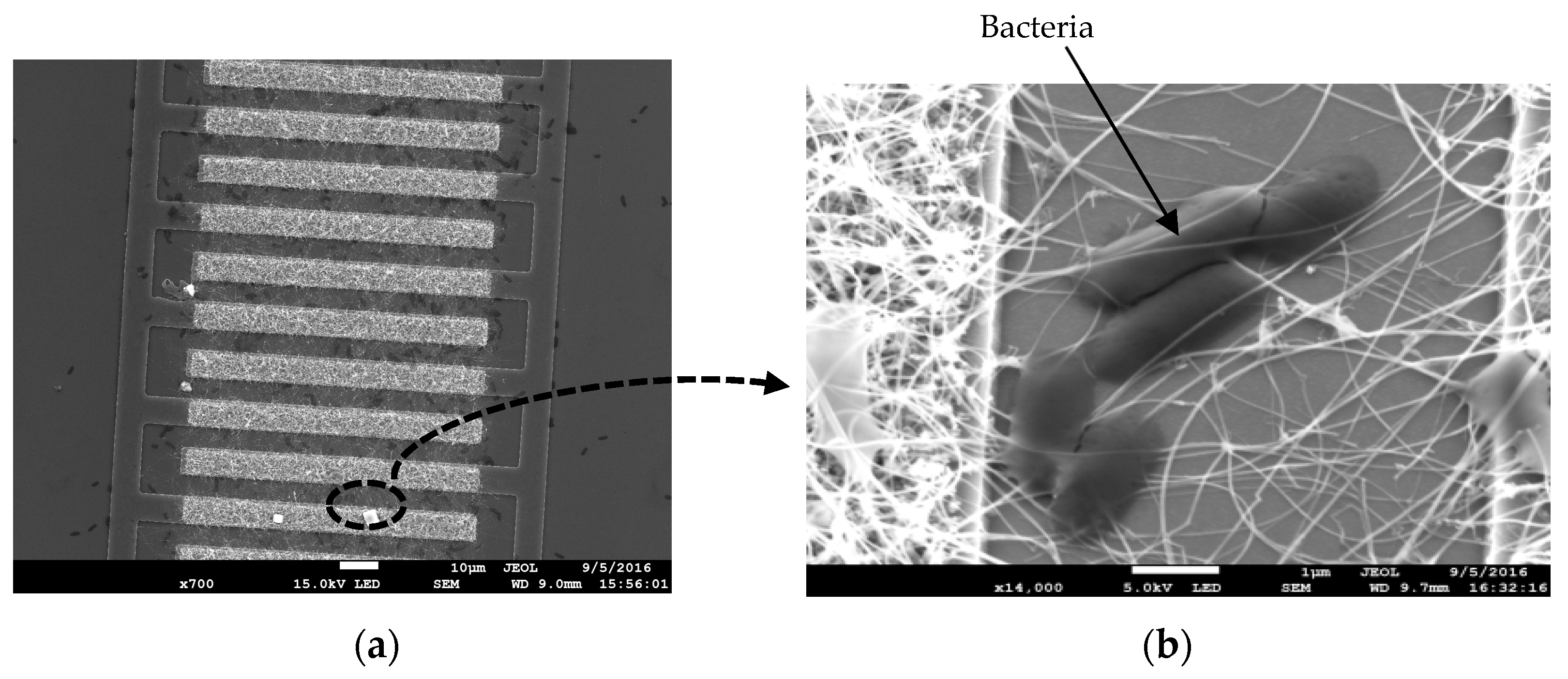

Resistors studied as bacteria sensors are fabricated following a classical CMOS silicon technology process. At first, heavily phosphorous in-situ doped amorphous silicon is deposited by Low Pressure Chemical Deposition (LPCVD) at 550 °C and 90 Pa on oxidized silicon substrate. A thermal annealing is carried out at 600 °C under vacuum to get highly doped crystallized N-type polycrystalline silicon (poly-Si). Then, a plasma etching by reactive ion etched (RIE) of the N

+-type poly-Si is carried to define the inter-digitated comb-shaped electrodes (

Figure 1a). Gold thin film (<5 nm) is then thermally evaporated and locally deposited on the electrodes using a lift off technique in order to define precise location for SiNWs growth (

Figure 1b). SiNWs are grown in LPCVD reactor using vapor liquid solid (VLS) method [

8] at 460 °C and 40 Pa, with gold and silane (SiH

4) as catalyst and gas precursor respectively. Due to the duration of the SiNWs growth a tangled Au-catalyst VLS-SiNWs network results in SiNWs (

Figure 1c) whose length can exceed 20 μm, bridges and SiNWs crossing contacts ensure the electrical connection between these two heavily doped polysilicon islands, leading to the formation of resistors in a 3D configuration (

Figure 2).

3. Discussion

Bacteria (

Escherichia coli ATCC 35128) were first immersed into solution and then a droplet of solution was positioned onto the interdigitated electrodes of the resistor of

Figure 1. Results have shown that bacteria are preferentially hanged into the SiNWs network (

Figure 3). After drying of droplet, electrical measurements were performed on interdigitated SiNWs based resistors, and as illustrated in the

Figure 4, I-V electrical characteristics show significant increase of the current (rectifying behavior) through the resistor due the presence of bacteria with a concentration of 8 × 10

6 CFU/mL. This effect could be explained because of the negative charge of bacteria due to the presence of phosphate in their structure.

Such electrical effect of bacteria on the global resistance of the device illustrates the possibilities of the resistor to act as new kind of bacteria sensors based on SiNWs. The performances (detection limit, sensitivity…) of the sensor could be optimized acting on the design of the resistor (number and space between interdigitated electrodes), the density, the diameter, the length of the SiNWs.

4. Conclusions

A simple and low-cost fabrication technology bacteria sensors is presented, using SiNWs as sensitive units fabricated by self-assembly method (VLS mechanism), compatible with CMOS silicon technology for miniaturization and integration of lab-on-a-chip systems. Innovation is to take advantage of the use of SiNWs array to favour bacteria hanging and thus increase the sensitivity for detection of bacteria.

These first results are proof of concept and are promising for the development of further SiNWs based resistors, taking advantages of both benefits at nanoscale and microtechnology, for achievement of label free, ultrasensitive and real time pathogen bacteria detection to monitor contamination in controlled environment hygiene (health, pharmaceutical…).