Evaluation of MOX Sensor Characteristics in Ultra-Low Power Operation Modes: Application to a Semi-Passive RFID Tag for Food Logistics †

Abstract

:1. Introduction

2. Materials and Methods

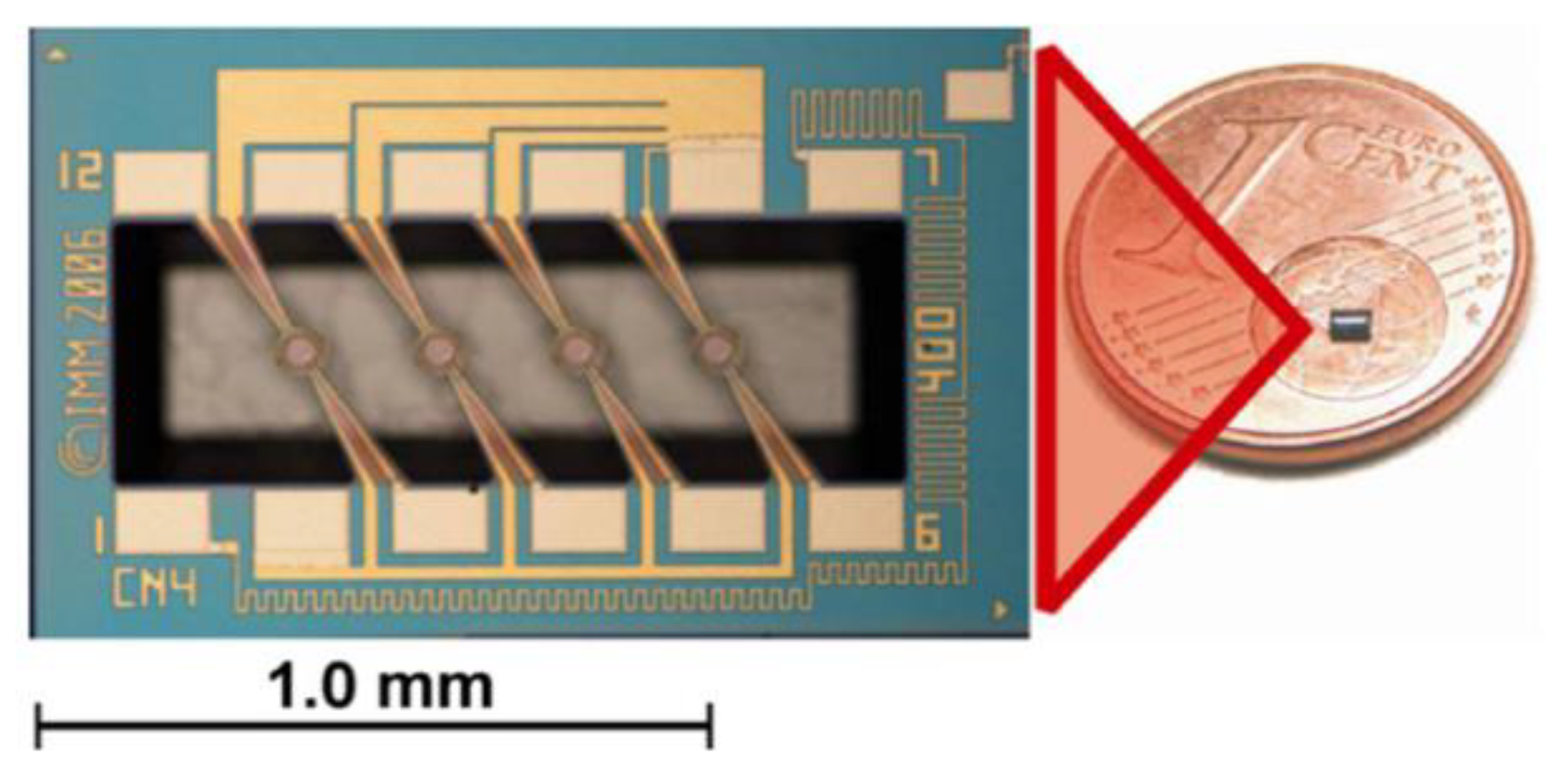

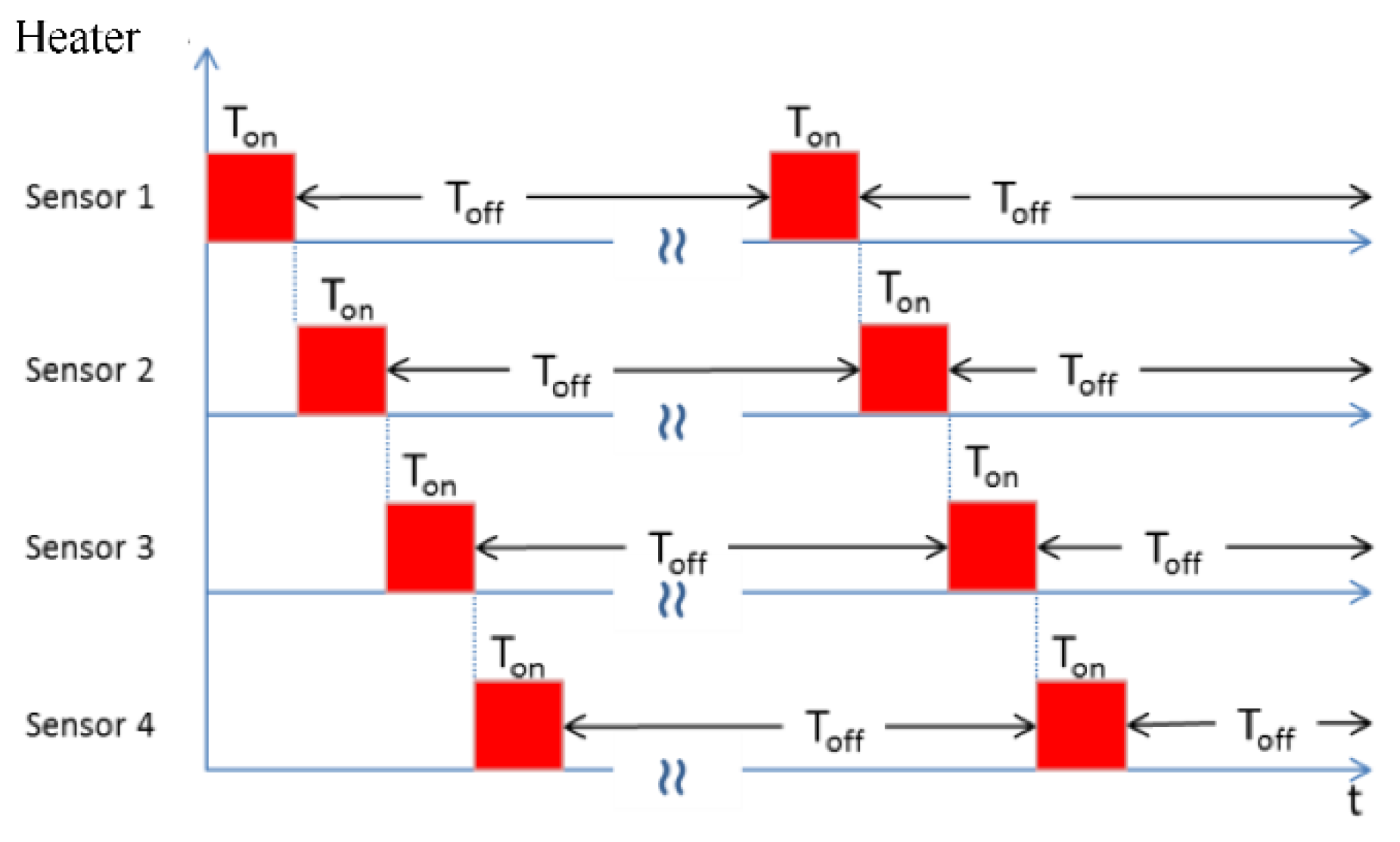

2.1. The Sensor Matrix and Pulsed Temperature Control

2.2. Operation Mode

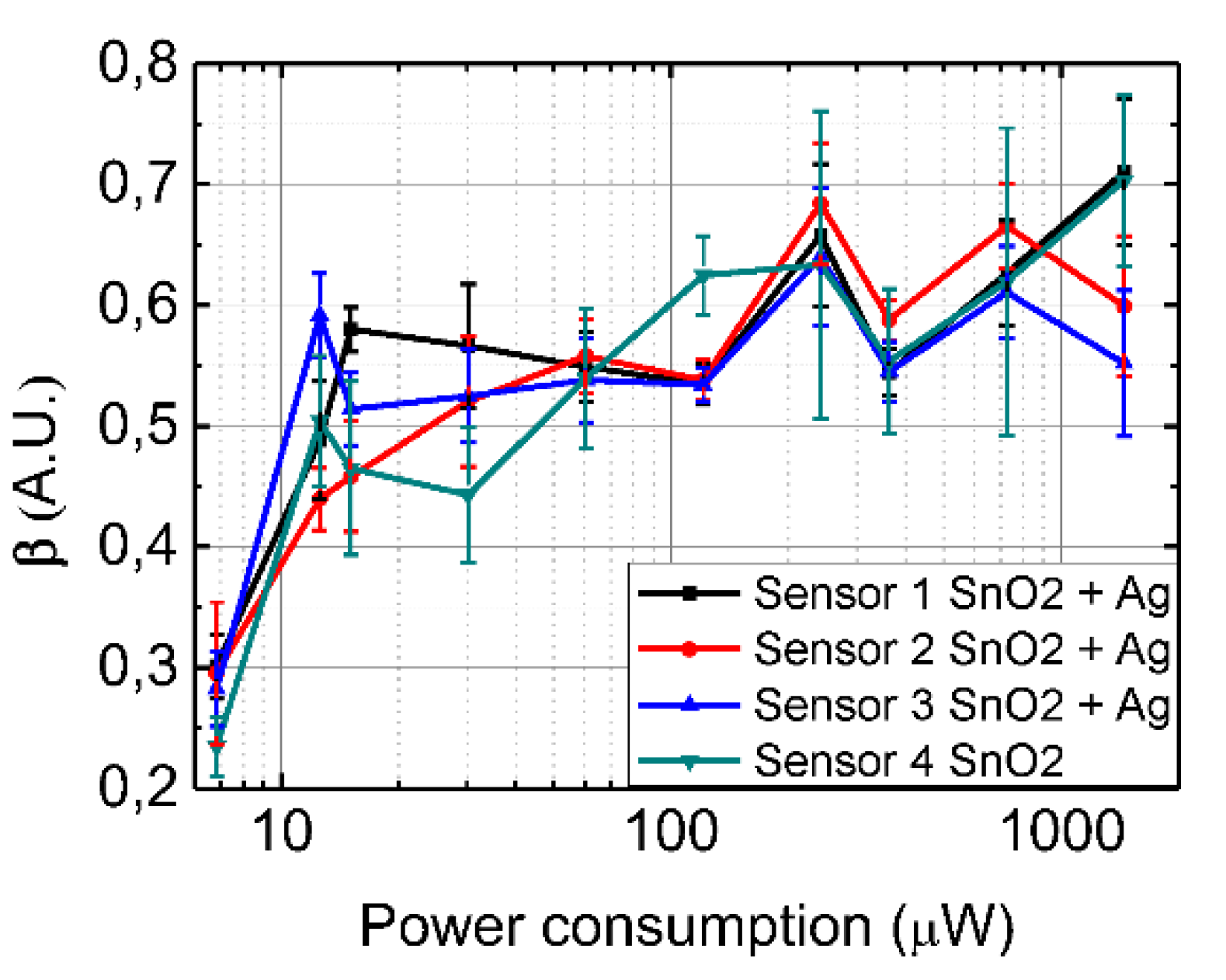

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Zampolli, S.; Elmi, I.; Cozzani, E.; Passini, M.; Cardinalli, G.C.; Severi, M. Ultra-low-power MOX sensors arrays for wireless sensor networks and RFID applications. In EUROSENSORS XX Book of Abstracts; 2016; Volume 2, pp. 292–293. [Google Scholar]

- Elmi, I.; Zampolli, S.; Cozzani, E.; Mancarella, F.; Cardinali, G.C. Development of ultra-low-power consumption MOX sensors with ppb-level VOC detection capabilities for emerging applications. Sens. Actuators B 2008, 135, 342–351. [Google Scholar] [CrossRef]

- Palacio, F.; Cano, X.; Gomez, J.M.; Vilar, C.; Scorzoni, A.; Cicioni, M.; Abad, E.; Juarros, A.; Gómez, D.; Nuin, M.; Gonzalez, A. Radio frequency identification semi-active tag with sensing capabilities for the food logistic chain. Sens. Lett. 2009, 7, 942–951. [Google Scholar] [CrossRef]

- Abad, E.; Palacio, F.; Nuin, M.; De Zarate, A.G.; Juarros, A.; Gómez, J.M.; Marco, S. RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain. J. Food Eng. 2009, 93, 394–399. [Google Scholar] [CrossRef]

- Lee, A.P.; Brian, J.R. Temperature modulation in semiconductor gas sensing. Sens. Actuator B. 1999, 60, 35–42. [Google Scholar] [CrossRef]

- Ortega, A.; Marco, S.; Perera, A.; Šundic, T.; Pardo, A.; Samitier, J. An intelligent detector based on temperature modulation of a gas sensor with a digital signal processor. Sens. Actuator B 2001, 78, 32–39. [Google Scholar] [CrossRef]

- Huang, X.; Meng, F.; Pi, Z.; Xu, W.; Liu, J. Gas sensing behavior of a single tin dioxide sensor under dynamic temperature modulation. Sens. Actuator B 2004, 99, 444–450. [Google Scholar] [CrossRef]

- Vergara, A.; Ramírez, J.L.; Llobet, E. Reducing power consumption via a discontinuous operation of temperature-modulated micro-hotplate gas sensors: Application to the logistics chain of fruit. Sens. Actuator B 2008, 129, 311–318. [Google Scholar] [CrossRef]

| PTO Mode | Power Consumption (μW) | RFID Tag Operation Time (Days) | LOD Ammonia (ppm) |

|---|---|---|---|

| 2/20 | 1450 | 1.2 | 2 |

| 2/40 | 725 | 2.4 | 2 |

| 2/80 | 362 | 4.5 | 2 |

| 2/120 | 241 | 6.7 | 2 |

| 1/120 | 120 | 12.7 | 2 |

| 0.5/120 | 60 | 23.3 | 2 |

| 0.25/120 | 30 | 39.3 | 2 |

| 0.125/120 | 15 | 60.9 | 2 |

| 0.065/75 | 12 | 83.8 | 2 |

| 0.0325/69 | 6.83 | 103.2 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palacio, F.; Gómez, J.M.; Burgués, J.; Pruna, R.; López, M.; Scorzoni, A.; Zampolli, S.; Marco, S. Evaluation of MOX Sensor Characteristics in Ultra-Low Power Operation Modes: Application to a Semi-Passive RFID Tag for Food Logistics. Proceedings 2017, 1, 459. https://doi.org/10.3390/proceedings1040459

Palacio F, Gómez JM, Burgués J, Pruna R, López M, Scorzoni A, Zampolli S, Marco S. Evaluation of MOX Sensor Characteristics in Ultra-Low Power Operation Modes: Application to a Semi-Passive RFID Tag for Food Logistics. Proceedings. 2017; 1(4):459. https://doi.org/10.3390/proceedings1040459

Chicago/Turabian StylePalacio, Francisco, José María Gómez, Javier Burgués, Raquel Pruna, Manel López, Andrea Scorzoni, Stefano Zampolli, and Santiago Marco. 2017. "Evaluation of MOX Sensor Characteristics in Ultra-Low Power Operation Modes: Application to a Semi-Passive RFID Tag for Food Logistics" Proceedings 1, no. 4: 459. https://doi.org/10.3390/proceedings1040459

APA StylePalacio, F., Gómez, J. M., Burgués, J., Pruna, R., López, M., Scorzoni, A., Zampolli, S., & Marco, S. (2017). Evaluation of MOX Sensor Characteristics in Ultra-Low Power Operation Modes: Application to a Semi-Passive RFID Tag for Food Logistics. Proceedings, 1(4), 459. https://doi.org/10.3390/proceedings1040459