Tuning of the Humidity-Interference in Gas Sensitive Columnar ZnO Structures †

Abstract

:1. Introduction

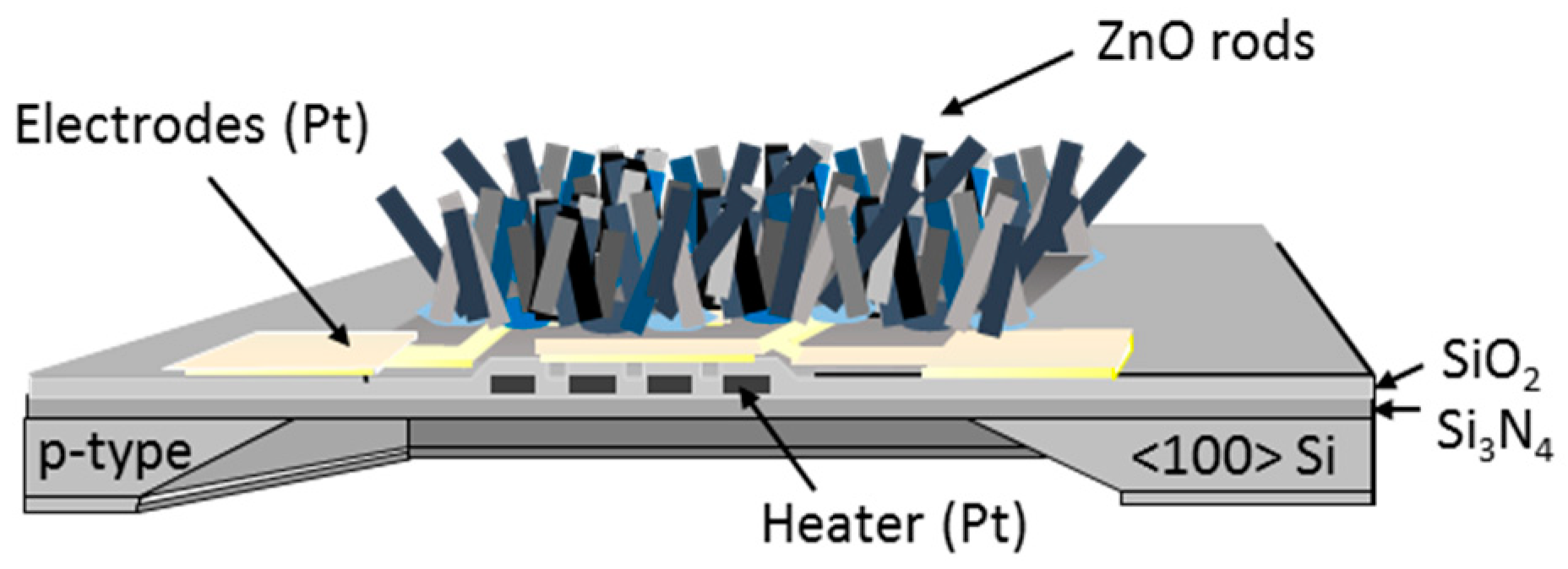

2. Materials and Methods

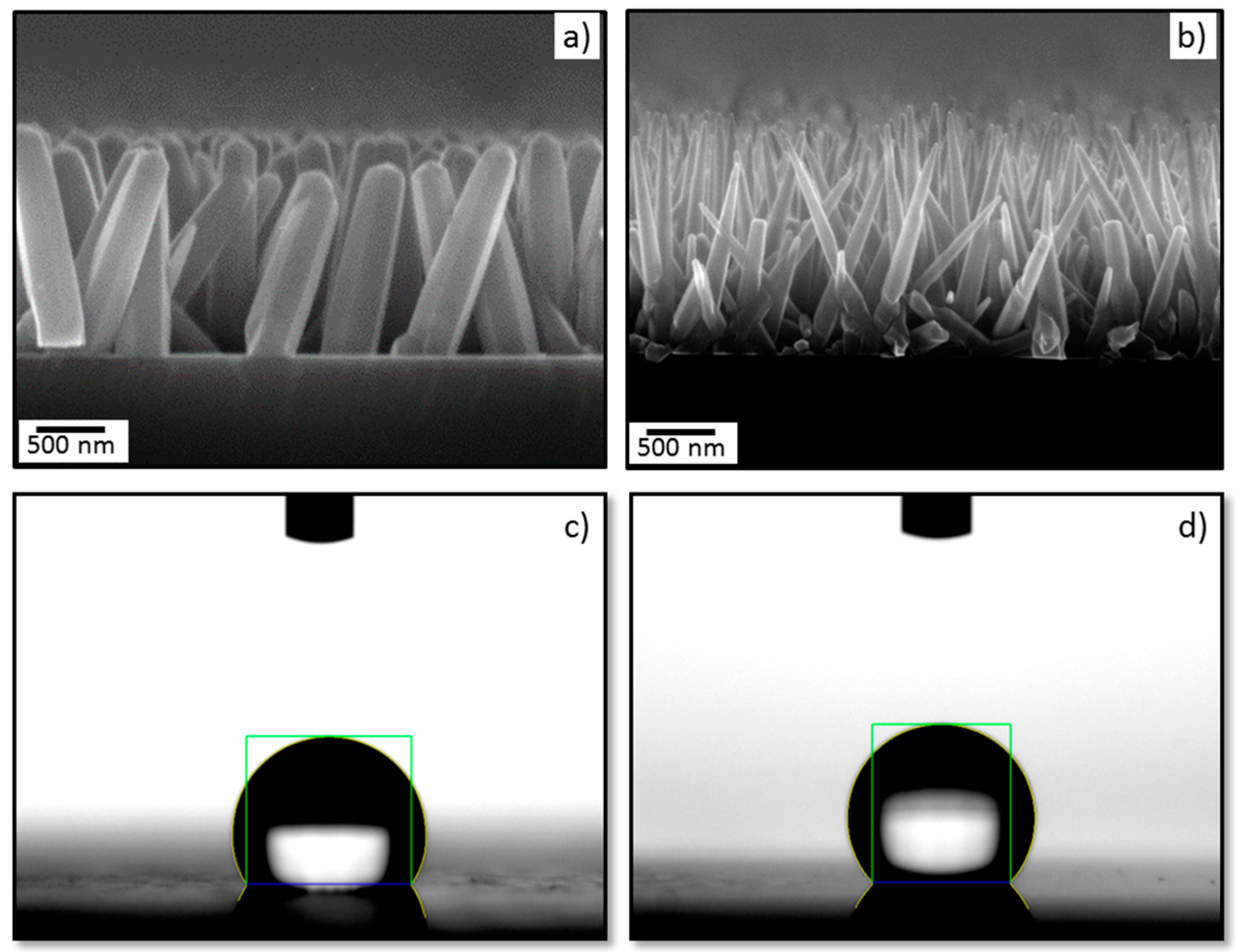

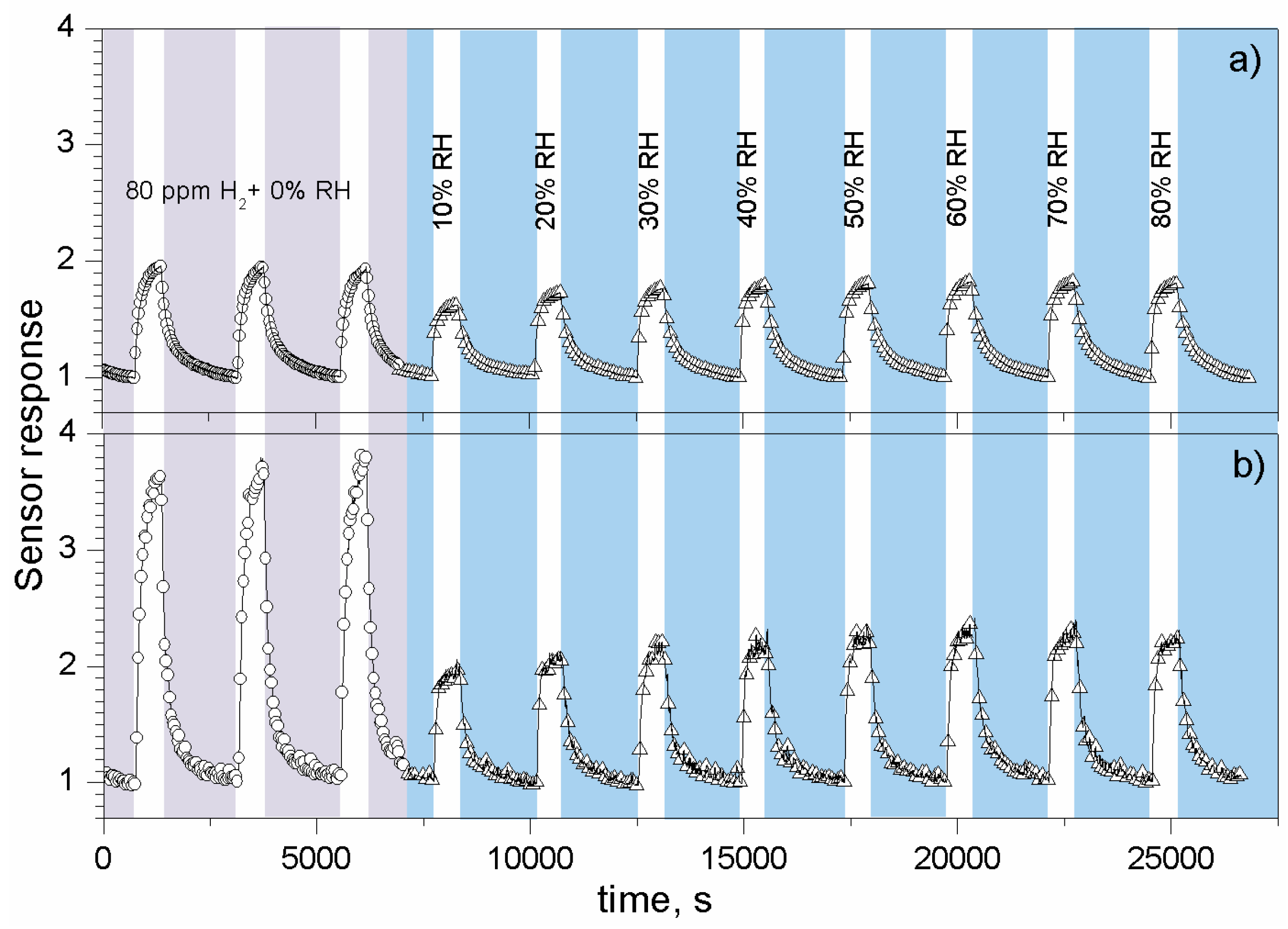

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Gurlo, A. Nanosensors: Towards morphological control of gas sensing activity. SnO2, In2O3, ZnO and WO3 case studies. Nanoscale 2011, 3, 154–165. [Google Scholar] [CrossRef] [PubMed]

- Chao, C.-H.; Chi, P.-W.; Wei, D.-H. Investigations on the Crystallographic Orientation Induced Surface Morphology Evolution of ZnO Thin Films and Their Wettability and Conductivity. J. Phys. Chem. C 2016, 120, 8210–8219. [Google Scholar] [CrossRef]

- Vallejos, S.; Pizúrová, N.; Gràcia, I.; Sotelo-Vazquez, C.; Čechal, J.; Blackman, C.; Parkin, I.; Cané, C. ZnO Rods with Exposed {100} Facets Grown via a Self-Catalyzed Vapor—Solid Mechanism and Their Photocatalytic and Gas Sensing Properties. ACS Appl. Mater. Inter. 2016, 8, 33335–33342. [Google Scholar] [CrossRef] [PubMed]

- Vallejos, S.; Grácia, I.; Chmela, O.; Figueras, E.; Hubálek, J.; Cané, C. Chemoresistive micromachined gas sensors based on functionalized metal oxide nanowires: Performance and reliability. Sens. Actuator B 2016, 235, 525–534. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vallejos, S.; Gràcia, I.; Pizúrová, N.; Figueras, E.; Hubálek, J.; Cané, C. Tuning of the Humidity-Interference in Gas Sensitive Columnar ZnO Structures. Proceedings 2017, 1, 417. https://doi.org/10.3390/proceedings1040417

Vallejos S, Gràcia I, Pizúrová N, Figueras E, Hubálek J, Cané C. Tuning of the Humidity-Interference in Gas Sensitive Columnar ZnO Structures. Proceedings. 2017; 1(4):417. https://doi.org/10.3390/proceedings1040417

Chicago/Turabian StyleVallejos, Stella, Isabel Gràcia, Nadezda Pizúrová, Eduard Figueras, Jaromir Hubálek, and Carles Cané. 2017. "Tuning of the Humidity-Interference in Gas Sensitive Columnar ZnO Structures" Proceedings 1, no. 4: 417. https://doi.org/10.3390/proceedings1040417

APA StyleVallejos, S., Gràcia, I., Pizúrová, N., Figueras, E., Hubálek, J., & Cané, C. (2017). Tuning of the Humidity-Interference in Gas Sensitive Columnar ZnO Structures. Proceedings, 1(4), 417. https://doi.org/10.3390/proceedings1040417