A Simple Method to Allow Parylene-C Coatings on Gold Substrates †

Abstract

:1. Introduction

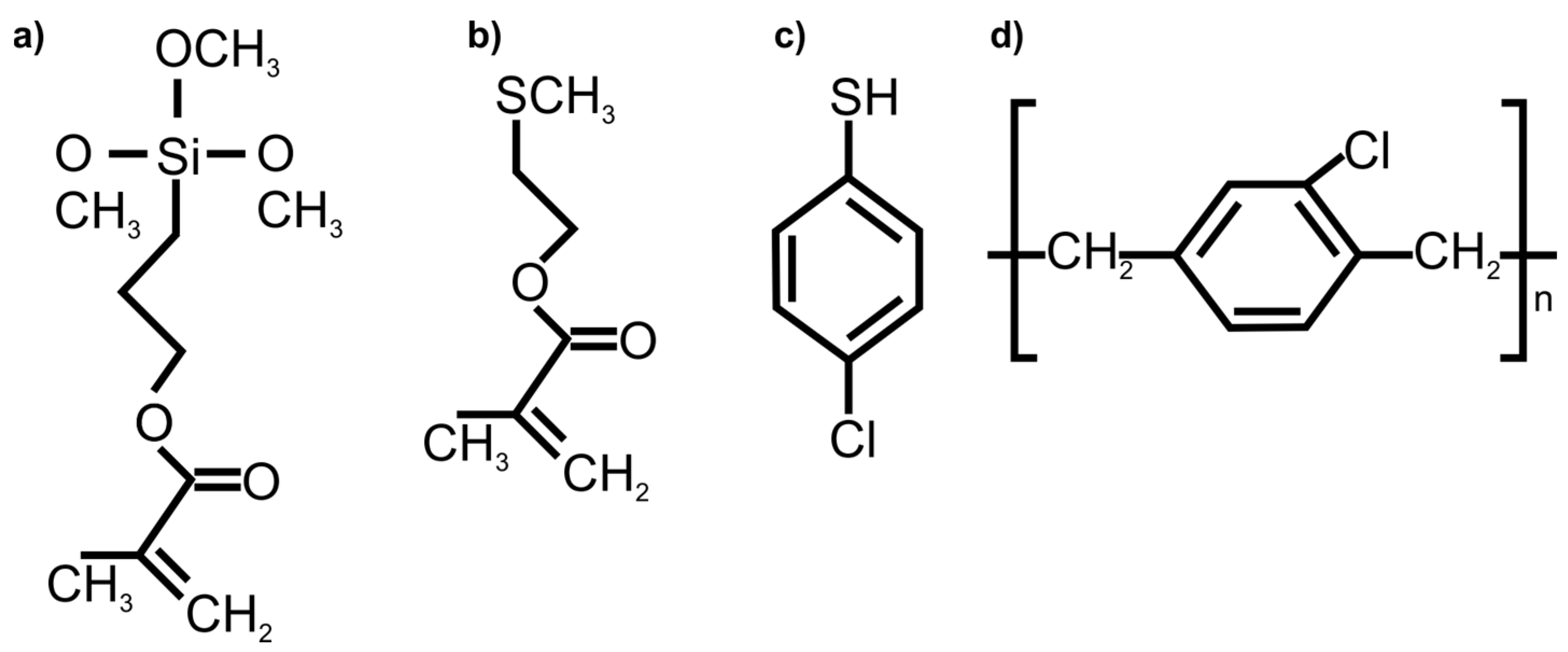

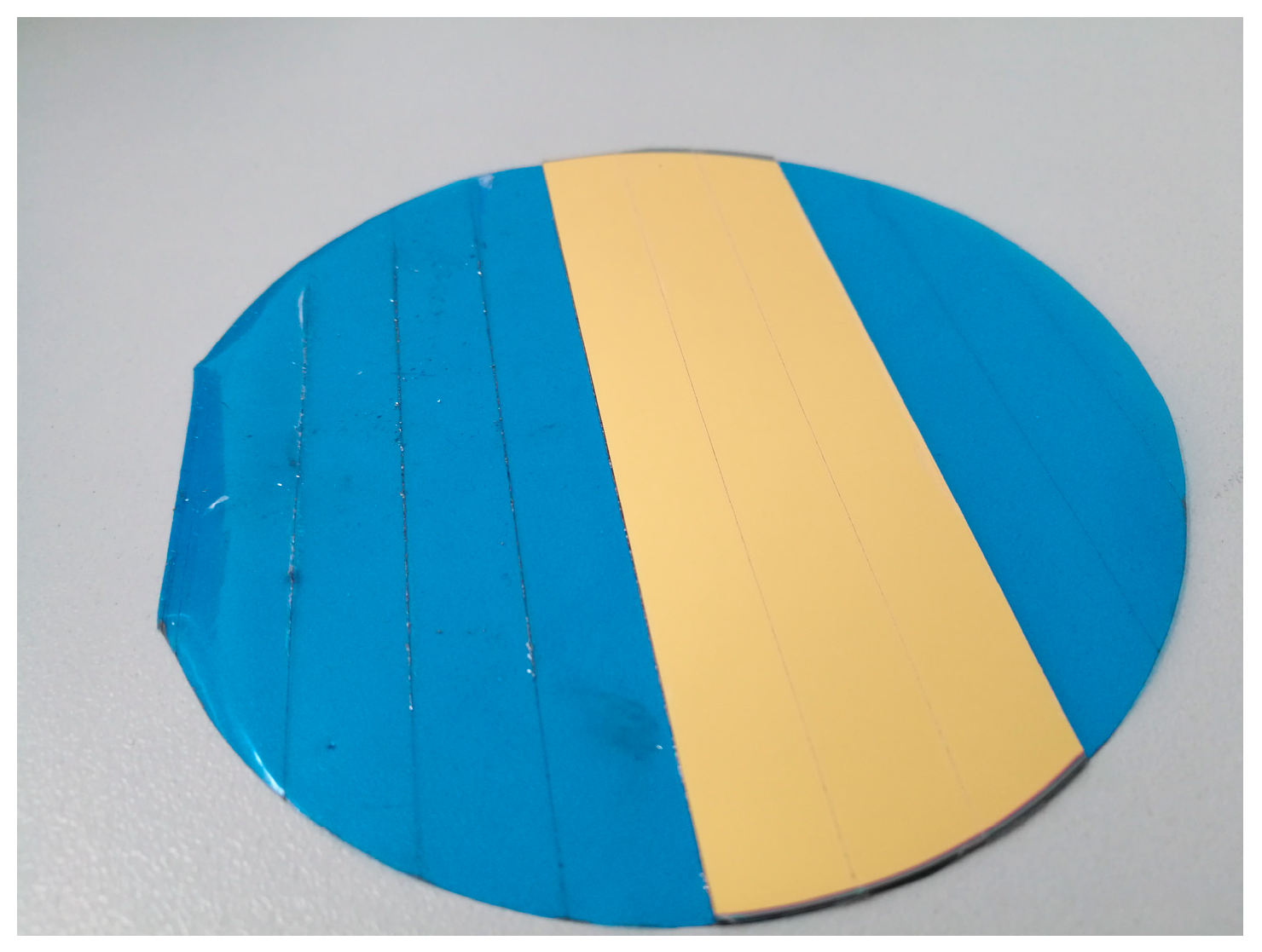

2. Materials and Methods

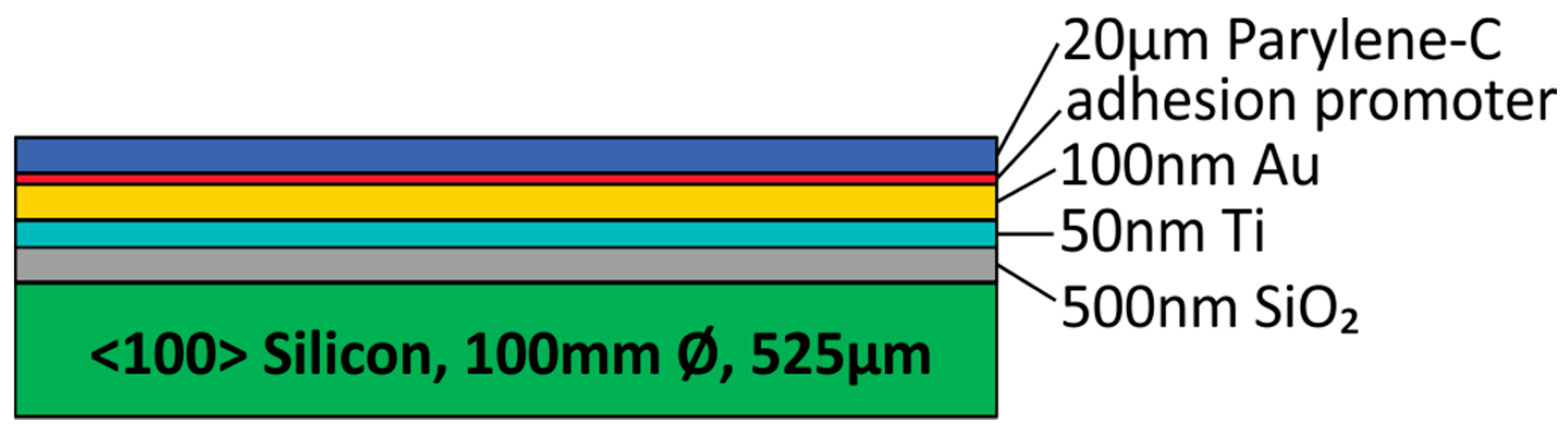

2.1. Wafer Preparation

2.2. Adhesion Promoter and Parylene-C Deposition

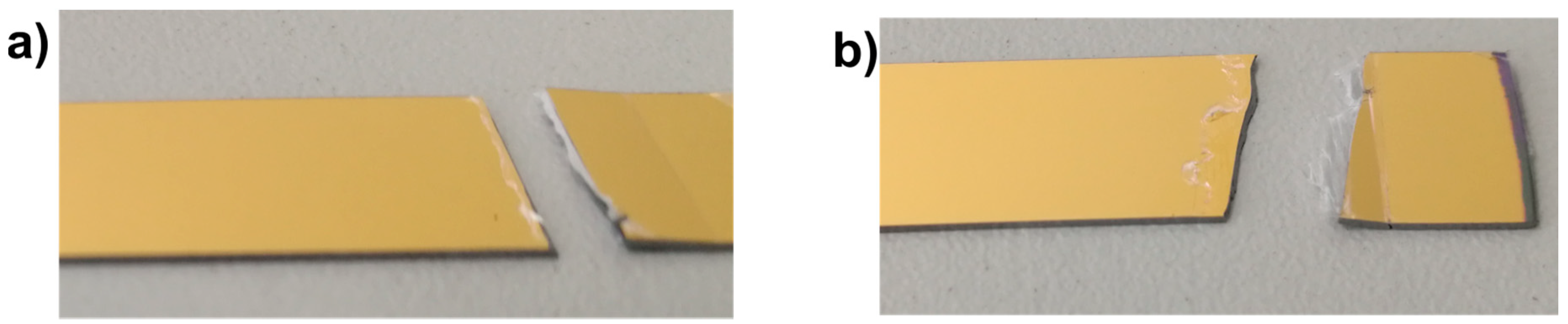

2.3. Adhesion Test Method

3. Results and Discussion

4. Conclusions

Conflicts of Interest

References

- Satyanarayana, S.; McCormick, D.T.; Majumdar, A. Parylene micro membrane capacitive sensor array for chemical and biological sensing. Sens. Actuators B Chem. 2006, 115, 494–502. [Google Scholar] [CrossRef]

- Tan, C.P.; Craighead, H.G. Surface engineering and patterning using parylene for biological applications. Materials 2010, 3, 1803–1832. [Google Scholar] [CrossRef]

- Takeuchi, S.; Ziegler, D.; Yoshida, Y.; Mabuchi, K.; Suzuki, T. Parylene flexible neural probes integrated with microfluidic channels. Lab Chip 2005, 5, 519–523. [Google Scholar] [CrossRef] [PubMed]

- Plasma-Parylene Systems GmbH. Available online: http://www.plasmaparylene.de/ (accessed on 6 April 2017).

- Zeniieh, D.; Bajwa, A.; Ledernez, L.; Urban, G. Effect of Plasma Treatments and Plasma-Polymerized Films on the Adhesion of Parylene-C to Substrates. Plasma Process. Polym. 2013, 10, 1081–1089. [Google Scholar] [CrossRef]

- Love, J.C.; Estroff, L.A.; Kriebel, J.K.; Nuzzo, R.G.; Whitesides, G.M. Self-Assembled Monolayers of Thiolates on Metals as a Form of Nanotechnology. Chem. Rev. 2005, 105, 1103–1170. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Driesche, S.v.d.; Habben, C.; Bödecker, A.; Lang, W.; Vellekoop, M.J. A Simple Method to Allow Parylene-C Coatings on Gold Substrates. Proceedings 2017, 1, 299. https://doi.org/10.3390/proceedings1040299

Driesche Svd, Habben C, Bödecker A, Lang W, Vellekoop MJ. A Simple Method to Allow Parylene-C Coatings on Gold Substrates. Proceedings. 2017; 1(4):299. https://doi.org/10.3390/proceedings1040299

Chicago/Turabian StyleDriesche, Sander van den, Christian Habben, Andre Bödecker, Walter Lang, and Michael J. Vellekoop. 2017. "A Simple Method to Allow Parylene-C Coatings on Gold Substrates" Proceedings 1, no. 4: 299. https://doi.org/10.3390/proceedings1040299

APA StyleDriesche, S. v. d., Habben, C., Bödecker, A., Lang, W., & Vellekoop, M. J. (2017). A Simple Method to Allow Parylene-C Coatings on Gold Substrates. Proceedings, 1(4), 299. https://doi.org/10.3390/proceedings1040299