Enhanced Characteristics of Nondispersive Infrared CO2 Gas Sensor by Deposition of Hydrophobic Thin Film †

Abstract

:1. Introduction

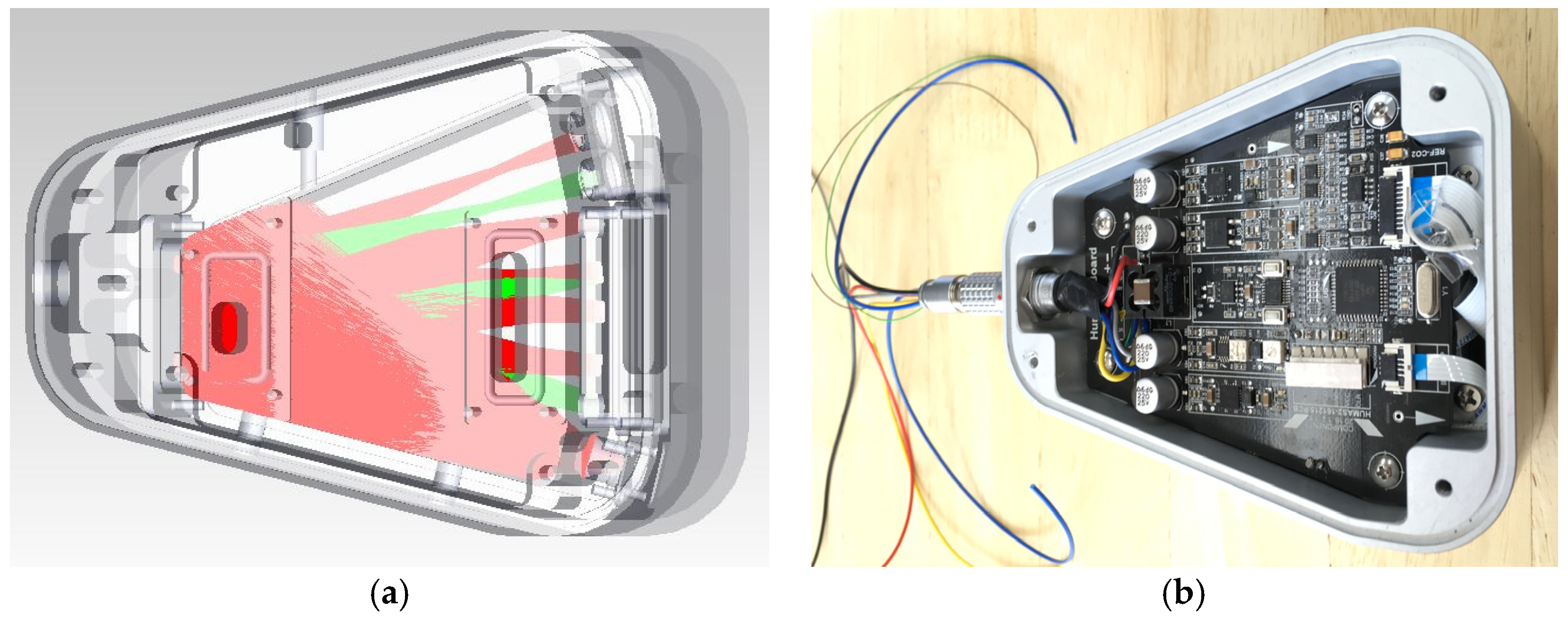

2. Theoretical Background and Fabrication

2.1. Theoretical Background

2.2. Fabrication

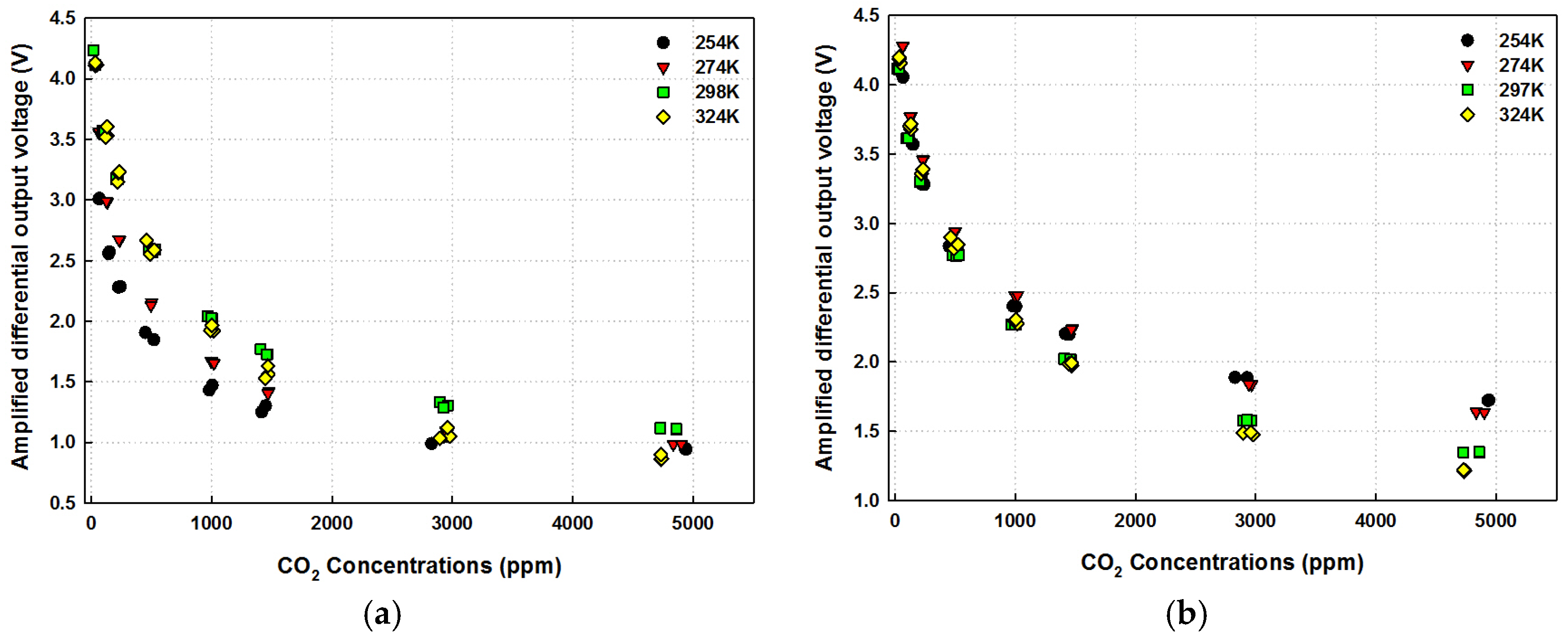

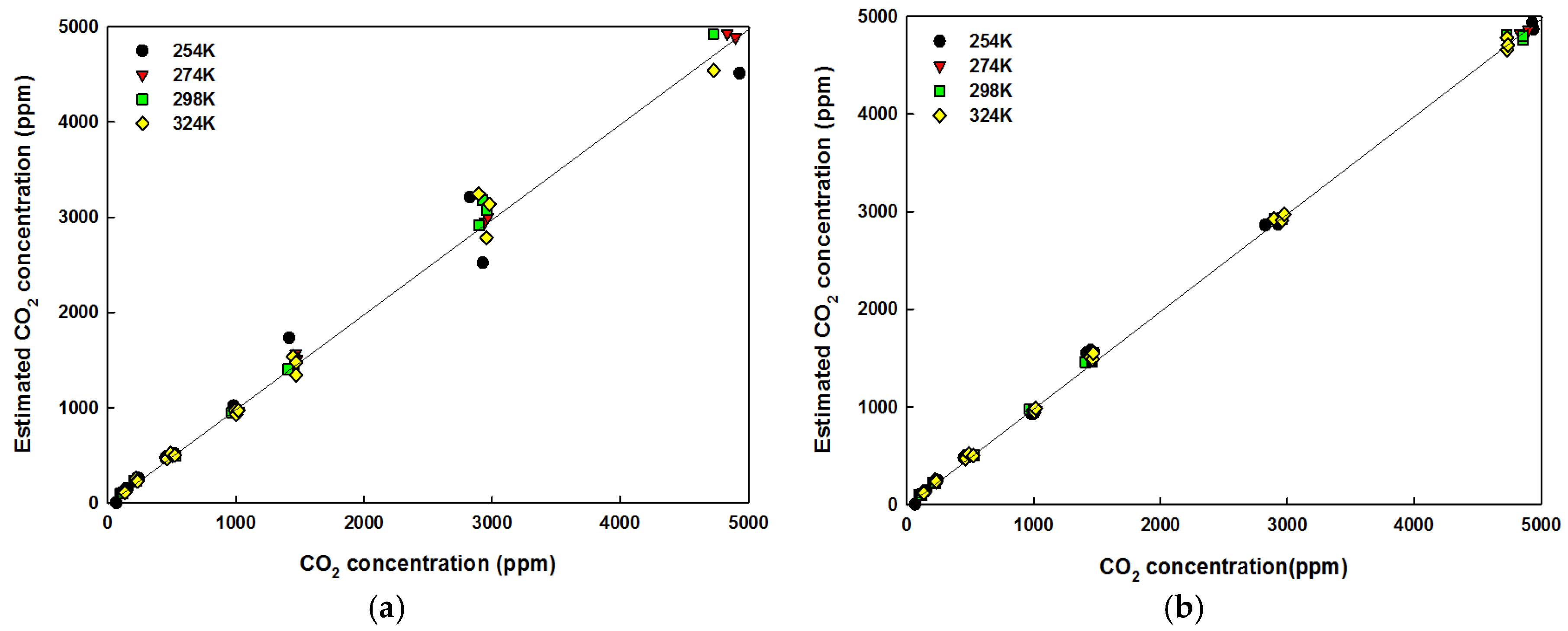

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Kaneyasu, K.; Otsuka, K.; Setoguchi, Y.; Sonoda, S.; Nakahara, T.; Aso, I.; Nakagaichi, N. A carbon dioxide gas sensor based on solid electrolyte for air quality control. Sens. Actuators B Chem. 2000, 66, 56–58. [Google Scholar] [CrossRef]

- Yi, S.H.; Park, J.S.; Park, J.M. Temperature compensation of novel NDIR CO2 gas sensor. In Proceedings of the IEEE 5th Conference on Sensors, Daegu, Korea, 22–25 October 2006. [Google Scholar]

- Visco, G.; Campanella, L.; Nobili, V. Organic carbons and TOC in waters: An overview of the international norm for its measurements. Microchem. J. 2005, 79, 185–191. [Google Scholar] [CrossRef]

- Tian, K.; Dasgupta, P.K. A permeable memebrane capacitance sensor for ionorganic gases: Application to the measurement of total organic carbon. Anal. Chem. Acta 2009, 652, 245–250. [Google Scholar] [CrossRef] [PubMed]

- Kawasaki, N.; Matsushige, K.; Komatsu, K.; Kohzu, A.; Watanabe Nara, F.; Ogishi, F.; Mikami, H.; Goto, T.; Imai, A. Fast and precise method for HLPC-size exclusion chromatography with UV and TOC(NDIR) detection: Importance of multiple detectors to evaluate the characteristics of dissolved organic matter. Water Res. 2011, 45, 6240–6248. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.H. Temperature dependency of non-dispersive infrared carbon dioxide gas sensor by using infrared sensor for compensation. J. Sen. Sci. Technol. 2016, 25, 124–130. [Google Scholar] [CrossRef]

- Jun, L.; Qiulin, T.; Wendong, Z.; Chengyang, X.; Tao, G.; Jijun, X. Miniature low-power IR monitor for methane detection. Measurement 2011, 44, 823–831. [Google Scholar] [CrossRef]

- Yi, S.H. Temperature compensation methods of nondispersive infrared CO2 sensor with dual elliptical waveguide. Sens. Mater. 2017, 29, 243–252. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Lee, J.; Lee, K.; Yi, S. Enhanced Characteristics of Nondispersive Infrared CO2 Gas Sensor by Deposition of Hydrophobic Thin Film. Proceedings 2017, 1, 410. https://doi.org/10.3390/proceedings1040410

Kim J, Lee J, Lee K, Yi S. Enhanced Characteristics of Nondispersive Infrared CO2 Gas Sensor by Deposition of Hydrophobic Thin Film. Proceedings. 2017; 1(4):410. https://doi.org/10.3390/proceedings1040410

Chicago/Turabian StyleKim, Jinho, Jayoung Lee, Keunheon Lee, and Seunghwan Yi. 2017. "Enhanced Characteristics of Nondispersive Infrared CO2 Gas Sensor by Deposition of Hydrophobic Thin Film" Proceedings 1, no. 4: 410. https://doi.org/10.3390/proceedings1040410

APA StyleKim, J., Lee, J., Lee, K., & Yi, S. (2017). Enhanced Characteristics of Nondispersive Infrared CO2 Gas Sensor by Deposition of Hydrophobic Thin Film. Proceedings, 1(4), 410. https://doi.org/10.3390/proceedings1040410