Laser-Microstructured Double-Sided Adhesive Tapes for Integration of a Disposable Biochip †

Abstract

:1. Introduction

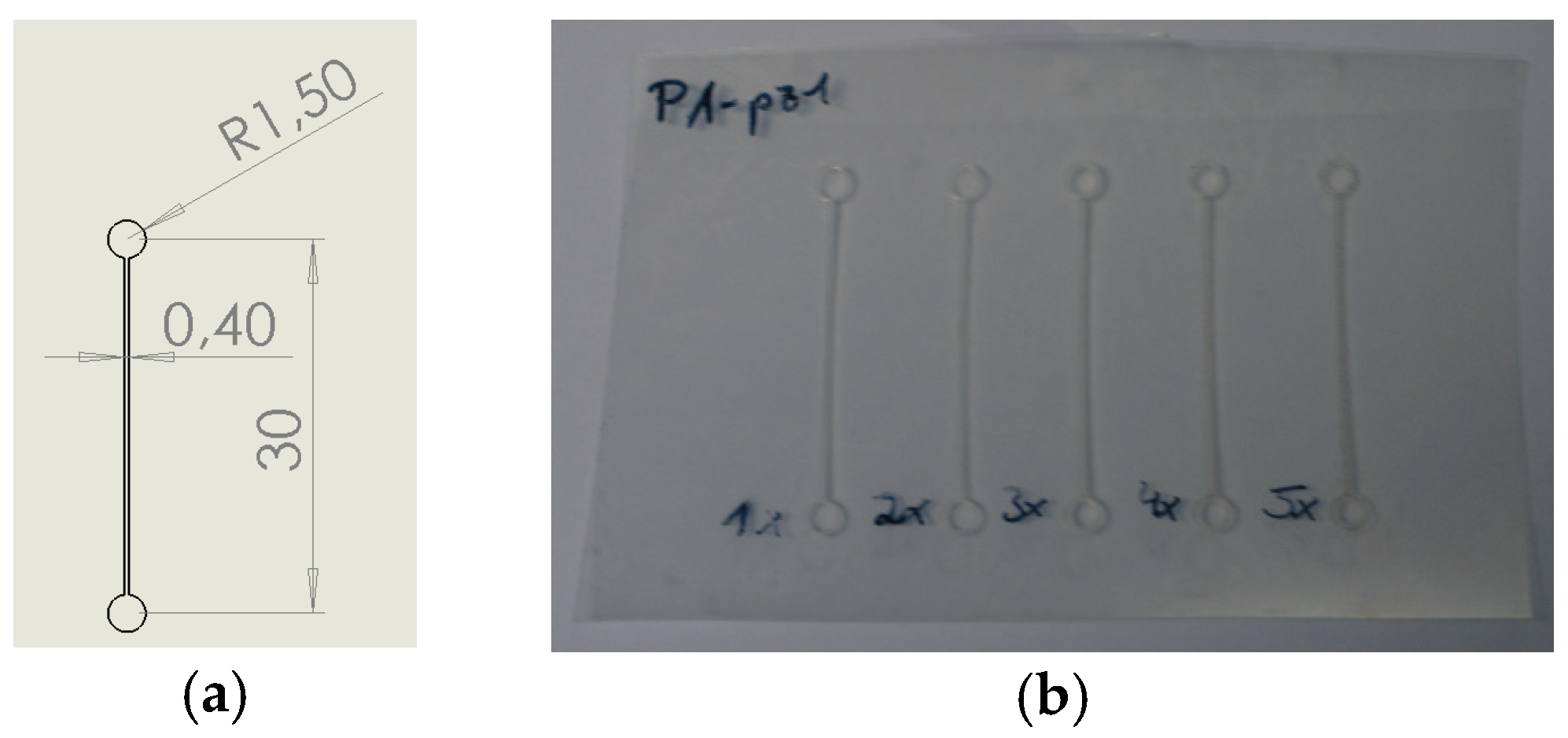

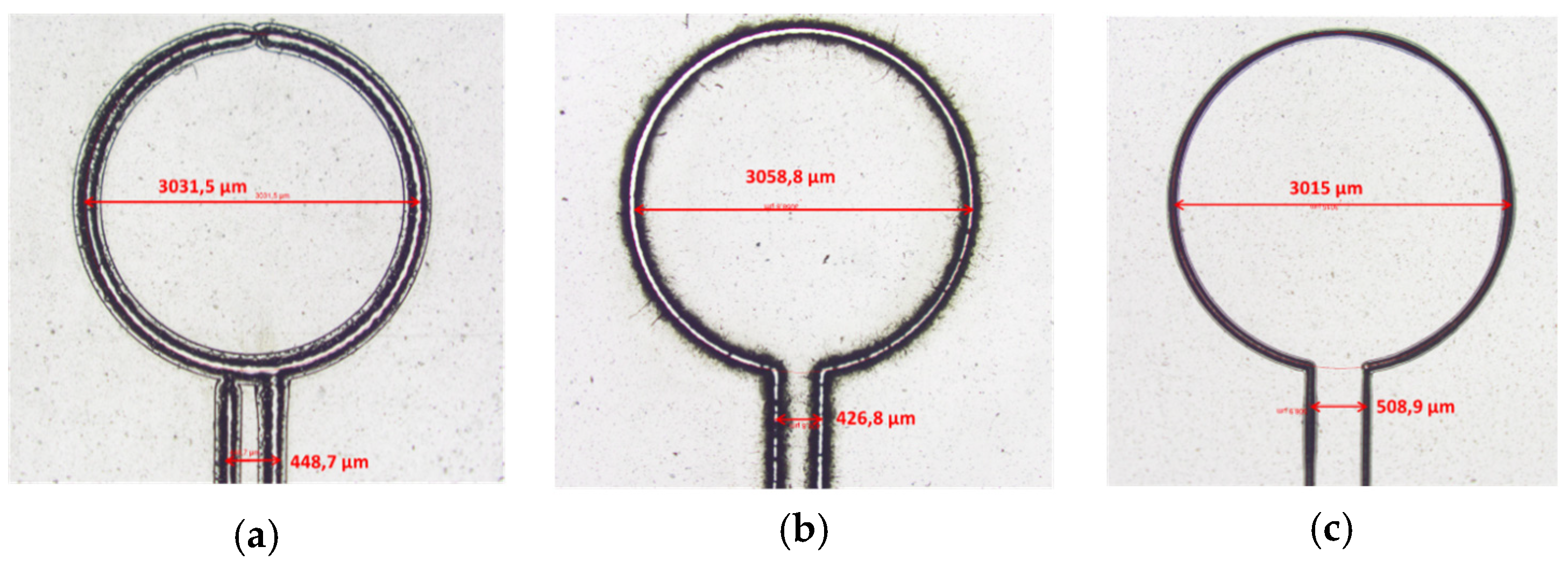

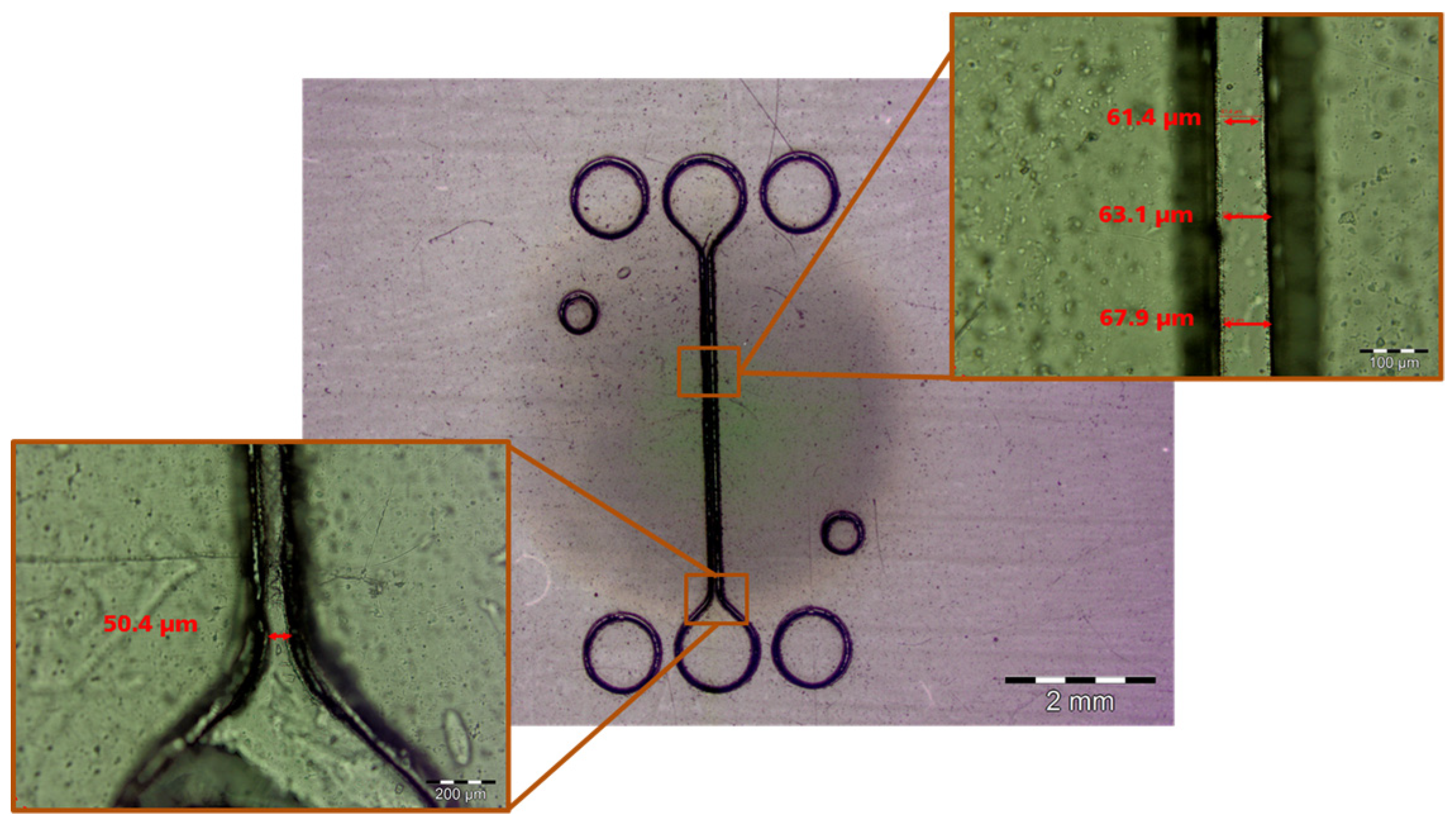

2. Materials and Methods

2.1. Double-Sided Adhesive Tapes

2.2. Laser Structuring Methods

2.3. Preliminary Bonding and Leakeage Tests

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Estevez, M.C.; Alvarez, M.; Lechuga, L.M. Integrated optical devices for lab-on-a-chip biosensing applications. Laser Photon. Rev. 2012, 6, 463–487. [Google Scholar] [CrossRef]

- Patko, D.; Mártonfalvi, Z.; Kovacs, B.; Vonderviszt, F.; Kellermayer, M.; Horvath, R. Microfluidics channels laser-cut in thin double-sided tapes: Cost-effective biocompatible fluidics in minutes from design to final integration with optical biochips. Sens. Act. 2014, 196, 352–356. [Google Scholar] [CrossRef]

- Böttger, G.; Queisser, M.; Arndt-Staufenbiel, N.; Schröder, H.; Lang, K.D. Building blocks for actively-aligned micro-optical systems in rapid prototyping and small series production. In Proceedings of the SPIE Photonics West Conference, San Francisco, CA, USA, 9–11 February 2015. [Google Scholar]

- Raciukaitis, G.; Gedvilas, M. Processing of polymers by UV picosecond lasers. In Proceedings of the 24th International Congress on Applications of Lasers & Electro-Optics (ICALEO), Miami, FL, USA, 31 October–3 November 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamora, V.; Marx, S.; Arndt-Staufenbiel, N.; Janeczka, C.; Havlik, G.; Queisser, M.; Schröder, H. Laser-Microstructured Double-Sided Adhesive Tapes for Integration of a Disposable Biochip. Proceedings 2017, 1, 606. https://doi.org/10.3390/proceedings1040606

Zamora V, Marx S, Arndt-Staufenbiel N, Janeczka C, Havlik G, Queisser M, Schröder H. Laser-Microstructured Double-Sided Adhesive Tapes for Integration of a Disposable Biochip. Proceedings. 2017; 1(4):606. https://doi.org/10.3390/proceedings1040606

Chicago/Turabian StyleZamora, Vanessa, Sebastian Marx, Norbert Arndt-Staufenbiel, Christian Janeczka, George Havlik, Marco Queisser, and Henning Schröder. 2017. "Laser-Microstructured Double-Sided Adhesive Tapes for Integration of a Disposable Biochip" Proceedings 1, no. 4: 606. https://doi.org/10.3390/proceedings1040606

APA StyleZamora, V., Marx, S., Arndt-Staufenbiel, N., Janeczka, C., Havlik, G., Queisser, M., & Schröder, H. (2017). Laser-Microstructured Double-Sided Adhesive Tapes for Integration of a Disposable Biochip. Proceedings, 1(4), 606. https://doi.org/10.3390/proceedings1040606