Plasma Oxidized W-WOx Sensor for Sub-ppm H2S Detection †

Abstract

:1. Introduction

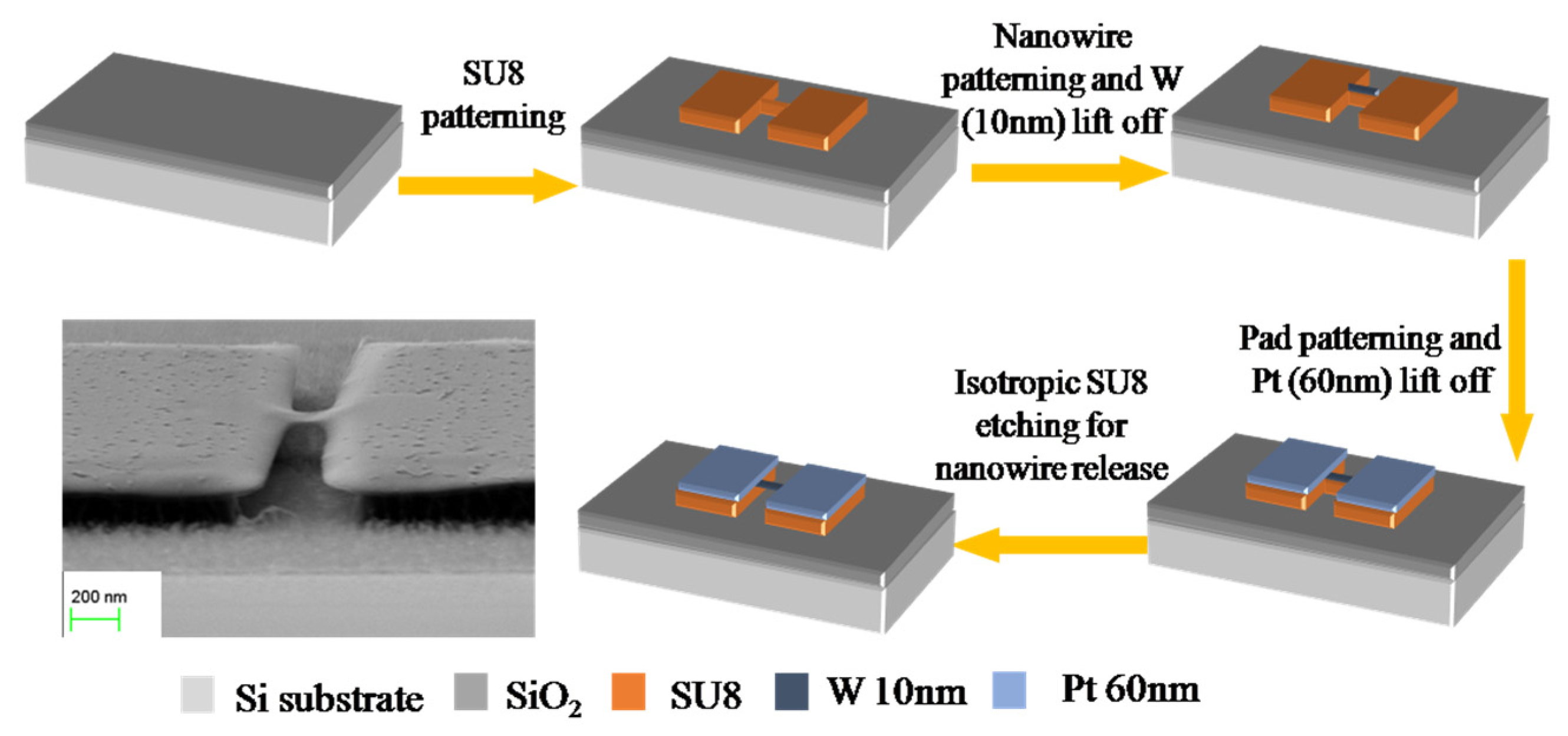

2. Fabrication

3. Results and Discussion

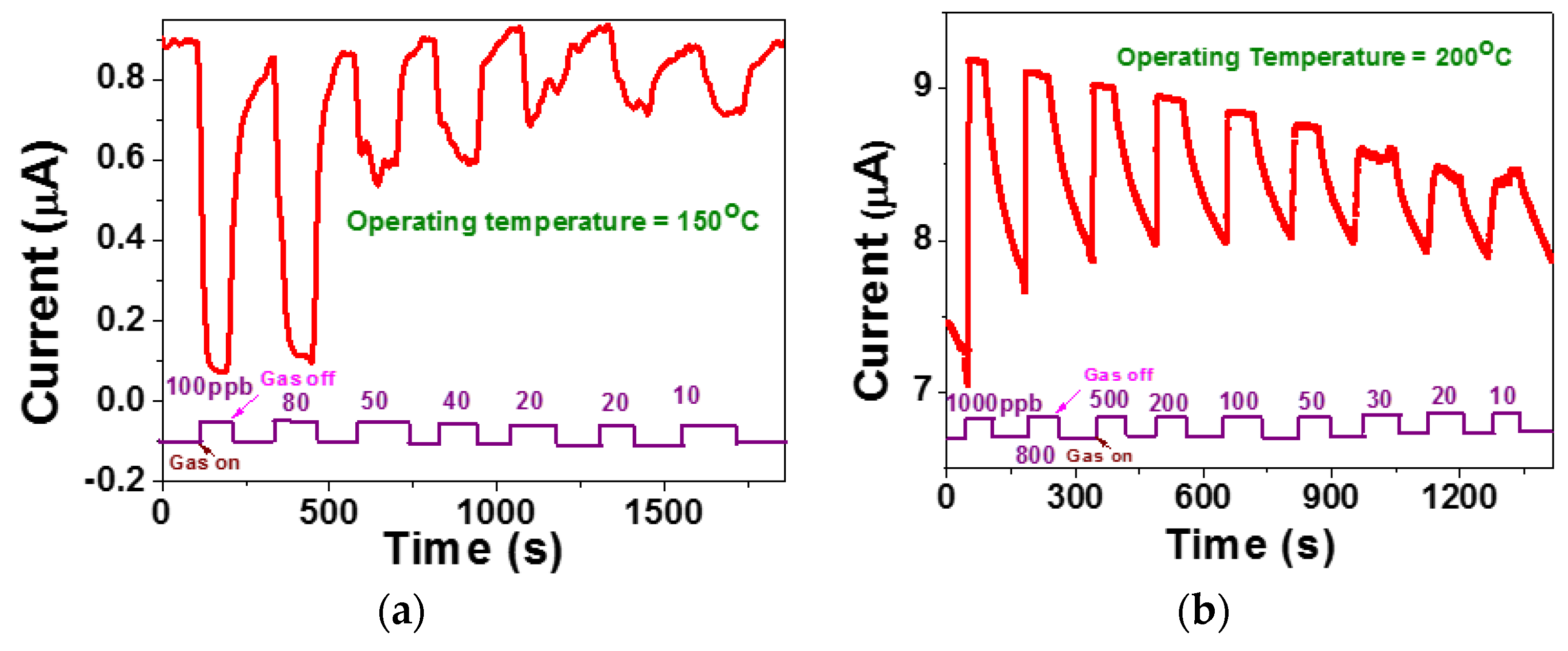

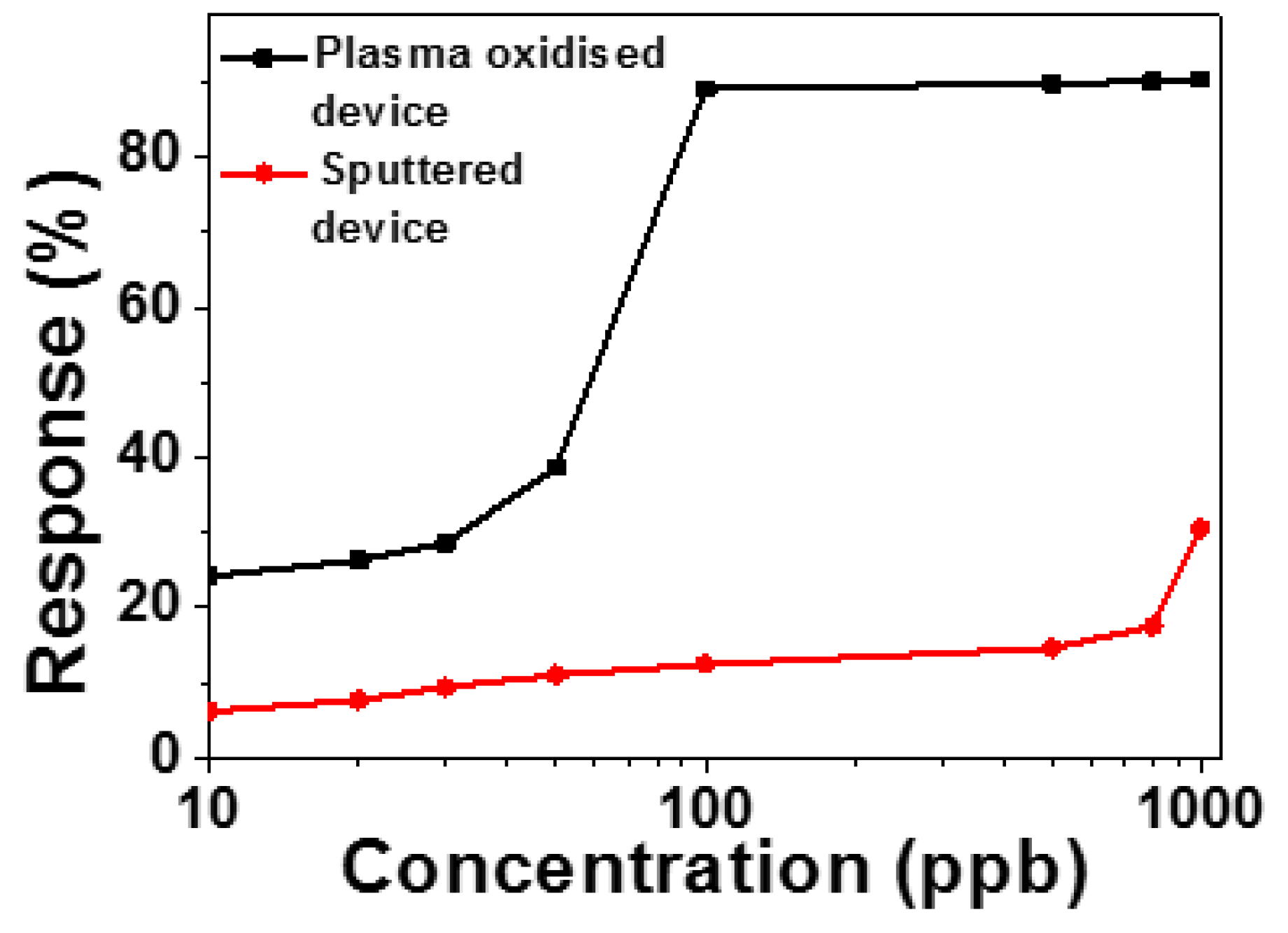

Sensing Characterization

4. Conclusions

Conflicts of Interest

References

- Yu, Y.-T.; Dutta, P. Examination of Au/SnO2 core shell architecture nanoparticle for low temperature gas sensing applications. Sens. Actuators B Chem. 2011, 157, 440–449. [Google Scholar] [CrossRef]

- Basu, P.K.; Kallat, S.; Anmol, E.A.; Bhat, N. Suspended core-shell Pt-PtOx nanostructure for ultrasensitive hydrogen gas sensor. J. Appl. Phys. 2015, 117, 224501–224510. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benedict, S.; Bhat, N. Plasma Oxidized W-WOx Sensor for Sub-ppm H2S Detection. Proceedings 2017, 1, 402. https://doi.org/10.3390/proceedings1040402

Benedict S, Bhat N. Plasma Oxidized W-WOx Sensor for Sub-ppm H2S Detection. Proceedings. 2017; 1(4):402. https://doi.org/10.3390/proceedings1040402

Chicago/Turabian StyleBenedict, Samatha, and Navakanta Bhat. 2017. "Plasma Oxidized W-WOx Sensor for Sub-ppm H2S Detection" Proceedings 1, no. 4: 402. https://doi.org/10.3390/proceedings1040402

APA StyleBenedict, S., & Bhat, N. (2017). Plasma Oxidized W-WOx Sensor for Sub-ppm H2S Detection. Proceedings, 1(4), 402. https://doi.org/10.3390/proceedings1040402