Effect of Electrode Configuration on High Temperature Thickness Shear Gallium Phosphate Transducer †

Abstract

1. Introduction

2. Modelling of GaPO4 Piezoelectric Transducer

2.1. Material Properties

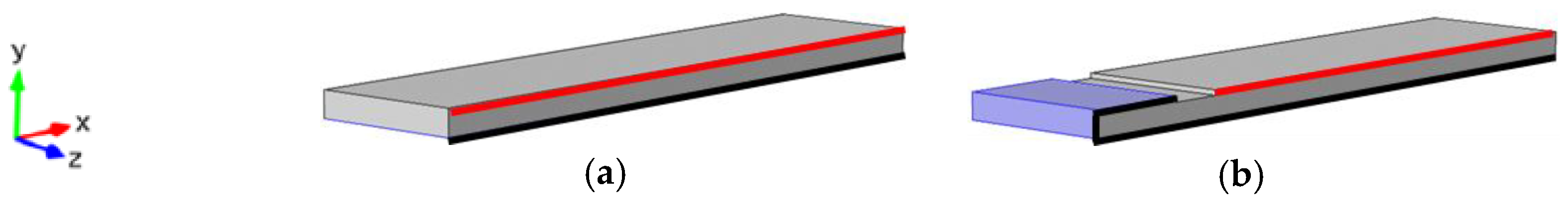

2.2. Model Setup

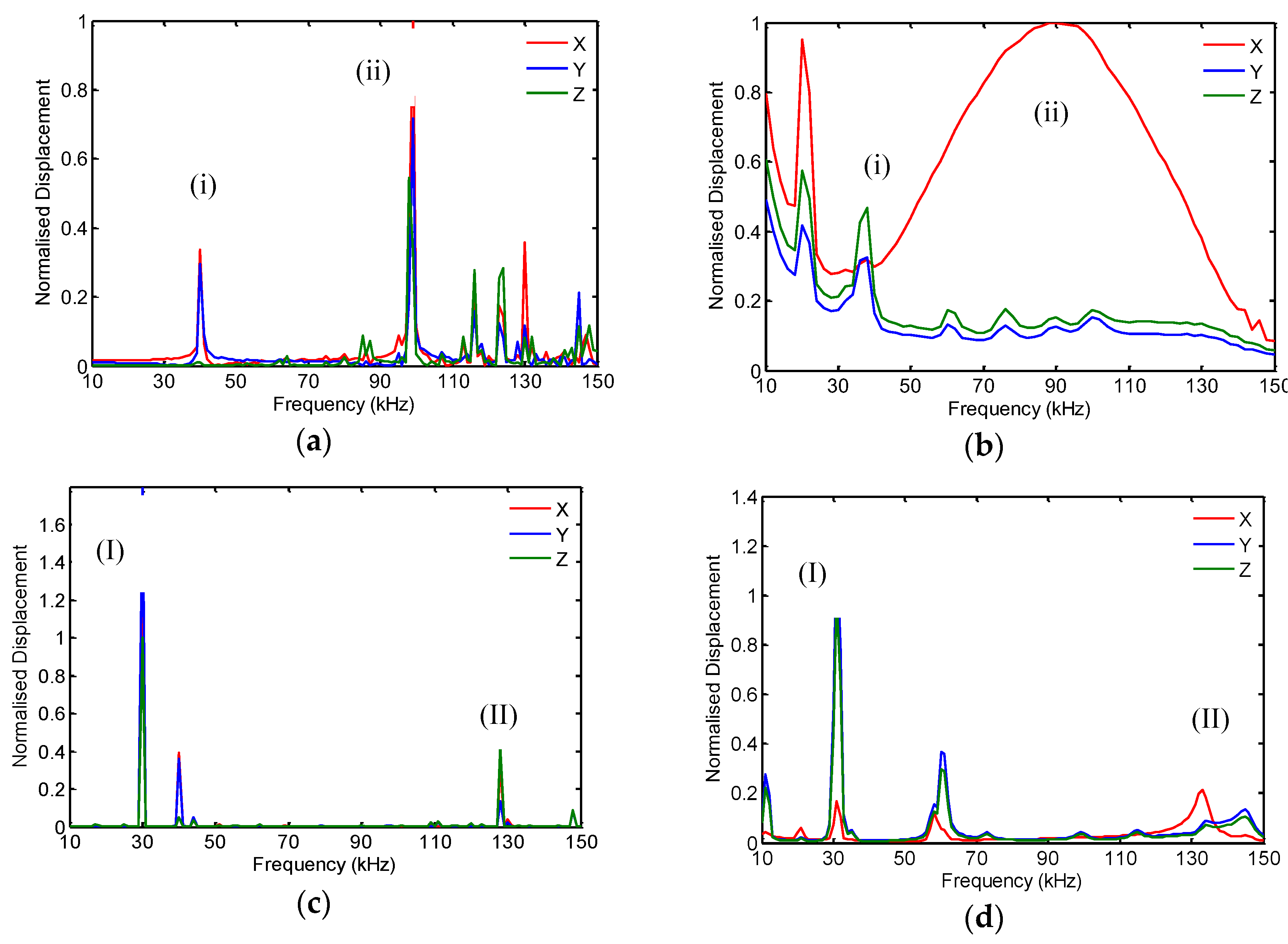

3. Experimental Validation of the Model

4. Results and Conclusions

Conflicts of Interest

References

- Fritze, H. High-temperature piezoelectric crystals and devices. J. Electroceram. 2011, 26, 122–126. [Google Scholar] [CrossRef]

- Davulis, P.; Kosinski, J.A.; Da Cunha, M.P. GaPO4 stiffness and piezoelectric constants measurements using the combined thickness excitation and lateral field technique. In Proceedings of the 2006 IEEE International Frequency Control Symposium and Exposition, Miami, FL, USA, 4–7 June 2006; pp. 664–669. [Google Scholar]

- Cao, W.; Zhu, S.; Jiang, B. Analysis of shear modes in a piezoelectric vibrator. J. Appl. Phys. 1998, 83, 4415–4420. [Google Scholar] [CrossRef][Green Version]

- Gerber, P.; Roelofs, A.; Kügeler, C.; Böttger, U.; Waser, R.; Prume, K. Effects of the top-electrode size on the piezoelectric properties (d33 and S) of lead zirconate titanate thin films. J. Appl. Phys. 2004, 96, 2800–2804. [Google Scholar] [CrossRef]

- Desilets, C.S.; Powell, D.J.; Abboud, N.; Wojcik, G.L. Effect of wraparound electrodes on ultrasonic array performance. In Proceedings of the 1998 IEEE Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; Volume 2, pp. 993–997. [Google Scholar]

- Krempl, P.; Schleinzer, G.; Wallno, W. Gallium phosphate, GaPO4: A new piezoelectric crystal material for high-temperature sensorics. Sens. Actuators A Phys. 1997, 61, 361–363. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhutti, A.; Gan, T.-H.; Mohimi, A.; Balachandran, W.; Kanfoud, J. Effect of Electrode Configuration on High Temperature Thickness Shear Gallium Phosphate Transducer. Proceedings 2017, 1, 381. https://doi.org/10.3390/proceedings1040381

Dhutti A, Gan T-H, Mohimi A, Balachandran W, Kanfoud J. Effect of Electrode Configuration on High Temperature Thickness Shear Gallium Phosphate Transducer. Proceedings. 2017; 1(4):381. https://doi.org/10.3390/proceedings1040381

Chicago/Turabian StyleDhutti, Anurag, Tat-Hean Gan, Abbas Mohimi, Wamadeva Balachandran, and Jamil Kanfoud. 2017. "Effect of Electrode Configuration on High Temperature Thickness Shear Gallium Phosphate Transducer" Proceedings 1, no. 4: 381. https://doi.org/10.3390/proceedings1040381

APA StyleDhutti, A., Gan, T.-H., Mohimi, A., Balachandran, W., & Kanfoud, J. (2017). Effect of Electrode Configuration on High Temperature Thickness Shear Gallium Phosphate Transducer. Proceedings, 1(4), 381. https://doi.org/10.3390/proceedings1040381