Abstract

The application of thin LTCC is a very interesting and promising approach to the fabrication of ceramic MEMS gas sensors. The attempts to use this material were restricted till now by the thickness of commercial material (>50 μm). In this work, we found a possibility to fabricate thin LTCC membranes (20–30 μm) stretched on a frame made of 100 μm thick LTCC. Aerosol jet printed Pt microheater and laser cutting of the membrane gave a cantilever shaped microhotplate with hot spot of about 300 × 300 μm. Power consumption of the heater is ~150 mW at 450 °C.

1. Introduction

Ceramic substrates based on LTCC is one of popular objects enabling the fabrication of high temperature microhotplate for MOX gas sensors, fast thermometers, flowmeters, etc. The main problem restricting the application of such convenient material is relatively high power consumption of resulting sensor due to thickness of commercially available ceramics, 50–100 μm minimum.

The application of LTCC for the microhotpales of metal oxide gas sensors and other high-temperature microelectronic devices was investigated by several research groups, first of all those from Technical Uuniversity of Wroclaw (Poland) [1], University of Bayteuth (Germany) [2] some others. Though the power consumption of MEMS devices based on LTCC is higher than the power consumption of alumina MEMS [3] or, especially, silicon MEMS devices, the application of LTCC has obvious advantage, because LTCC green tape is cheap commercially available product.

In this work, we developed very thin LTCC films (~20 μm) and applied aerosol and ink jet printing for the fabrication of narrow (30–50 μm) platinum heating lines. The application of laser cutting of thin LTCC membrane permitted us to get stable at temperature cycling cantilever shaped microheaters with power consumption of 150 mW at 450 °C. We decreased significantly the power consumption of LTCC devices compared to, for example, microhotplates described in [2] (Figure 1). In [2], the researchers used thinnest commercially available green tape (100 μm thick). As a result, the microheater consumes ~600 mW at 400 °C. This high power consumption makes this very interesting device compatible with thick film sensors. For example, the thick film methane sensor of Figaro Ink. consumes ~280 mW , whereas the methane sensor described in [4] (chip size 2.5 × 0.5 × 0.1 mm) consumes ~220 mW at working temperature of 450 °C.

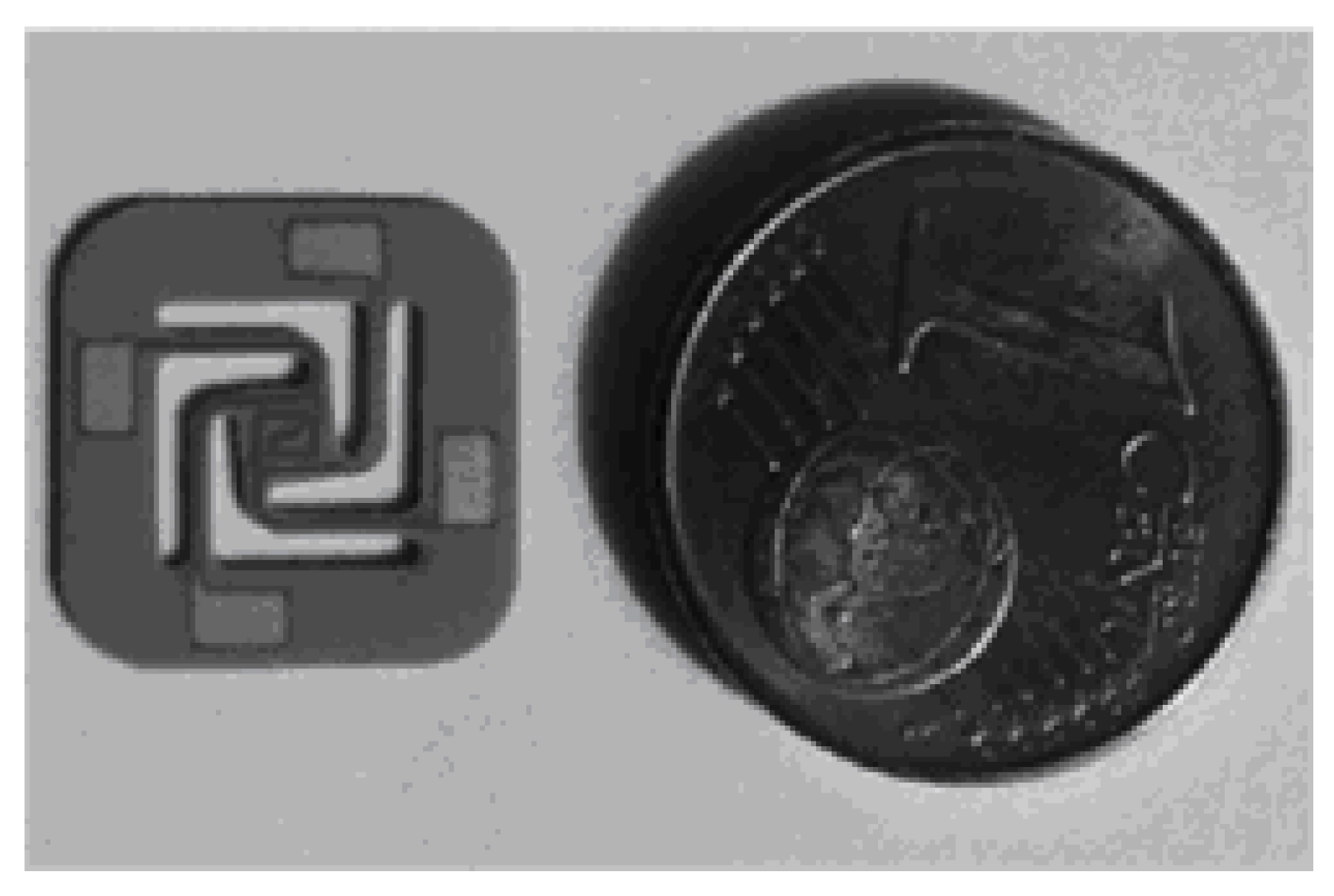

Figure 1.

Gas sensor microheater fabricated using LTCC ceramics [2]. Hotplate size of about 2 mm.

2. Experiment and Discussion

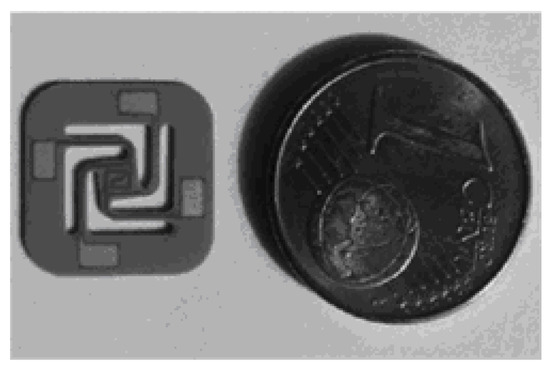

We used in our work much thinner, specially prepare by company “Istok” (Fryasino, Russia), 20 μm thick LTCC ceramics stretched on LTCC frame with hole (100 μm thick, Figure 2). This last was used to make the sensor chip robust enough. The sensor was assembled in TO8 holder (Figure 3).

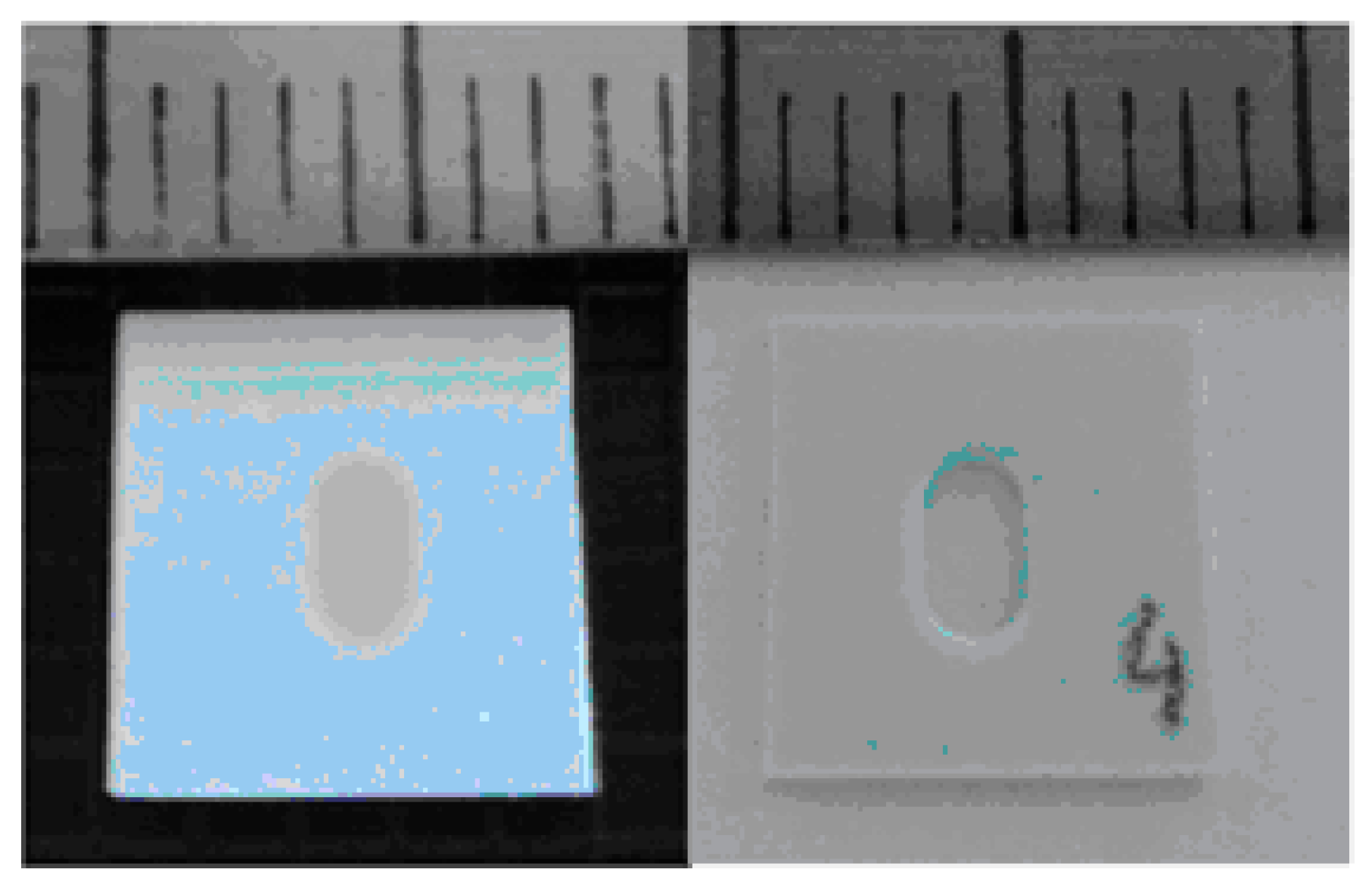

Figure 2.

20 μm thick LTCC membrane stretched on 100 μm thick LTCC frame. Top and bottom view.

Figure 3.

LTCC MEMS with 20 μm thick cantilever laser shaped microheater.

The platinum microheater was aerosol jet printed over 20 μm thick LTCC membrane using ink containing 3–8 nm Pt particles (AkKoLab Company, Moscow, Russia). This ink consists of platinum particles (fraction from 3 to 8 nm) suspended in ethylene glycol. The nanoparticles of platinum were produced by direct reduction of H2PtCl6 by ethylene glycol. The viscosity of the printable ink (~10 cP) is convenient for both aerosol and ink get printing of the microheater.

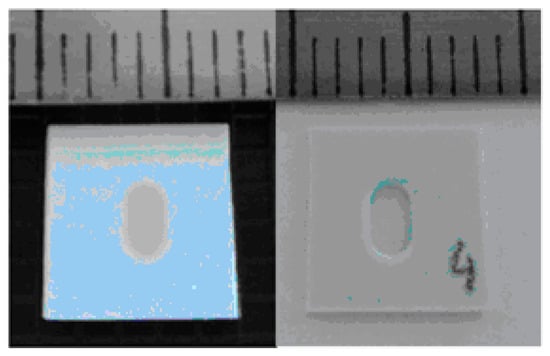

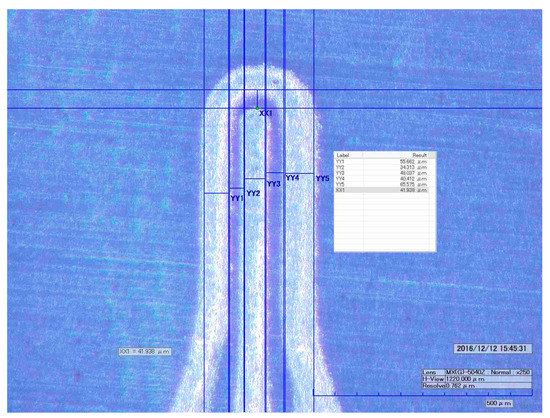

Photo of high-resistance part of microheater is presented in Figure 4. The width of the lines ranged from 30 to 60 μm, Pt thickness—from 1 to 2 μm, heater resistance—from 20 to 60 Ohm. To get cantilever shaped microhotplate, LTCC membrane surrounding Pt heater was cut away by 10 W laser (λ = 1.06 μm). Resulting chip with 3 mm hole and microheater cantilever suspended in this hole has dimension of 6 × 6 mm.

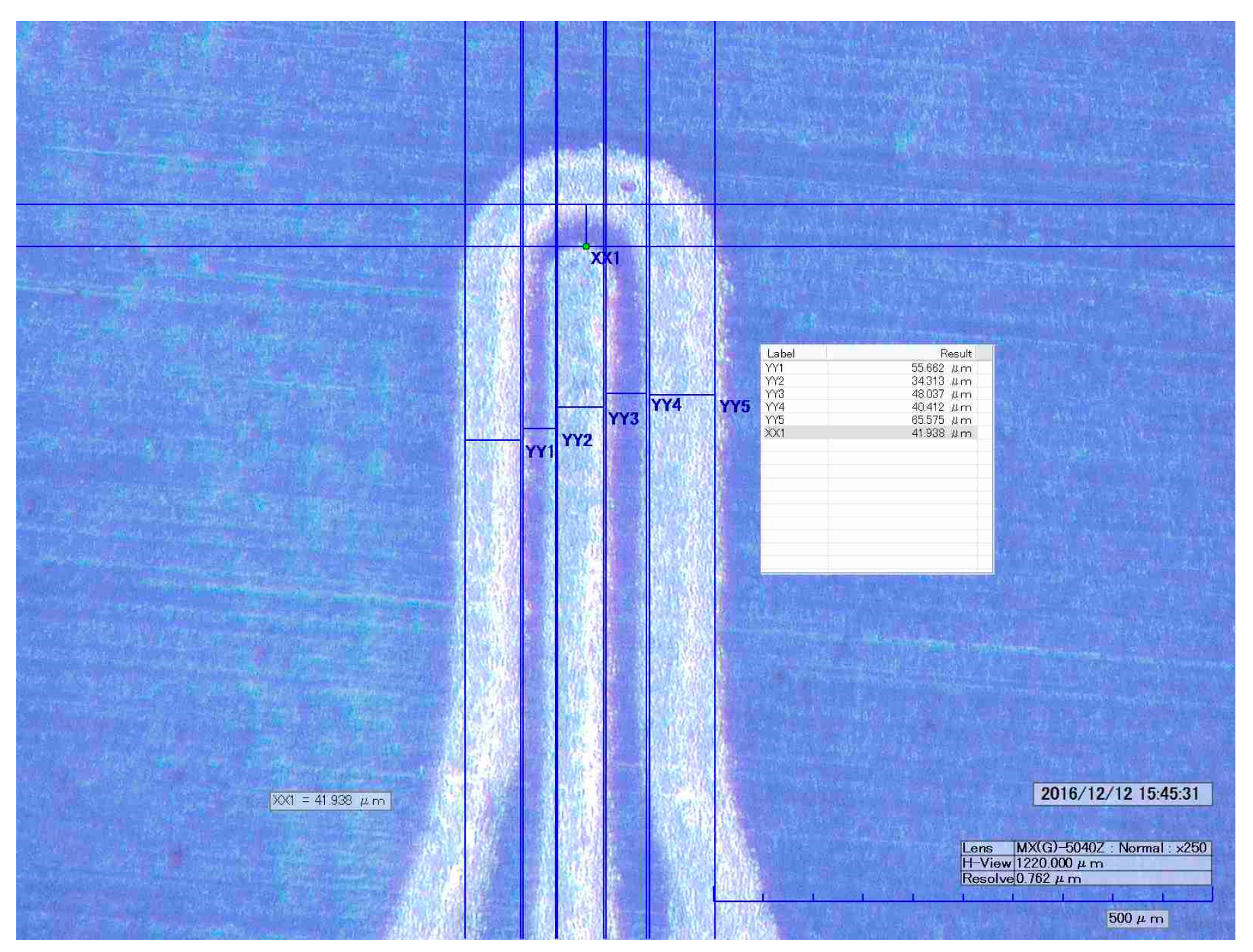

Figure 4.

Aerosol printed high-resistance part of the microheater. Heater material is platinum ink (particle size of 3–8 nm), line width is ~50 μm (average).

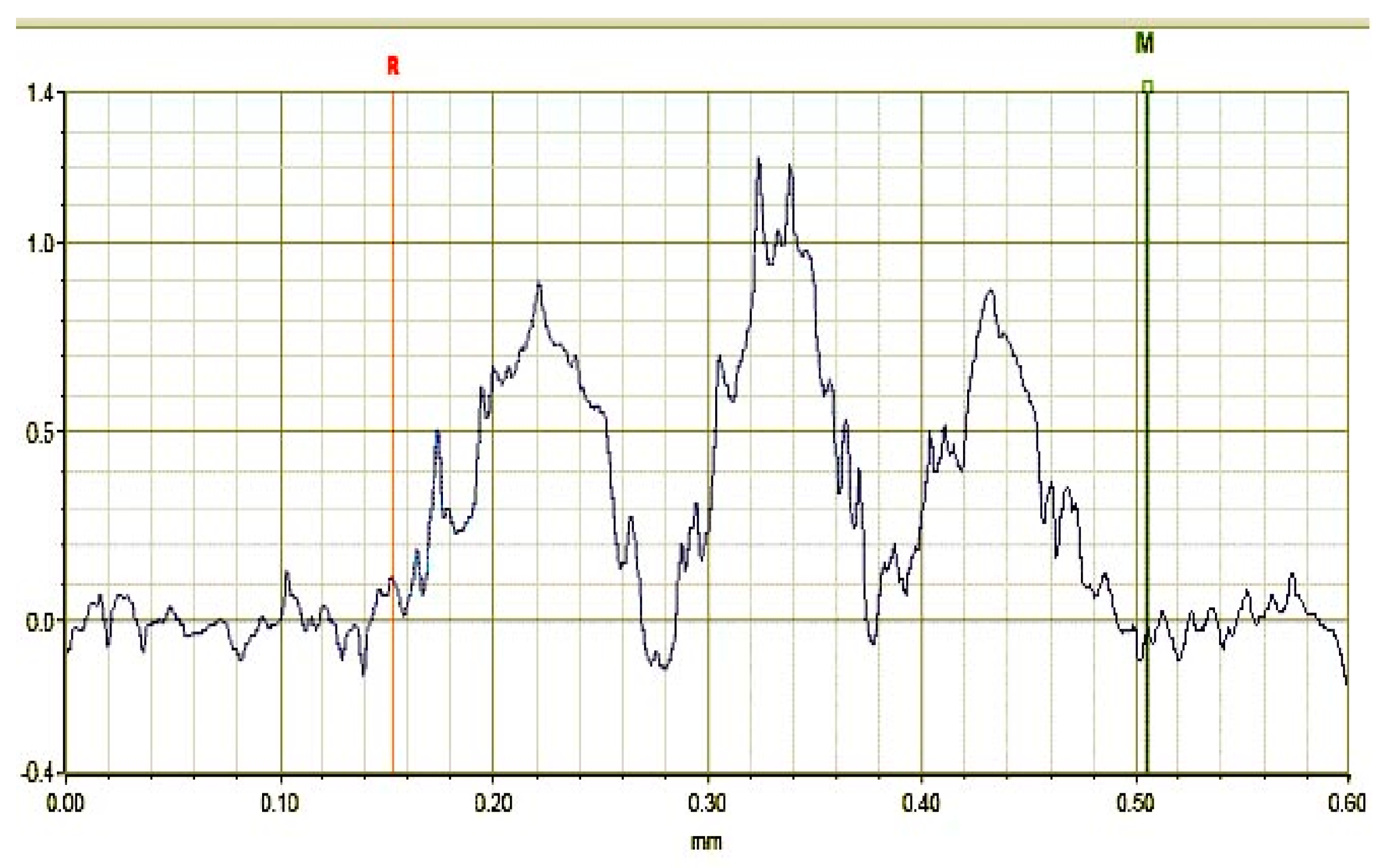

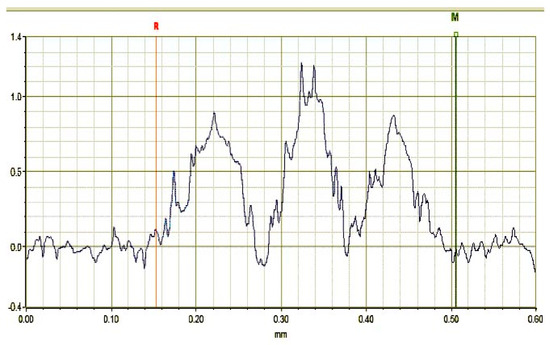

The results presented in Figure 5 demonstrate the profile of the lines made by aerosol jet printing of platinum. The thickness of platinum was varied from 1 to 2 μm, line width from 40 to 60 μm. In all cases the separation of the lines was good enough, any parasitic leakage between heater (horse shoe shaped electrode in Figure 5) and electrode to the sensing layer (central electrode in Figure 5) was not found.

Figure 5.

Figure 5. Pt line profile. Line width is of about 50 μm, line height is of about 1 μm.

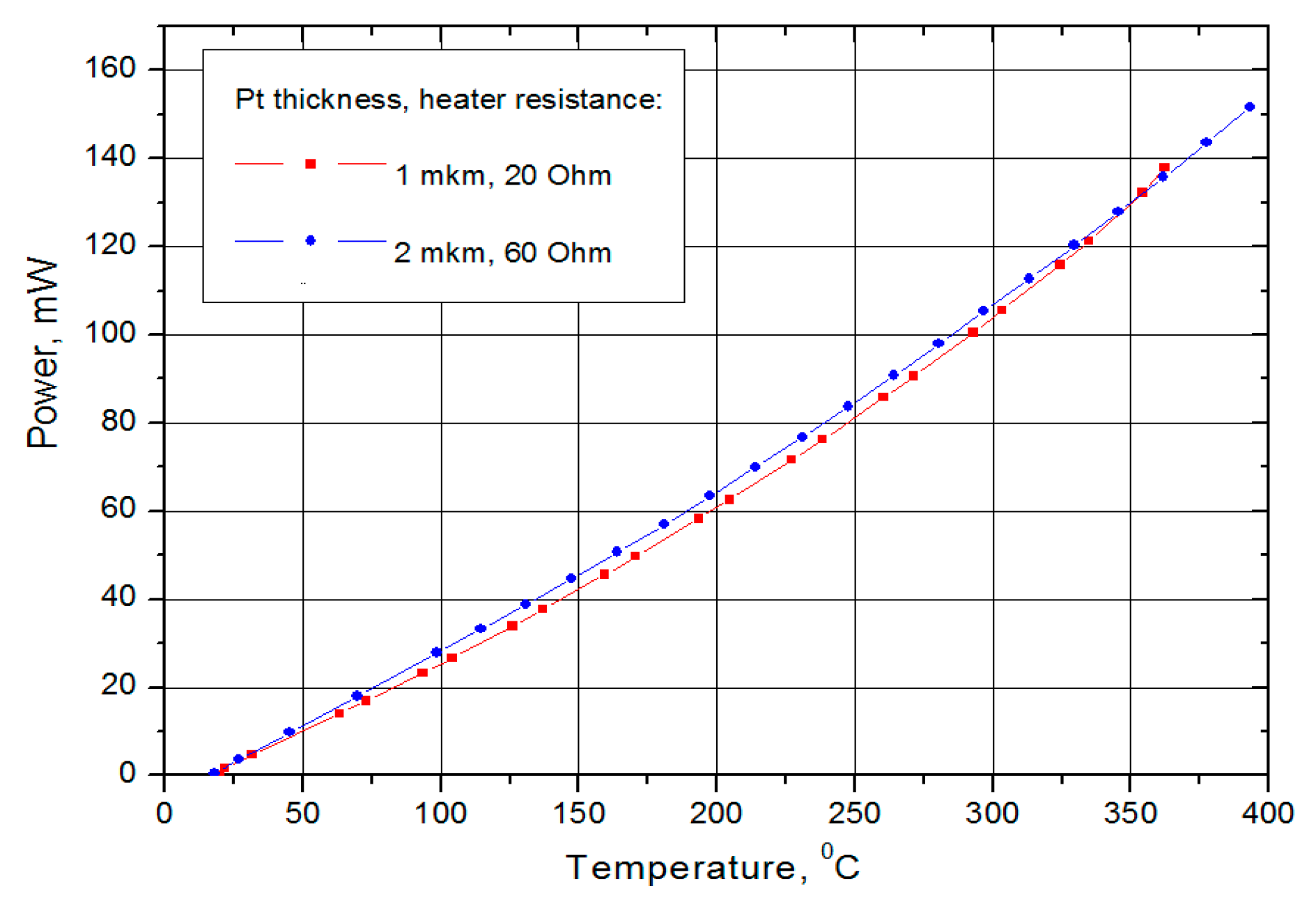

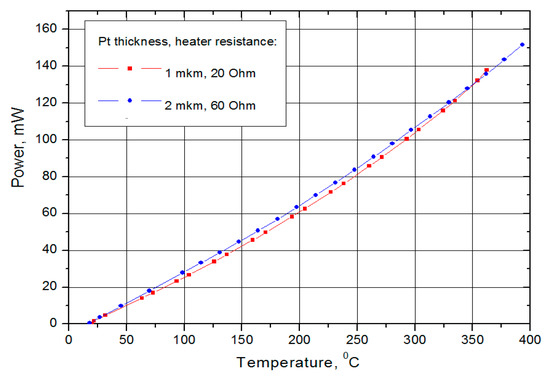

The results of tests (Figure 6) showed that the microheater consumes ~150 mW at working temperature of 450 °C. In this figure, the power consumption of the microheaters with the thickness of platinum layer of ~1 and ~3 μm (heater resistance of 60 and 20 Ohm, respectively) is presented. Our assumption was the application of thin LTCC with low heat conductivity of ~3 W/m·K would allow a significant decease in power consumption compared to the application of this alumina substrates described in [3], for example, because the power consumption of alumina exceed the power consumption of LTCC by a factor of 7 approximately. In [3], we used alumina with thickness of 12 μm obtained by anodic oxidation of aluminum as a substrate for the deposition of platinum microheater with approximately the same size as in this work. The results of [3] demonstrated that power consumption of the microheater is of about 70 mW at 450 °C.

Figure 6.

Platinum microheater power consumption as a function of working temperature. The resistance of heaters with two different thicknesses is shown in the plot.

The result presented in Figure 6 means that the main mechanism of heat dissipation by the microhotplate is related with the heat conductivity of LTCC substrate itself, but not by the heat conductivity of sintered metallic platinum. Otherwise, the power consumption of the microheaters with different platinum thickness would be significantly different.

The drift of microheater resistance doesn’t exceed 5% per year at working temperature. Gas sensing layer deposited on the end part of the microheater (10 nm particles of SnO2 decorated with 3 wt % of Pd) demonstrate usual response to methane of about factor of 7 at 1% concentration.

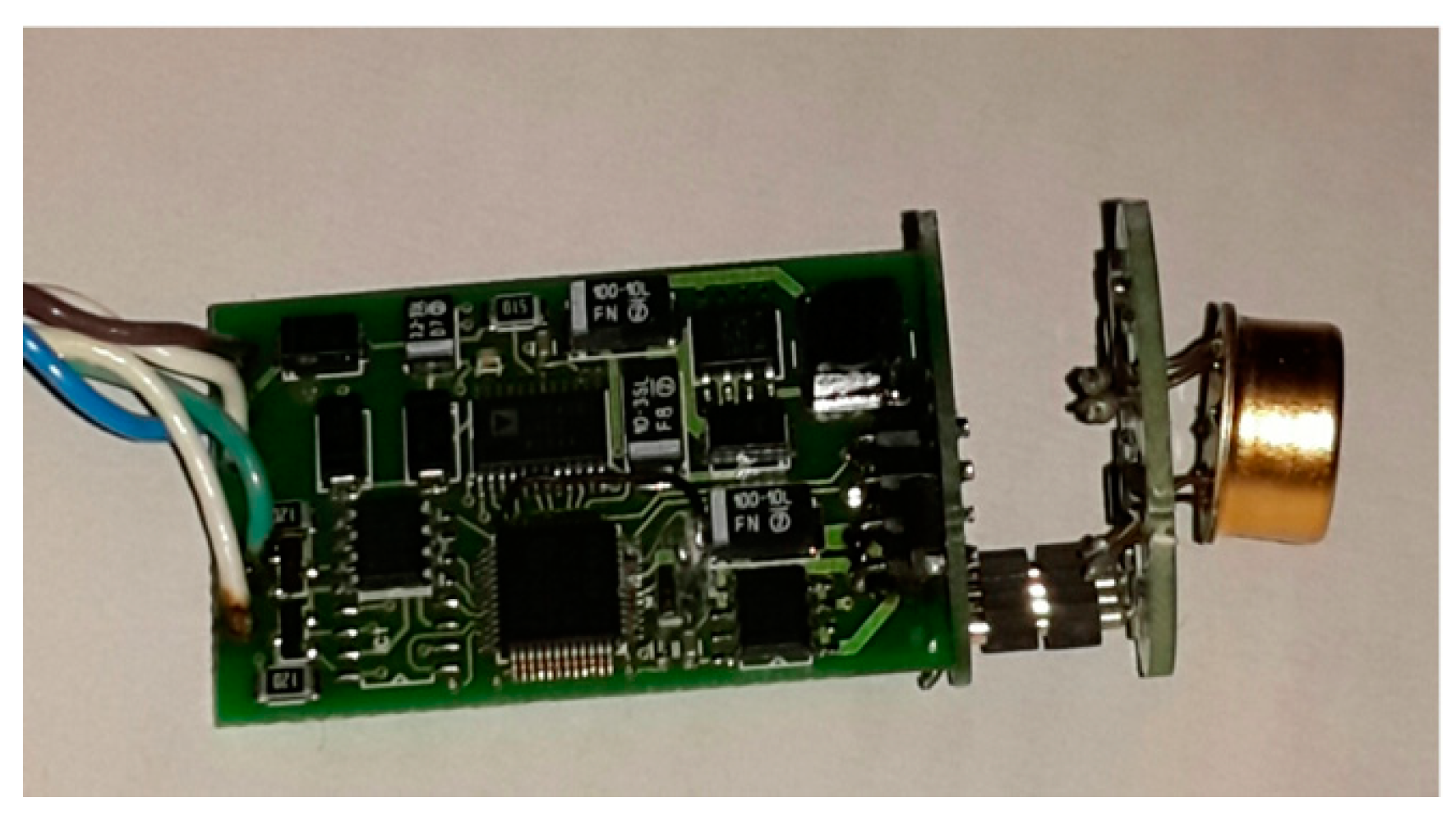

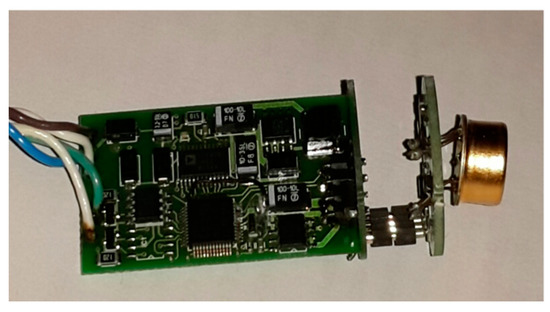

To control the sensor we used specially designed microprocessor based unit stabilizing sensor temperature in PWM mode, measuring sensor resistance, providing sensor calibration, humidity compensation and enabling connection with external device using UART interface (Figure 7).

Figure 7.

Figure 7. Smart sensor module enabling the stabilization of sensor temperature, humidity compensation, and transmission of information about gas concentration, type of sensor, calibration, etc. in plug-and-play regime. Smart sensor board is 25 mm in diameter.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kita, J.; Dziedzic, A.; Golonka, L.; Licznerski, B.; Nitscha, K.; Wiśniewskia, K. New design of SnO2 gas sensor on low temperature cofiring ceramics. Sens. Actuators B 1998, 47, 100–103. [Google Scholar]

- Kita, J.; Rettig, F.; Moos, R.; Drüe, K.H.; Thust, H. Hot plate gas sensors—Are ceramics better? Int. J. Appl. Ceram. Technol. 2005, 2, 383–389. [Google Scholar] [CrossRef]

- Vasiliev, A.A.; Pisliakov, A.V.; Sokolov, A.V.; Samotaev, N.N.; Soloviev, S.A.; Oblov, K.; Guarnieri, V.; Lorenzelli, L.; Brunelli, J.; Maglione, A.; et al. Non-silicon MEMS platforms for gas sensors. Sens. Actuators B 2016, 224, 700–713. [Google Scholar] [CrossRef]

- Vasiliev, A.; Pavelko, R.; Gogish-Klushin, S.; Kharitonov, D.; Gogish-Klushina, O.; Pisliakov, A.; Sokolov, A.; Samotaev, N.; Guarnieri, V.; Zen, M.; et al. Sensors based on technology “nano-on-micro” for wireless instruments preventing ecological and industrial catastrophes. In Sensors for Environment, Health and Security; Baraton, M.-I., Ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 205–228. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).