Laser Interferometry for Broad Area SPR-Grating Couplers in Chemical Applications †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication Process

2.2. Instrumentation

3. Results

3.1. Optical Characterization

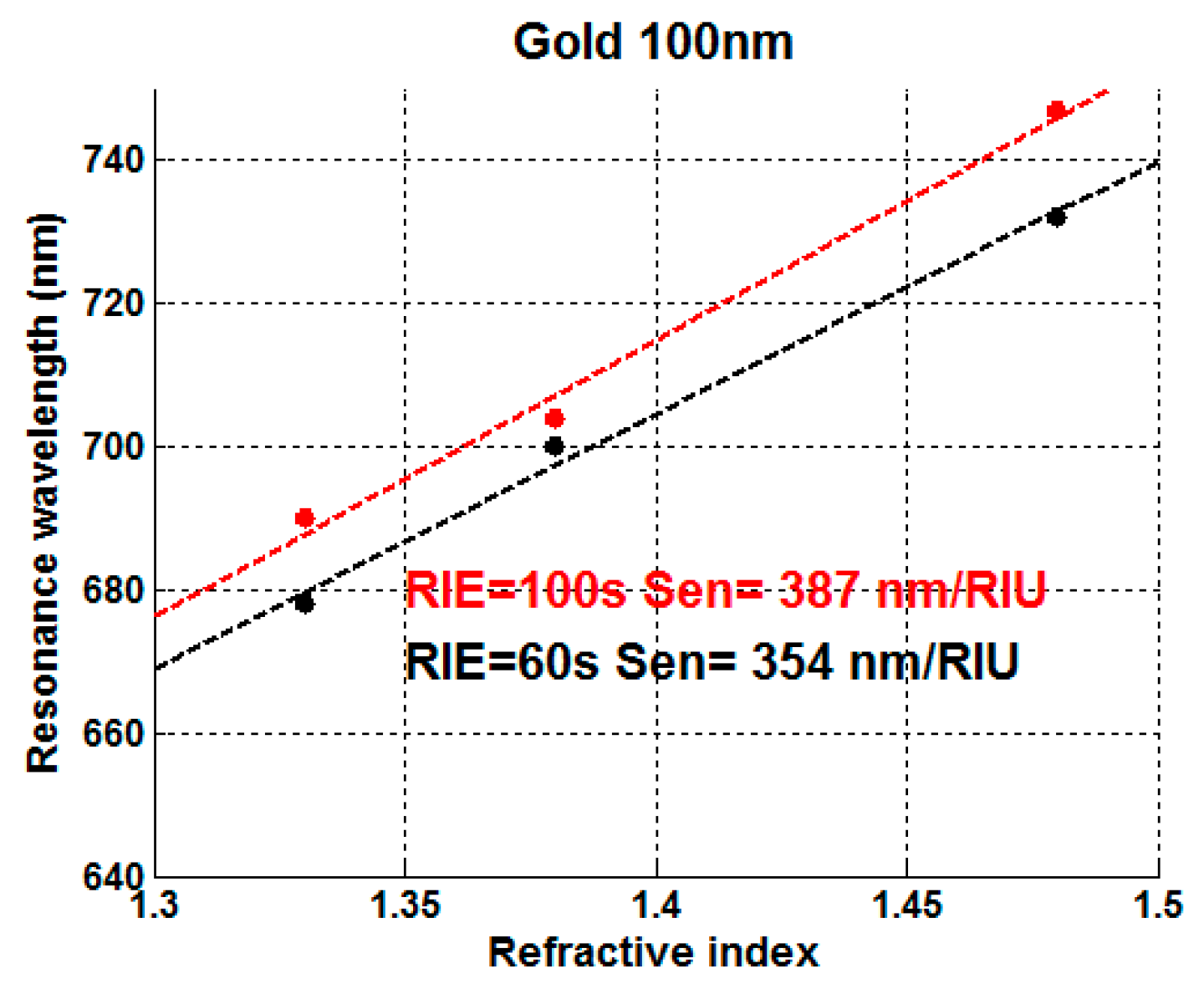

3.2. Bulk Characterization

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Homola, J. (Volume Ed.); Surface Plasmon Resonance Based Sensors; Series on Chemical Sensors and Biosensors: Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Rodríguez-Franco, P.; Arriola, A.; Darwish, N.; Jaramillo, J.J.; Keshmiri, H.; Tavera, T.; Olaizola, S.M.; Moreno, M. Fabrication of broad area optical nanostructures for high throughput chemical sensing. Sens. Actuators B Chem. 2013, 187, 356–362. [Google Scholar] [CrossRef]

- Kumari, S.; Mohapatra, S.; Moirangthem, R.S. Nano-imprint gold grating as refractive index sensor. AIP Conf. Proc. 2016, 1728, 020539. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Sereno, M.; Pérez, N.; Domenech-Gil, G.; Parellada-Monreal, L.; Martínez-Calderón, M.; Gómez-Aranzadi, M.; Darwish, N.; Mandayo, G.G.; Romano-Rodriguez, A. Laser Interferometry for Broad Area SPR-Grating Couplers in Chemical Applications. Proceedings 2017, 1, 323. https://doi.org/10.3390/proceedings1040323

Moreno-Sereno M, Pérez N, Domenech-Gil G, Parellada-Monreal L, Martínez-Calderón M, Gómez-Aranzadi M, Darwish N, Mandayo GG, Romano-Rodriguez A. Laser Interferometry for Broad Area SPR-Grating Couplers in Chemical Applications. Proceedings. 2017; 1(4):323. https://doi.org/10.3390/proceedings1040323

Chicago/Turabian StyleMoreno-Sereno, Mauricio, Noemi Pérez, Guillem Domenech-Gil, Laura Parellada-Monreal, Miguel Martínez-Calderón, Mikel Gómez-Aranzadi, Nasser Darwish, Gemma G. Mandayo, and Albert Romano-Rodriguez. 2017. "Laser Interferometry for Broad Area SPR-Grating Couplers in Chemical Applications" Proceedings 1, no. 4: 323. https://doi.org/10.3390/proceedings1040323

APA StyleMoreno-Sereno, M., Pérez, N., Domenech-Gil, G., Parellada-Monreal, L., Martínez-Calderón, M., Gómez-Aranzadi, M., Darwish, N., Mandayo, G. G., & Romano-Rodriguez, A. (2017). Laser Interferometry for Broad Area SPR-Grating Couplers in Chemical Applications. Proceedings, 1(4), 323. https://doi.org/10.3390/proceedings1040323