Thermal Stability of Micro-Structured PDMS Piezo-Electrets under Various Polymeric Reticulation Ratios for Sensor Applications †

Abstract

:1. Introduction

2. Experimental Considerations

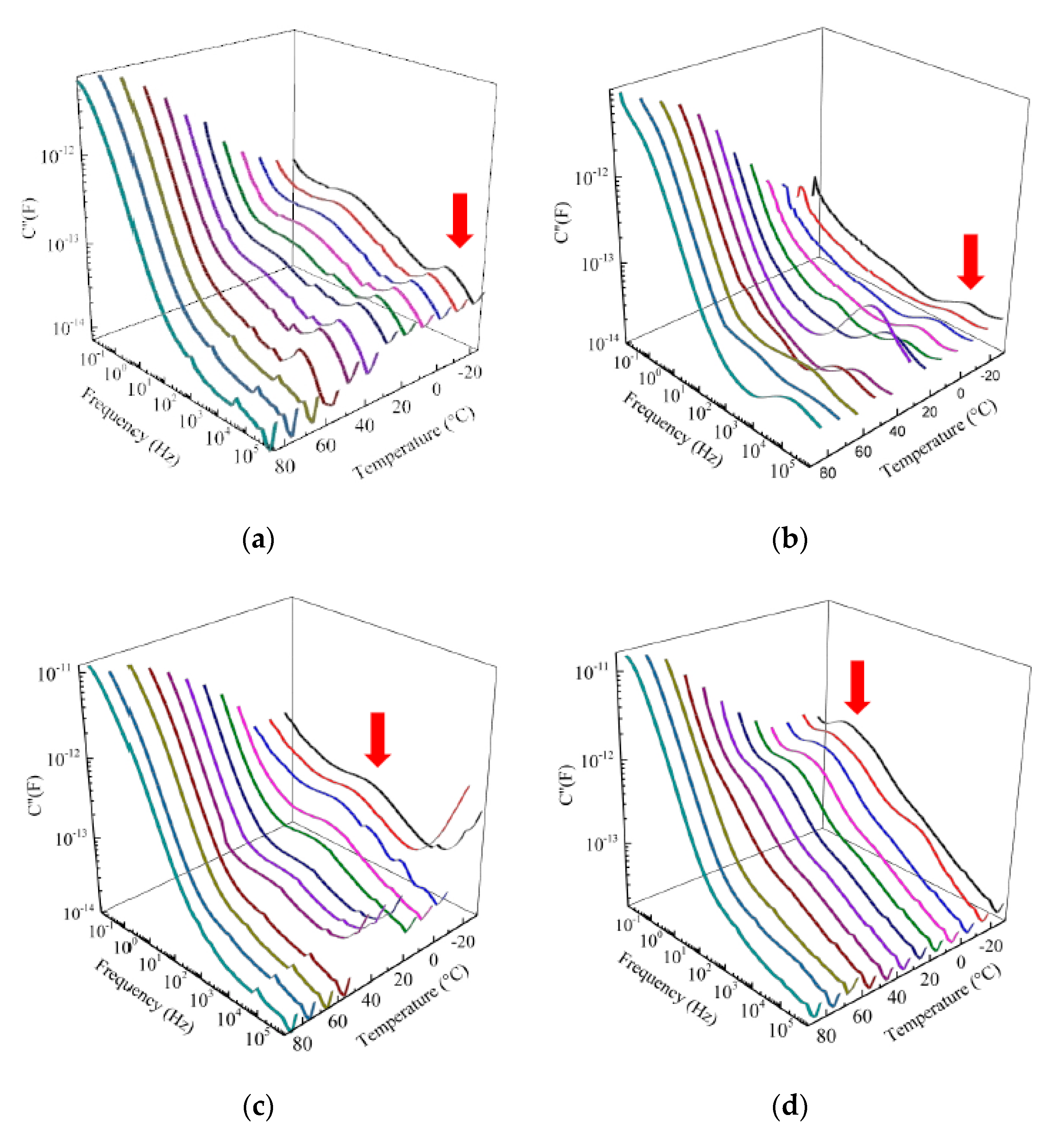

3. Results and Discussion

4. Conclusions and Future Work

Conflicts of Interest

References

- Jaffe, B. Piezoelectric Ceramics; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 978-0-323-15568-7. [Google Scholar]

- Ramadan, K.S.; Sameoto, D.; Evoy, S. A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 2014, 23, 33001. [Google Scholar] [CrossRef]

- Kim, J.Y.H.; Cheng, A.; Tai, Y.C. Parylene-C as a piezoelectric material. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 473–476. [Google Scholar]

- Kachroudi, A.; Basrour, S.; Rufer, L.; Sylvestre, A.; Jomni, F. Micro-structured PDMS piezoelectric enhancement through charging conditions. Smart Mater. Struct. 2016, 25, 105027. [Google Scholar] [CrossRef]

- Kachroudi, A.; Basrour, S.; Rufer, L.; Jomni, F. Piezoelectric cellular micro-structured PDMS material for micro-sensors and energy harvesting. J. Phys. Conf. Ser. 2015, 660, 12040. [Google Scholar] [CrossRef]

- Kachroudi, A.; Basrour, S.; Rufer, L.; Sylvestre, A.; Jomni, F. Dielectric properties modelling of cellular structures with PDMS for micro-sensor applications. Smart Mater. Struct. 2015, 24, 125013. [Google Scholar] [CrossRef]

- Kachroudi, A.; Basrour, S.; Rufer, L.; Jomni, F. Air-spaced PDMS piezo-electret cantilevers for vibration energy harvesting. J. Phys. Conf. Ser. 2016, 773, 12072. [Google Scholar] [CrossRef]

- Mellinger, A. Dielectric resonance spectroscopy: A versatile tool in the quest for better piezoelectric polymers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 842–861. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kachroudi, A.; Basrour, S.; Sylvestre, A. Thermal Stability of Micro-Structured PDMS Piezo-Electrets under Various Polymeric Reticulation Ratios for Sensor Applications. Proceedings 2017, 1, 310. https://doi.org/10.3390/proceedings1040310

Kachroudi A, Basrour S, Sylvestre A. Thermal Stability of Micro-Structured PDMS Piezo-Electrets under Various Polymeric Reticulation Ratios for Sensor Applications. Proceedings. 2017; 1(4):310. https://doi.org/10.3390/proceedings1040310

Chicago/Turabian StyleKachroudi, Achraf, Skandar Basrour, and Alain Sylvestre. 2017. "Thermal Stability of Micro-Structured PDMS Piezo-Electrets under Various Polymeric Reticulation Ratios for Sensor Applications" Proceedings 1, no. 4: 310. https://doi.org/10.3390/proceedings1040310

APA StyleKachroudi, A., Basrour, S., & Sylvestre, A. (2017). Thermal Stability of Micro-Structured PDMS Piezo-Electrets under Various Polymeric Reticulation Ratios for Sensor Applications. Proceedings, 1(4), 310. https://doi.org/10.3390/proceedings1040310