Incorporation of ZnO Nanostructures in MIS Architecture through Chemical Routes †

Abstract

:1. Introduction

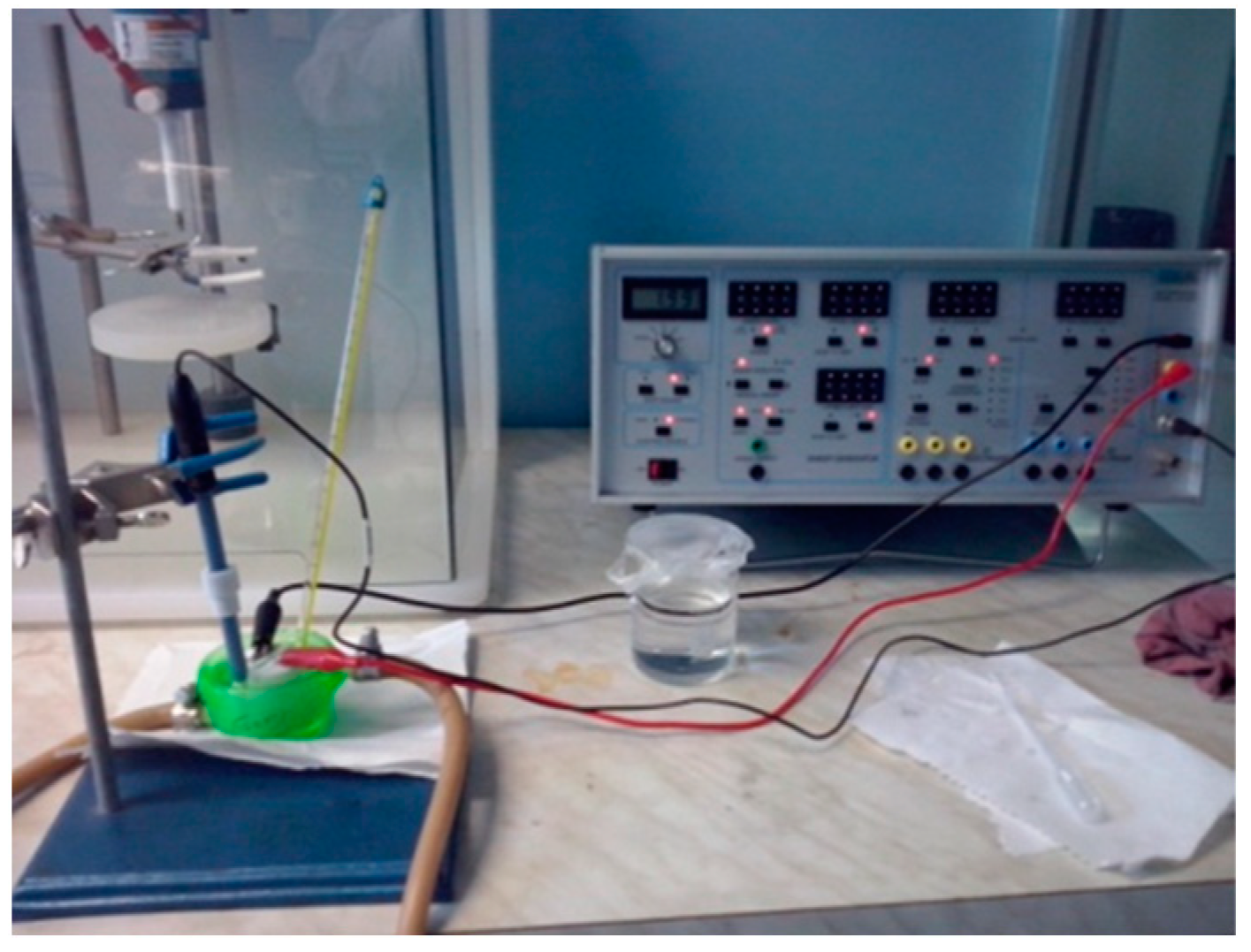

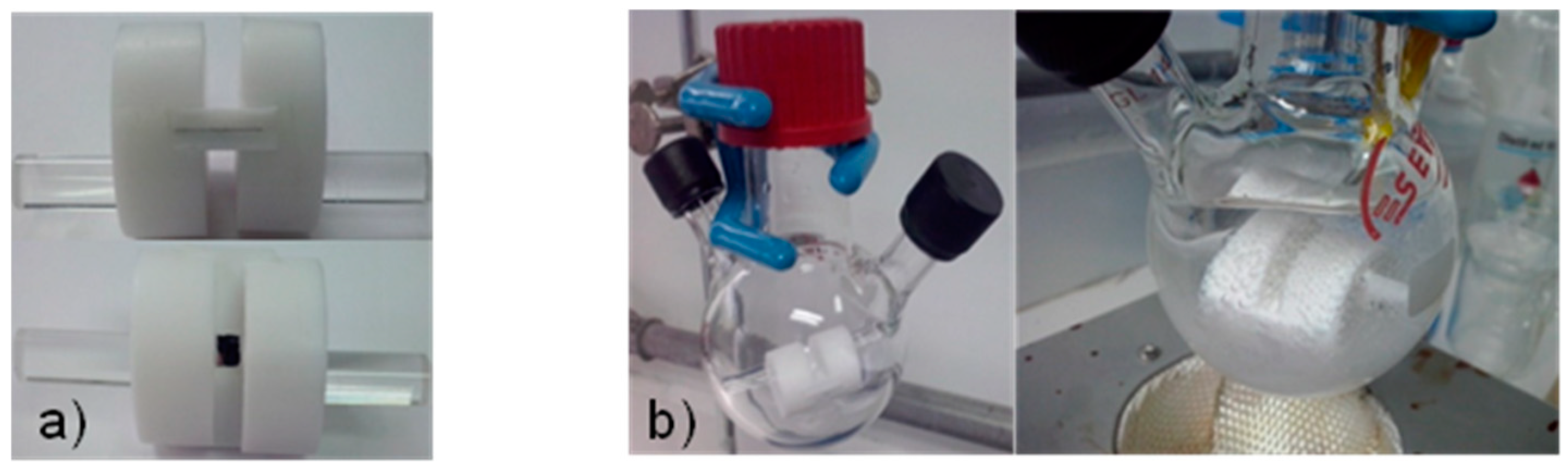

2. Materials and Methods

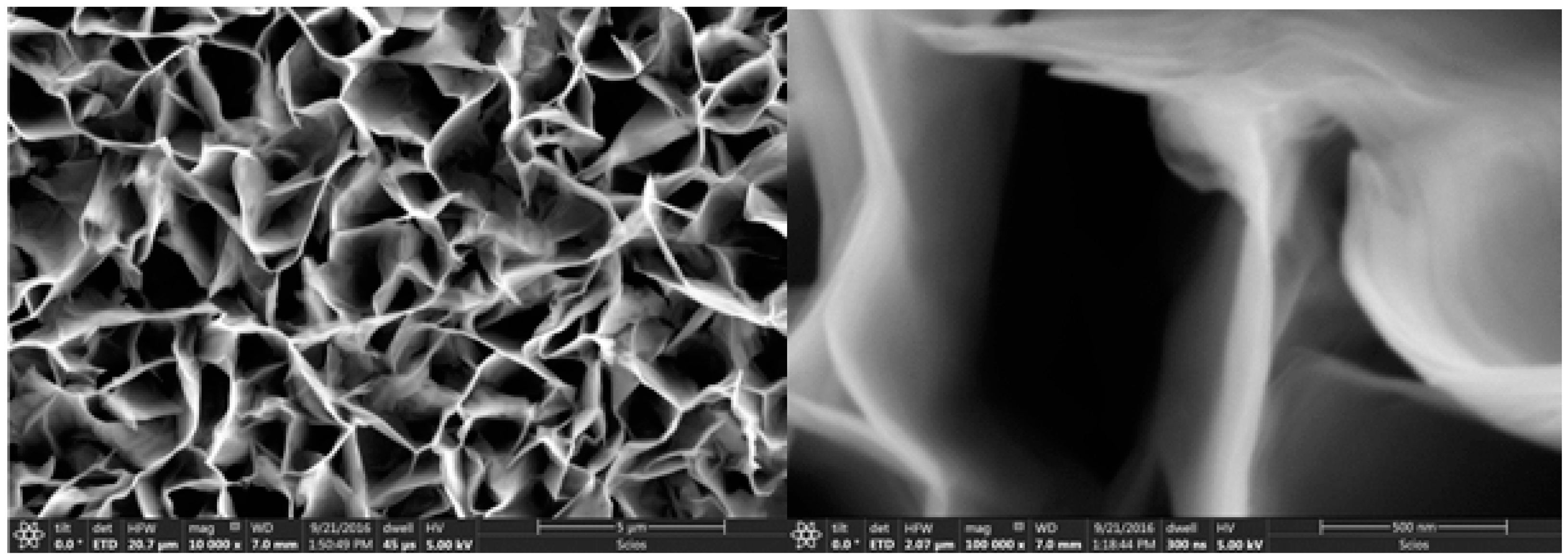

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Li, W.; Reisdorffer, F.; Nguyen, T.P.; Kwok, H.L. Electronic properties of ZnO nanorod MIS structure. Sci. Mater. Electron. 2013, 24, 3788–3792. [Google Scholar] [CrossRef]

- Diggle, J.W.; Downie, T.C.; Goulding, C.W. Porous Anodic Aluminum Oxide: Anodization and Templated Synthesis of Functional Nanostructures. Chem. Rev. 1969, 69, 365–405. [Google Scholar] [CrossRef]

- Amin, G.; Willander, P.M. ZnO and CuO Nanostructures: Low Temperature Growth, Characterization, Their Optoelectronic and Sensing Application; Linköping University Electronic Press: Linköping, Sweden, 2012; pp. 238–256. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, R.J.A.; Morales, A.E.; López, J.C.; Jimenez, M.D.; Ramírez, N.C.; López, J.A.L. Incorporation of ZnO Nanostructures in MIS Architecture through Chemical Routes. Proceedings 2017, 1, 308. https://doi.org/10.3390/proceedings1040308

García RJA, Morales AE, López JC, Jimenez MD, Ramírez NC, López JAL. Incorporation of ZnO Nanostructures in MIS Architecture through Chemical Routes. Proceedings. 2017; 1(4):308. https://doi.org/10.3390/proceedings1040308

Chicago/Turabian StyleGarcía, Rubén J. Aranda, A. Escobedo Morales, J. Carrillo López, M. Dominguez Jimenez, N. Carlos Ramírez, and José Alberto Luna López. 2017. "Incorporation of ZnO Nanostructures in MIS Architecture through Chemical Routes" Proceedings 1, no. 4: 308. https://doi.org/10.3390/proceedings1040308

APA StyleGarcía, R. J. A., Morales, A. E., López, J. C., Jimenez, M. D., Ramírez, N. C., & López, J. A. L. (2017). Incorporation of ZnO Nanostructures in MIS Architecture through Chemical Routes. Proceedings, 1(4), 308. https://doi.org/10.3390/proceedings1040308