Beyond Soil Inoculation: Cyanobacteria as a Fertilizer Replacement

Abstract

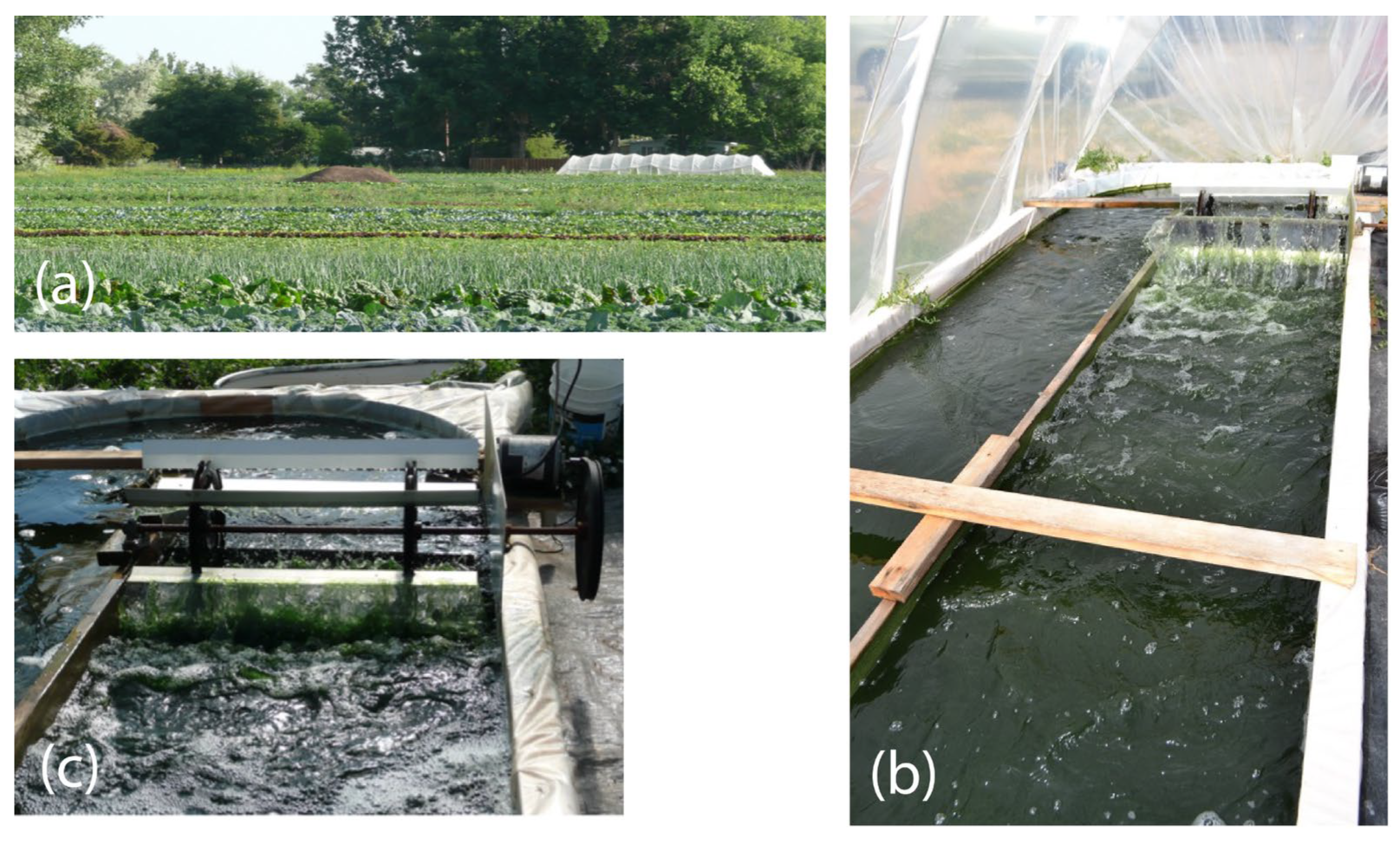

1. Going beyond Soil Inoculation

2. Disadvantages of Fertilizers Produced by the Haber–Bosch Process

3. Potential Benefits of Cyanobacterial Fertilizer

4. Challenges for Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, U.; Pabbi, S. Cyanobacteria: A potential biofertilizer for rice. Resonance 2004, 9, 6–10. [Google Scholar] [CrossRef]

- Okon, Y.; Labandera-Gonzalez, C.A. Agronomic applications of Azospirillum: An evaluation of 20 years of worldwide field inoculation. Soil Biol. Biochem. 1994, 26, 1591–1601. [Google Scholar] [CrossRef]

- Dobbelaere, S.; Croonenborghs, A.; Thys, A.; Ptacek, D.; Vanderleyden, J.; Dutto, P.; Labandera-Gonzalez, C.; Caballero-Mellado, J.; Aguirre, J.F.; Kapulnik, Y.; et al. Responses of agronomically important crops to inoculation with Azospirillum. Aust. J. Plant Physiol. 2001, 28, 871–879. [Google Scholar] [CrossRef]

- Smith, R.L.; Schank, S.C.; Milam, J.R.; Baltensperger, A.A. Responses of Sorghum and Pennisetum species to the N2-fixing bacterium Azospirillum brasilense. Appl. Environ. Microbiol. 1984, 47, 1331–1336. [Google Scholar] [CrossRef]

- Fukami, J.; Cerezini, P.; Hungria, M. Azospirillum: Benefits that go far beyond biological nitrogen fixation. AMB Expr. 2018, 8, 73. [Google Scholar] [CrossRef]

- Obana, S.; Miyamoto, K.; Morita, S.; Ohmori, M.; Inubushi, K. Effect of Nostoc sp. on soil characvteristics, plant growth and nutrient uptake. J. Appl. Phycol. 2007, 19, 641–646. [Google Scholar] [CrossRef]

- Chamizo, S.; Mugnai, G.; Rossi, F.; Certini, G.; De Philippis, R. Cyanobacteria inoculation improves soil stability and fertility on different textured soils: Gaining insights for applicability in soil restoration. Front. Environ. Sci. 2018, 6, 49. [Google Scholar] [CrossRef]

- Roncero-Ramos, B.; Román, J.R.; Gómez-Serrano, C.; Cantón, Y.; Acién, F.G. Production of a biocrust-cyanobacteria strain (Nostoc commune) for large-scale restoration of dryland soils. J. Appl. Phycol. 2019, 31, 2217–2230. [Google Scholar] [CrossRef]

- Silva, P.G.; Silva, H.J. A retained viability index (RVI10) for evaluation of a cyanobacterial powder fertilizer. World J. Microbiol. Biotechnol. 2003, 19, 891–895. [Google Scholar] [CrossRef]

- Silva, P.G.; Silva, H.J. Effect of mineral nutrients on cell growth and self-flocculation of Topothrix tenuis for the production of a biofertilizer. Bioresour. Technol. 2007, 98, 607–611. [Google Scholar] [CrossRef]

- Silva, P.G.; Ferrari, S.G.; Silva, H.J. Preservation methods of Tolypothrix tenuis for use as a cyanobacterial fertilizer. J. Appl. Phycol. 2007, 19, 239–246. [Google Scholar] [CrossRef]

- Maqubela, M.P.; Mnkeni, P.N.S.; Issa, O.M.; Pardo, M.T.; D’Acqui, L.P. Nostoc cyanobacterial inoculation in South African agricultural soils enhances soil stucture, soil fertility, and maize growth. Plant Soil 2009, 315, 79–92. [Google Scholar] [CrossRef]

- Smil, V. Detonator of the population explosion. Nature 1999, 400, 415. [Google Scholar] [CrossRef]

- Gruber, N.; Galloway, J.N. An Earth-system perspective of the global nitrogen cycle. Nature 2008, 451, 293–296. [Google Scholar] [CrossRef]

- Fowler, D.; Coyle, M.; Skiba, U.; Sutton, M.A.; Cape, J.N.; Reis, S.; Sheppard, L.J.; Jenkins, A.; Grizzetti, B.; Galloway, J.N.; et al. The global nitrogen cycle in the twenty-first century. Phil. Trans. R. Soc. B 2013, 368, 20130164. [Google Scholar] [CrossRef]

- Erisman, J.W.; Sutton, M.A.; Galloway, J.; Klimont, Z.; Winiwarter, W. How a century of ammonia synthesis changed the world. Nat. Geosci. 2008, 1, 636–639. [Google Scholar] [CrossRef]

- Erisman, J.W.; Galloway, J.N.; Seitzinger, S.; Bleeker, A.; Dise, N.B.; Petrescu, A.M.R.; Leach, A.M.; de Vries, W. Consequences of human modification of the global nitrogen cycle. Phil. Trans. R. Soc. B 2013, 368, 20130116. [Google Scholar] [CrossRef]

- Sandström, V.; Valin, H.; Krisztin, T.; Havlík, P.; Herrero, M.; Kastner, T. The role of trade in the greenhouse gas footprints of EU diets. Glob. Food Secur. 2018, 19, 48–55. [Google Scholar] [CrossRef]

- Daramola, D.A.; Hatzell, M.C. Energy demand of nitrogen and phosphorus based fertilizers and approaches to circularity. ACS Energy Lett. 2023, 8, 1493–1501. [Google Scholar] [CrossRef]

- Chen, J.G.; Crooks, R.M.; Seefeldt, L.C.; Bren, K.L.; Bullock, R.M.; Darensbourg, M.Y.; Holland, P.L.; Hoffman, B.; Janik, M.J.; Jones, A.K.; et al. Beyond fossil fuel-driven nitrogen transformations. Science 2018, 360, eaar6611. [Google Scholar] [CrossRef]

- Sainju, U.M.; Jabro, J.D.; Stevens, W.B. Soil carbon dioxide emission and carbon content as affected by irrigation, tillage, cropping system, and nitrogen fertilization. J. Environ. Qual. 2008, 37, 98–106. [Google Scholar] [CrossRef] [PubMed]

- Reay, D.S.; Davidson, E.A.; Smith, K.A.; Smith, P.; Melillo, J.M.; Dentener, F.; Crutzen, P.J. Global agriculture and nitrous oxide emissions. Nat. Clim. Chang. 2012, 2, 410–416. [Google Scholar] [CrossRef]

- Vitousek, P.M.; Naylor, R.; Crews, T.; David, M.B.; Drinkwater, L.E.; Holland, E.; Johnes, P.J.; Katzenberger, J.; Martinelli, L.A.; Matson, P.A.; et al. Nutrient imbalances in agricultural development. Science 2009, 324, 1519–1520. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Zhang, K.; Liang, Z.; Zou, R.; Xu, Q. Electrochemical nitrogen fixation and utilization: Theories, advanced catalyst materials and system design. Chem. Soc. Rev. 2019, 48, 5658–5716. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Gu, J.; Lin, S.; Zhang, S.; Chen, Z.; Huang, S. Tackling the activity and selectivity challenges of electrocatalysts toward the nitrogen reduction reaction via atomically dispersed biatom catalysts. J. Am. Chem. Soc. 2020, 142, 5709–5721. [Google Scholar] [CrossRef]

- Fu, X.; Pedersen, J.B.; Zhou, Y.; Saccoccio, M.; Li, S.; Sazinas, R.; Li, K.; Andersen, S.Z.; Xu, A.; Deissler, N.H.; et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 2023, 379, 707–712. [Google Scholar] [CrossRef]

- Du, H.-L.; Chatti, M.; Hodgetts, R.Y.; Cherepanov, P.V.; Nguyen, C.K.; Matuszek, K.; McFarlane, D.R.; Simonov, A.N. Electroreduction of nitrogen with almost 100% current-to-ammonia efficiency. Nature 2022, 609, 722–727. [Google Scholar] [CrossRef]

- Singh, J.S.; Kumar, A.; Rai, A.N.; Singh, D.P. Cyanobacteria: A precious bio-resource in agriculture, ecosystem, and environmental sustainability. Front. Microbiol. 2016, 7, 529. [Google Scholar] [CrossRef]

- Alvarez, A.L.; Weyers, S.L.; Goemann, H.M.; Peyton, B.M.; Gardner, R.D. Microalgae, soil and plants: A critical review of microalgae as renewable resources for agriculture. Algal Res. 2021, 54, 102200. [Google Scholar] [CrossRef]

- Barminski, R.; Storteboom, H.; Davis, J.G. Development and evaluation of an organically-certifiable growth medium for cyanobacteria. J. Appl. Phycol. 2016, 28, 2623–2630. [Google Scholar] [CrossRef]

- Wolde, G.; Asmamaw, M.; Sido, M.Y.; Yigrem, S.; Wolde-meskel, E.; Chala, A.; Storteboom, H.; Davis, J.G. Optimizing a cyanobacterial biofertilizer manufacturing system for village-level production in Ethiopia. J. Appl. Phycol. 2020, 32, 3983–3994. [Google Scholar] [CrossRef]

- Asmamaw, M.; Wolde, G.; Yohannes, M.; Yigrem, S.; Woldemeskel, E.; Chala, A.; Davis, J.G. Comparison of cyanobacterial bio-fertilizer with urea on three crops and two soils of Ethiopia. Afr. J. Agric. Res. 2019, 14, 588–596. [Google Scholar]

- Wickham, A.; Davis, J.G. Optimizing organic carrot yield and quality using fish emulsions, cyanobacterial fertilizer, and seaweed extracts. Agronomy 2023, 13, 1329. [Google Scholar] [CrossRef]

- Jama, A.; Widiastuti, D.P.; Gafur, S.; Davis, J.G. Azolla biofertilizer is an effective replacement for urea fertilizer in vegetable crops. Sustainability 2023, 15, 6045. [Google Scholar] [CrossRef]

- Toonsiri, P.; Del Grosso, S.J.; Sukor, A.; Davis, J.G. Greenhouse gas emissions from solid and liquid organic fertilizers applied to lettuce. J. Environ. Qual. 2016, 45, 1812–1821. [Google Scholar] [CrossRef]

- Erwiha, G.M.; Ham, J.; Sukor, A.; Wickham, A.; Davis, J.G. Organic fertilizer source and application method impact ammonia volatilization. Commun. Soil Sci. Plant Anal. 2020, 51, 1469–1482. [Google Scholar] [CrossRef]

- Cameron, H.J.; Julian, G.R. Utilization of hydroxyapatite by Cyanobacteria as their sole source of phosphate and calcium. Plant Soil 1988, 109, 123–124. [Google Scholar] [CrossRef]

- Mandal, B.; Das, S.C.; Mandal, L.N. Effect of growth and subsequent decomposition of cyanobacteria on the transformation of phosphorus in submerged soils. Plant Soil 1992, 143, 289–297. [Google Scholar] [CrossRef]

- Vaishampayan, A.; Sinha, R.P.; Häder, D.P.; Dey, T.; Gupta, A.K.; Bhan, U.; Rao, A.L. Cyanobacterial biofertilizers in rice agriculture. Bot. Rev. 2001, 67, 453–516. [Google Scholar] [CrossRef]

- Yandigeri, M.S.; Yadav, A.K.; Srinivasan, R.; Kashyap, S.; Pabbi, S. Studies on mineral phosphate solubilization by cyanobacteria Westiellopsis and Anabaena. Microbiology 2011, 80, 558–565. [Google Scholar] [CrossRef]

- Afkairin, A.; Ippolito, J.A.; Stromberger, M.; Davis, J.G. Solubilization of organic phosphorus sources by cyanobacteria and a commercially available bacterial consortium. Appl. Soil Ecol. 2021, 162, 103900. [Google Scholar] [CrossRef]

- Wenz, J.; Davis, J.G.; Storteboom, H. Influence of light on endogenous phytohormone concentrations of a nitrogen-fixing Anabaena sp. cyanobacterium culture in open raceways for use as fertilizer for horticultural crops. J. Appl. Phycol. 2019, 31, 3371–3384. [Google Scholar] [CrossRef]

- Sukor, A.; Amer, F.S.M.; Vanamala, J.; Davis, J.G. Phytohormones in organic fertilizers influence β-carotene concentration and marketable yield of lettuce (Lactuca sativa). Acta Hortic. 2022, 1348, 15–22. [Google Scholar] [CrossRef]

- Yoder, N.; Davis, J.G. Organic fertilizer comparison on growth and nutrient content of three kale cultivars. HortTechnology 2020, 30, 176–184. [Google Scholar] [CrossRef]

- Sterle, D.G.; Stonaker, F.; Ela, S.; Davis, J.G. Cyanobacterial biofertilizer as a supplemental fertilizer for peaches: Yield, trunk growth, leaf nutrients and chlorosis. J. Am. Pomol. Soc. 2021, 75, 165–175. [Google Scholar]

- Sukor, A. Organic Nitrogen Fertilizers Influence Nutritional Value, Water Use Efficiency, and Nitrogen Dynamics of Drip Irrigated Lettuce and Sweet Corn. Ph.D. Dissertation, Colorado State University, Fort Collins, CO, USA, 2016. [Google Scholar]

- Sukor, A.; Qian, Y.; Davis, J.G. Organic nitrogen fertilizer selection influences water use efficiency in drip-irrigated sweet corn. Agriculture 2023, 13, 923. [Google Scholar] [CrossRef]

- Rogers, S.L.; Burns, R.G. Changes in aggregate stability, nutrient status, indigenous microbial populations, and seedling emergence, following inoculation of soil with Nostoc muscorum. Biol. Fert. Soils 1994, 18, 209–215. [Google Scholar] [CrossRef]

- Afkairin, A. Cyanobacteria Biofertilizer Solubilizes Soil Phosphorus and Alters Soil Microbial Communities. Ph.D. Dissertation, Colorado State University, Fort Collins, CO, USA, 2022. [Google Scholar]

- Poveda, J. Cyanobacteria in plant health: Biological strategy against abiotic and biotic stresses. Crop Prot. 2021, 141, 105450. [Google Scholar] [CrossRef]

- Tsedeke, A.; Degefu, T.; Wolde-meskel, E.; Davis, J. The effect of pond depth and lining plastic color on nitrogen fixing capacity of the cyanobacteria, Anabaena sp. E3. Afr. J. Biotechnol. 2016, 15, 1442–1451. [Google Scholar] [CrossRef]

- Hurisso, T.T.; Davis, J.G.; Chala, A.; Getachew, A.; Wolde-meskel, E. Impacts of grinding and acidification of animal bones with coffee wastewater on plant dry matter yield and recovery of phosphorus. Commun. Soil Sci. Plant Anal. 2021, 52, 1076–1088. [Google Scholar] [CrossRef]

- Pathak, J.; Rajneesh; Maurya, P.K.; Singh, S.P.; Häder, D.-P.; Sinha, R.P. Cyanobacterial farming for environment friendly sustainable agriculture practices: Innovations and perspectives. Front. Environ. Sci. 2018, 6, 7. [Google Scholar] [CrossRef]

- Buratti, F.M.; Manganelli, M.; Vichi, S.; Stefanelli, M.; Scardala, S.; Testai, E.; Funari, E. Cyanotoxins: Producing organisms, occurrence, toxicity, mechanism of action and human health toxicological risk evaluation. Arch. Toxicol. 2017, 91, 1049–1130. [Google Scholar] [CrossRef]

- Svirčev, Z.; Lalić, D.; Savić, G.B.; Tokodi, N.; Backović, D.D.; Chen, L.; Meiluoto, J.; Codd, G.A. Global geographical and historical overview of cyanotoxin distribution and cyanobacterial poisonings. Arch. Toxicol. 2019, 93, 2429–2481. [Google Scholar] [CrossRef]

- Dolman, A.M.; Rücker, J.; Pick, F.R.; Fastner, J.; Rohrlack, T.; Mischke, U.; Wiedner, C. Cyanobacteria and cyanotoxins: The influence of nitrogen versus phosphorus. PLoS ONE 2012, 7, e38757. [Google Scholar] [CrossRef]

- Do Nascimento, M.; Battaglia, M.E.; Rizza, L.S.; Ambrosio, R.; Di Palma, A.A.; Curatti, L. Prospects of using biomass of N2-fixing cyanobacteria as an organic fertilizer and soil conditioner. Algal Res. 2019, 43, 101652. [Google Scholar] [CrossRef]

- Bravo-Fritz, C.P.; Sáez-Navarrete, C.A.; Herrera-Zeppelin, L.A.; Varas-Concha, F. Multi-scenario energy-economic evaluation for a biorefinery based on microalgae biomass with application of anaerobic digestion. Algal Res. 2016, 16, 292–307. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massey, M.S.; Davis, J.G. Beyond Soil Inoculation: Cyanobacteria as a Fertilizer Replacement. Nitrogen 2023, 4, 253-262. https://doi.org/10.3390/nitrogen4030018

Massey MS, Davis JG. Beyond Soil Inoculation: Cyanobacteria as a Fertilizer Replacement. Nitrogen. 2023; 4(3):253-262. https://doi.org/10.3390/nitrogen4030018

Chicago/Turabian StyleMassey, Michael S., and Jessica G. Davis. 2023. "Beyond Soil Inoculation: Cyanobacteria as a Fertilizer Replacement" Nitrogen 4, no. 3: 253-262. https://doi.org/10.3390/nitrogen4030018

APA StyleMassey, M. S., & Davis, J. G. (2023). Beyond Soil Inoculation: Cyanobacteria as a Fertilizer Replacement. Nitrogen, 4(3), 253-262. https://doi.org/10.3390/nitrogen4030018