Study on Multi-Scale Damage Evolution of Sandstone Under Freeze–Thaw Cycles: A Computational Perspective Based on Pore Structure and Fractal Dimension

Abstract

1. Introduction

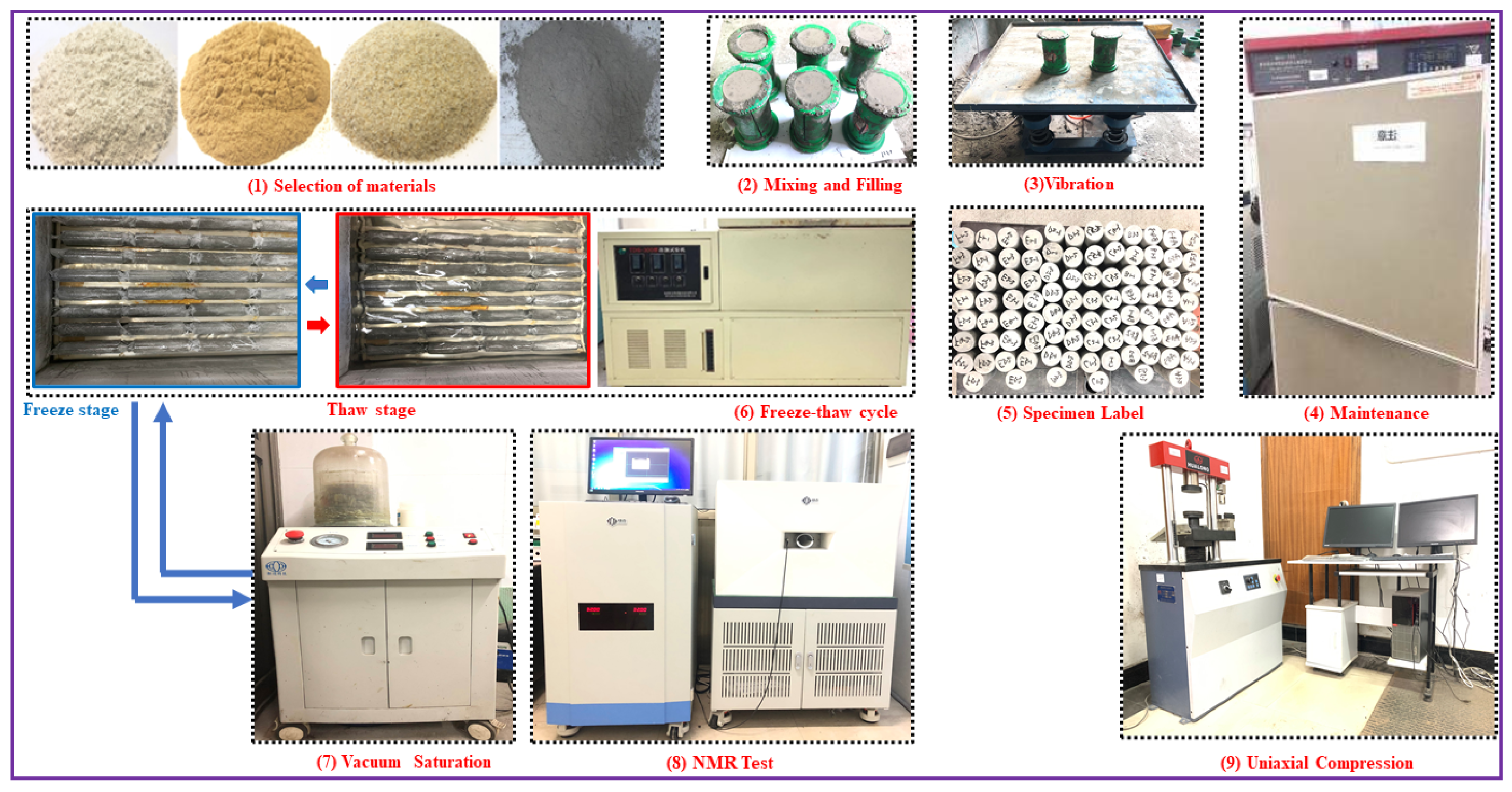

2. Materials and Methods

2.1. Raw Material Selection and Sample Preparation

2.2. Laboratory Test

2.3. Pore Radius Decision and Fractal Dimension Calculation

3. Results’ Analysis

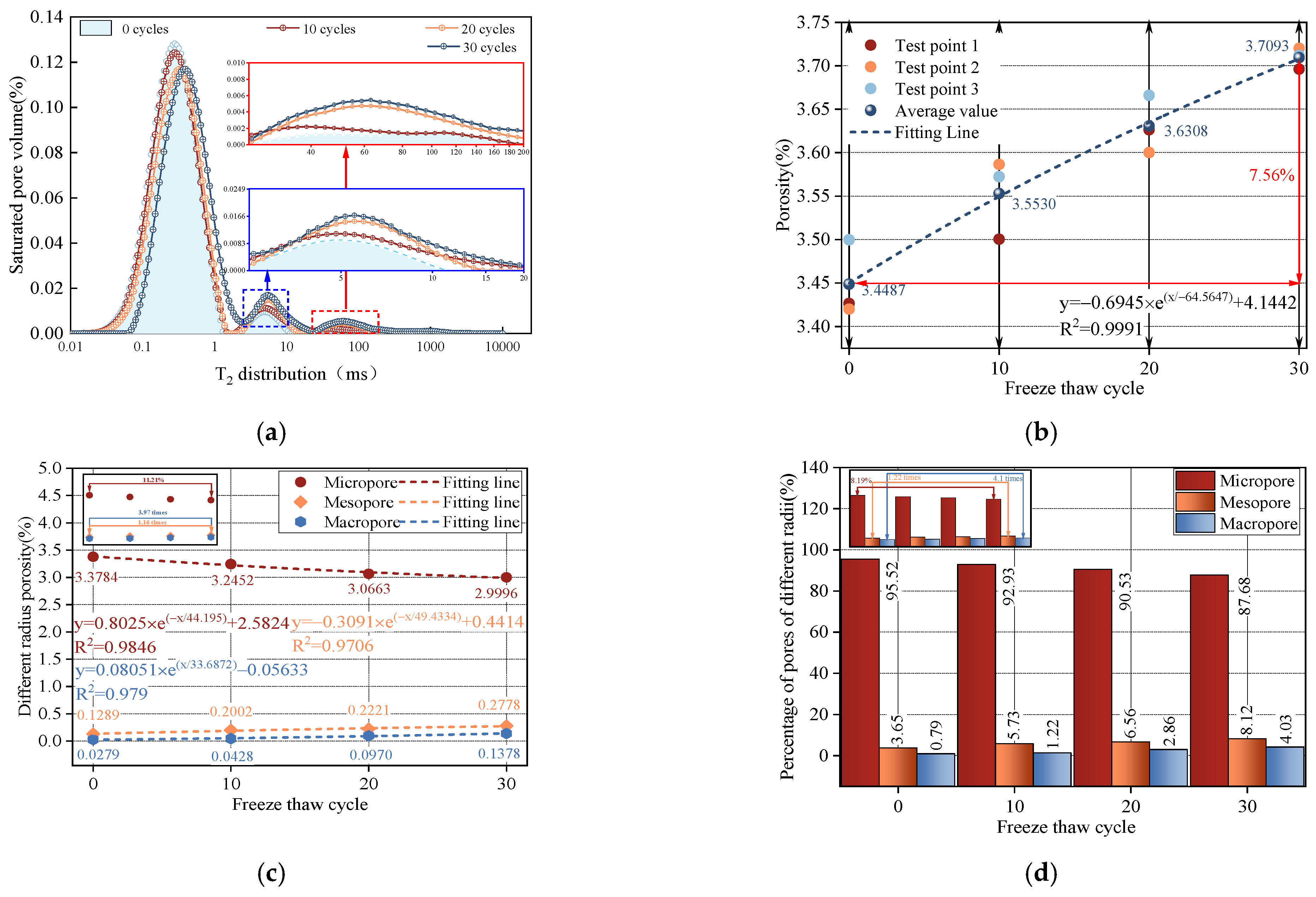

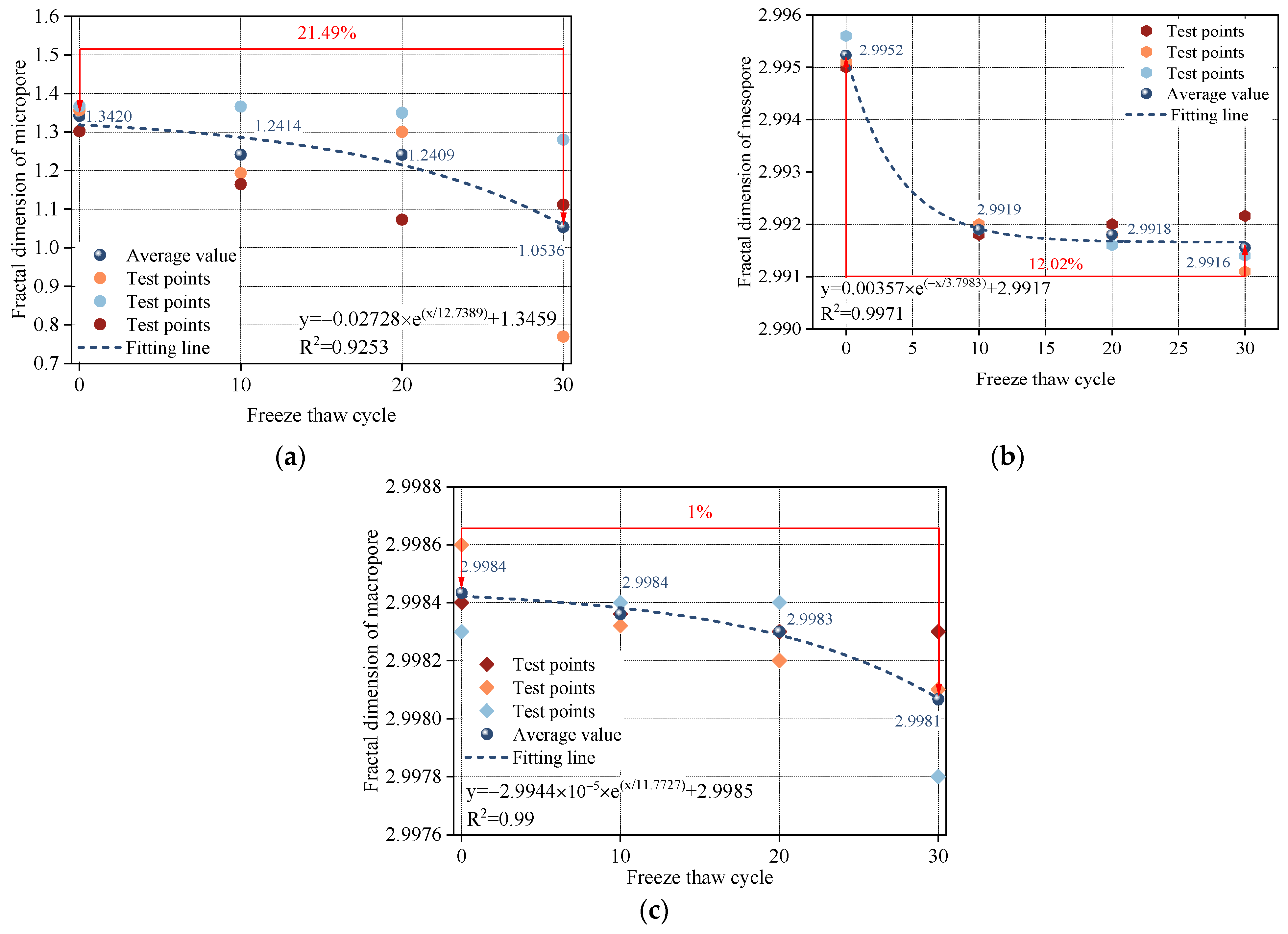

3.1. Evolutionary Patterns of Microstructural Parameters Under F-T Cycles

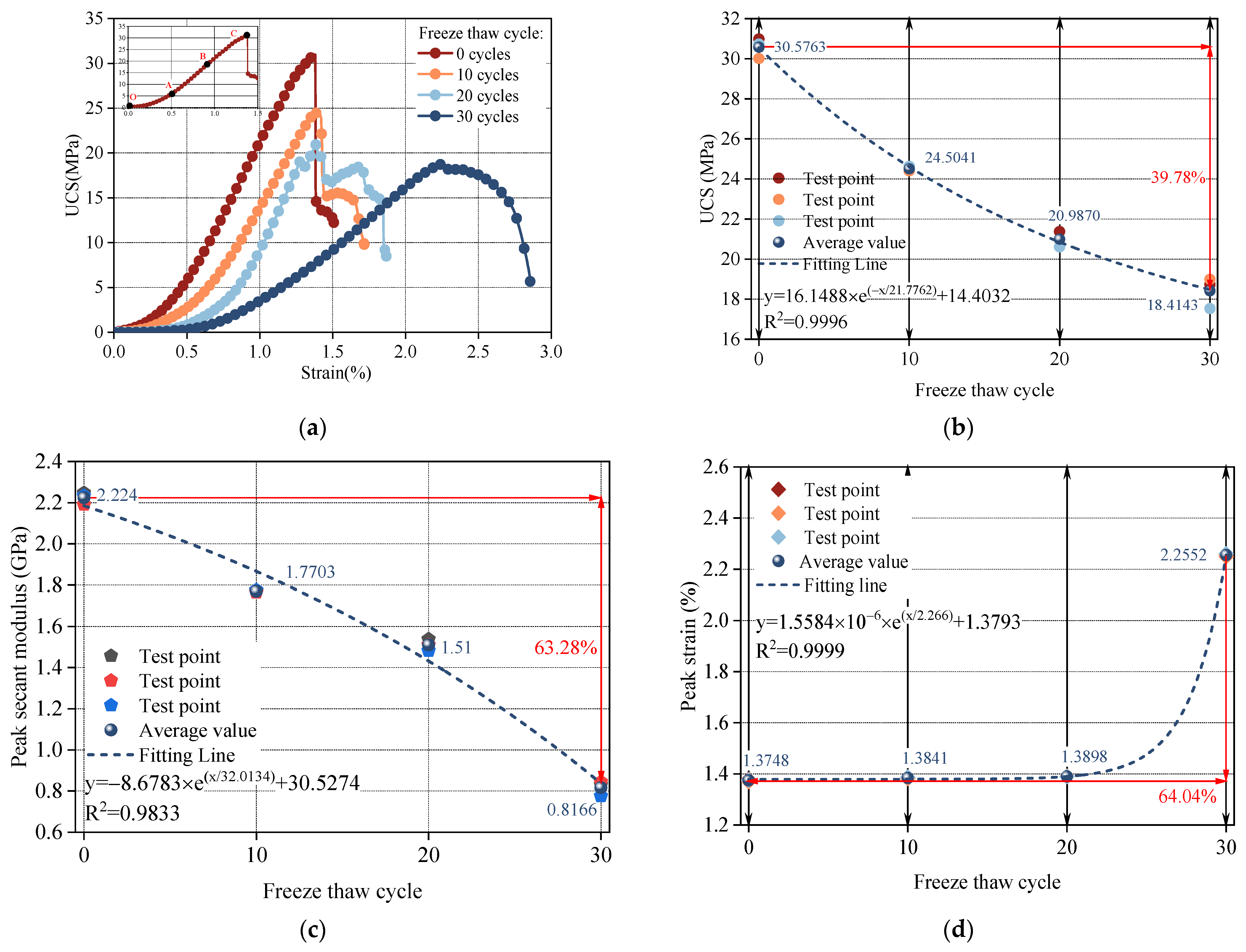

3.2. Evolutionary Patterns of Uniaxial Mechanical Properties Under F-T Cycles

4. Discussion

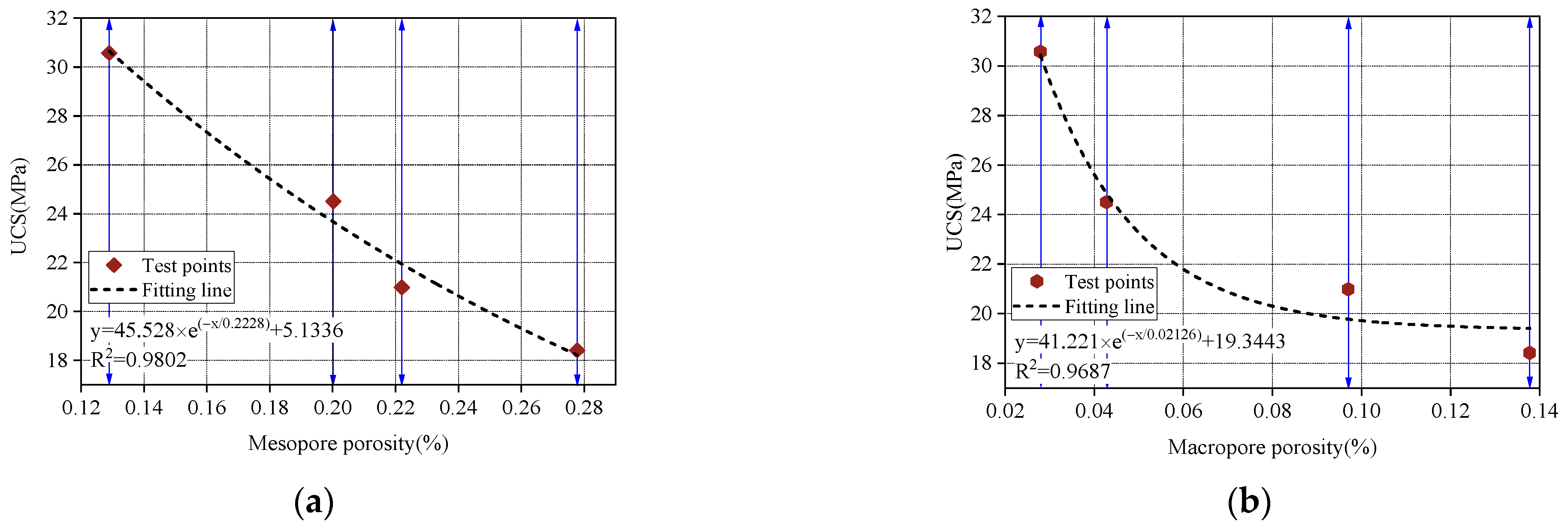

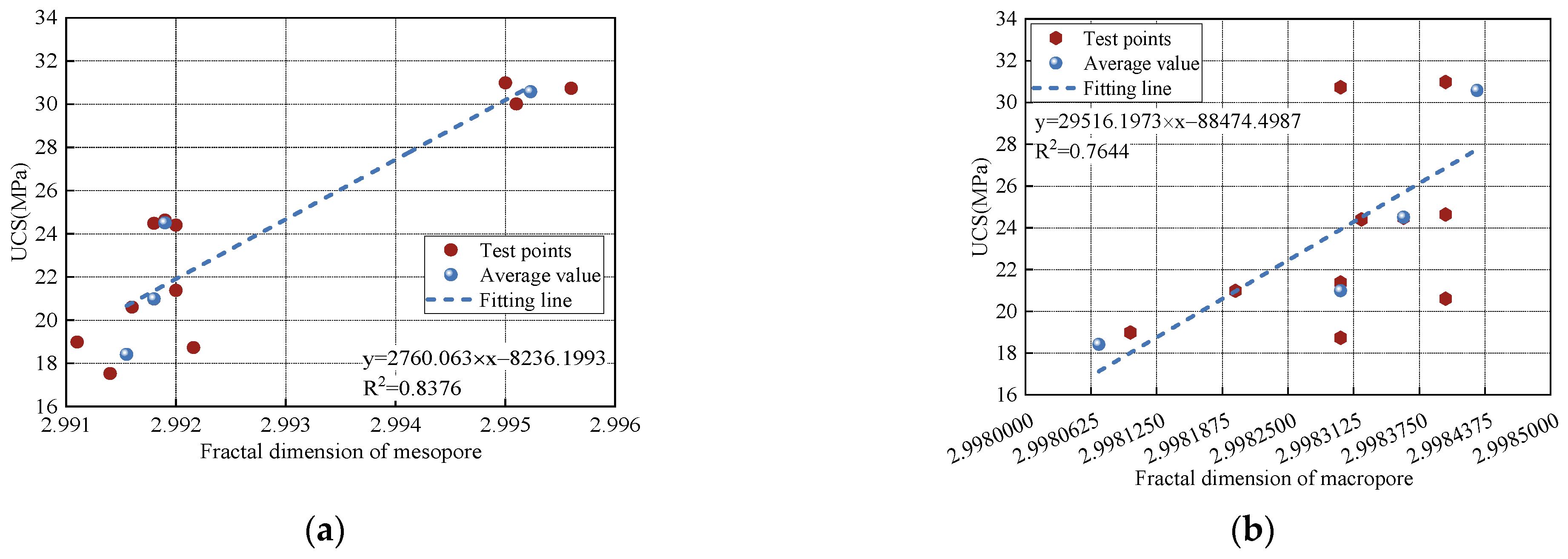

4.1. Correlation Analysis Between Microscopic Structure and Uniaxial Strength Under F-T Cycles

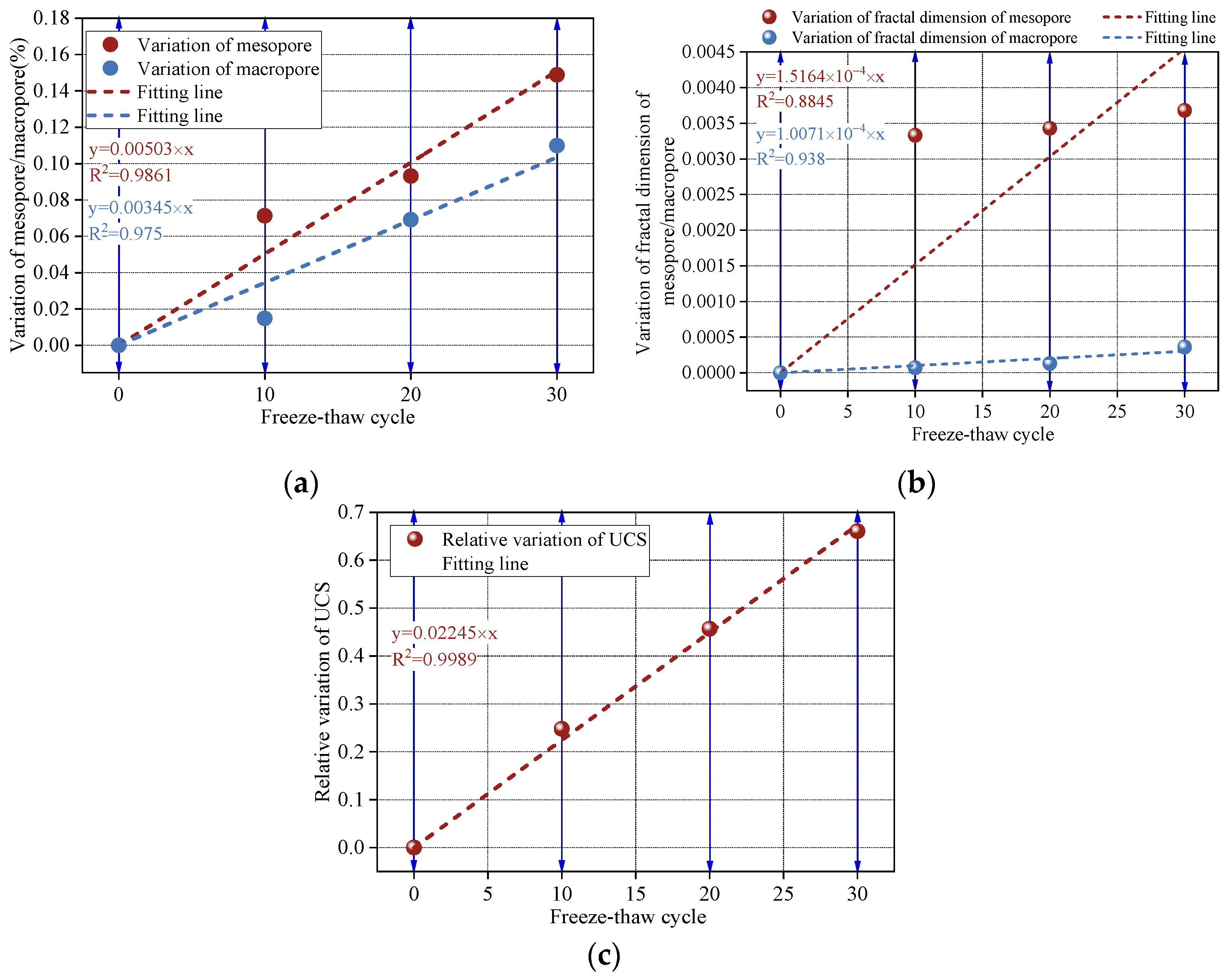

4.2. Construction of a F-T Deterioration Model for UCS Based on Mesopore Porosity

5. Conclusions

- (1)

- With increasing F-T cycles, the total porosity, mesopore porosity, and macropore porosity of sandstone all showed an increasing trend, while the micropore ratio decreased. All porosity parameters exhibited clear exponential relationships with the number of cycles. Additionally, the fractal dimensions of micropores, mesopores, and macropores decreased exponentially with F-T cycles.

- (2)

- The compaction stage in the stress–strain curve became more pronounced as the number of F-T cycles increased. Meanwhile, both the peak strength and peak secant modulus decreased, whereas peak strain increased. All these parameters exhibited significant exponential relationships with the number of cycles.

- (3)

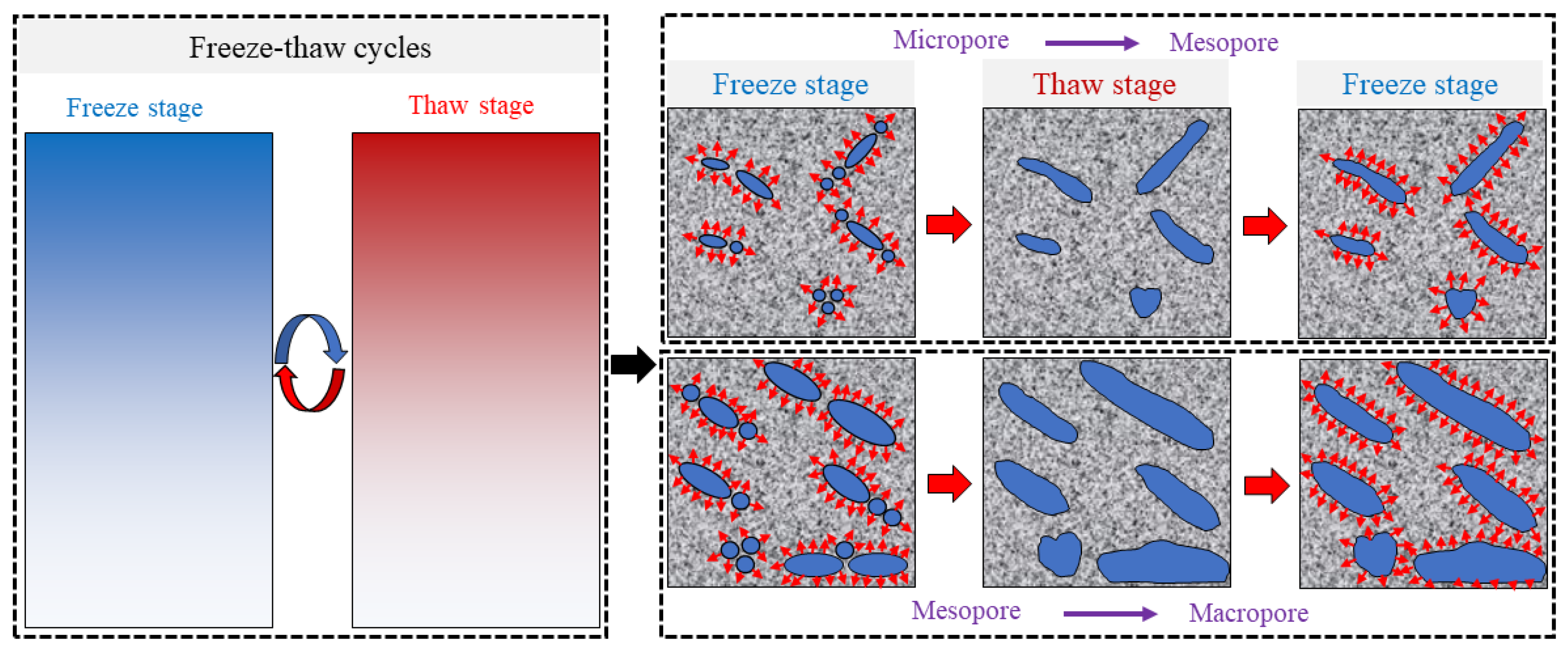

- Repeated F-T cycles induced water–ice phase transitions within pore water. When the volumetric expansion caused by the phase change exceeded the tensile resistance of the pore walls, micropores tended to expand into mesopores, and mesopores further evolved into macropores. Consequently, the micropore ratio decreased while mesopore and macropore ratios increased, resulting in an overall increase in total porosity. Micropores did not exhibit fractal characteristics, whereas mesopores and macropores showed clear fractal features. The transition from micropores to mesopores and from mesopores to macropores disrupted the self-similar power-law distribution of pore radii, leading to a decrease in fractal dimensions.

- (4)

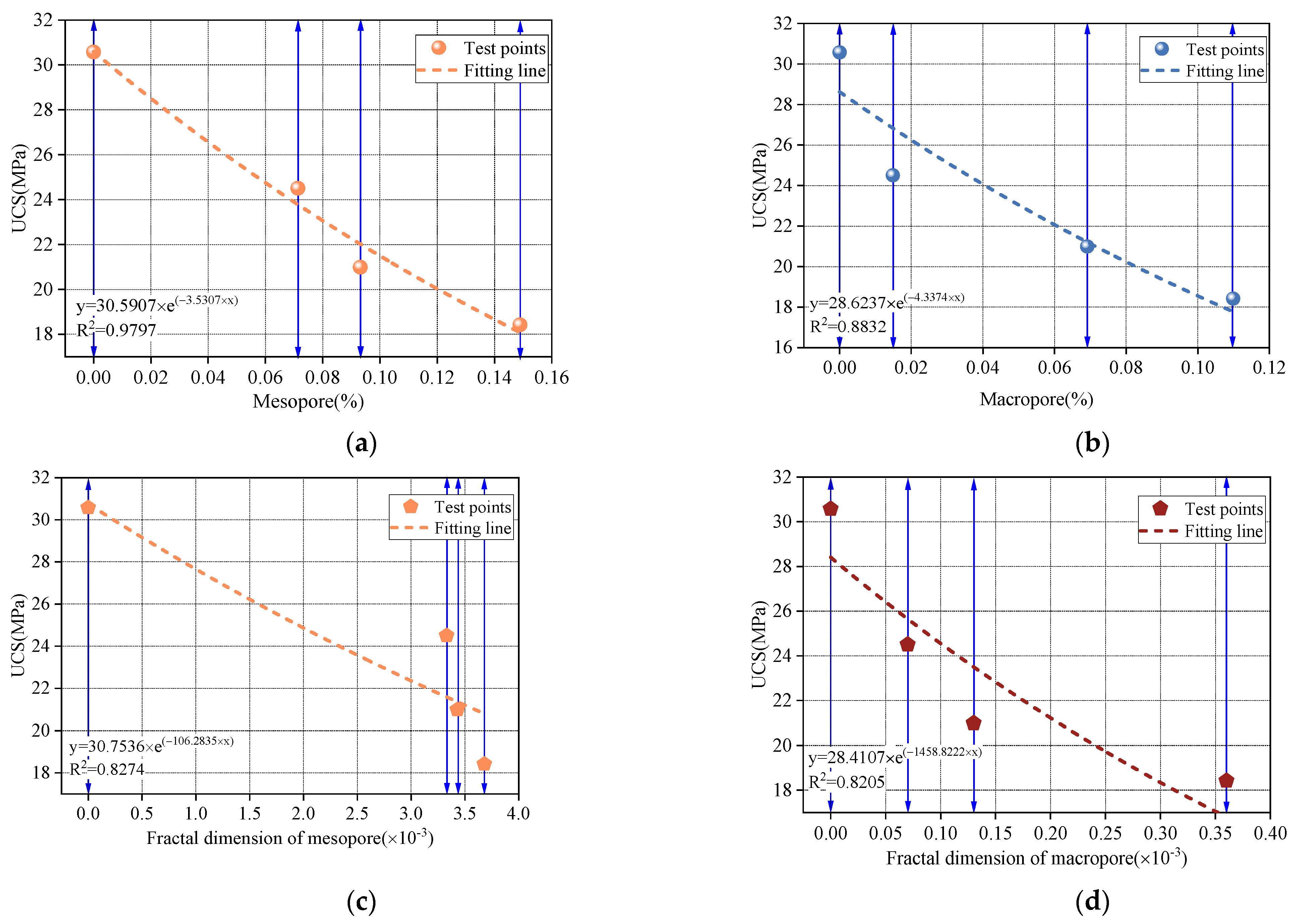

- The mesopore and macropore porosity both exhibited strong exponential correlations with UCS, with the mesopore ratio showing a stronger correlation. Similarly, the fractal dimensions of mesopores and macropores also showed exponential relationships with strength, with the mesopore fractal dimension demonstrating a stronger association. As the mesopore and macropore ratios increased, the compaction stage in the stress–strain curve became more evident, and peak strain increased. During loading failure, the interconnected mesopores caused by freeze–thaw damage reduced the deformation resistance and bearing capacity, resulting in a decrease in both the peak secant modulus and peak strength.

- (5)

- The variation in mesopore showed a strong exponential correlation with UCS. The F-T degradation model established based on mesopore variation provided a reliable means to evaluate the peak mechanical strength of sandstone subjected to different F-T cycles.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Pu, H.; Xue, K.; Xu, J.; Ni, H. Mechanical Response and Damage Characteristics of Frozen–Thawed Sandstone Across Various Temperature Ranges Under Impact Loads. Fractal Fract. 2025, 9, 128. [Google Scholar] [CrossRef]

- Li, J.; Tan, S.; Yang, C.; Chen, H.; Lin, Y. Analysis of damage characteristics for skarn subjected to F-T cycles based on fractal theory. Fractal Fract. 2023, 7, 354. [Google Scholar] [CrossRef]

- Kang, X.; Li, H.; Zhang, G.; Li, S.; Shan, L.; Zhao, J.; Zhang, Z. A Binary Medium Constitutive Model for Frozen Solidified Saline Soil in Cold Regions and Its Fractal Characteristics Analysis. Fractal Fract. 2024, 8, 33. [Google Scholar] [CrossRef]

- Xiong, X.; Gao, F.; Zhou, K.; Yang, C.; Li, J. Mechanical Properties and Strength Evolution Model of Sandstone Subjected to Freeze–Thaw Weathering Process: Considering the Confining Pressure Effect. Mathematics 2022, 10, 3841. [Google Scholar] [CrossRef]

- Yu, S.; Deng, J.; Deng, H.; Gao, F.; Li, J.; Wang, Y. Brittle Characteristic and Microstructure of Sandstone under Freezing-Thawing Weathering. Adv. Civ. Eng. 2020, 2020, 8893278. [Google Scholar] [CrossRef]

- Deng, H.; Yu, S.; Deng, J.; Ke, B.; Bin, F. Experimental investigation on energy mechanism of freezing-thawing treated sandstone under uniaxial static compression. KSCE J. Civ. Eng. 2019, 23, 2074–2082. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Ke, B.; Liu, C.; Yang, X. Degradation of physical and mechanical properties of sandstone subjected to freeze-thaw cycles and chemical erosion. Cold Reg. Sci. Technol. 2018, 155, 37–46. [Google Scholar] [CrossRef]

- Li, J.; Zhou, K.; Liu, W.; Deng, H. NMR research on deterioration characteristics of microscopic structure of sandstones in F-T cycles. Trans. Nonferrous Met. Soc. China 2016, 26, 2997–3003. [Google Scholar] [CrossRef]

- Gao, F.; Wang, Q.; Deng, H.; Zhang, J.; Tian, W.; Ke, B. Coupled effects of chemical environments and freeze–thaw cycles on damage characteristics of red sandstone. Bull. Eng. Geol. Environ. 2017, 76, 1481–1490. [Google Scholar] [CrossRef]

- Liu, C.; Deng, H.; Zhao, H.; Zhang, J. Effects of F-T treatment on the dynamic tensile strength of granite using the Brazilian test. Cold Reg. Sci. Technol. 2018, 155, 327–332. [Google Scholar] [CrossRef]

- Xiong, X.; Gao, F.; Li, J.; Zhou, K.; Yang, C. Pore Structure Evolution Characteristics and Damage Mechanism of Sandstone Subjected to Freeze–Thaw Cycle Treatment: Insights from Low-Field Nuclear Magnetic Resonance Testing and Fractal Theory. Fractal Fract. 2025, 9, 293. [Google Scholar] [CrossRef]

- Gao, F.; Xiong, X.; Xu, C.; Zhou, K. Mechanical property deterioration characteristics and a new constitutive model for rocks subjected to F-T weathering process. Int. J. Rock Mech. Min. Sci. 2021, 140, 104642. [Google Scholar] [CrossRef]

- Gao, F.; Xiong, X.; Zhou, K.; Li, J.; Shi, W. Strength deterioration model of saturated sandstone under F-T cycles. Rock Soil Mech. 2019, 40, 926–932. [Google Scholar]

- Yang, C.; Zhou, K.; Xiong, X.; Deng, H.; Pan, Z. Experimental investigation on rock mechanical properties and infrared radiation characteristics with F-T cycle treatment. Cold Reg. Sci. Technol. 2021, 183, 103232. [Google Scholar] [CrossRef]

- Li, J.; Zhu, L.; Zhou, K.; Chen, H.; Gao, L.; Lin, Y.; Shen, Y. Non-linear creep damage model of sandstone under F-T cycle. J. Cent. South Univ. 2021, 28, 954–967. [Google Scholar] [CrossRef]

- Yu, M.; Wang, Z.; Xu, Y.; Wang, Y.; Wang, L.; Wen, J. Study on mechanical properties and energy evolution characteristics of excavation unloading rock under freeze–thaw temperature range. Eng. Fract. Mech. 2025, 325, 111293. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, N.; Niu, H.; Shi, J. Study on in-situ CT damage of concrete subjected to compressive loading after F-T cycles based on deep learning and DVC technology. Constr. Build. Mater. 2025, 482, 141599. [Google Scholar] [CrossRef]

- Wu, B.; Zhu, H.H.; Guo, X.H.; Wang, D.Y.; Wang, C.; Meguid, M.A. Experimental investigation of thermo-hydro-mechanical interactions in frozen soil using an integrated monitoring system. Eng. Geol. 2025, 335, 108136. [Google Scholar] [CrossRef]

- Gou, D.; Li, Y.; Hu, Y.; Zhou, Z.; Zhang, S.; Li, K.; Wang, K. Investigations on mechanical behaviors and failure mechanisms of rock-concrete composite specimens with different interface inclinations subjected to F-T cycles and uniaxial compression. Eng. Fract. Mech. 2025, 332, 111196. [Google Scholar] [CrossRef]

- Jiang, C.; Guo, W.; Chen, H.; Zhu, Y.; Jin, C. Effect of filler type and content on mechanical properties and microstructure of sand concrete made with superfine waste sand. Constr. Build. Mater. 2018, 192, 442–449. [Google Scholar] [CrossRef]

- Diambra, A.; Festugato, L.; Ibraim, E.; Peccin da Silva, A.; Consoli, N.C. Modelling tensile/compressive strength ratio of artificially cemented clean sand. Soils Found. 2018, 58, 199–211. [Google Scholar] [CrossRef]

- Ueyendah, S.; Lezgy-Nazargah, M.; Eskandari-Naddaf, H.; Emamian, S.A. Predicting the mechanical properties of cement mortar using the support vector machine approach. Constr. Build. Mater. 2021, 291, 123396. [Google Scholar] [CrossRef]

- Chuta, E.; Colin, J.; Jeong, J. The impact of the water-to-cement ratio on the surface morphology of cementitious materials. J. Build. Eng. 2020, 32, 101716. [Google Scholar] [CrossRef]

- Dai, S.; Sun, Q.; Hao, R.; Xiao, Y. Study on failure characteristics and Acoustic Emission laws of Rock-like specimens under Uniaxial Compression. Appl. Sci. 2024, 14, 8893. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, C.; Xue, L.; Dong, J.; Jiang, T. Experimental study on the reasonable proportions of rock-like materials for water-induced strength degradation in rock slope model test. Sci. Rep. 2023, 13, 9288. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Zhang, M.; Chen, H.; Zhang, C.; Ma, F.; Zheng, P. Mechanical properties of cement-based rocks with arc-shaped cracks under uniaxial compression. Constr. Build. Mater. 2025, 484, 141838. [Google Scholar] [CrossRef]

- SL/T 264-2020; Rock Test Regulations for Water Conservancy and Hydropower Engineering. People’s Republic of China Ministry of Water Resources: Beijing, China, 2020. (In Chinese)

- Jiang, Z.; Cai, G.; Liu, Y.; Wang, P.; Yu, S. Pore structure and mechanical characteristics of CRS mortar based on NMR and fractal theory. Constr. Build. Mater. 2024, 457, 139459. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, H.; Jiang, Z.; Tian, G.; Wang, P.; Yu, S. Research on influence laws of aggregate sizes on pore structures and mechanical characteristics of cement mortar. Constr. Build. Mater. 2024, 442, 137606. [Google Scholar] [CrossRef]

- Jiang, Z.; Cai, G.; He, H.; Tian, G.; Liu, Y.; Wu, M. Pore structure evolution of mortars with manufactured sand aggregate under the influence of aggregate size and water saturation environment. Measurement 2025, 241, 115736. [Google Scholar] [CrossRef]

- Jiang, Z.; Deng, H.; Liu, T.; Tian, G.; Tang, L. Study on Microstructural Evolution of Marble Under Cyclic Dynamic Impact Based on NMR. IEEE Access 2019, 7, 138043–138055. [Google Scholar] [CrossRef]

- Li, K.S.; Chen, L.X.; Yang, S.Q.; Song, G.L.; Liu, C.X. Multiscale Deterioration of Physical and Triaxial Mechanical Behaviors of Fine-Grained Sandstone Under Cyclic Freezing–Thawing: Experimental Observation and Microstructural Interpretation. Rock Mech. Rock Eng. 2025, 1–25. [Google Scholar] [CrossRef]

- Shi, Y.; Mu, Y.; Ma, W.; Zhang, L.; Yang, C.; Ding, Z.; Han, D. A novel NMR-based experimental study of the water-heat transfer of coarse-grained soil during the F-T process. Int. Commun. Heat Mass Transf. 2025, 165, 109011. [Google Scholar]

| Material | Traits | Main Ingredients | Particle Size | Density (g/cm3) | |||

|---|---|---|---|---|---|---|---|

| Portland cement | Taupe powder | 3CaO·SiO2 | 2CaO·SiO2 | 3CaO·Al2O3 | 4CaO·Al2O3·Fe2O3 | - | - |

| 52.8% | 20.7% | 11.5% | 8.8% | ||||

| Quartz sand | Yellow and white particles | Quartz > 99% | 0.5–1.0 mm | 1.49 | |||

| Naphthalene water reduction | Brow–yellow powder | β-Naphthalene sulfonate sodium formaldehyde condensate | - | - | |||

| Silica fumes | White powder | SiO2 > 99% | 1 µm | 2.2–2.6 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, J.; Zhou, K.; Tian, G.; Liu, T. Study on Multi-Scale Damage Evolution of Sandstone Under Freeze–Thaw Cycles: A Computational Perspective Based on Pore Structure and Fractal Dimension. Fractal Fract. 2025, 9, 534. https://doi.org/10.3390/fractalfract9080534

Qiu J, Zhou K, Tian G, Liu T. Study on Multi-Scale Damage Evolution of Sandstone Under Freeze–Thaw Cycles: A Computational Perspective Based on Pore Structure and Fractal Dimension. Fractal and Fractional. 2025; 9(8):534. https://doi.org/10.3390/fractalfract9080534

Chicago/Turabian StyleQiu, Jianhui, Keping Zhou, Guanglin Tian, and Taoying Liu. 2025. "Study on Multi-Scale Damage Evolution of Sandstone Under Freeze–Thaw Cycles: A Computational Perspective Based on Pore Structure and Fractal Dimension" Fractal and Fractional 9, no. 8: 534. https://doi.org/10.3390/fractalfract9080534

APA StyleQiu, J., Zhou, K., Tian, G., & Liu, T. (2025). Study on Multi-Scale Damage Evolution of Sandstone Under Freeze–Thaw Cycles: A Computational Perspective Based on Pore Structure and Fractal Dimension. Fractal and Fractional, 9(8), 534. https://doi.org/10.3390/fractalfract9080534