Effect of Layer Spacing on Fracture Development and Seepage Evolution of Surrounding Rocks During Repeated Mining Under Insufficiently Collapsed Gob

Abstract

1. Introduction

2. Methodology

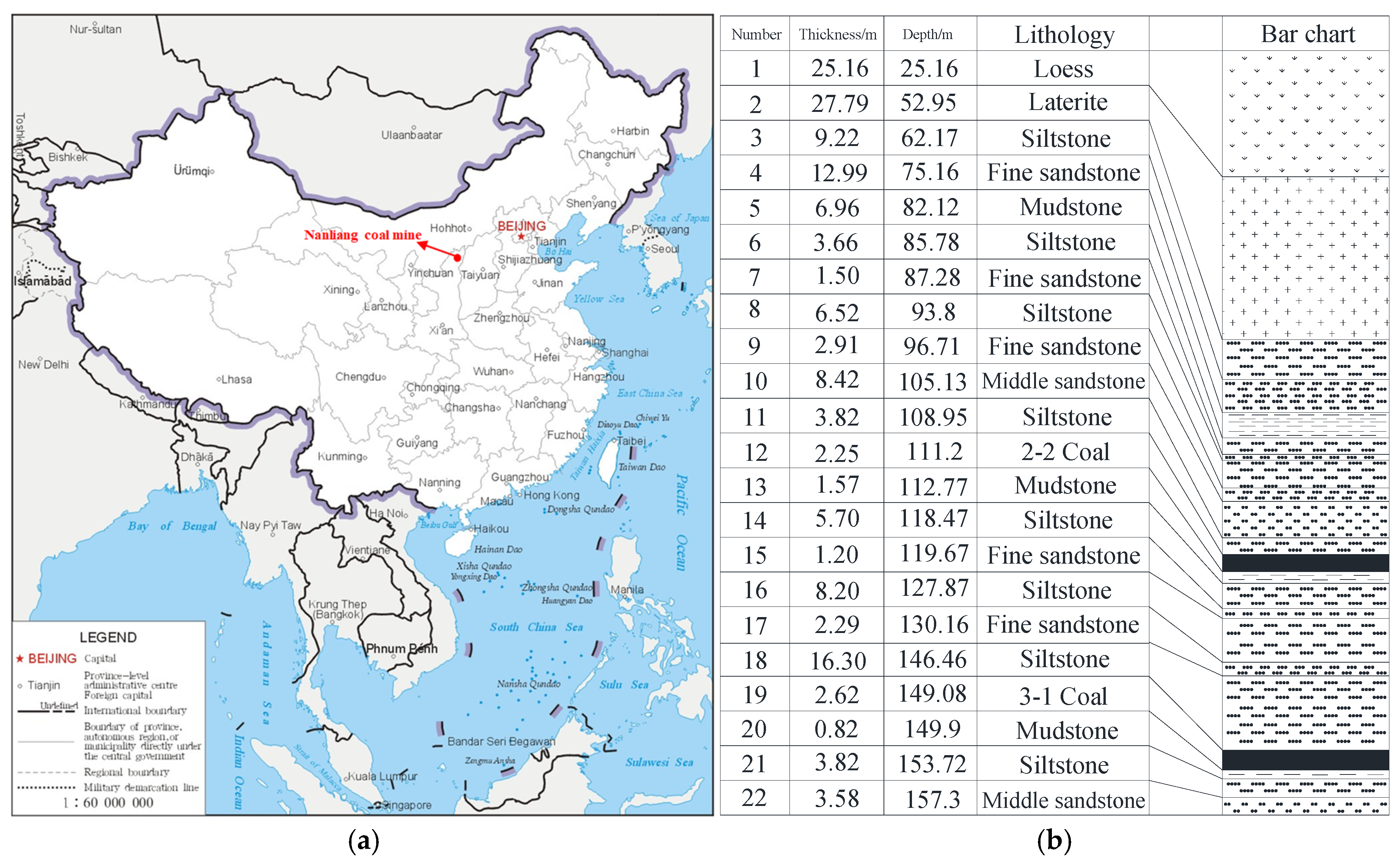

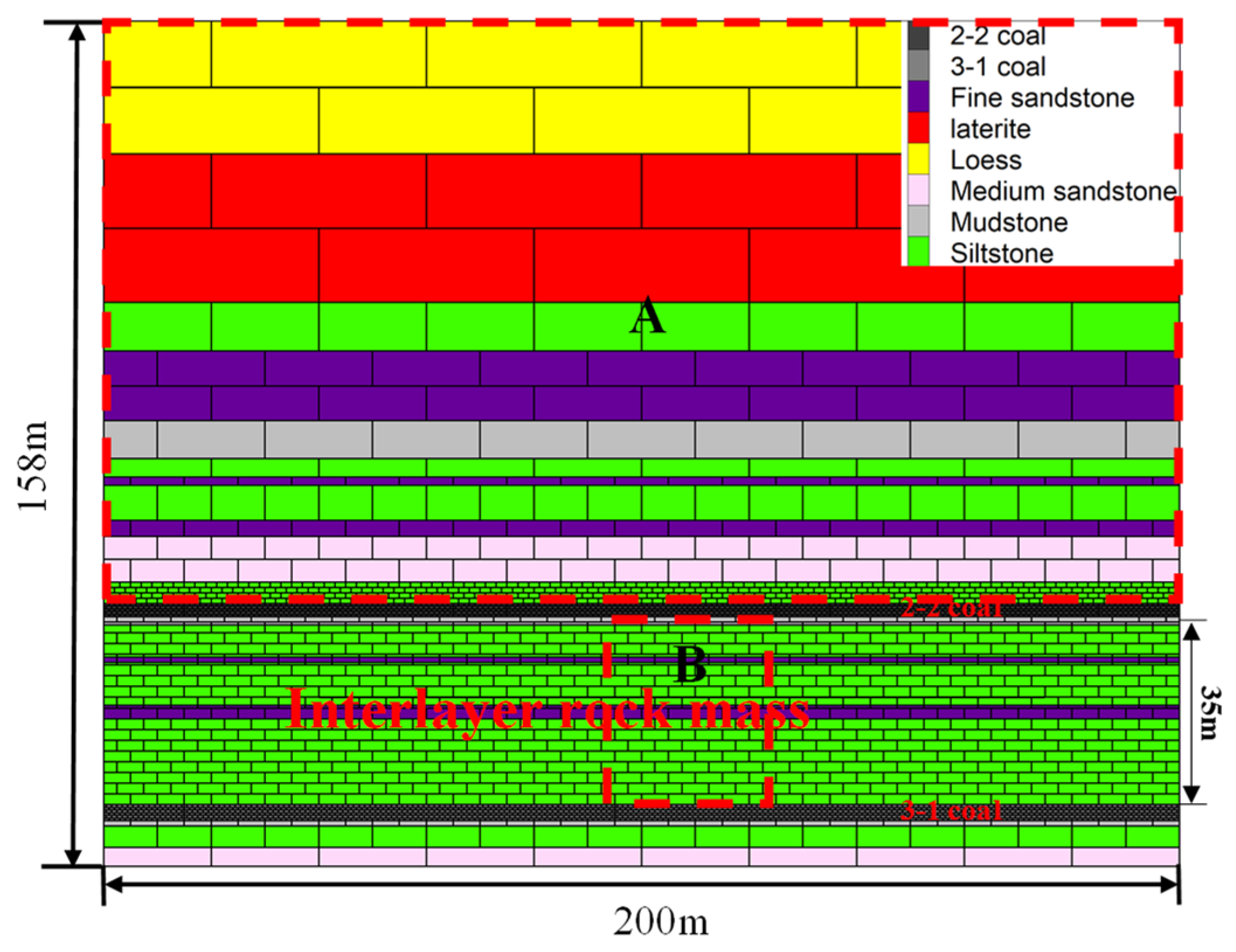

2.1. Numerical Modeling of Repeated Mining Under Insufficiently Collapsed Gob

2.2. Seepage Simulation of Repeated Mining Under Insufficiently Collapsed Gob

3. Results and Discussion

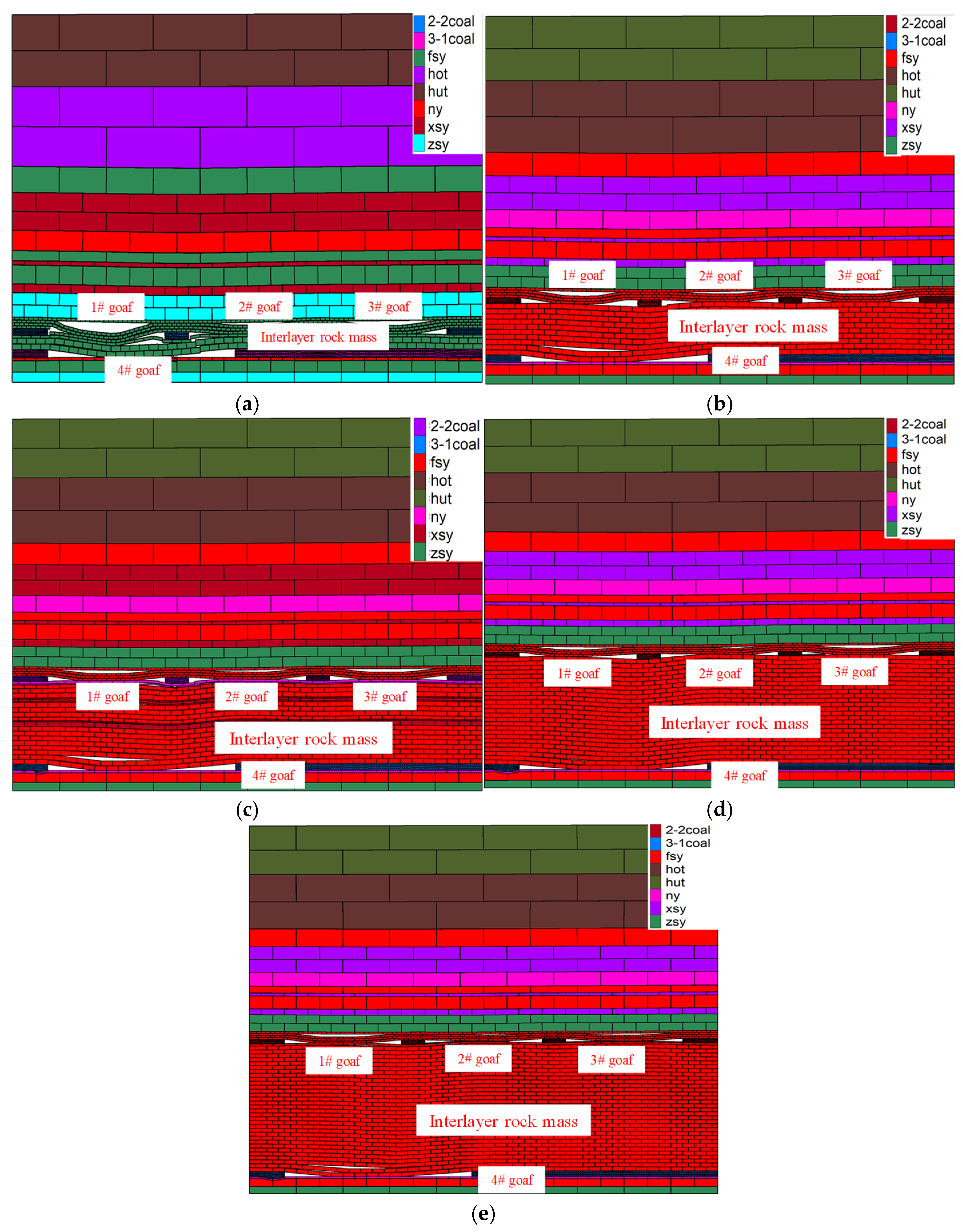

3.1. Effect of Layer Spacing on Strata Collapse

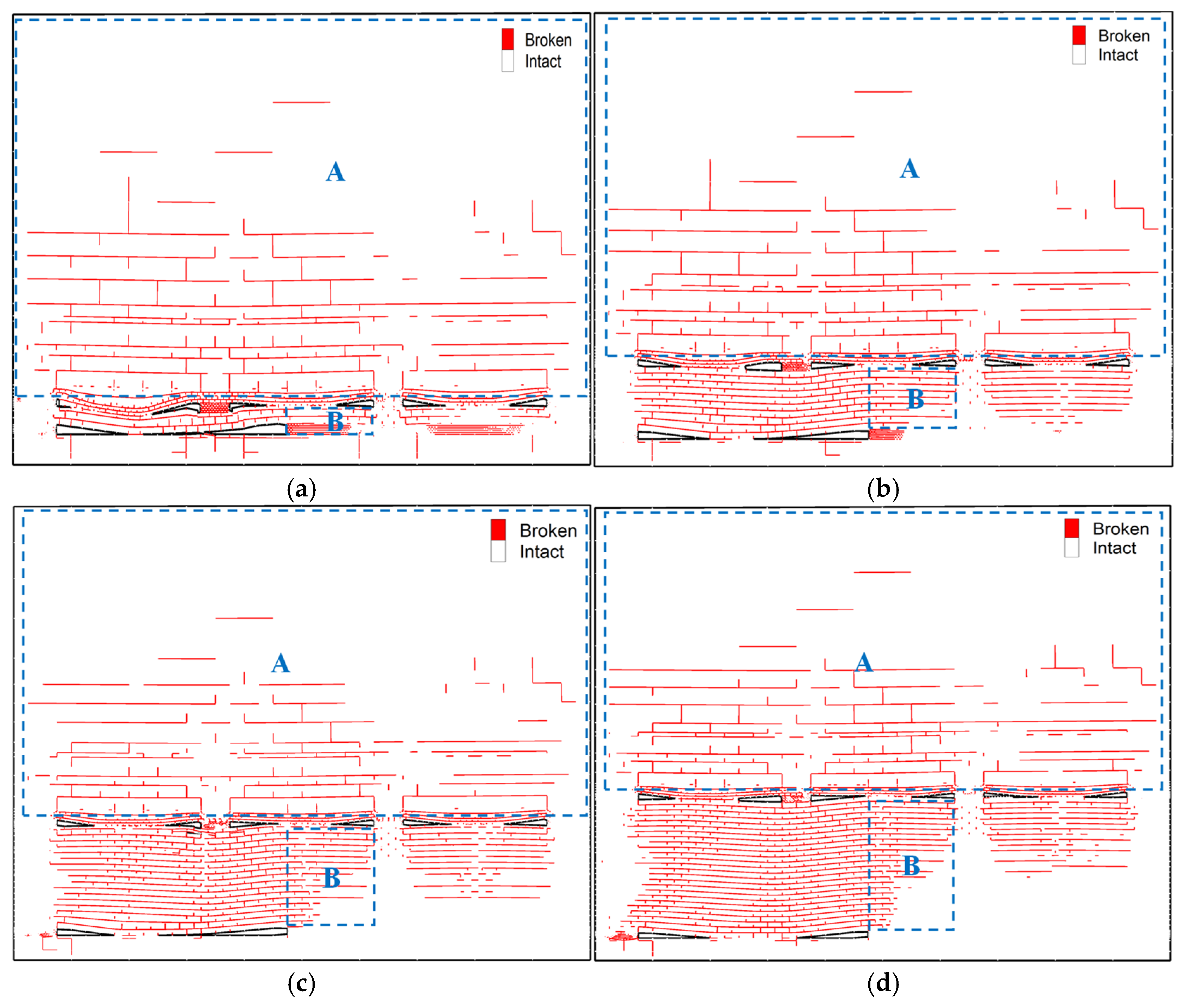

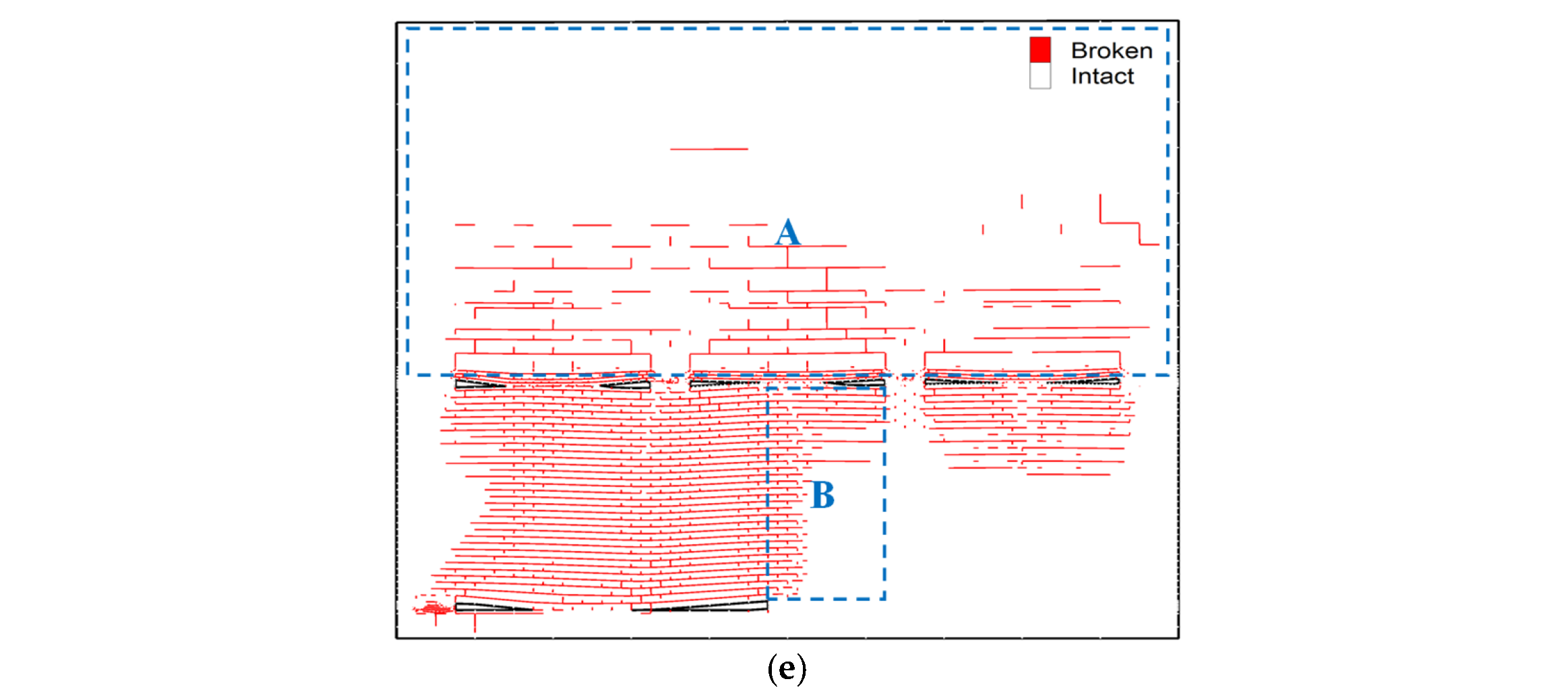

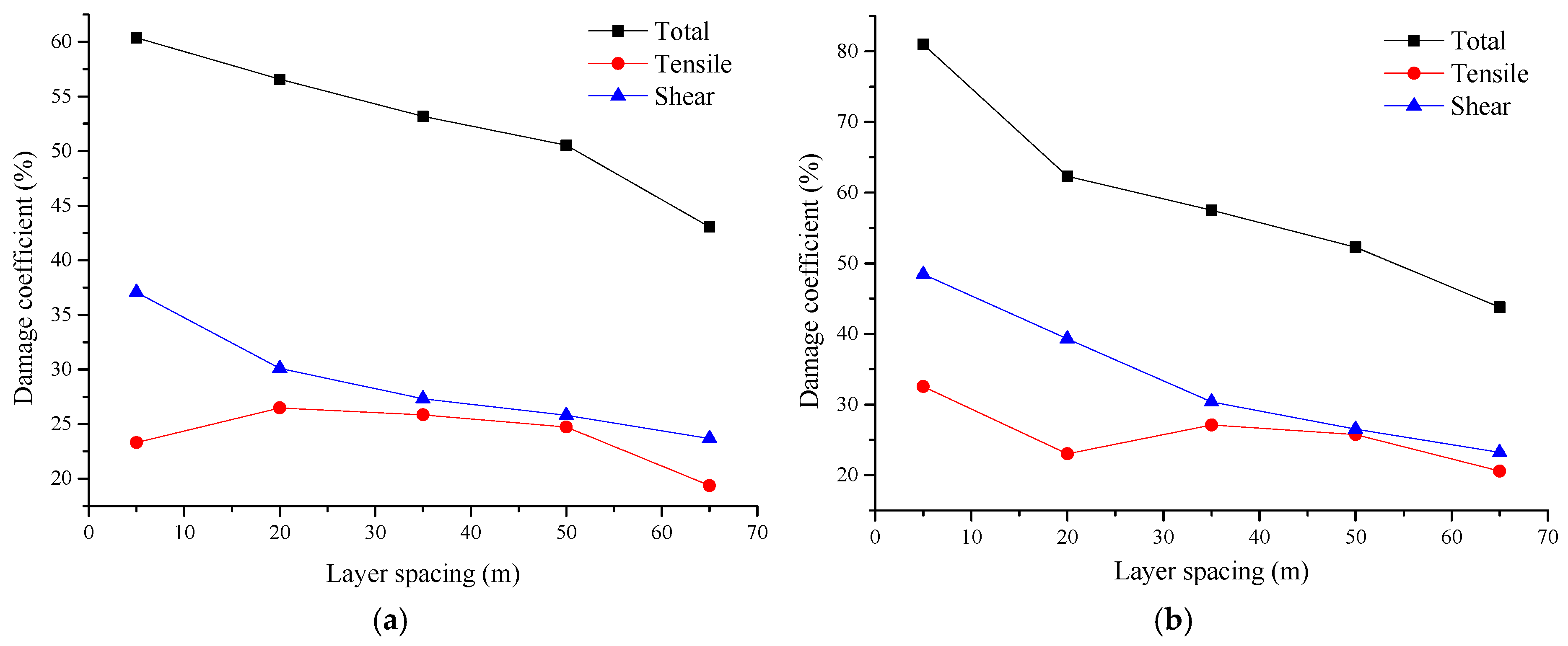

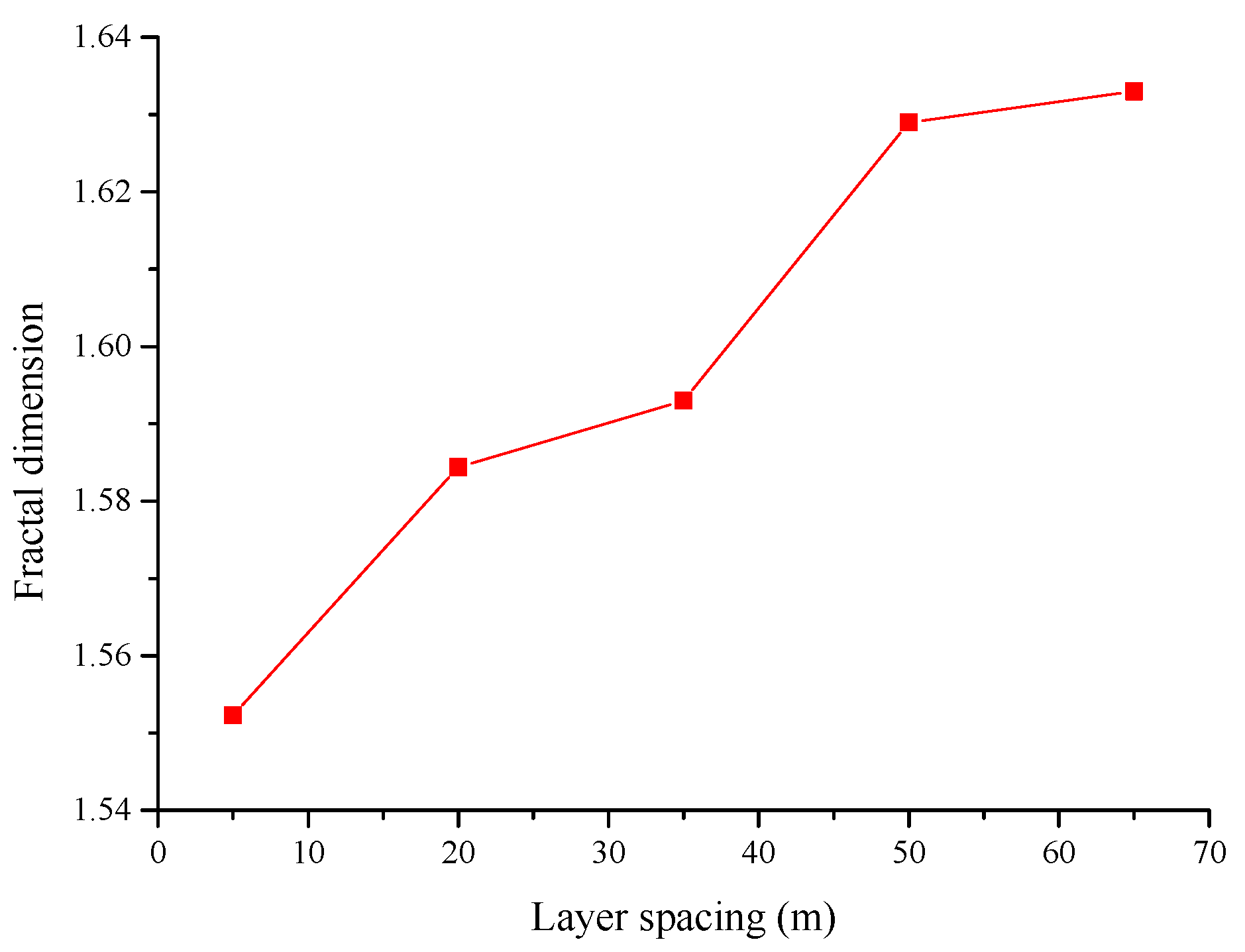

3.2. Effect of Layer Spacing on the Fracture Development of Surrounding Rocks

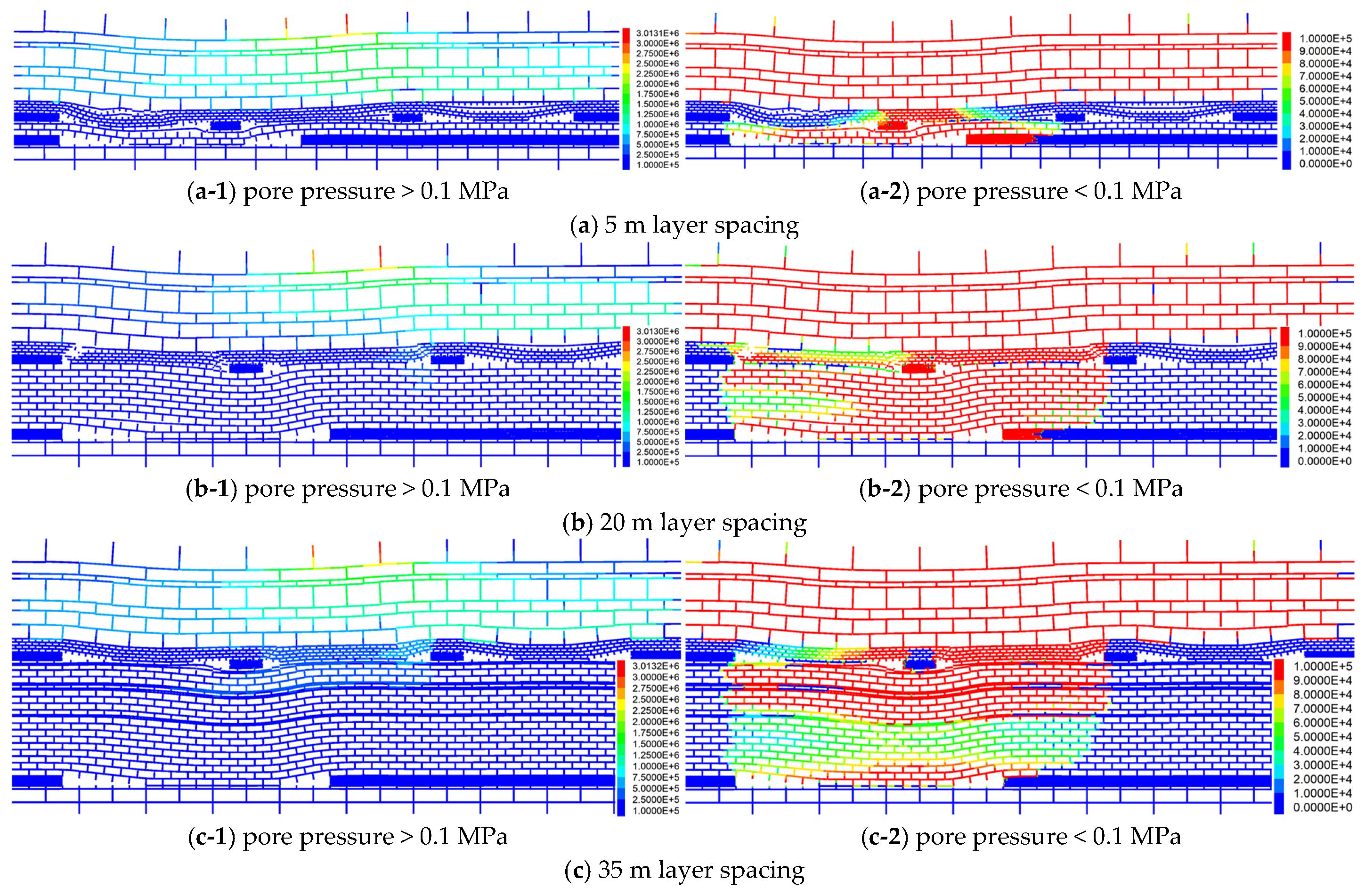

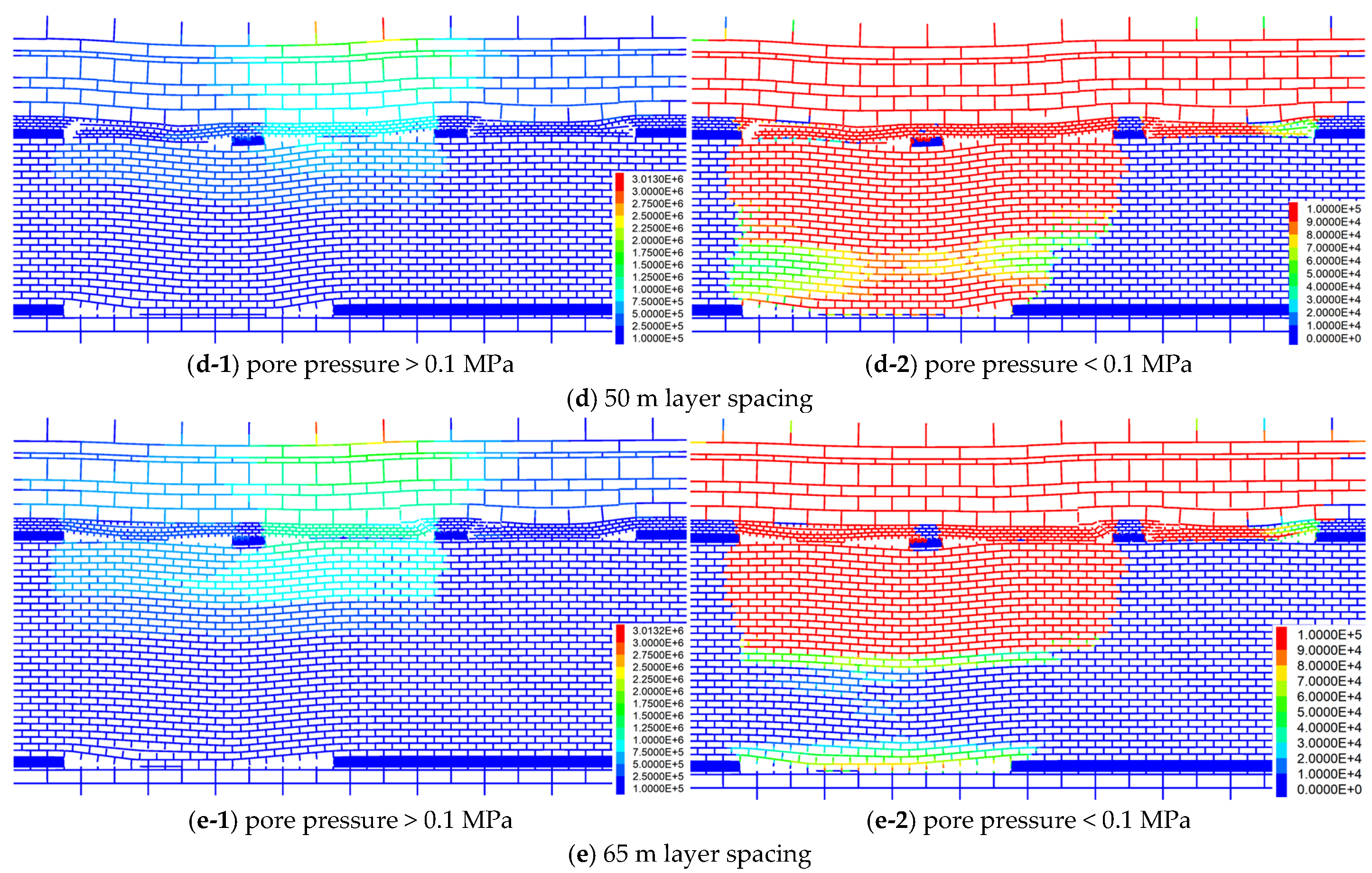

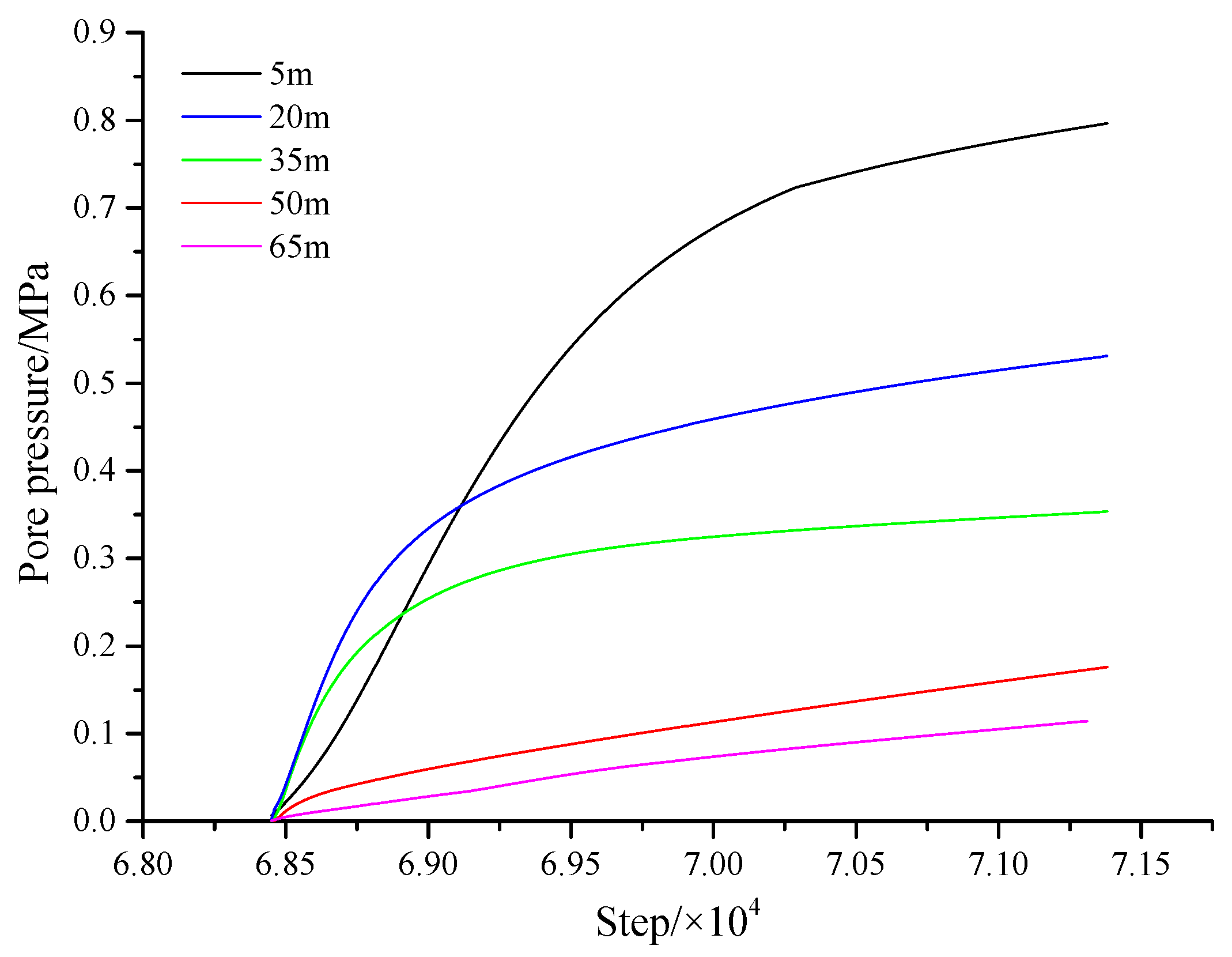

3.3. Effect of Layer Spacing on the Seepage Evolution of Surrounding Rocks

4. Conclusions

- (1)

- An increase in the layer spacing was found to be related to a decrease in the collapse magnitude of the interlayer rock. The proposed damage coefficient—the ratio of the tension and shear failure lengths to the total structural contact—helped confirm the progressive decline in the fracture development intensity within the overburden and pre-face zones. Fractal analysis revealed enhanced fracture complexity at wider spacings, although shear failure dominated across all interlayer configurations. Notably, minimal spacing (5 m) amplified shear−tension disparities.

- (2)

- Layer spacing inversely influenced the pore pressure and permeability in the strata ahead of the advancing face. Wider spacings diminished the pore pressure zones and attenuated permeability−stress coupling, with reduction rates decelerating progressively. This trend suggests a decrease in the number of fluid channels and stress concentrations with increasing layer spacing, consistent with the observed decrease in the damage coefficients. These results are in good agreement with field expectations, emphasizing the role of layer spacing as a critical parameter controlling post-mining hydromechanical behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Chang, Z.; Yang, Z.; Wang, X.; Qin, D. Combined support technology of roadway under mined gob of ultra-distance seams in deep mine. J. Min. Saf. Eng. 2018, 35, 686–692. [Google Scholar]

- Cheng, Z.; Chen, L.; Su, S.; Wang, G.; Zou, Y.; Zhang, Y.; Zou, Q.; Jiang, L.; Yan, D.; Du, Z.; et al. Outburst prevention mode of ground and underground technology joint and its dynamic evaluation in contiguous coal seams. J. China Coal Soc. 2020, 45, 1635–1647. [Google Scholar]

- Lian, Z.; Wang, J.; Hao, C. Numerical simulation and experimental research of surrounding rock deformation of floor roadway under short-distance coal seam group combined mining. J. Coal Sci. Eng. (China) 2010, 16, 230–234. [Google Scholar] [CrossRef]

- Tulu, I.; Esterhuizen, G.; Klemetti, T.; Murphy, M.; Sumner, J.; Sloan, M. A case study of multi-seam coal mine entry stability analysis with strength reduction method. Int. J. Min. Sci. Technol. 2016, 26, 193–198. [Google Scholar] [CrossRef]

- Huang, Q.; Han, J. Study on fracture evolution mechanism of shallow-buried close coal seam mining. J. Min. Saf. Eng. 2019, 36, 706–711. [Google Scholar]

- Zhang, C.; Wu, J.; Wei, C.; Yang, Y.; Shen, W. Fracture Evolution Regularity of Surrounding Rock Under Different Interlaminar Strata Structure in Short-Distance Coal Seams Group: A Case Study in China. Geotech. Geol. Eng. 2021, 39, 3193–3206. [Google Scholar] [CrossRef]

- Li, J.; Jiao, Z. Dynamic evolution characteristics and mechanism of surrounding rock fractures during the repeated mining of closed distance deep coal seam. Rev. Int. Contam. Ambient. 2019, 35, 165–176. [Google Scholar] [CrossRef]

- Zou, J.; Wang, M.; Bai, L.; Yan, C. Numerical study on migration of overlying strata and propogation of cracks during multi-coal seams mining. Front. Earth Sci. 2023, 11, 1326597. [Google Scholar] [CrossRef]

- Pan, W.; Jiang, P.; Li, B.; Li, J.; Yang, Y. The spatial evolution law and water inrush mechanism of mining-induced overburden in shallow and short coal seam group. Sustainability 2022, 14, 5320. [Google Scholar] [CrossRef]

- Huang, H.; Yan, Z.; Yao, B.; Xu, H. Research on the Process of Fracture Development in Overlying Rocks Under Coal Seams Group Mining in Wanli Mining Area. J. Min. Saf. Eng. 2012, 29, 619–624. [Google Scholar]

- Cui, F.; Jia, C.; Lai, X.; Yang, Y.; Dong, S. Study on the law of fracture evolution under repeated mining of close-distance coal seams. Energies 2020, 13, 6064. [Google Scholar] [CrossRef]

- Iwanec, A.; Carter, J.; Hambleton, J. Geomechanics of subsidence above single and multi-seam coal mining. J. Rock Mech. Geotech. Eng. 2016, 8, 304–313. [Google Scholar] [CrossRef]

- Ghabraie, B.; Ren, G.; Smith, J. Characterising the multi-seam subsidence due to varying mining configuration, insights from physical modelling. Int. J. Rock Mech. Min. Sci. 2017, 93, 269–279. [Google Scholar] [CrossRef]

- Hoek, E.; Martin, C. Fracture initiation and propagation in intact rock—A review. J. Rock Mech. Geotech. Eng. 2014, 6, 287–300. [Google Scholar] [CrossRef]

- Moradian, Z.; Einstein, H.; Ballivy, G. Detection of Cracking Levels in Brittle Rocks by Parametric Analysis of the Acoustic Emission Signals. Rock Mech. Rock Eng. 2016, 49, 785–800. [Google Scholar] [CrossRef]

- Ning, J.; Liu, X.; Tan, Y.; Lu, Y. In situ investigations on failure evolution of overlying strata induced by mining multiple coal seams. Geotech. Test. J. 2017, 40, 244. [Google Scholar]

- Cheng, Z.; Qi, Q.; Li, H.; Zhang, L.; Liu, X. Evolution of the superimposed mining induced stress-fissure field under extracting of close distance coal seam group. J. China Coal Soc. 2016, 41, 367–375. [Google Scholar]

- Teng, F.; Yu, M.; Han, X.; Chao, J. Study on the mechanism of coal pillar breaking and fracture development under repeated mining in a close seam group. Front. Earth Sci. 2023, 10, 991304. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.; Cheng, Z.; Wen, Z.; Ma, Z.; Wu, G.; Liu, Y. Instability control of roadway surrounding rock in close-distance coal seam groups under repeated mining. Energies 2021, 14, 5193. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Z.; Zhang, S.; Liu, G.; Bai, Y. Relationship between failure characteristics and fracture spacing of surrounding rock of short-distance coal seams group. J. China Coal Soc. 2015, 40, 766–773. [Google Scholar]

- Guo, Q.; Li, J.; Cao, Z.; Guo, J. Evolution of overburden fracture and water seepage in coal seam group mining an example in lingxin coal mine. Therm. Sci. 2023, 27, 671–677. [Google Scholar] [CrossRef]

- Kong, D.; Pu, S.; Zheng, S.; Wang, C.; Lou, Y. Roof broken characteristics and overburden migration law of upper seam in upward mining of close seam group. Geotech. Geol. Eng. 2019, 37, 3193–3203. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Tan, Y.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y. Research on the fracture evolution law and combined bearing structure load of shallow buried coal seam group. Coal Sci. Technol. 2023, 51, 65–76. [Google Scholar]

- Zheng, C.; Kizil, M.; Chen, Z.; Aminossadati, S. Role of multi-seam interaction on gas drainage engineering design for mining safety and environmental benefits: Linking coal damage to permeability variation. Process Saf. Environ. Prot. 2018, 114, 310–322. [Google Scholar] [CrossRef]

- Shi, J.; Sun, W.; Zhang, W. Numerical Simulation on Seepage Flow in Multiplayer Gob Area of Coal Seam Group Under Small Mine Fire Zone. Saf. Coal Mines 2015, 46, 18–21. [Google Scholar]

- Jia, H.; Wang, K.; Xu, C.; Fu, Q. Permeability distribution characteristics of underlying coal seam disturbed by mining activity. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 44, 1–16. [Google Scholar] [CrossRef]

- Tian, F.; Qin, Y.; Liang, Y.; Chang, X. The application research of overlying strata stress field and gas flow field coupling mechanism under the long vertical distance coal seam group mining conditions. J. Min. Saf. Eng. 2015, 32, 1031–1036. [Google Scholar]

- He, A.; Fu, H.; Huo, B.; Fan, C. Permeability enhancement of coal seam by lower protective layer mining for gas outburst prevention. Shock Vib. 2020, 2020, 78873. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, J. Deformation and permeability characteristic of outburst coal under step unloading conditions. J. China Coal Soc. 2017, 42, 1451–1457. [Google Scholar]

- Ren, W.; Zhou, H.; Xue, D.; Wang, L.; Rong, T.; Liu, J. Mechanical behavior and permeability of coal and rock under strong mining disturbance in protected coal seam mining. J. China Coal Soc. 2019, 44, 1473–1481. [Google Scholar]

- Xue, Y.; Gao, F.; Gao, Y.; Liang, X. Research on mining-induced permeability evolution model of damaged coal in post-peak stage. J. China Univ. Min. Technol. 2017, 46, 521–527. [Google Scholar]

- Zhang, L.; Kan, Z.; Xue, J.; Li, M.; Zhang, C. Study on permeability law of intact and fractured coals under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2021, 40, 2487–2499. [Google Scholar]

- Zhang, L.; Huang, M.; Li, M.; Lu, S.; Yuan, X.; Li, J. Experimental study on evolution of fracture network and permeability characteristics of bituminous coal under repeated mining effect. Nat. Resour. Res. 2022, 31, 463–486. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, L.; Zhang, C.; Chen, S. Characteristics of permeability changes in bituminous coal under conditions of stress variation due to repeated mining activities. Nat. Resour. Res. 2020, 29, 1687–1704. [Google Scholar] [CrossRef]

- Li, B.; Zou, Q.; Liang, Y. Experimental research into the evolution of permeability in a broken coal mass under cyclic loading and unloading conditions. Appl. Sci. 2019, 9, 762. [Google Scholar] [CrossRef]

- Kan, Z.; Zhang, L.; Li, M.; Yuan, X.; Huang, M. Investigation of seepage law in broken coal and rock mass under different loading and unloading cycles. Geofluids 2021, 2021, 27250. [Google Scholar] [CrossRef]

- Hao, D. Study on Fracture Development Law and Seepage Characteristics of Surrounding Rock with Repeated Mining Under Insufficient Collapsed Gob; China University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar]

- Bai, Q.; Tu, S.; Zhang, C.; Zhu, D. Discrete element modeling of progressive failure in a wide coal roadway from water-rich roofs. Int. J. Coal Geol. 2016, 167, 215–229. [Google Scholar] [CrossRef]

- Bai, Q.; Tu, S. Numerical observations of the failure of a laminated and jointed roof and the effective of different support schemes: A case study. Environ. Earth Sci. 2020, 79, 202. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

| Lithology | Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (GPa) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Compressive Strength (MPa) | Tensile Strength (MPa) | Cohesion (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|---|---|---|

| Loess | 1800 | 0.44 | 0.07 | 0.19 | 0.02 | 0.18 | 0.10 | 0.15 | 10 |

| Mudstone | 2033 | 0.36 | 3.0 | 3.57 | 1.10 | 25.20 | 1.90 | 2.2 | 30 |

| Fine sandstone | 2268 | 0.24 | 4.1 | 4.19 | 1.56 | 37.80 | 2.83 | 2.91 | 43 |

| Middle sandstone | 2182 | 0.32 | 3.9 | 3.61 | 1.48 | 35.20 | 2.50 | 2.8 | 35 |

| Siltstone | 2293 | 0.31 | 4.9 | 4.30 | 1.87 | 47.22 | 3.73 | 5.37 | 36 |

| 2-2 coal seam | 1251 | 0.29 | 2.6 | 2.06 | 1.01 | 20.43 | 1.45 | 2.98 | 44 |

| 3-1 coal seam | 1251 | 0.31 | 2.8 | 2.46 | 1.07 | 22.50 | 1.24 | 2.97 | 37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, D.; Liu, G.; Tu, S.; Li, W. Effect of Layer Spacing on Fracture Development and Seepage Evolution of Surrounding Rocks During Repeated Mining Under Insufficiently Collapsed Gob. Fractal Fract. 2025, 9, 376. https://doi.org/10.3390/fractalfract9060376

Hao D, Liu G, Tu S, Li W. Effect of Layer Spacing on Fracture Development and Seepage Evolution of Surrounding Rocks During Repeated Mining Under Insufficiently Collapsed Gob. Fractal and Fractional. 2025; 9(6):376. https://doi.org/10.3390/fractalfract9060376

Chicago/Turabian StyleHao, Dingyi, Guozhong Liu, Shihao Tu, and Wenlong Li. 2025. "Effect of Layer Spacing on Fracture Development and Seepage Evolution of Surrounding Rocks During Repeated Mining Under Insufficiently Collapsed Gob" Fractal and Fractional 9, no. 6: 376. https://doi.org/10.3390/fractalfract9060376

APA StyleHao, D., Liu, G., Tu, S., & Li, W. (2025). Effect of Layer Spacing on Fracture Development and Seepage Evolution of Surrounding Rocks During Repeated Mining Under Insufficiently Collapsed Gob. Fractal and Fractional, 9(6), 376. https://doi.org/10.3390/fractalfract9060376