Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium- and High-Rank Coals via Nuclear Magnetic Resonance

Abstract

1. Introduction

2. Experimental Methods and Analyses

2.1. Sample Collection and Preparation

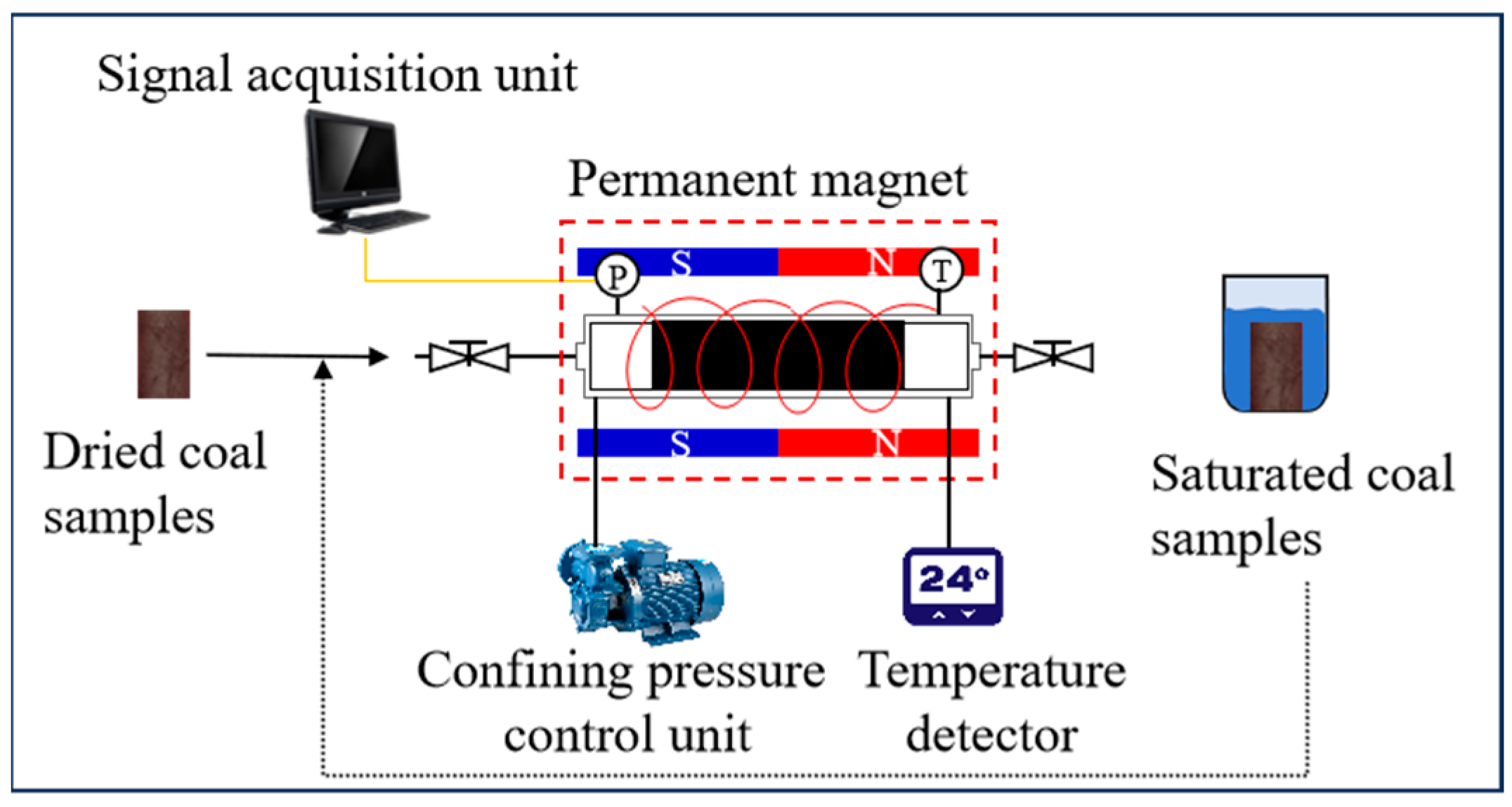

2.2. Experimental Process

2.3. NMR and Multifractal Theories

3. Results

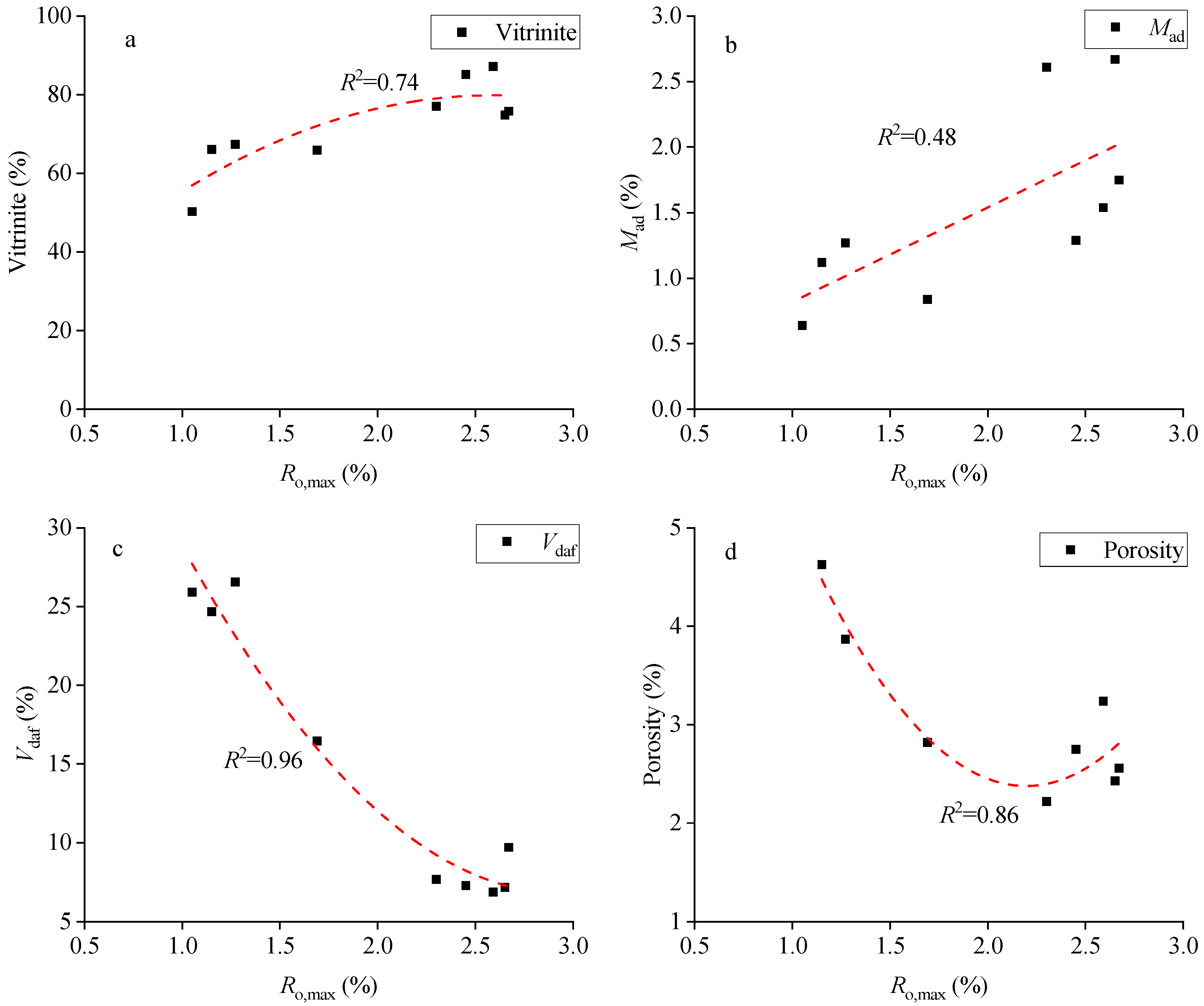

3.1. Coal Characteristics

3.2. T2 Spectrum Distribution and Validation

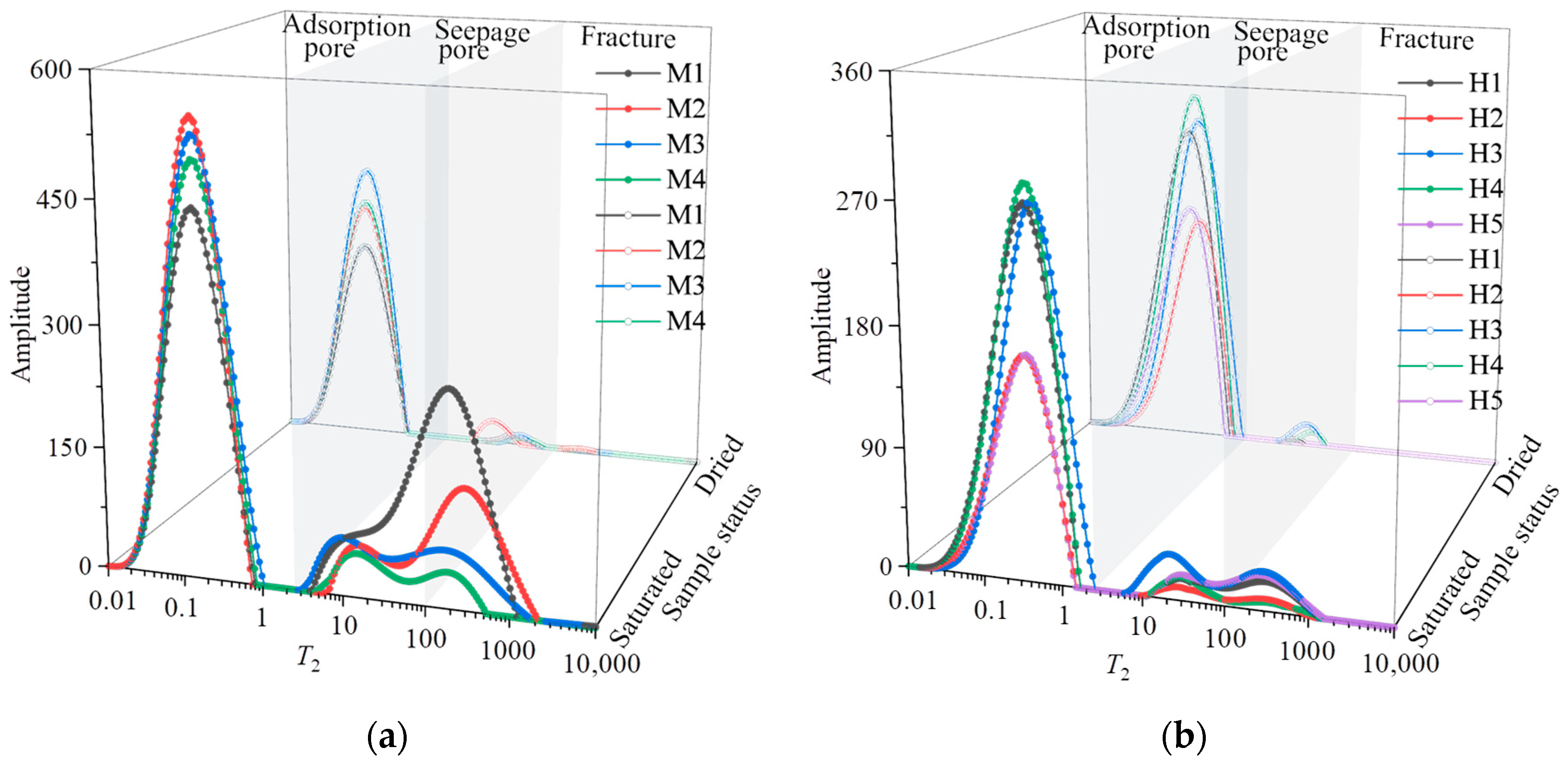

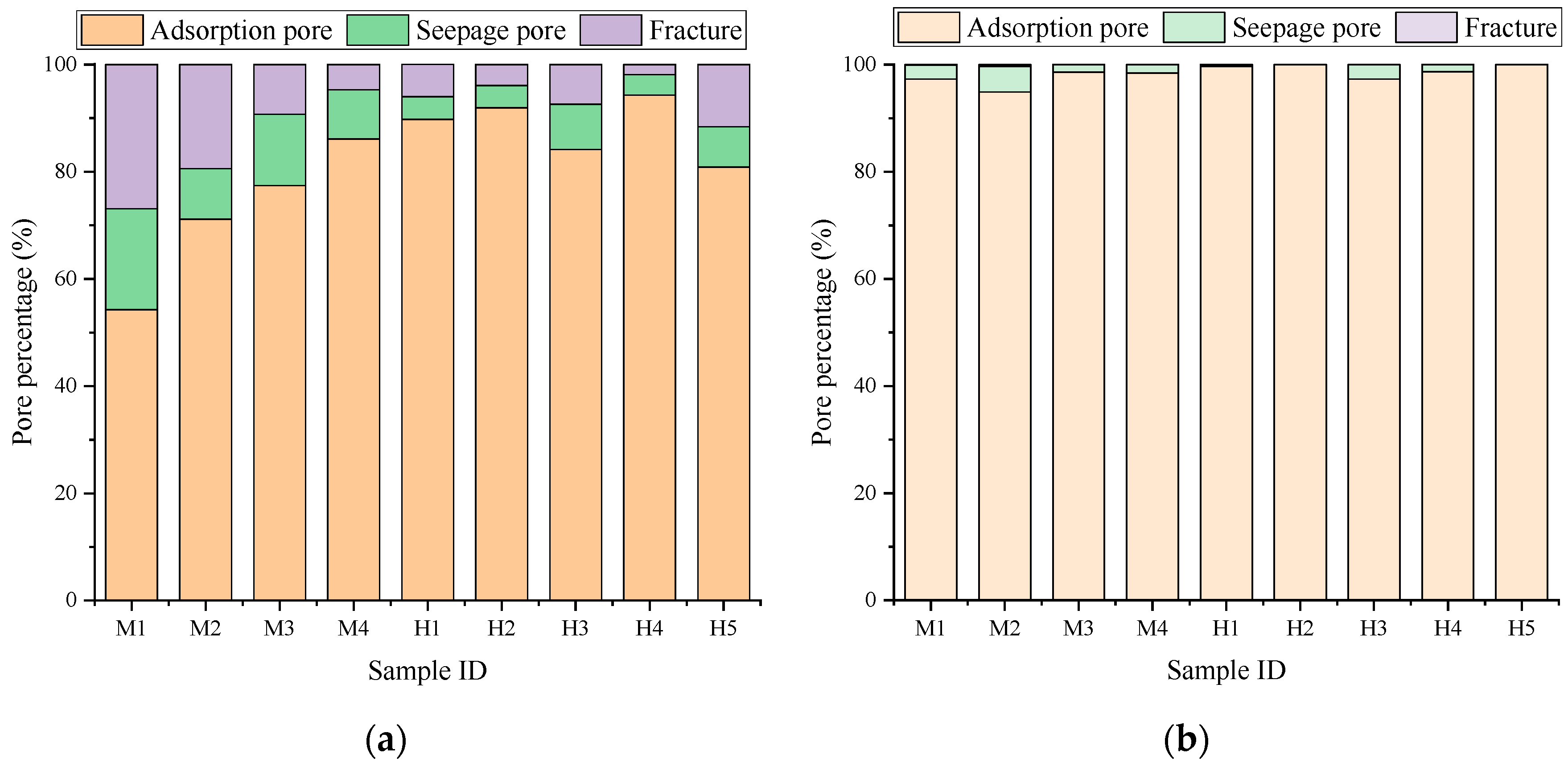

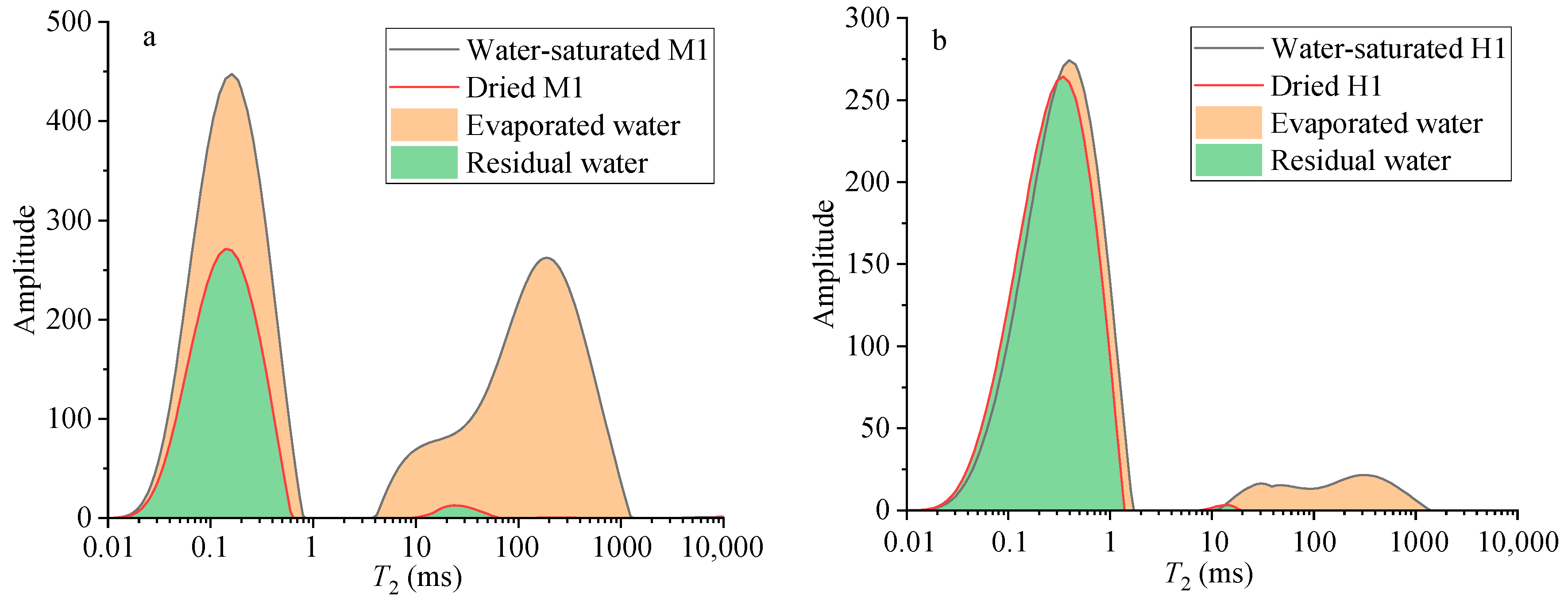

3.2.1. T2 Characteristics of Saturated and Dried Coal Samples

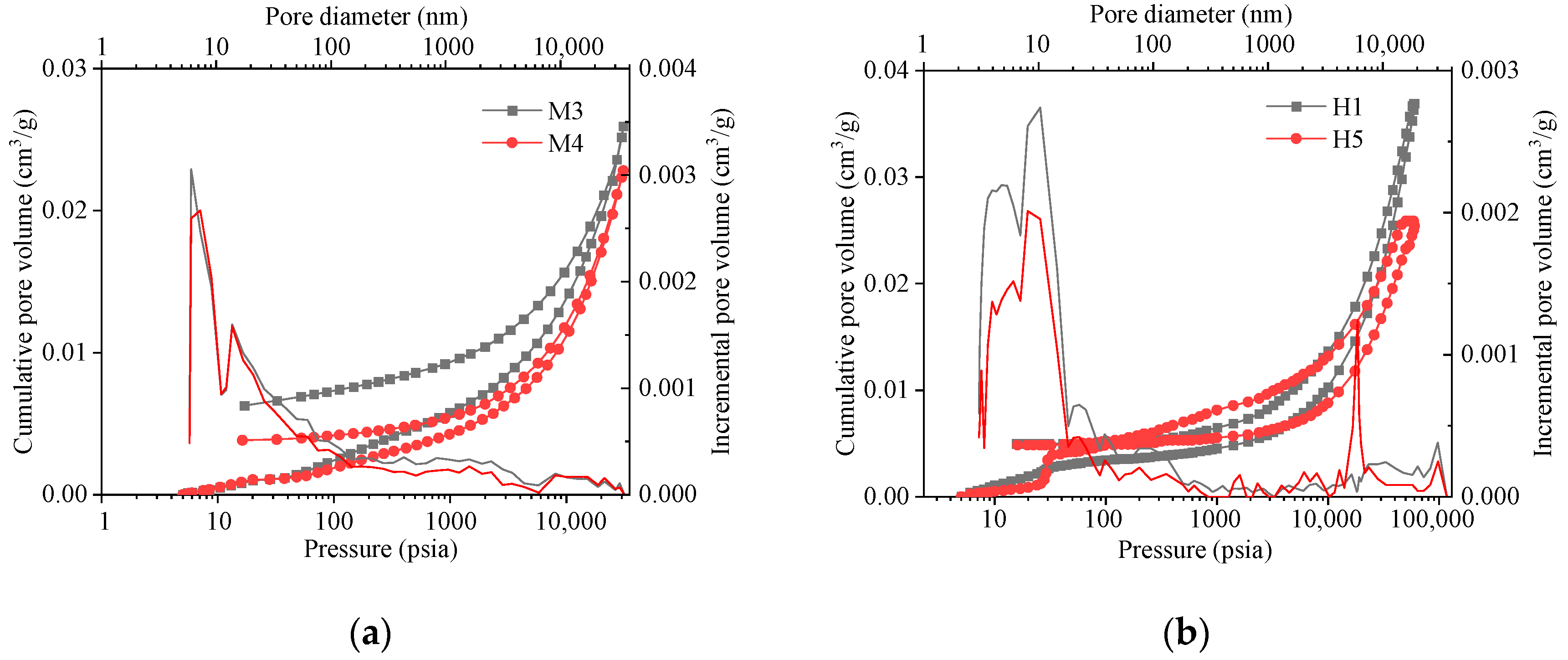

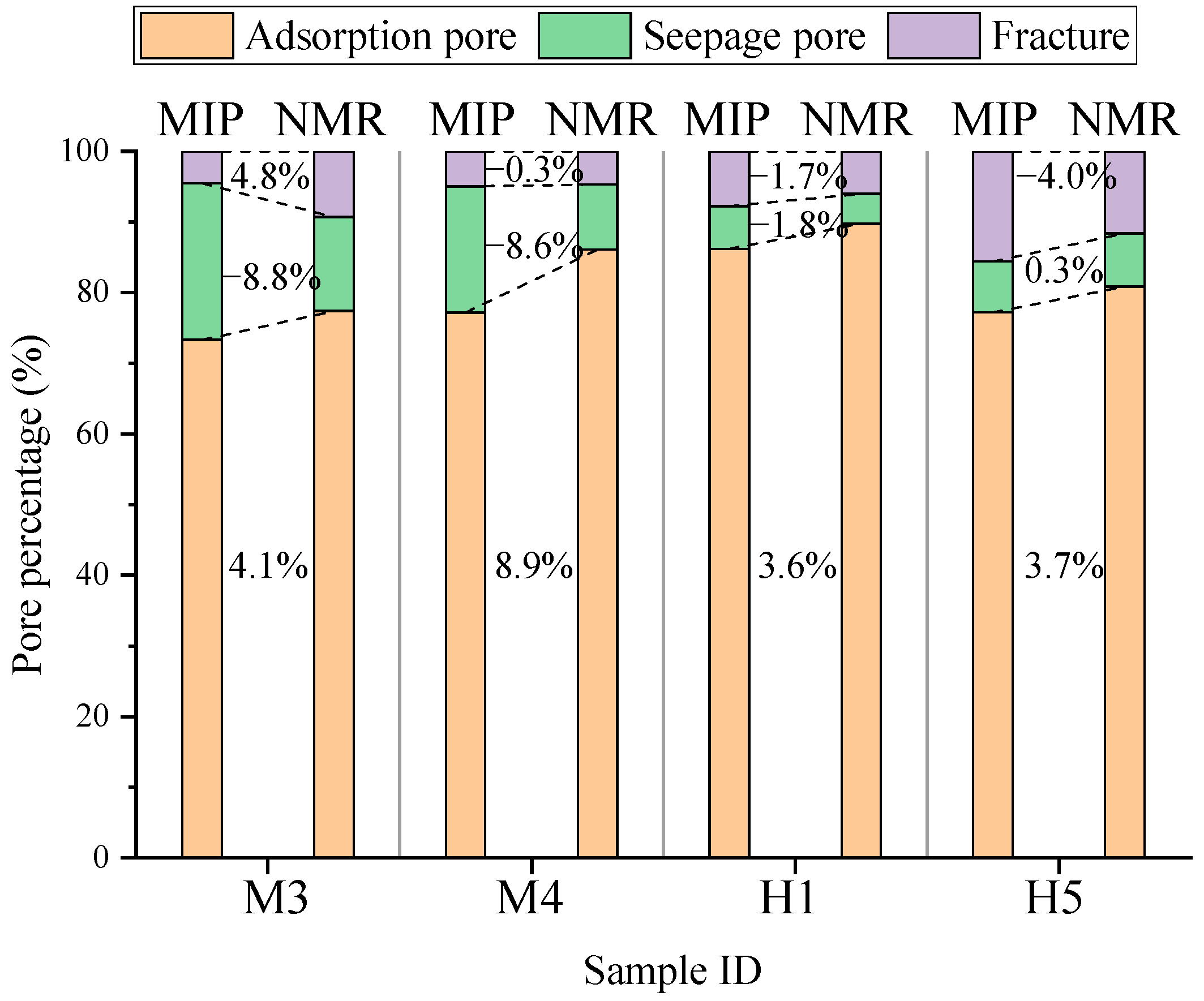

3.2.2. Validation of Pore Size Distribution Between NMR and MIP

3.3. Multifractal Characteristics

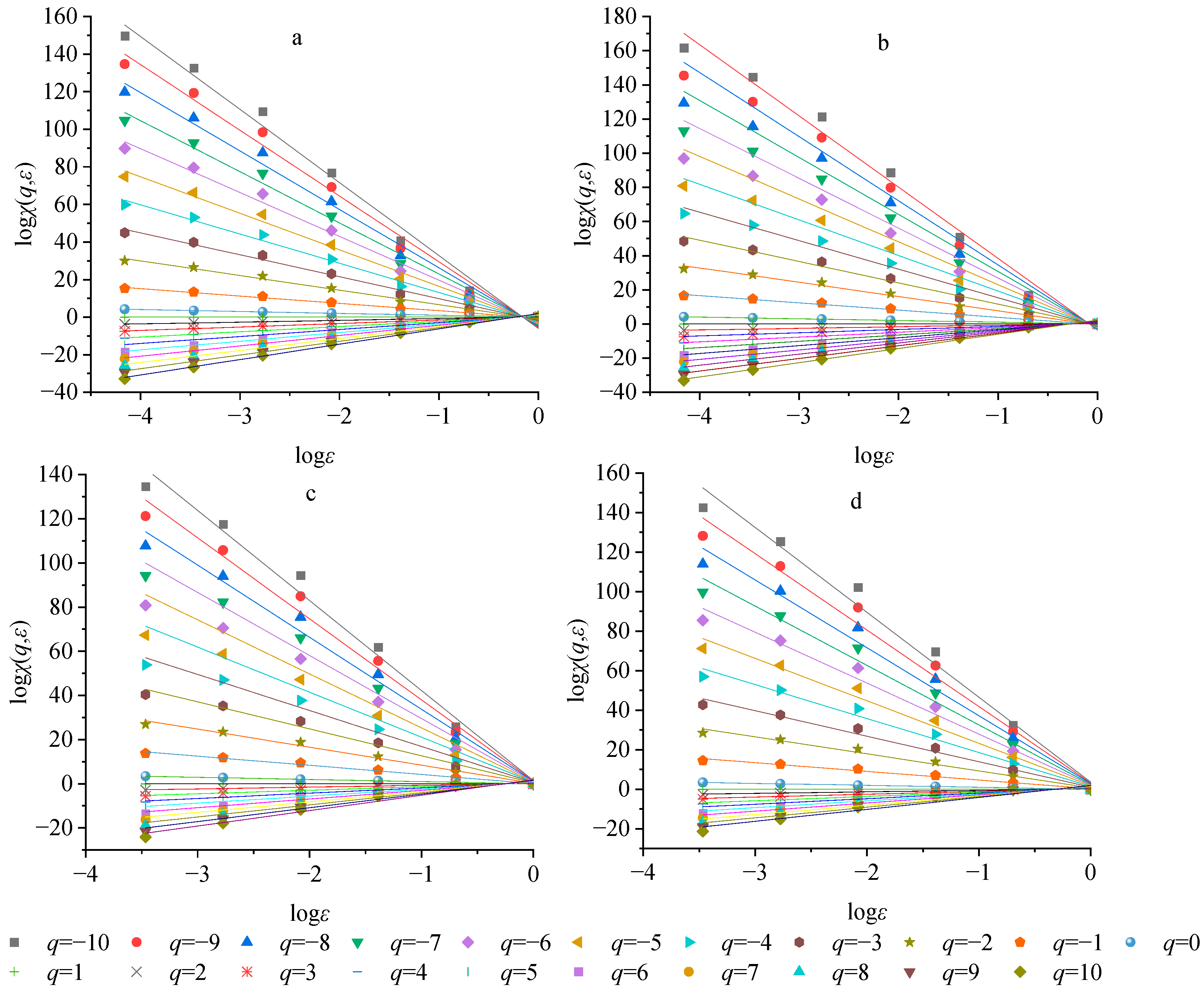

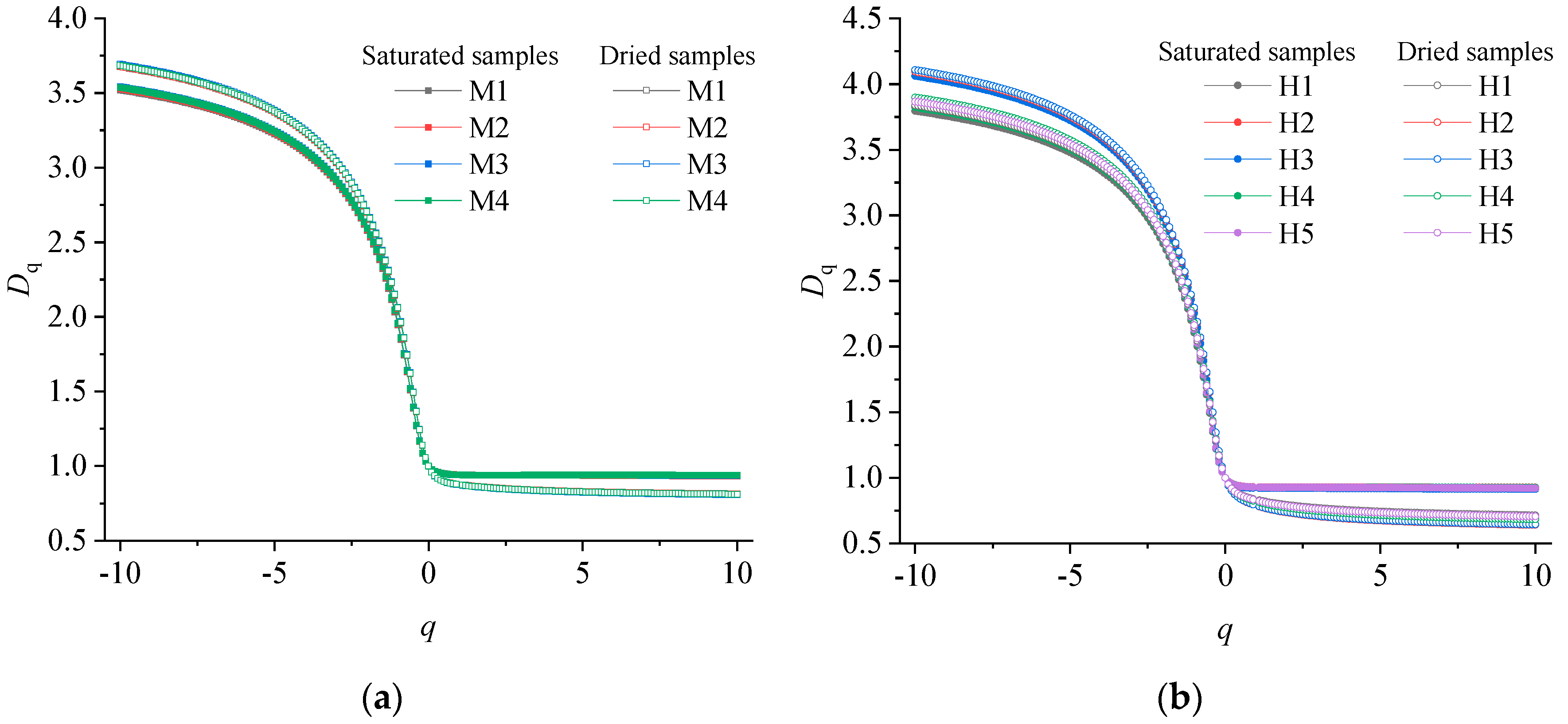

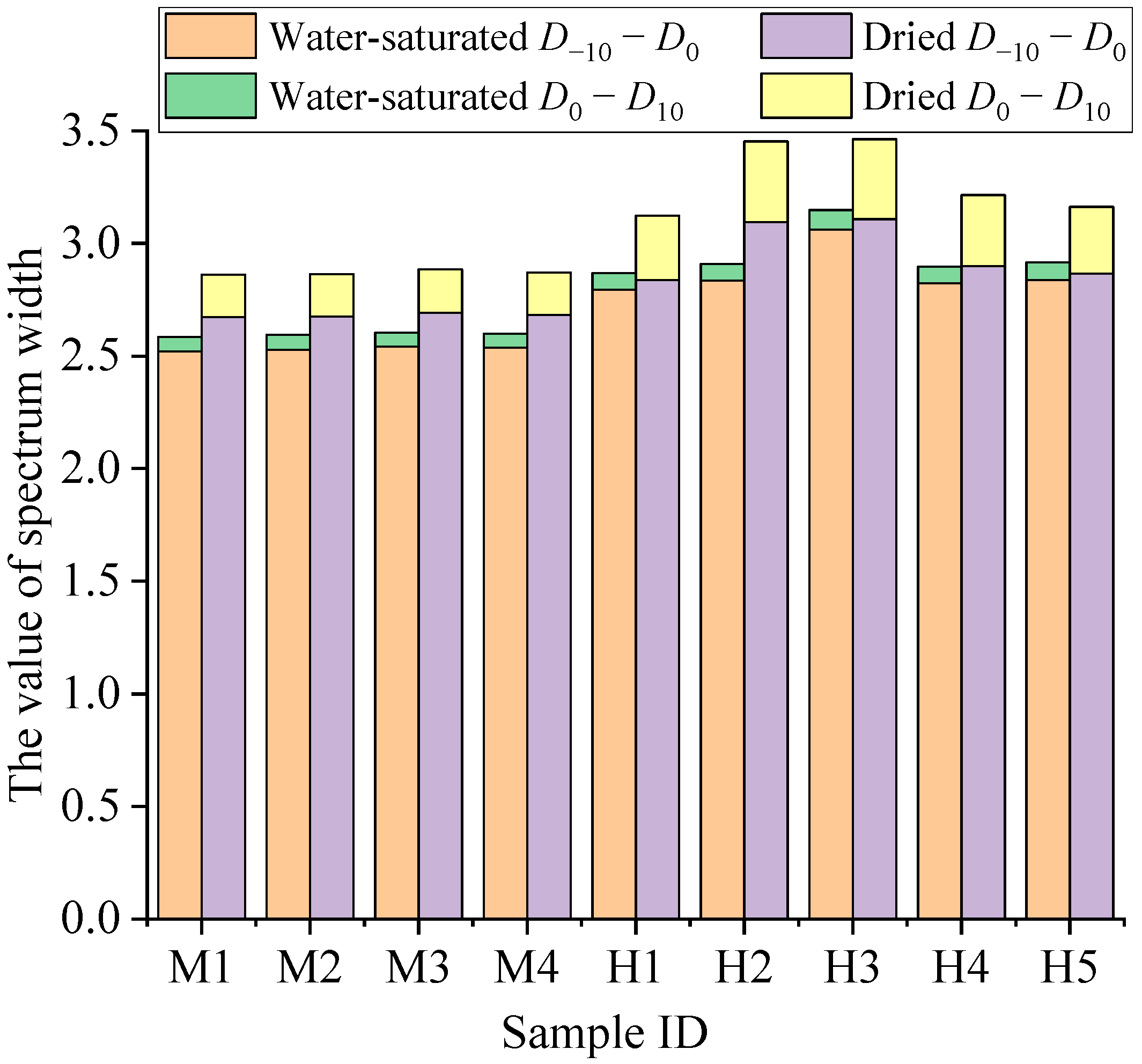

3.3.1. The Generalized Dimensional Spectrum Characteristics

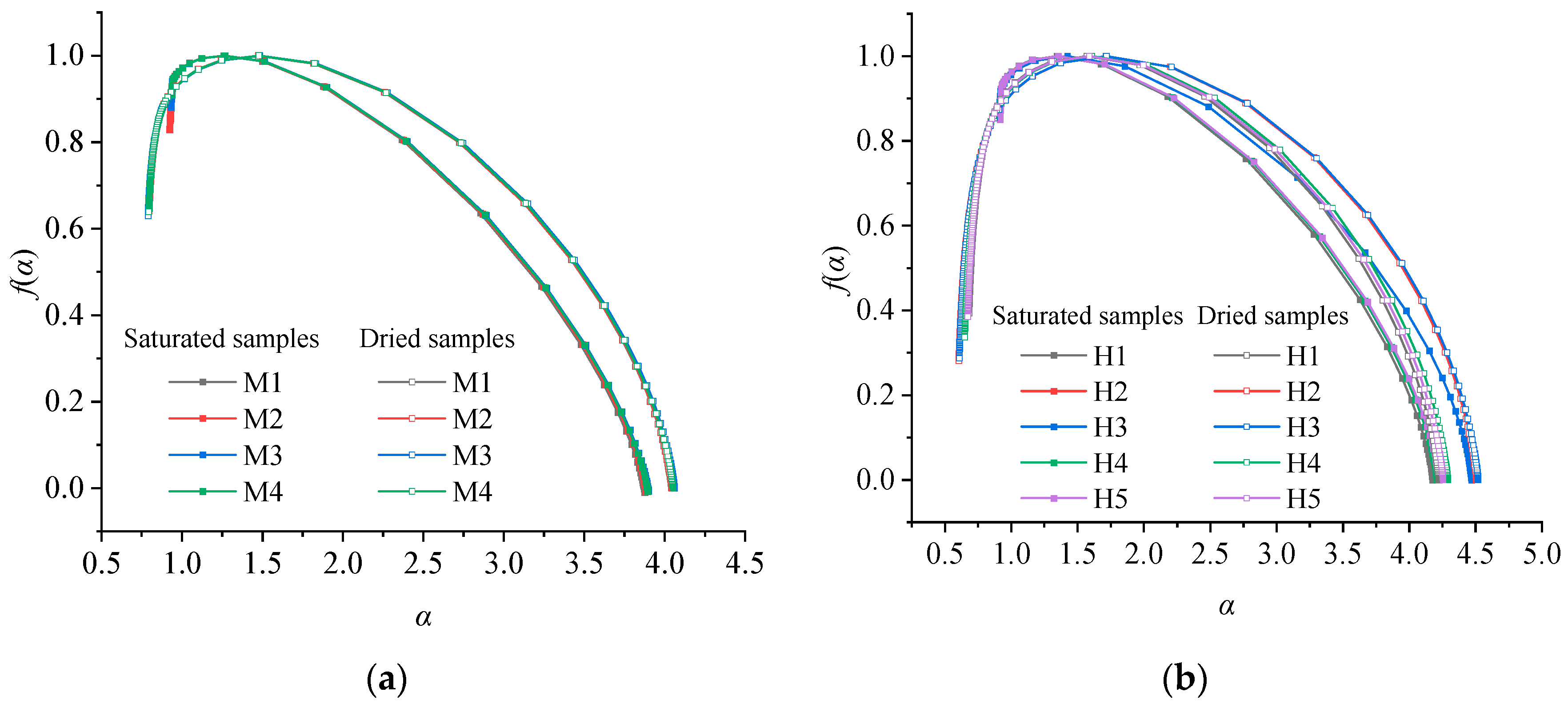

3.3.2. The Multifractal Singular Spectrum Characteristics

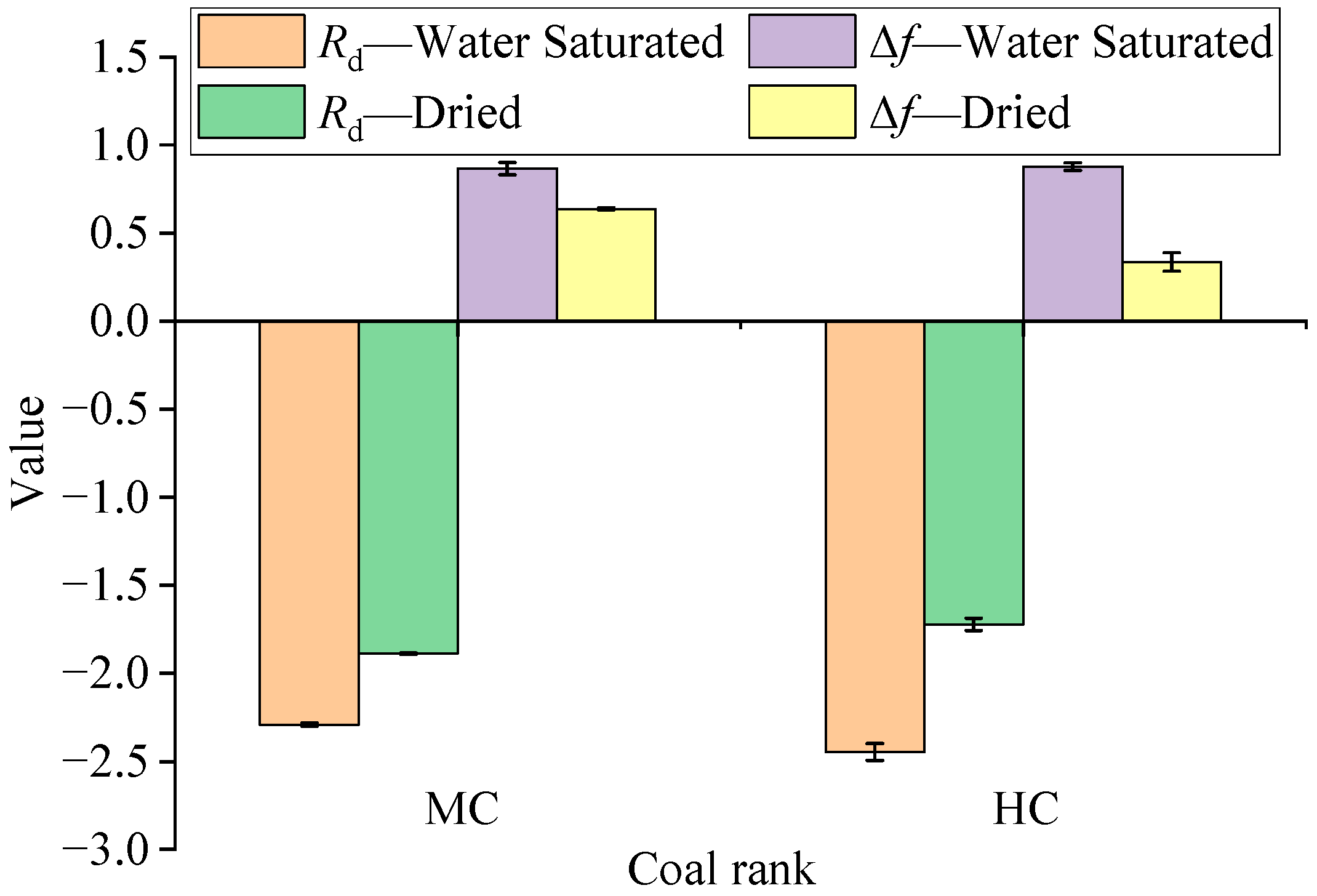

4. Discussion

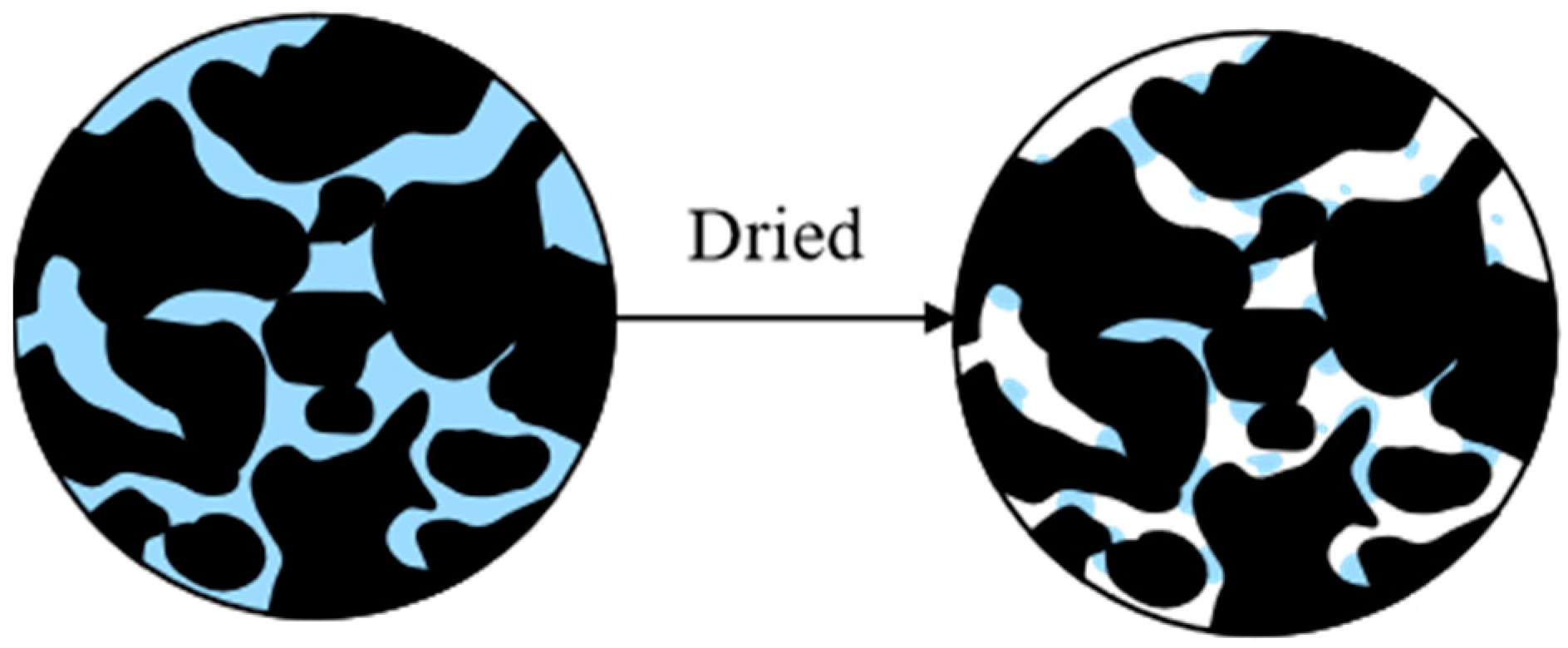

4.1. The Distribution of Multiphase Water Based on NMR

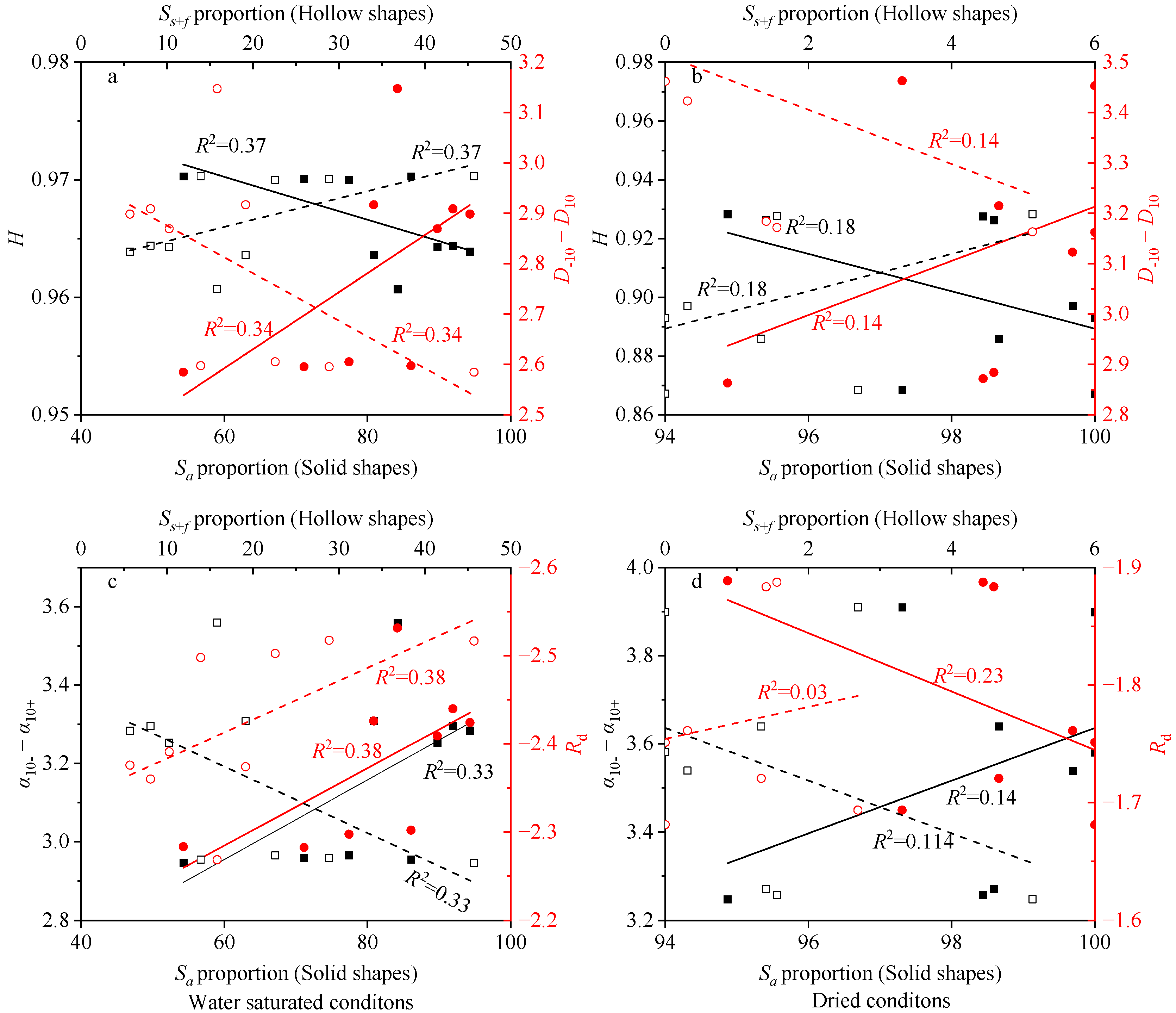

4.2. The Relationship Between T2 Spectra and Multifractal Parameters

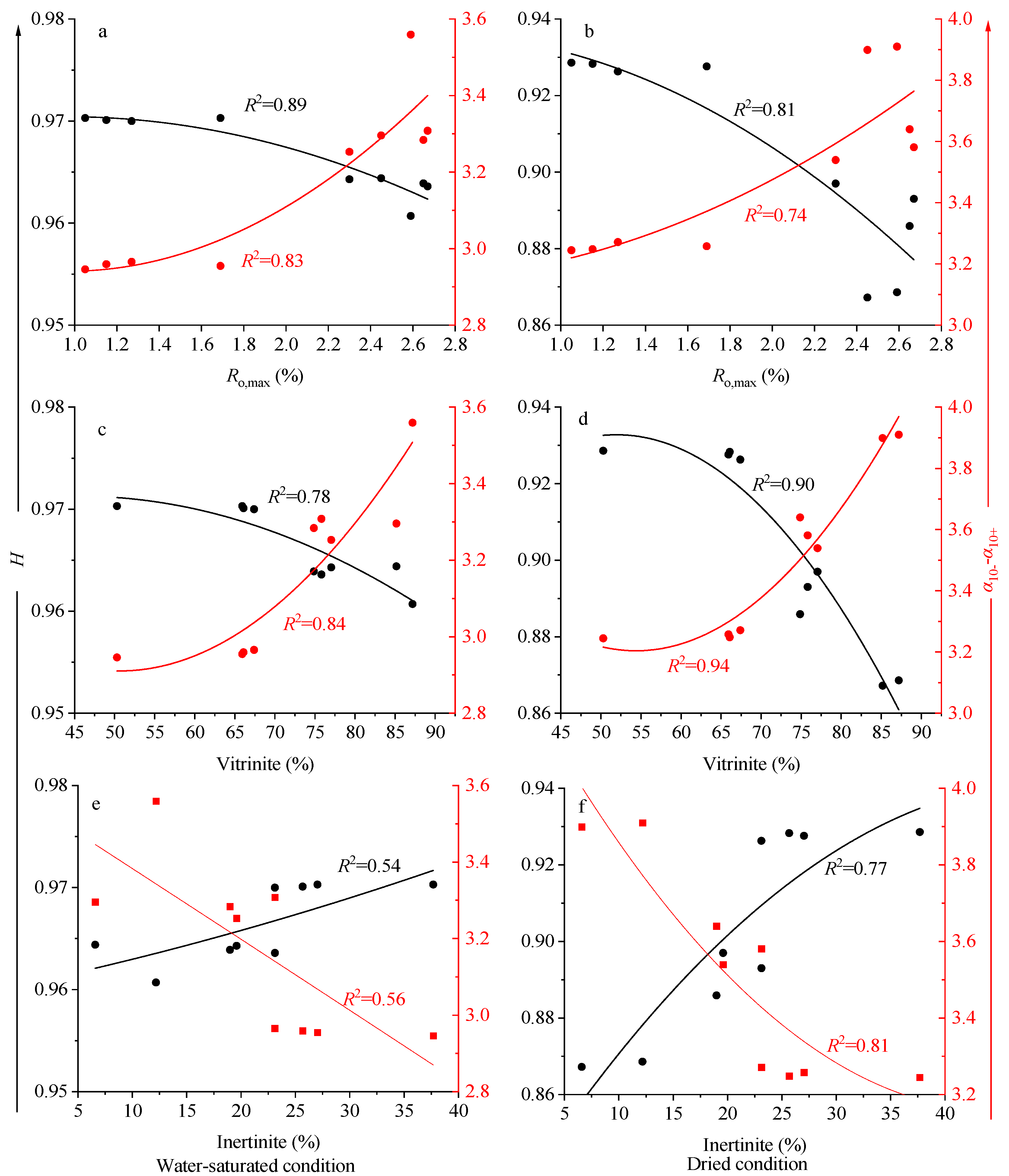

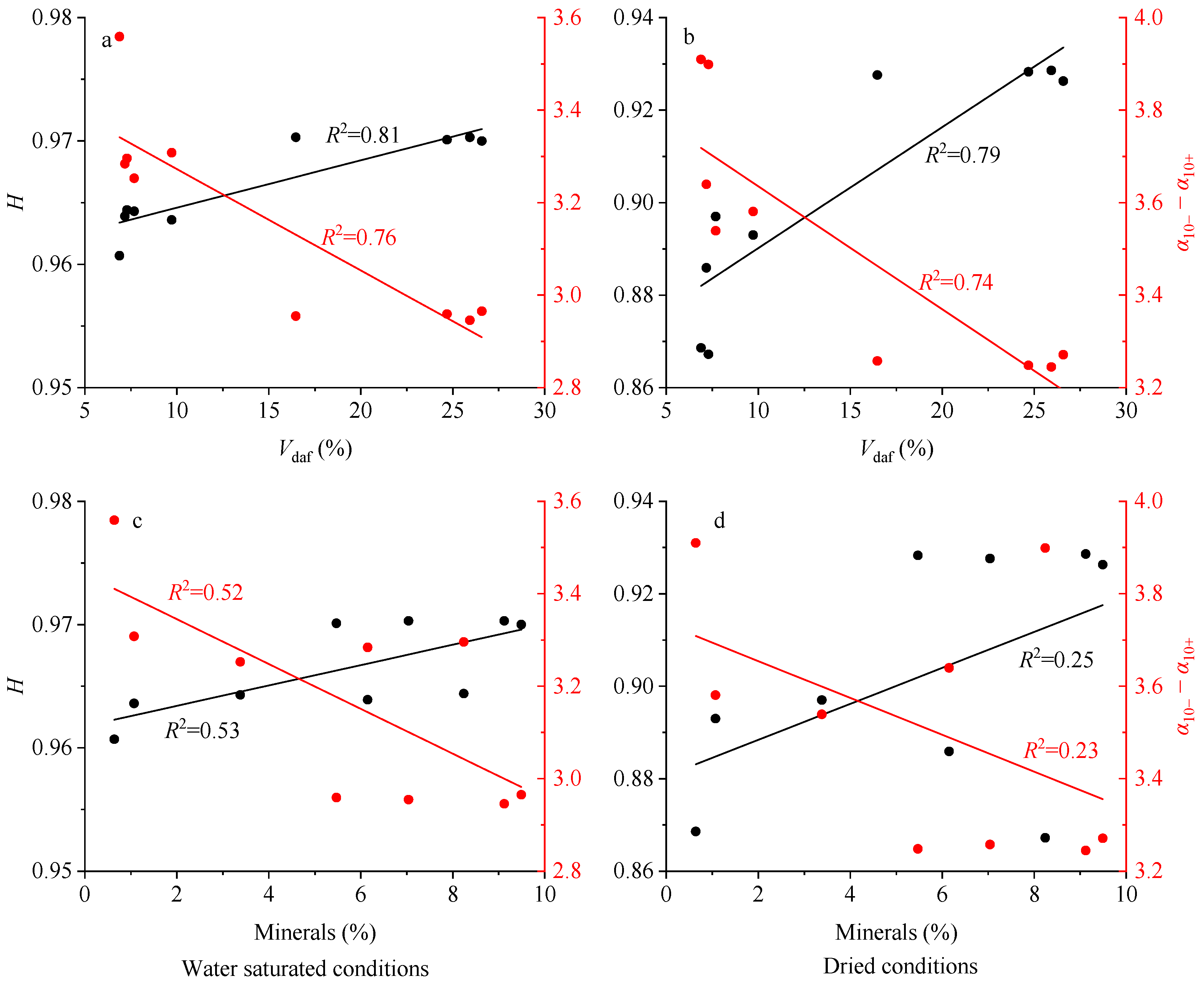

4.3. Influencing Factors of Multifractal Parameters in Coal Samples

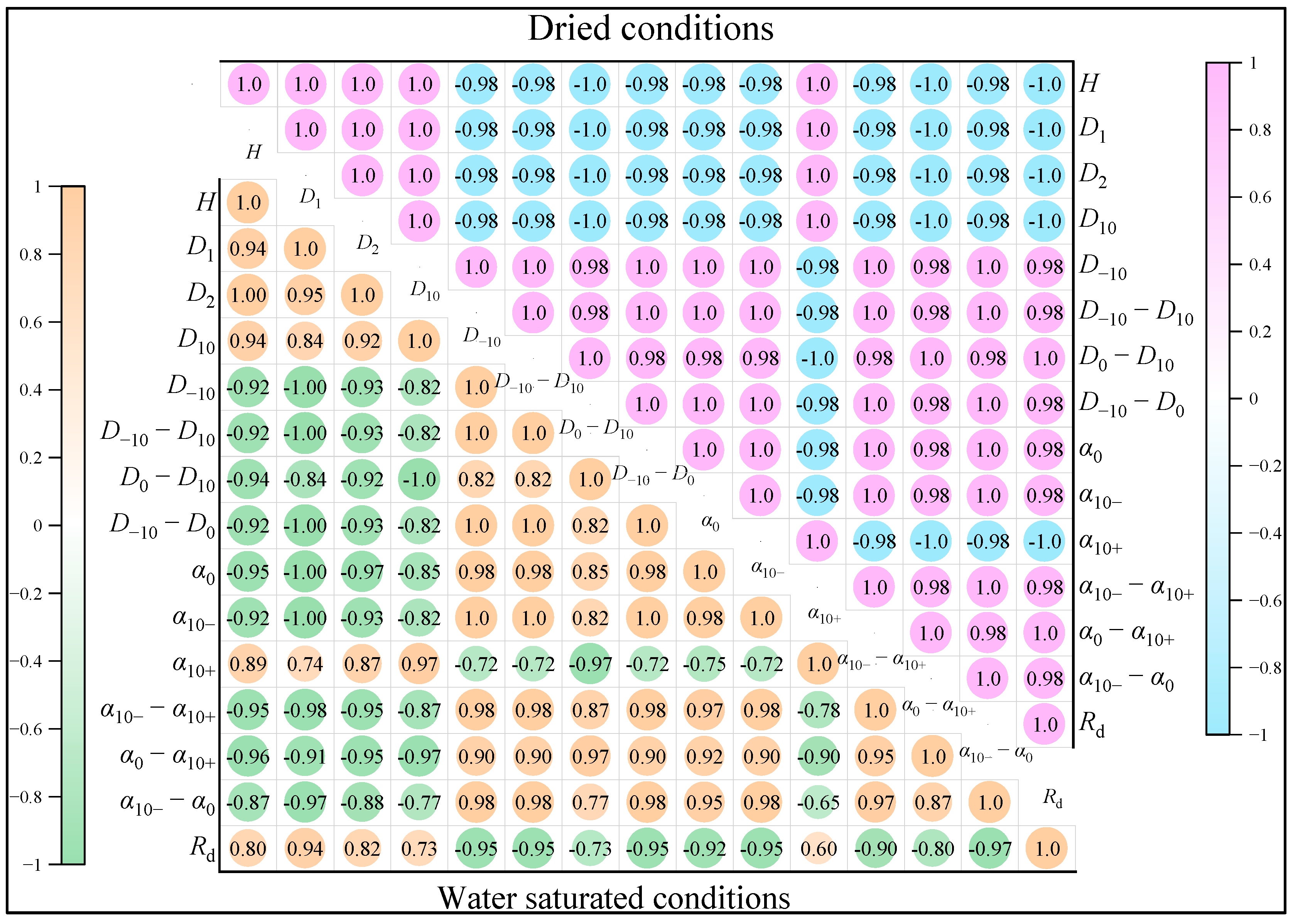

4.3.1. Correlation Analysis of Multifractal Parameters

4.3.2. Influence Factors

5. Conclusions

- (1)

- The T2 spectra of water-saturated coal samples exhibit three peaks: an isolated P1 peak (adsorption pores, 0.01–2.5 ms) dominates all samples, followed by overlapping P2 (seepage pores, 2.5–100 ms), and P3 (fractures, >100 ms). Drying preferentially removes free water in P2 and P3 regions, leading to significant reductions in the T2 spectrum, especially in medium-rank coals;

- (2)

- Multifractal characteristics derived from NMR reveal that coal rank dictates pore heterogeneity evolution. High-rank coals exhibit greater pore heterogeneity and complexity and lower pore connectivity due to aromatization-driven micropore dominance. Drying intensifies heterogeneity asymmetrically, with high-rank coals showing pronounced right-branch spectral broadening;

- (3)

- Free water dehydration in coal follows a size-dependent sequence: fractures/seepage pores → adsorption pores. Under dry conditions, multifractal analysis shows that the distribution of residual water is more complex, primarily occupying the adsorption pores and pore throat corners, which are controlled by the retention of bound water and the surface relaxation enhancement effects;

- (4)

- Strong correlations between the multifractal dimension spectrum (q-Dq) and singularity spectrum (f(α)-α) validate dual-spectrum consistency in characterizing pore fluid systems. The degree of coalification, vitrinite content, inertinite content, and Vdaf are the primary factors affecting pore heterogeneity, connectivity, and water distribution. Additionally, no significant correlations exist between multifractal parameters and Mad or Ad, excluding these as key heterogeneity drivers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Zhang, J.; Xiao, Q.; Liu, B.; Lin, W.; Li, W. Experimental Study on Differential Thermal Response and Pore-Fracture Structure Evolution Characteristics of Coals under Microwave Irradiation: A Case Study of Five Different Rank Coals. Energy Fuels 2024, 38, 9497–9514. [Google Scholar] [CrossRef]

- Yan, M.; Yang, F.; Zhang, B.; Lin, H.; Li, S. Influence of Pore Structure Characteristics of Low Permeability Coal on Gas Nonlinear Seepage. Nat. Resour. Res. 2024, 33, 1209–1225. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Liu, D.; Sang, S.; Liu, S.; Wang, M.; Zhou, X.; Wang, R.; Han, S.; Liu, T. Re-Evaluating the Accurate Multiphase Water Distribution in Coals: Unifying Experiment and Theory. Chem. Eng. J. 2023, 464, 142637. [Google Scholar] [CrossRef]

- Hodot, B.B. Outburst of Coal and Coalbed Gas; National Mining Scientific and Technical Documentation Press: Moscow, Russia, 1961; pp. 60–63. [Google Scholar]

- Wang, D.; Hu, H.; Wang, T.; Tang, T.; Li, W.; Zhu, G.; Chen, X. Difference between of Coal and Shale Pore Structural Characters Based on Gas Adsorption Experiment and Multifractal Analysis. Fuel 2024, 371, 132044. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, X.; Wang, S.; Wang, R.; Wu, J.; Li, Z.; Song, Y. Multifractal Characteristics on Pore Structure of Longmaxi Shale Using Nuclear Magnetic Resonance (NMR). Geoenergy Sci. Eng. 2024, 241, 213176. [Google Scholar] [CrossRef]

- Li, F.; Jiang, B.; Song, Y.; Cheng, G.; Lu, G. Multifractal Behavior of the Micro- and Mesopore Structures of Brittle Tectonically Deformed Coals and Its Influence on Methane Adsorption Capacity. Energy Fuels 2021, 35, 3042–3064. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, Z.; Ji, W.; Zhang, C.; Yuan, Y.; Chen, L.; Yin, L. Heterogeneity of Intergranular, Intraparticle and Organic Pores in Longmaxi Shale in Sichuan Basin, South China: Evidence from SEM Digital Images and Fractal and Multifractal Geometries. Mar. Pet. Geol. 2016, 72, 122–138. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, C. How Does Pore Structure Affect the NMR Relaxation in Unsaturated Porous Media: A Simulation Study. Water Resour. Res. 2025, 61, e2024WR038139. [Google Scholar] [CrossRef]

- Yu, X.; Xu, H.; Zhai, C.; Regenauer-Lieb, K.; Sang, S.; Sun, Y.; Jing, Y. Characterization of Water Migration Behavior during Spontaneous Imbibition in Coal: From the Perspective of Fractal Theory and NMR. Fuel 2024, 355, 129499. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, J.; Lv, D.; Vandeginste, V.; Chang, X.; Zhang, X.; Wang, D.; Han, S.; Liu, Y. Effect of Water Occurrence in Coal Reservoirs on the Production Capacity of Coalbed Methane by Using NMR Simulation Technology and Production Capacity Simulation. Geoenergy Sci. Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, C.; Li, G.; Fu, X.; Zhong, Q.; Liu, H.; Dong, Z. Determinations of the Multifractal Characteristics of the Pore Structures of Low-, Middle-, and High-Rank Coal Using High-Pressure Mercury Injection. J. Pet. Sci. Eng. 2021, 203, 108656. [Google Scholar] [CrossRef]

- Li, Y.; Pan, J.; Cheng, N.; Wang, Z.; Zhang, L.; Liu, W. Relationship Between Micropore Structure of Different Coal Ranks and Methane Diffusion. Nat. Resour. Res. 2022, 31, 2901–2917. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Lin, X.; Liu, H.; Li, D. Evaluating Damage Growth and Outburst Trend during Gas Drainage under Coupled Microstructure-Multi-Field Behaviour. Rock Mech. Rock Eng. 2025, 58, 1671–1692. [Google Scholar] [CrossRef]

- Guan, W.; Cai, W.; Li, Z.; Lu, H. Microscopic Characterization and Fractal Analysis of Pore Systems for Unconventional Reservoirs. J. Mar. Sci. Eng. 2024, 12, 908. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Wu, C.; Jin, Z. Influence of Particle Size on Pore Structure and Multifractal Characteristics in Coal Using Low-Pressure Gas Adsorption. J. Pet. Sci. Eng. 2022, 212, 110273. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.; Liu, H. Comprehensive Characteristics of Pore Structure and Factors Influencing Micropore Development in the Laochang Mining Area, Eastern Yunnan, China. J. Pet. Sci. Eng. 2020, 190, 107090. [Google Scholar] [CrossRef]

- Guan, M.; Liu, X.; Jin, Z.; Lai, J. The Heterogeneity of Pore Structure in Lacustrine Shales: Insights from Multifractal Analysis Using N2 Adsorption and Mercury Intrusion. Mar. Pet. Geol. 2020, 114, 104150. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Liu, S.; Ji, X.; Hao, H. Evaluation of Pore Properties in Coal through Compressibility Correction Based on Mercury Intrusion Porosimetry: A Practical Approach. Fuel 2021, 291, 120130. [Google Scholar] [CrossRef]

- Yu, Y.; Luo, X.; Wang, Z.; Cheng, M.; Lei, Y.; Zhang, L.; Yin, J. A New Correction Method for Mercury Injection Capillary Pressure (MICP) to Characterize the Pore Structure of Shale. J. Nat. Gas Sci. Eng. 2019, 68, 102896. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Ji, X.; Xu, H. Fractal Analysis of the Dynamic Variation in Pore-Fracture Systems under the Action of Stress Using a Low-Field NMR Relaxation Method: An Experimental Study of Coals from Western Guizhou in China. J. Pet. Sci. Eng. 2019, 173, 617–629. [Google Scholar] [CrossRef]

- Liu, X.; Wu, C. Simulation of Dynamic Changes of Methane State Based on NMR during Coalbed Methane Output. Fuel 2017, 194, 188–194. [Google Scholar] [CrossRef]

- Cheng, M.; Fu, X.; Kang, J.; Chen, Z.; Tian, Z. Effect of Water on Methane Diffusion in Coal under Temperature and Pressure: A LF-NMR Experimental Study on Successive Depressurization Desorption. Fuel 2022, 324, 124578. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, B.; Liu, T.; Zheng, Y.; Sun, Y.; Zhang, G.; Li, Q. Multifractal Analysis of Coal Pore Structure Based on NMR Experiment: A New Method for Predicting T2 Cutoff Value. Fuel 2021, 283, 119338. [Google Scholar] [CrossRef]

- Xue, D.J.; Liu, Y.T.; Zhou, J.; Sun, X.T. Visualization of Helium-Water Flow in Tight Coal by the Low-Field NMR Imaging: An Experimental Observation. J. Pet. Sci. Eng. 2020, 188, 106862. [Google Scholar] [CrossRef]

- San José Martínez, F.; Martín, M.A.; Caniego, F.J.; Tuller, M.; Guber, A.; Pachepsky, Y.; García-Gutiérrez, C. Multifractal Analysis of Discretized X-Ray CT Images for the Characterization of Soil Macropore Structures. Geoderma 2010, 156, 32–42. [Google Scholar] [CrossRef]

- Duan, R.; Xu, Z.; Dong, Y.; Liu, W. Characterization and Classification of Pore Structures in Deeply Buried Carbonate Rocks Based on Mono- and Multifractal Methods. J. Pet. Sci. Eng. 2021, 203, 108606. [Google Scholar] [CrossRef]

- Ge, X.; Fan, Y.; Li, J.; Aleem Zahid, M. Pore Structure Characterization and Classification Using Multifractal Theory—An Application in Santanghu Basin of Western China. J. Pet. Sci. Eng. 2015, 127, 297–304. [Google Scholar] [CrossRef]

- Han, Y.; Jiang, Z.; Liang, Z.; Lai, Z.; Wu, Y.; Shi, X.; Duan, X.; Zhang, Y.; Li, Y. Study on the Multifractal Characterization and Seepage of the Shale Matrix: A Case Study of the Longmaxi Formation in Southwestern Sichuan Basin, China. Geoenergy Sci. Eng. 2024, 238, 212924. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Zou, J.; Gentzis, T.; Rezaee, R.; Bubach, B.; Carvajal-Ortiz, H. Multifractal Analysis of Gas Adsorption Isotherms for Pore Structure Characterization of the Bakken Shale. Fuel 2018, 219, 296–311. [Google Scholar] [CrossRef]

- Zhong, B.; Zhu, Y.; Feng, G.; Xiang, J.; Wang, Y. Matrix Compression and Pore Heterogeneity in the Coal-Measure Shale Reservoirs of the Qinshui Basin: A Multifractal Analysis. Fractal Fract. 2024, 8, 580. [Google Scholar] [CrossRef]

- Yan, J.; Meng, Z.; Zhang, K.; Yao, H.; Hao, H. Pore Distribution Characteristics of Various Rank Coals Matrix and Their Influences on Gas Adsorption. J. Pet. Sci. Eng. 2020, 189, 107041. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Ju, W.; Yan, G.; Lu, G.; Hou, X.; Kai, Z. Stress Sensitivity Characterization and Heterogeneous Variation of the Pore-Fracture System in Middle-High Rank Coals Reservoir Based on NMR Experiments. Fuel 2019, 238, 331–344. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. Standards Press of China: Beijing, China, 2008.

- GB/T 8899-2013; Determination of Maceral Group Composition and Minerals in Coal. Standards Press of China: Beijing, China, 2013.

- Ouyang, Z.; Liu, D.; Cai, Y.; Yao, Y. Fractal Analysis on Heterogeneity of Pore–Fractures in Middle–High Rank Coals with NMR. Energy Fuels 2016, 30, 5449–5458. [Google Scholar] [CrossRef]

- Chen, H.; Tang, D.; Li, S.; Xu, H.; Tao, S.; Wang, J.; Liu, Y. Dynamic Evaluation of Heterogeneity in Pore-Fracture System of Different Rank Coals under Different Confining Pressure Based on Low-Field NMR. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1620–1634. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Ju, W.; Qin, Z.; Ji, Y.; Quan, F.; Hu, Y. Microscopic Distribution and Dynamic Variation of Water under Stress in Middle and High Rank Coal Samples. J. Nat. Gas Sci. Eng. 2020, 79, 103369. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical Characterization of Coals by Low-Field Nuclear Magnetic Resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Jin, Z.; Wu, C. Multifractal Analysis of Pore Structure in Middle- and High-Rank Coal by Mercury Intrusion Porosimetry and Low-Pressure N2 Adsorption. Nat. Resour. Res. 2021, 30, 4565–4584. [Google Scholar] [CrossRef]

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.; Chen, B.; Zhang, C.; Wang, L. Characteristics of Pore Structure and Fractal Dimension of Low-Rank Coal: A Case Study of Lower Jurassic Xishanyao Coal in the Southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Wei, Z.; Pang, Y.; Yang, C.; Cao, H.; Zhang, J. Pore Structure Monofractal and Multifractal Characteristics of High-Mature Organic-Rich Shale Using N2 Adsorption–Desorption Measurements. Nat. Resour. Res. 2025, 34, 459–482. [Google Scholar] [CrossRef]

- Muller, J. Characterization of Pore Space in Chalk by Multifractal Analysis. J. Hydrol. 1996, 187, 215–222. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Song, X. Multifractal Analysis of Hg Pore Size Distributions of Tectonically Deformed Coals. Int. J. Coal Geol. 2015, 144–145, 138–152. [Google Scholar] [CrossRef]

- Ferreiro, J.P.; Wilson, M.; Vázquez, E.V. Multifractal Description of Nitrogen Adsorption Isotherms. Vadose Zone J. 2009, 8, 209–219. [Google Scholar] [CrossRef]

- Posadas, A.N.D.; Giménez, D.; Bittelli, M.; Vaz, C.M.P.; Flury, M. Multifractal Characterization of Soil Particle-Size Distributions. Soil Sci. Soc. Am. J. 2001, 65, 1361–1367. [Google Scholar] [CrossRef]

- Cheng, G.; Jiang, B.; Li, M.; Li, F.; Xu, S. Quantitative Characterization of Fracture Structure in Coal Based on Image Processing and Multifractal Theory. Int. J. Coal Geol. 2020, 228, 103566. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Liu, J.; Xie, S. Assessing the Water Migration and Permeability of Large Intact Bituminous and Anthracite Coals Using NMR Relaxation Spectrometry. Transp. Porous Med. 2015, 107, 527–542. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.; Hong, Y.; Liu, T.; Huang, Z.; Wang, R.; Wang, Z. Assessing the Moisture Migration during Microwave Drying of Coal Using Low-Field Nuclear Magnetic Resonance. Dry. Technol. 2018, 36, 567–577. [Google Scholar] [CrossRef]

- Ma, Y.; Deng, Z.; Yue, J.; Zhao, A.; Hu, M.; Shen, L. Nuclear Magnetic Resonance Experiment on the Influence of Confining Pressure on Spontaneous Imbibition of Water in Coal. Energy Fuels 2022, 36, 4818–4829. [Google Scholar] [CrossRef]

- Pan, J.; Lv, M.; Hou, Q.; Han, Y.; Wang, K. Coal Microcrystalline Structural Changes Related to Methane Adsorption/Desorption. Fuel 2019, 239, 13–23. [Google Scholar] [CrossRef]

- Wang, T.; Deng, Z.; Hu, H.; Wang, H.; Jiang, Z.; Wang, D. Study on the Pore Structure and Multifractal Characteristics of Medium- and High-Rank Coals Based on the Gas Adsorption Method: A Case Study of the Benxi Formation in the Eastern Margin of the Ordos Basin. Energy Fuels 2024, 38, 4102–4121. [Google Scholar] [CrossRef]

- Mathews, J.P.; Sharma, A. The Structural Alignment of Coal and the Analogous Case of Argonne Upper Freeport Coal. Fuel 2012, 95, 19–24. [Google Scholar] [CrossRef]

| Sample ID | Coal Seam | Stratigraphic | Ro,max (%) | Maceral Composition (%) | Proximate Analysis (%) | Porosity (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vitrinite | Inertinite | Exinite | Minerals | Mad | Ad | Vdaf | FCd | |||||

| M1 | 7 | P3x | 1.05 | 50.30 | 37.68 | 2.90 | 9.12 | 0.64 | 13.77 | 25.93 | 63.87 | 4.19 |

| M2 | 8 | P3x | 1.15 | 66.08 | 25.67 | 2.78 | 5.47 | 1.12 | 8.41 | 24.69 | 68.98 | 4.63 |

| M3 | 8 | P3x | 1.27 | 67.40 | 23.11 | / | 9.49 | 1.27 | 14.55 | 26.58 | 62.74 | 3.87 |

| M4 | 21 | P3x | 1.69 | 65.93 | 27.03 | / | 7.04 | 0.84 | 10.92 | 16.47 | 74.41 | 2.82 |

| H1 | 7 | P3l | 2.30 | 77.03 | 19.59 | / | 3.38 | 2.61 | 8.23 | 7.68 | 84.73 | 2.22 |

| H2 | 8 | P3l | 2.45 | 85.17 | 6.59 | / | 8.24 | 1.29 | 13.17 | 7.29 | 80.50 | 2.75 |

| H3 | 3 | P3l | 2.59 | 87.18 | 12.18 | / | 0.64 | 1.54 | 9.72 | 6.88 | 84.06 | 3.24 |

| H4 | 7 | P3l | 2.65 | 74.87 | 18.98 | / | 6.15 | 2.67 | 10.12 | 7.18 | 83.43 | 2.43 |

| H5 | 3 | P3l | 2.67 | 75.81 | 23.12 | / | 1.07 | 1.75 | 14.94 | 9.72 | 76.80 | 2.56 |

| Sample ID | Water-Saturated Conditions | Dry Conditions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | D1 | D2 | D−10 − D10 | D−10 − D0 | D0 − D10 | H | D1 | D2 | D−10 − D10 | D−10 − D0 | D0 − D10 | |

| M1 | 0.9703 | 0.9430 | 0.9407 | 2.5849 | 2.5214 | 0.0634 | 0.9286 | 0.8780 | 0.8573 | 2.8602 | 2.6749 | 0.1853 |

| M2 | 0.9701 | 0.9428 | 0.9403 | 2.5956 | 2.5294 | 0.0663 | 0.9283 | 0.8767 | 0.8566 | 2.8632 | 2.6767 | 0.1865 |

| M3 | 0.9700 | 0.9420 | 0.9400 | 2.6055 | 2.5428 | 0.0627 | 0.9263 | 0.8740 | 0.8527 | 2.8842 | 2.6920 | 0.1922 |

| M4 | 0.9703 | 0.9426 | 0.9406 | 2.5977 | 2.5383 | 0.0595 | 0.9276 | 0.8758 | 0.8551 | 2.8719 | 2.6836 | 0.1883 |

| H1 | 0.9643 | 0.9301 | 0.9286 | 2.8695 | 2.7951 | 0.0744 | 0.8970 | 0.8339 | 0.7940 | 3.1232 | 2.8380 | 0.2852 |

| H2 | 0.9644 | 0.9289 | 0.9287 | 2.9091 | 2.8362 | 0.0729 | 0.8672 | 0.7875 | 0.7345 | 3.4536 | 3.0945 | 0.3591 |

| H3 | 0.9607 | 0.9219 | 0.9214 | 3.1475 | 3.0617 | 0.0858 | 0.8686 | 0.7886 | 0.7373 | 3.4632 | 3.1081 | 0.3551 |

| H4 | 0.9639 | 0.9289 | 0.9278 | 2.8986 | 2.8240 | 0.0746 | 0.8859 | 0.8192 | 0.7717 | 3.2151 | 2.8992 | 0.3159 |

| H5 | 0.9636 | 0.9285 | 0.9273 | 2.9170 | 2.8383 | 0.0787 | 0.8930 | 0.8260 | 0.7860 | 3.1621 | 2.8678 | 0.2943 |

| Sample ID | Water-Saturated Conditions | Dry Conditions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α0 | α10− − α0 | α0 − α10+ | α10− − α10+ | Rd | Δf | α0 | α10− − α0 | α0 − α10+ | α10− − α10+ | Rd | Δf | |

| M1 | 1.2591 | 2.6145 | 0.3312 | 2.9457 | −2.2833 | 0.8501 | 1.4749 | 2.5674 | 0.6773 | 3.2447 | −1.8902 | 0.6445 |

| M2 | 1.2616 | 2.6207 | 0.3384 | 2.9591 | −2.2824 | 0.8284 | 1.4759 | 2.5685 | 0.6797 | 3.2482 | −1.8887 | 0.6406 |

| M3 | 1.2656 | 2.6314 | 0.3339 | 2.9653 | −2.2975 | 0.8816 | 1.4838 | 2.5774 | 0.6938 | 3.2711 | −1.8836 | 0.6298 |

| M4 | 1.2638 | 2.6283 | 0.3263 | 2.9547 | −2.3020 | 0.9093 | 1.4794 | 2.5726 | 0.6850 | 3.2576 | −1.8876 | 0.6393 |

| H1 | 1.3437 | 2.8309 | 0.4219 | 3.2528 | −2.4091 | 0.8882 | 1.5715 | 2.6502 | 0.8890 | 3.5392 | −1.7613 | 0.3931 |

| H2 | 1.3520 | 2.8678 | 0.4279 | 3.2957 | −2.4399 | 0.8970 | 1.7139 | 2.7901 | 1.1089 | 3.8990 | −1.6813 | 0.2815 |

| H3 | 1.4225 | 3.0454 | 0.5140 | 3.5593 | −2.5314 | 0.8576 | 1.7172 | 2.8017 | 1.1082 | 3.9099 | −1.6936 | 0.2868 |

| H4 | 1.3523 | 2.8541 | 0.4300 | 3.2840 | −2.4241 | 0.8948 | 1.6089 | 2.6802 | 0.9596 | 3.6397 | −1.7206 | 0.3368 |

| H5 | 1.3551 | 2.8670 | 0.4410 | 3.3080 | −2.4260 | 0.8500 | 1.5884 | 2.6662 | 0.9148 | 3.5810 | −1.7513 | 0.3847 |

| Sample ID | P1 | P2 | P3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Water-Saturated Conditions | Dry Conditions | Variation | Water-Saturated Conditions | Dry Conditions | Variation | Water-Saturated Conditions | Dry Conditions | Variation | |

| M1 | 12,804.83 | 7396.46 | −42.24% | 4294.02 | 196.35 | −95.43% | 6502.29 | 7.50 | −99.88% |

| H1 | 8391.26 | 8110.20 | −3.35% | 384.85 | 25.20 | −93.45% | 572.50 | 0 | −100% |

| Parameter | D−10 − D0 | D0 − D10 | α10− − α0 | α0 − α10+ | |

|---|---|---|---|---|---|

| Water-saturated conditions | Sa | 0.34 | 0.18 | 0.34 | 0.29 |

| SS+f | −0.34 | −0.18 | −0.34 | −0.29 | |

| Dry conditions | Sa | 0.15 | 0.24 | 0.14 | 0.20 |

| SS+f | −0.15 | −0.24 | −0.13 | −0.20 | |

| Parameter | H | D−10 − D10 | α10− − α10+ | Rd | |

|---|---|---|---|---|---|

| Water-saturated conditions | Mad | −0.4246 | 0.3224 | 0.3189 | −0.3052 |

| Ad | 0.0303 | −0.0295 | −0.0295 | 0.0245 | |

| Dry conditions | Mad | −0.2666 | 0.1892 | 0.1941 | 0.3676 |

| Ad | 0.0076 | −0.0065 | −0.0067 | −0.0106 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, S.; Qiao, Y.; Xie, D.; Chang, L. Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium- and High-Rank Coals via Nuclear Magnetic Resonance. Fractal Fract. 2025, 9, 290. https://doi.org/10.3390/fractalfract9050290

Liu H, Zhang S, Qiao Y, Xie D, Chang L. Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium- and High-Rank Coals via Nuclear Magnetic Resonance. Fractal and Fractional. 2025; 9(5):290. https://doi.org/10.3390/fractalfract9050290

Chicago/Turabian StyleLiu, Huan, Shasha Zhang, Yu Qiao, Danfeng Xie, and Long Chang. 2025. "Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium- and High-Rank Coals via Nuclear Magnetic Resonance" Fractal and Fractional 9, no. 5: 290. https://doi.org/10.3390/fractalfract9050290

APA StyleLiu, H., Zhang, S., Qiao, Y., Xie, D., & Chang, L. (2025). Multifractal Characterization of Pore Heterogeneity and Water Distribution in Medium- and High-Rank Coals via Nuclear Magnetic Resonance. Fractal and Fractional, 9(5), 290. https://doi.org/10.3390/fractalfract9050290