Pore–Fracture Structure and Fractal Features of Carboniferous Taiyuan Formation Hydrocarbon Source Rocks as Investigated Using MICP, LFNMR, and FESEM

Abstract

1. Introduction

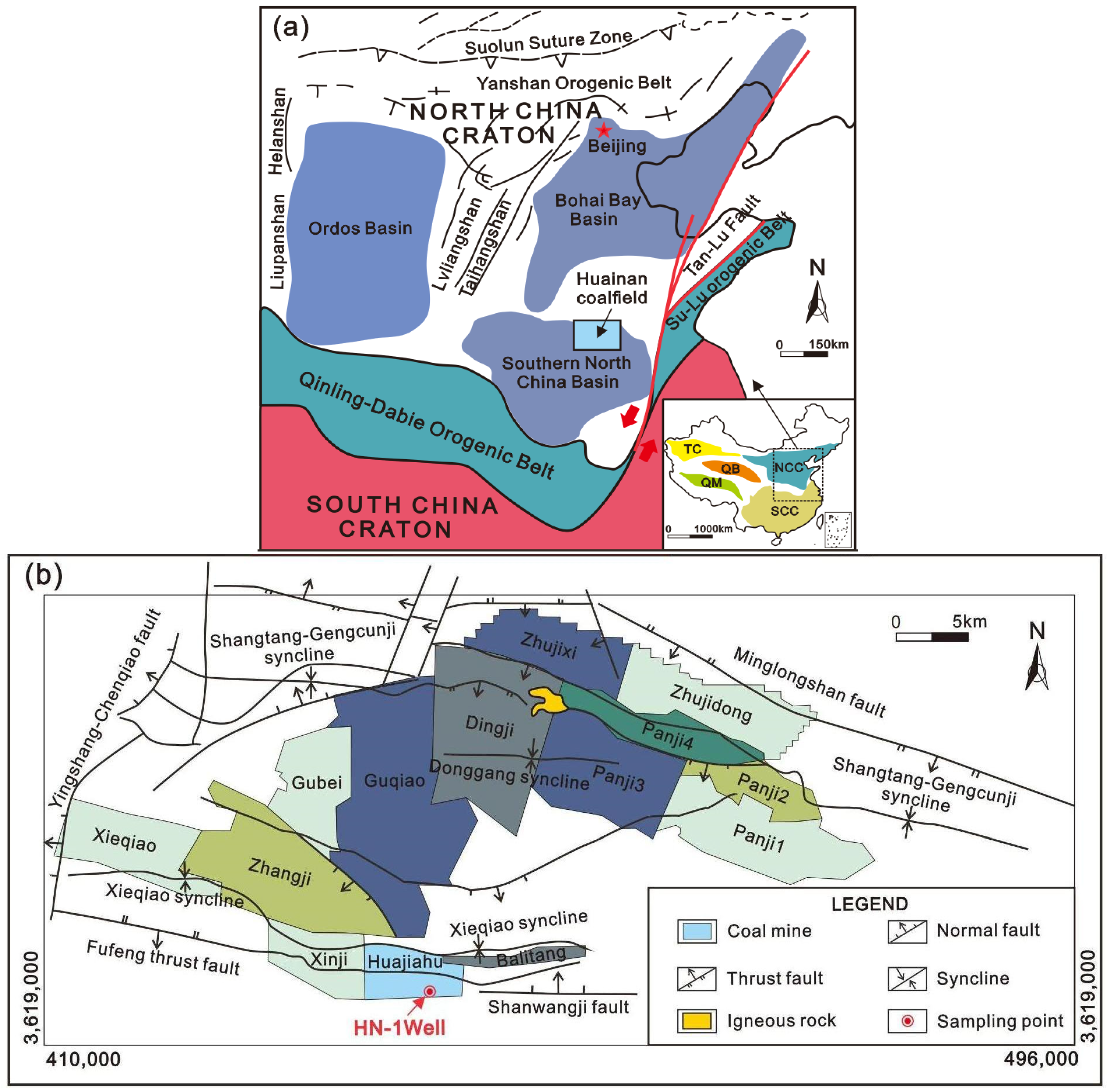

2. Geological Setting

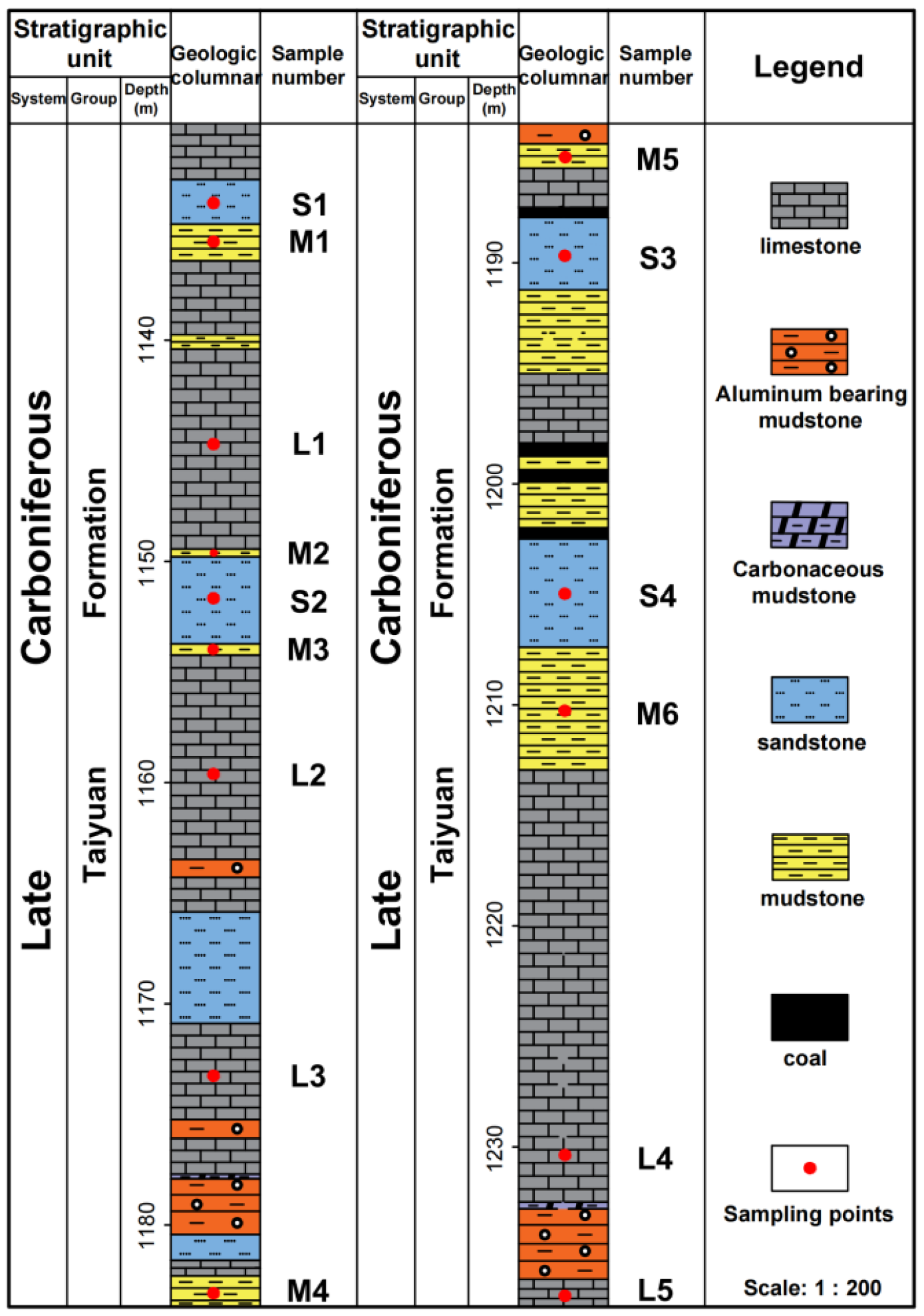

2.1. Stratigraphy of the Study Area

2.2. Tectonics of the Study Area

3. Methodology

4. Samples and Experiments

4.1. Hydrocarbon Rock Sample Collection

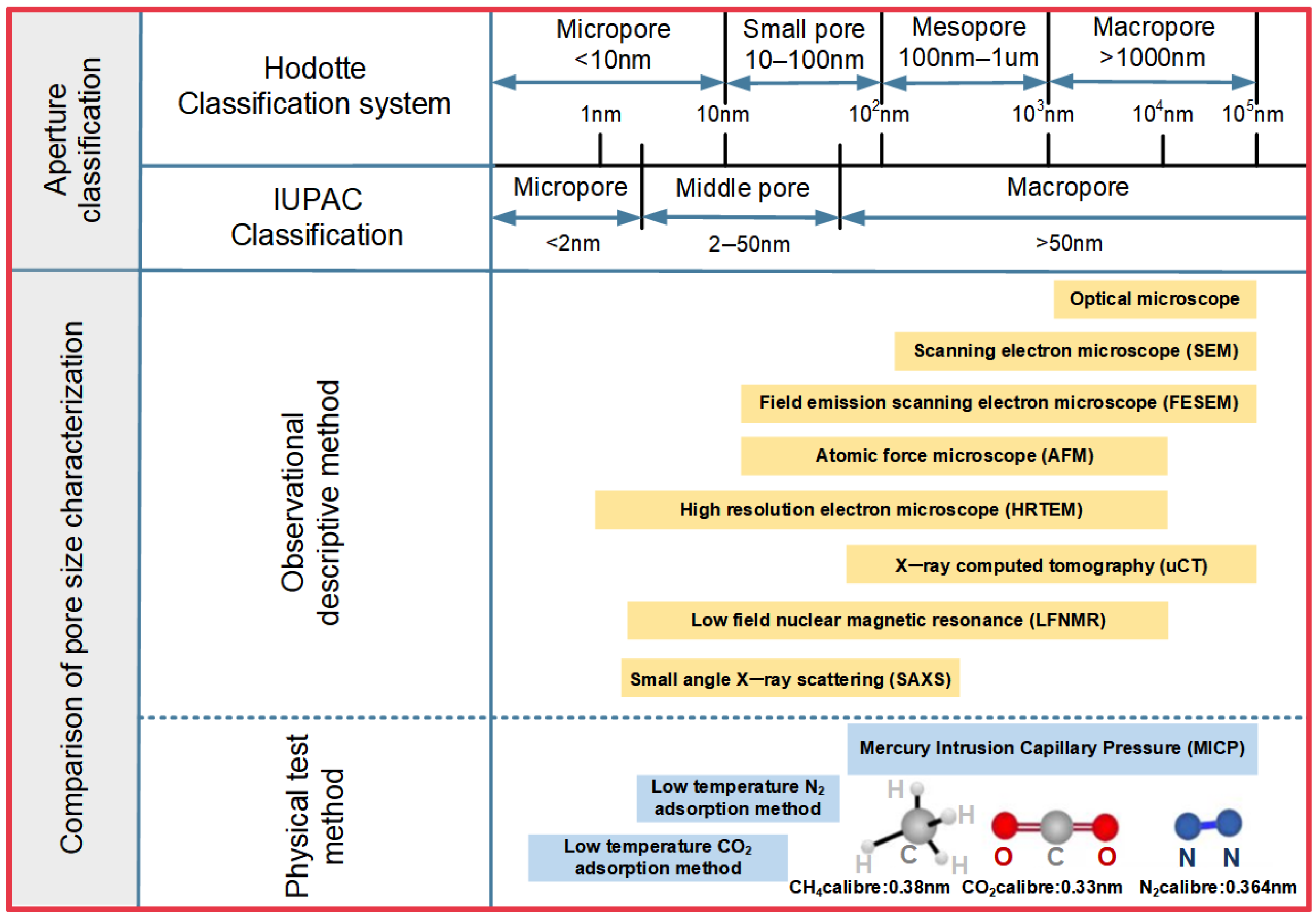

4.2. Experimental Methods

4.2.1. Mercury Intrusion Capillary Pressure (MICP)

4.2.2. Low-Field Nuclear Magnetic Resonance (LFNMR)

4.2.3. Field Emission Scanning Electron Microscopy (FESEM)

4.2.4. Calculation of Fractal Dimension

5. Results and Analysis

5.1. Results of MICP Test

5.1.1. Pore Throat Size

5.1.2. Pore Throat Sorting Characteristics

5.1.3. Pore–Throat Connectivity and Seepage Performance

5.2. Capillary Pressure Curve Characteristics

5.3. Results of LFNMR Experiments

5.3.1. Low-Field Nuclear Magnetic Resonance Porosity

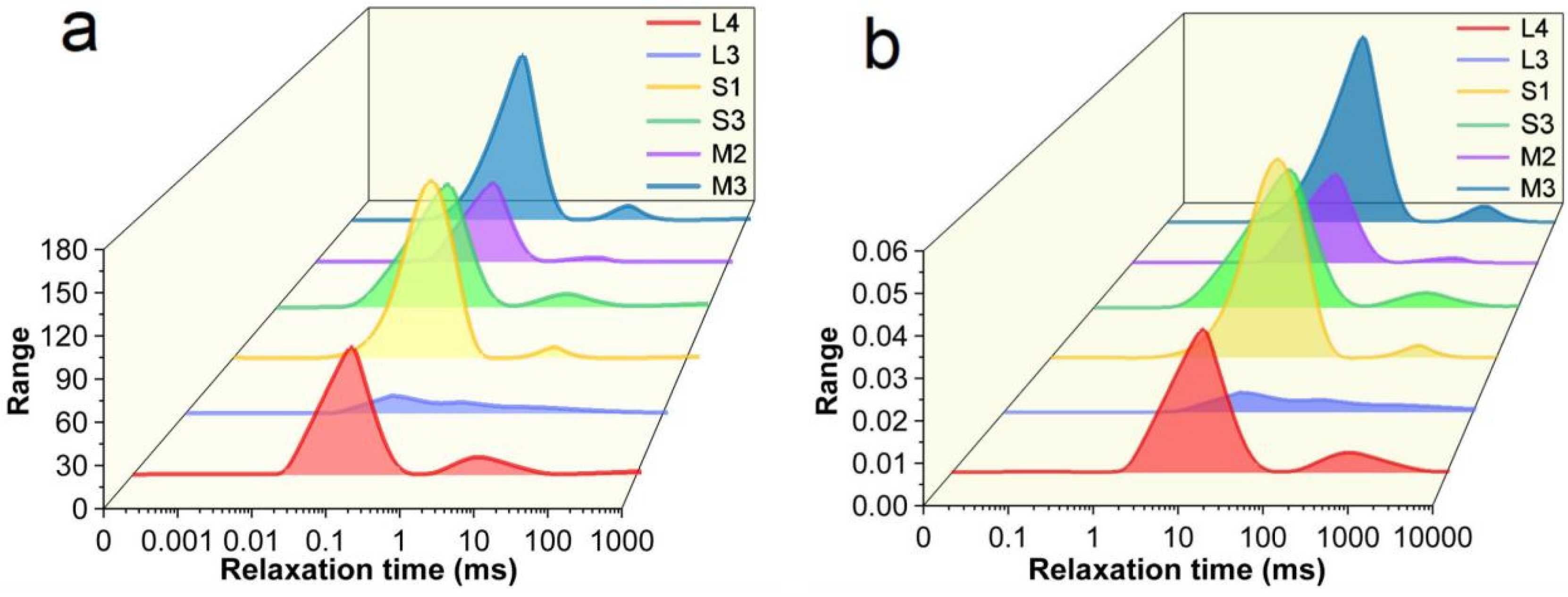

5.3.2. Pore Size Distribution

5.4. Pore Types and Their Distribution Characteristics

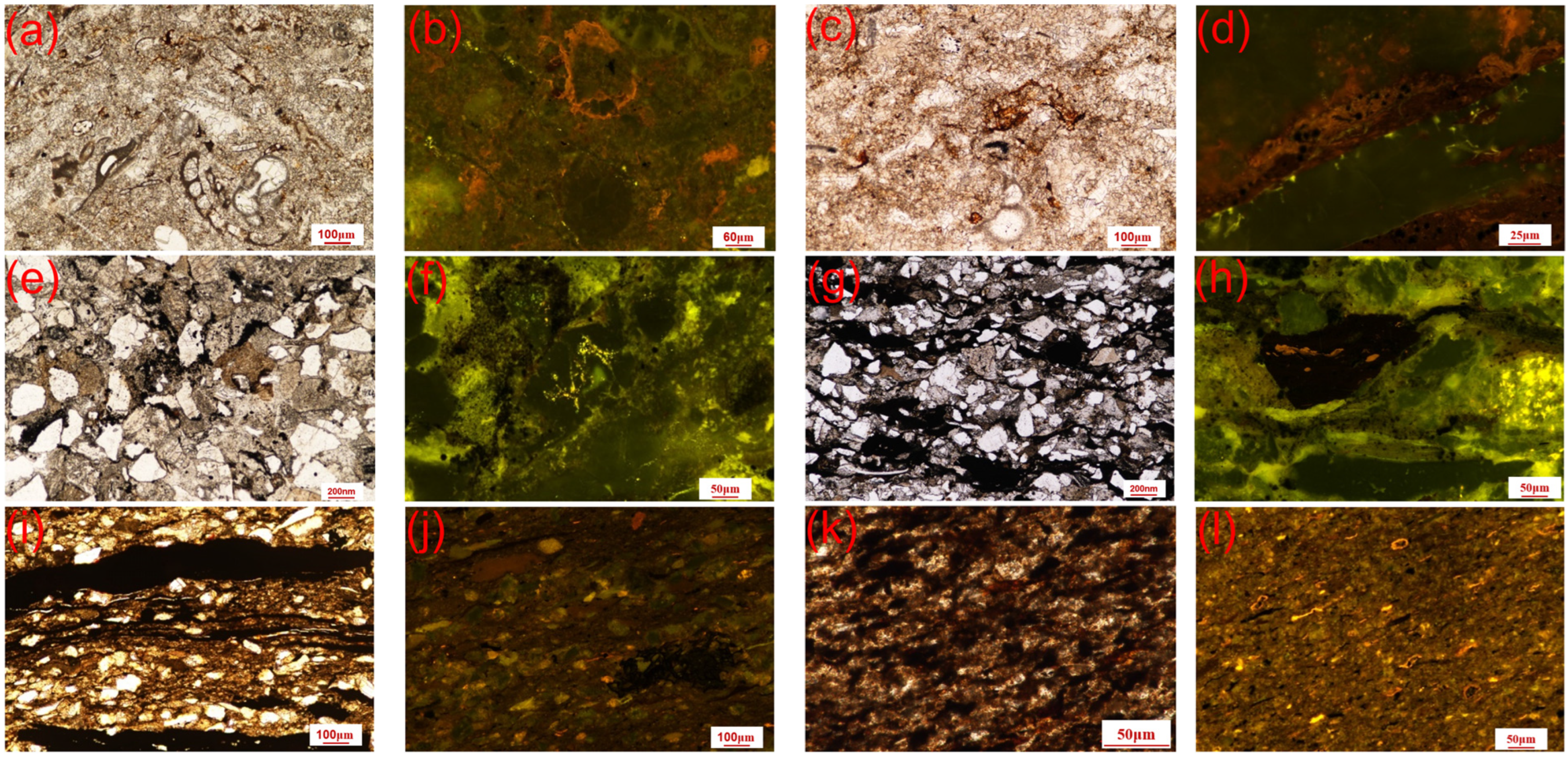

5.4.1. Organic Matter Type and Development of Micropores Based on POM

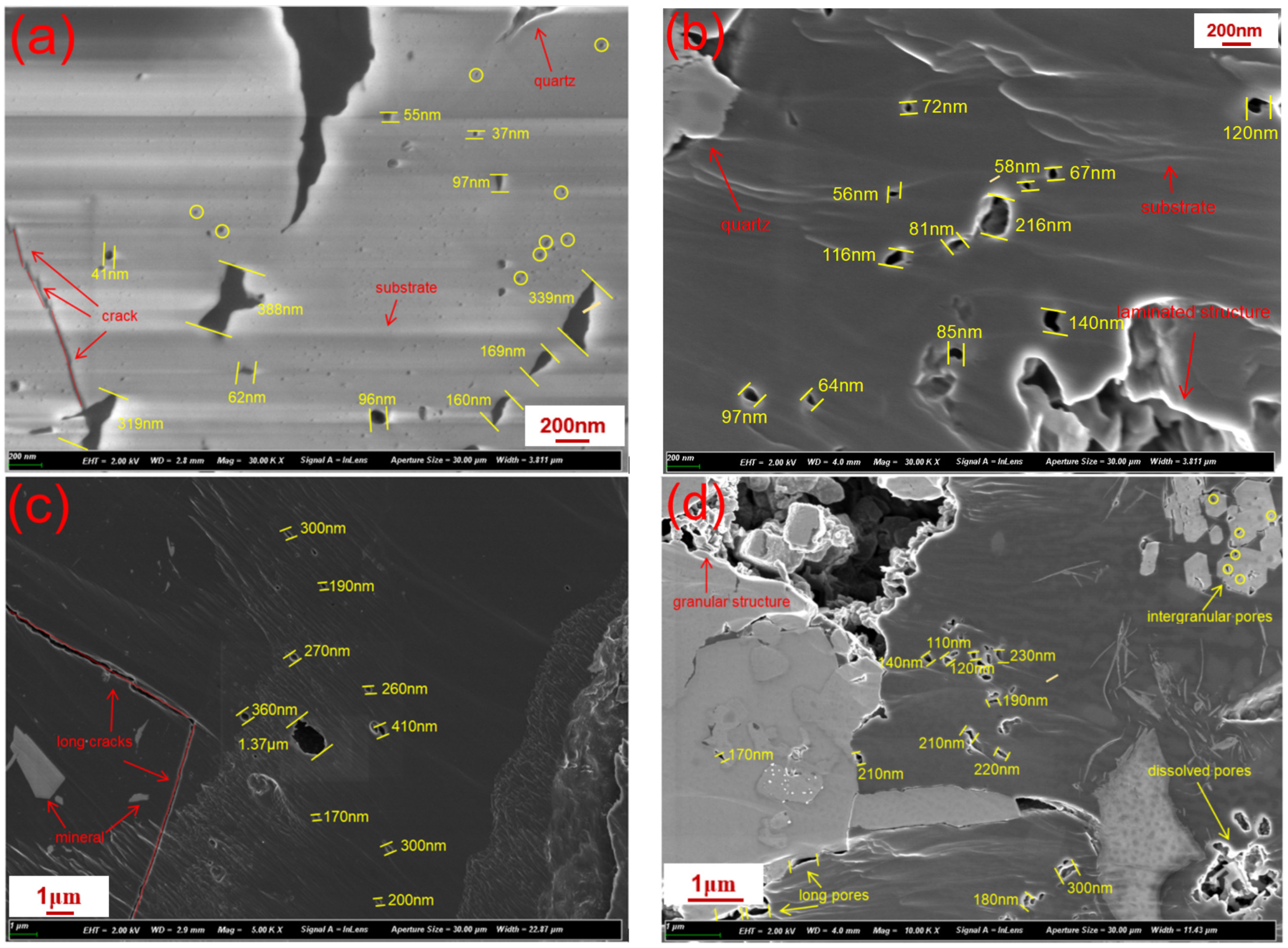

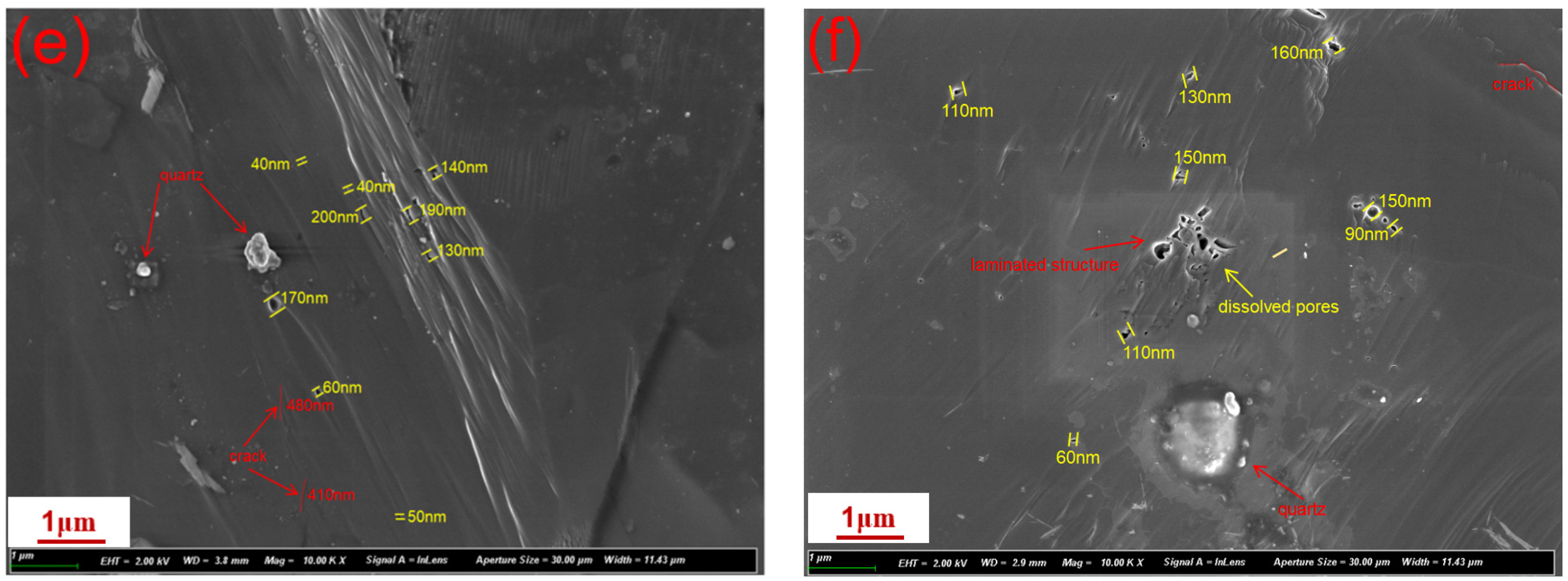

5.4.2. Surface Nanoscale Pore Fracture Characteristics Based on FESEM

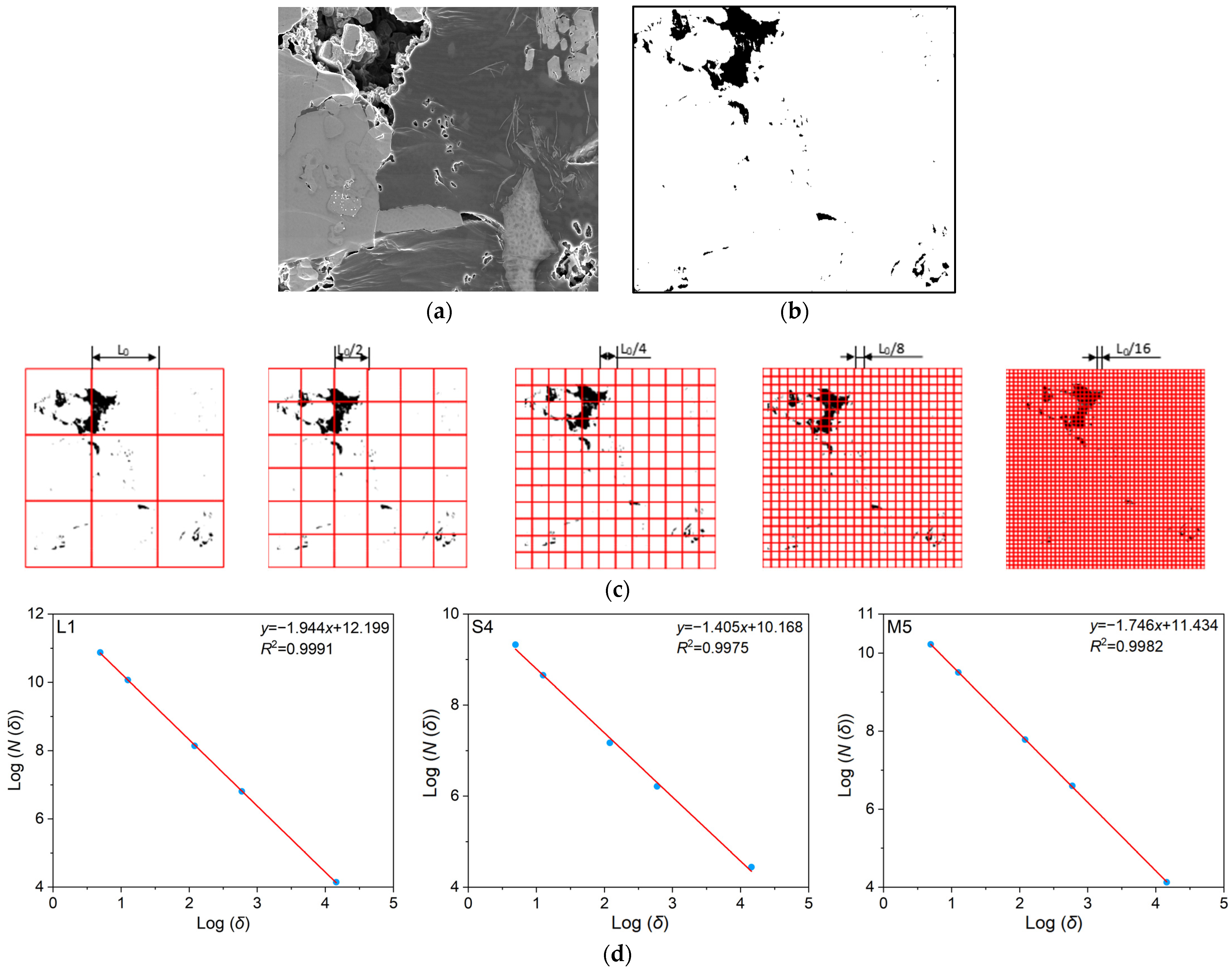

5.4.3. Fractal Dimension Calculation Based on FESEM

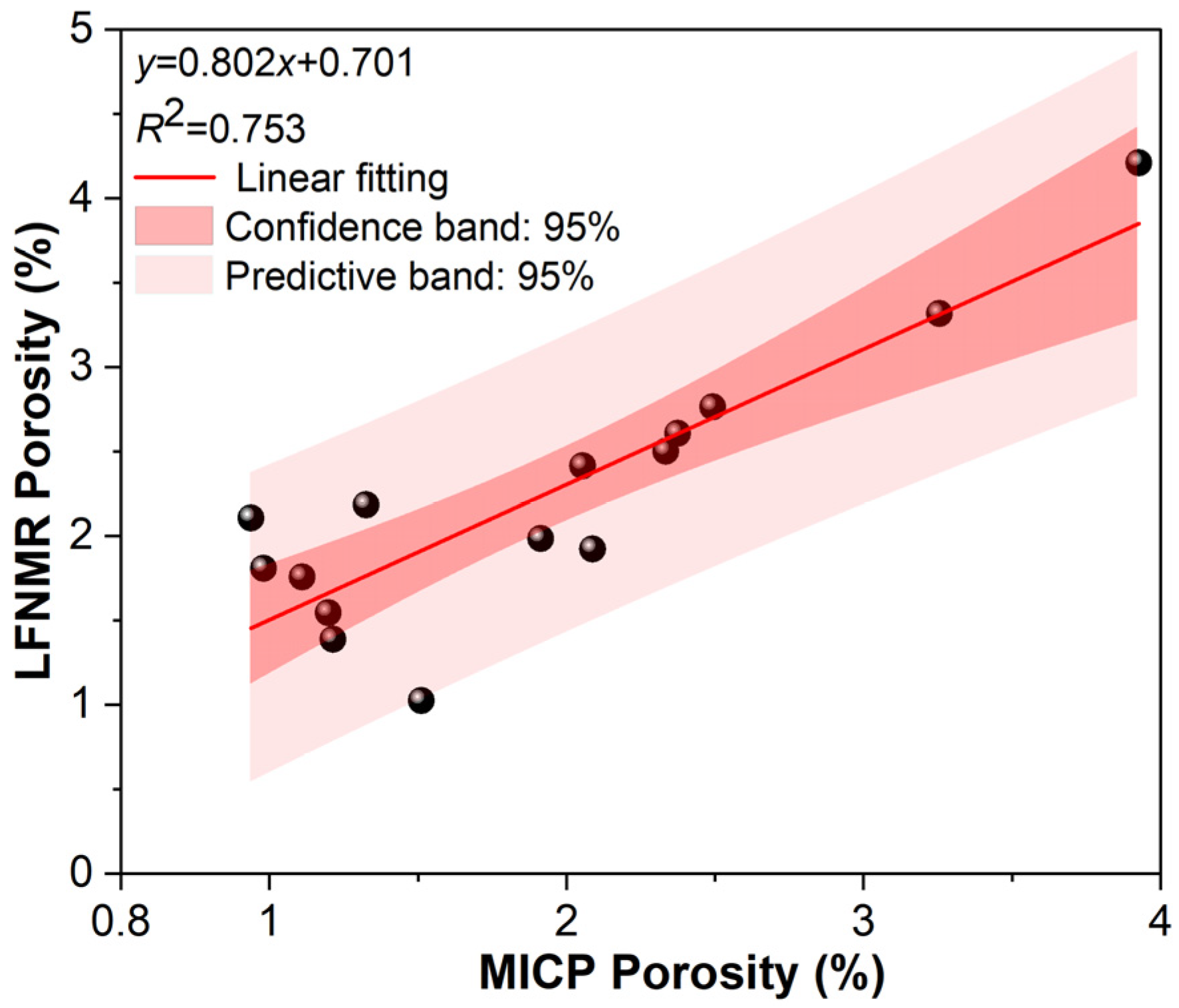

5.5. Differences Between MICP and LFNMR Porosity

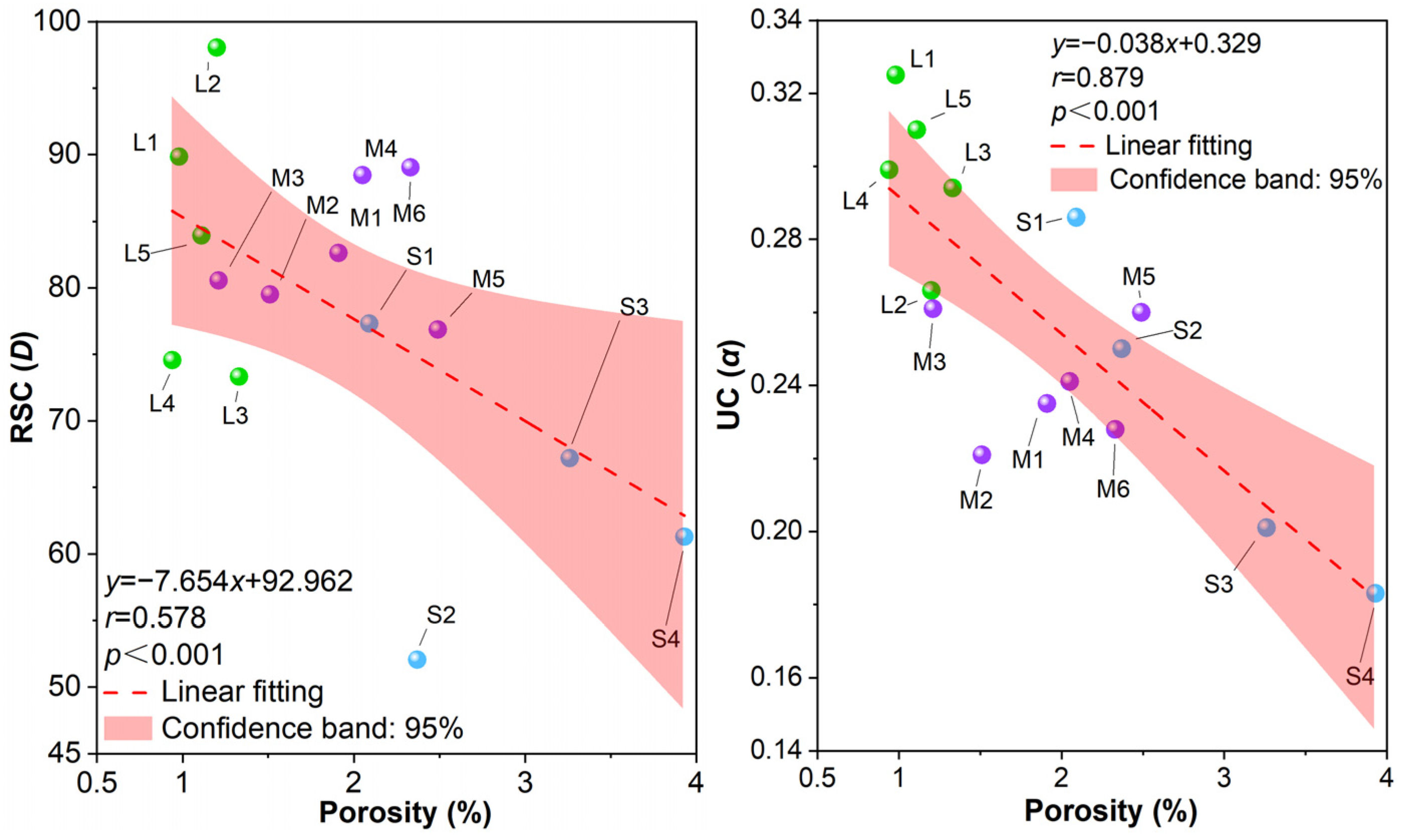

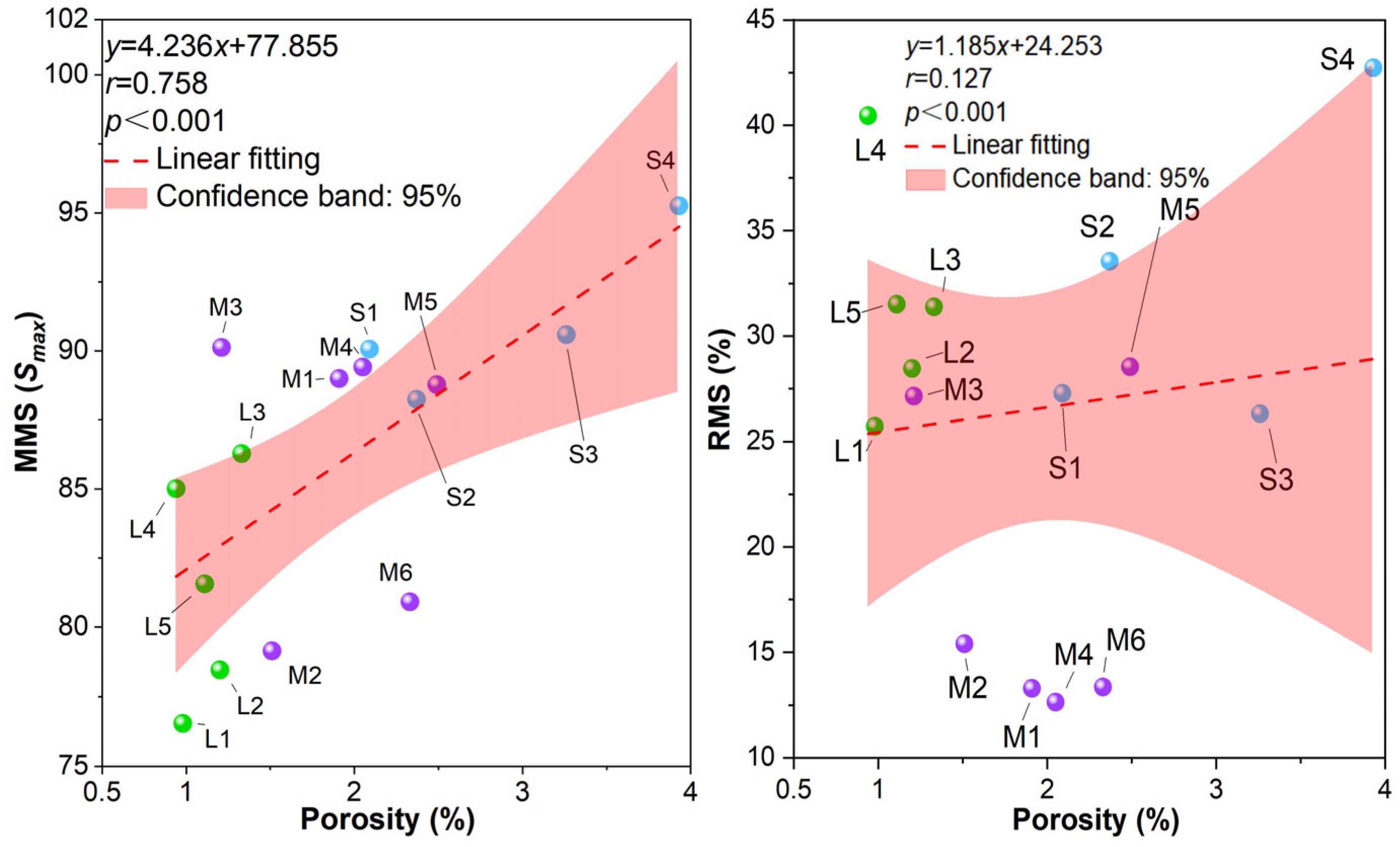

5.6. Relationship Between FESEM Fractal Dimension and Reservoir Physical Properties

6. Outlook

- (1)

- Deepening the understanding of pore structures and optimizing their practical applications, including expanding the sample size and regional research scope to cover different geological settings to enhance the universality of the data;

- (2)

- Developing high-resolution multi-scale characterization techniques, such as Nano-CT and FIB-SEM, combined with in situ experiments to simulate dynamic changes in formation environments for multi-factor coupling analysis; at the same time, establishing a comprehensive geological–geochemical–pore evolution model by comprehensively considering mineral composition, organic matter types, and fluid–rock interactions;

- (3)

- Utilizing experimental data to construct numerical simulation and prediction models, such as pore network models or machine learning algorithms, combining microscopic pore characteristics with macroscopic reservoir properties to optimize unconventional natural gas development strategies and assess the impact of pore structures on efficient unconventional natural gas development.

7. Conclusions

- (1)

- The MICP test results indicate that the displacement pressures for limestone, sandstone, and mudstone in the study area are 17.22 MPa, 7.57 MPa, and 13.78 MPa, respectively. This suggests that sandstone has coarser pore throats, better permeability, and a superior pore structure. Sandstone exhibits the lowest mean D value (64.48), while the mean α values for the three rock types are similar (ranging from 0.2 to 0.3), indicating a uniform distribution of pore throats. The skewness of pore throats in all three rock types is less than 0, and the kurtosis is less than 1, presenting a negatively skewed, fine pore throat distribution with a flat kurtosis curve. Sandstone has an average Smax of 91.04 and a mercury withdrawal efficiency of 64.45%, indicating excellent connectivity and fluid flow properties, followed by mudstone. DP and α are negatively correlated with porosity, while Kp and Smax are positively correlated with porosity.

- (2)

- The T2 spectrum characteristic maps of six representative samples were characterized using LFNMR, and the study found that the pore distribution patterns were consistent with those obtained from MICP experiments, the signal intensity of sandstone types in different relaxation time segments was better, and the width of the T2 spectra was wider, which indicated that the sandstone types had better pore structure and connectivity. The T2 spectra of different rock types have the double-peak type with the left peak dominant, and the wave valley and inflection point are obvious, which indicates that the pore distribution tends to be uniform, and the pores of different diameters are developed with a wide range of pore diameters, among which micropores and mesopores are dominant, and a small number of macropores are developed at the same time. However, the spectra of the limestones do not show significant characteristics, which indicates that the pore development of limestones is not uniform.

- (3)

- The results of POM indicate that the rocks are predominantly characterized by organic matter development. Specifically, limestones are dominated by bituminous matter and organic inclusions, sandstones are primarily composed of vitrinite with a small amount of inertinite, and exhibit relatively developed exinite, while mudstones are mainly composed of vitrinite with well-developed exinite and some inertinite macerals. The FESEM results reveal that the pore development in limestones is mostly below 100 nm, with highly developed nanoscale pores in the matrix. Sandstones exhibit good and uniform pore development, with the emergence of microscale macropores; however, the pores in sandstones are still primarily composed of nanopores. Mudstone samples contain numerous pores dissolved in quartz minerals, ranging from nanoscale to microscale in size, with mostly irregular pore shapes. The degree of fracture development varies significantly among the three rock types, but sandstone fractures are dominated by macrofractures above the micron scale, demonstrating a certain oil storage capacity of the sandstone.

- (4)

- The MICP method mainly characterizes pore sizes larger than 50 nm and may not be accurate enough for smaller pores. In contrast, the LFNMR method mainly characterizes pore sizes from 2 nm to 1000 nm, which is advantageous for both large and small pores. This characteristic leads to the relatively small value of the MICP method in characterizing the porosity of limestone samples, which results in the largest difference between the pressed mercury method and the LFNMR method in the mean porosity values of limestone and the smallest difference in sandstone among the three types of rock samples.

- (5)

- The results of the fractal dimensions indicate that sandstone samples have the lowest fractal dimension, implying a more uniform pore structure distribution, better connectivity, and relatively higher permeability, thus exhibiting superior reservoir performance, followed by mudstone. These fractal dimension results are consistent with the experimental results obtained from the MICP and LFNMR conducted in this study. Additionally, there is a good correlation between the fractal dimensions derived from field emission scanning electron microscopy (FESEM) and the porosity and permeability of source rock reservoirs, suggesting that FESEM fractal dimensions can serve as an important parameter for evaluating the physical properties of source rock reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, X.; Dai, C.; Wang, R.; Liu, H.; Meng, S.; Jin, X.; Wu, Y. Experimental study on countercurrent imbibition in tight oil reservoirs using nuclear magnetic resonance and AFM: Influence of liquid–liquid/solid interface characteristics. Fuel 2024, 358, 130026. [Google Scholar] [CrossRef]

- Liu, B.; Gao, S.; Mohammadian, E. Comprehensive outlook into critical roles of pressure, volume, and temperature (PVT) and phase behavior on the exploration and development of shale oil. Energy Fuels 2022, 36, 14534–14553. [Google Scholar] [CrossRef]

- Yuan, D.E.; Yan, D.T.; Tang, Y. Genesis of clay minerals in gravel reservoirs and their influence on reservoir quality—An example from the Triassic Baikouquan Formation in the western part of the Mahu Depression, Junggar Basin. J. Geol. 2024, 98, 3588–3600. [Google Scholar]

- Qin, Y.; Shen, J.; Shen, Y.L. Co-mining compatibility of stacked gas-bearing systems—A common geological problem in coal system “three gases” and deep coalbed methane mining. J. Coal 2016, 41, 14–23. [Google Scholar]

- Zhang, X.; Wei, B.; You, J.; Liu, J.; Wang, D.; Lu, J.; Tong, J. Characterizing pore-level oil mobilization processes in unconventional reservoirs assisted by state-of-the-art nuclear magnetic resonance technique. Energy 2021, 236, 121549. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Zhou, S.; Luo, Y.; Liu, X.; Zhang, Y.; Niu, Z. Research on characterization and heterogeneity of microscopic pore throat structures in tight oil reservoirs. ACS Omega 2021, 6, 24672–24682. [Google Scholar] [CrossRef]

- Du, S.; Shi, Y. Nanostructures in tight oil reservoirs: Multiple perspectives. Int. J. Hydrogen Energy 2024, 49, 884–896. [Google Scholar] [CrossRef]

- Davoodi Shadfar, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Experimental and field applications of nanotechnology for enhanced oil recovery purposes: A review. Fuel 2022, 324, 124669. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Zheng, S.; Luo, Z.; Sheng, Y.; Wang, X. Full-scale pore structure and its controlling factors of the Wufeng-Longmaxi shale, southern Sichuan Basin, China: Implications for pore evolution of highly overmature marine shale. J. Nat. Gas Sci. Eng. 2019, 67, 134–146. [Google Scholar] [CrossRef]

- He, L.; Cao, J.; Lu, J.; Lin, B.; Lu, Y.; Shi, S.; Liu, M. Effect of microwave-assisted cyclic oxidation on the coal internal and surface structure based on NMR and AFM. Energy 2024, 288, 129872. [Google Scholar]

- Zeng, F.; Dong, C.; Lin, C.; Tian, S.; Wu, Y.; Lin, J.; Zhang, X. Pore structure characteristics of reservoirs of Xihu Sag in East China Sea Shelf Basin based on dual resolution X-ray computed tomography and their influence on permeability. Energy 2022, 239, 122386. [Google Scholar] [CrossRef]

- Shi, S.; He, J.; Zhang, X.; Yu, Z.; Wang, J.; Yang, T.; Wang, W. Pore structure evolution of tar-rich coal with temperature-pressure controlled simulation experiments. Fuel 2023, 354, 129298. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Bai, B.; Yang, Z.; Wu, S.; Su, L.; Dong, D.; Li, X. The first discovery of nanopores in oil and gas reservoirs in China and its scientific value. Acta Petrol. Sin. 2011, 27, 1857–1864. [Google Scholar]

- Kirchofer, A.; Firouzi, M.; Psarras, P.; Wilcox, J. Modeling CO2 Transport and Sorption in Carbon Slit Pores. J. Phys. Chem. C 2017, 121, 21018–21028. [Google Scholar] [CrossRef]

- Bernard, S.; Wirth, R.; Schreiber, A. Formation of nanoporous pyrobitumen residues during maturation of the Barnett Shale (Fort Worth Basin). Int. J. Coal Geol. 2012, 103, 3–11. [Google Scholar] [CrossRef]

- Li, J.; Hu, L.; Jiang, W.; Cai, M.; He, J.; Wang, Q.; Li, D. Shale pore characteristics and their impact on the gas-bearing properties of the Longmaxi Formation in the Luzhou area. Sci. Rep. 2024, 14, 16896. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhu, Y.; Li, P.; Wang, Y.; Xiang, J. Applicability of Nuclear Magnetic Resonance Experiment in Analyzing Pore and Fluid Distribution Characteristics of Tight Sandstone: A Case Study in the Julu Area, Bohai Bay Basin, China. ACS Omega 2023, 8, 43903–43919. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Xue, J.; Li, W.; Du, X.; Ma, Q.; Zhan, K.; Chen, Z. Comprehensive evaluation and interpretation of mercury intrusion porosimetry data of coals based on factal theory, Tait equation and matrix compressibility. Fuel 2021, 298, 120823. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman: New York, NY, USA, 1982. [Google Scholar]

- Zhang, G.; Guo, J.; Xu, B.; Xu, L.; Dai, Z.; Yin, S.; Soltanian, M.R. Quantitative analysis and evaluation of coal mine geological structures based on fractal theory. Energies 2021, 14, 1925. [Google Scholar] [CrossRef]

- Wang, D.; Zeng, Z.P.; Hu, H.Y.; Wang, T.; Zhu, G.G.; Li, S.T.; Li, L. Pore structure fractal characteristics and geological significance of deep terrestrial shales in the Lower Urho Formation, central Junggar Basin. Oil Gas Geol. Recovery 2024, 31, 23–35. [Google Scholar]

- Zhong, B.; Zhu, Y.; Feng, G.; Xiang, J.; Wang, Y. Matrix Compression and Pore Heterogeneity in the Coal-Measure Shale Reservoirs of the Qinshui Basin: A Multifractal Analysis. Fractal Fract. 2024, 8, 580. [Google Scholar] [CrossRef]

- Li, L.L. Evaluation of Coal System Oil and Gas Combined Exploration and Extraction Potential of Taiyuan Formation in Huainan Area. Master’s Thesis, Nanjing University, Nanjing, China, 2019. [Google Scholar]

- Zhang, W.Y.; Dou, X.Z.; Liu, G.J. Geochemical characterization and hydrocarbon potential of hydrocarbon source rocks in the deep coal system of the Panxie Mining Area, Huainan. J. Coal Sci. 2020, 45, 731–739. [Google Scholar]

- Sang, S.; Han, S.; Zhou, X.; Liu, S.; Wang, Y. Deep coalbed methane resources and prospects for exploration and development in East China. Reserv. Eval. Dev. 2023, 13, 403–415. [Google Scholar]

- Wu, D.; Wu, J.; Hu, G.; Cai, G.; Gao, X. Fine Structure Characterization of Representative Coal-Bearing Rocks of the Late Carboniferous Taiyuan Formation in Huainan Coalfield: Combined SEM, FESEM, and μCT Techniques. ACS Omega 2024, 9, 2850–2865. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, W.Y.; Liu, G.J. Characteristics and geological significance of germanium in Taiyuan coal formation of Huainan Coalfield, Anhui, China. Int. J. Coal Sci. Technol. 2020, 7, 662–675. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, W.Y.; Liu, G.J.; Zhan, R.; Hu, G.Q. Unconventional oil and gas exploration and development technology of the Taiyuan Formation coal system in Huainan Coalfield. Coalf. Geol. Explor. 2017, 45, 13–18. [Google Scholar] [CrossRef]

- Chen, B.Y.; Liu, G.J.; Wu, D.; Sun, R.Y. Elemental geochemical characterization of the Taiyuan Formation aluminous mudstone in Huainan Coalfield. Coalf. Geol. Explor. 2018, 46, 21–27. [Google Scholar]

- Yu, K.; Gan, Y.T.; Ju, Y.W.; Shao, C.J. Influence of sedimentary environment on the brittleness of coal-bearing shale: Evidence from geochemistry and micropetrology. J. Pet. Sci. Eng. 2020, 185, 106603. [Google Scholar] [CrossRef]

- GB/T 19222-2003. Available online: https://codeofchina.com/standard/GBT19222-2003.html (accessed on 16 March 2025).

- GB/T 29171-2012. Available online: https://codeofchina.com/standard/GBT29171-2012.html (accessed on 16 March 2025).

- Xie, H.P. Introduction to Fractal-Rock Mechanics; Science Publishing House: Beijing, China, 1997; pp. 18–23. [Google Scholar]

- Feder, J. Fractals; Plenum Press: New York, NY, USA, 1988. [Google Scholar]

- Yang, X. Research on Rock Pore Imaging Based on Oblique Incident Light Reflection Difference Technique. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2022. [Google Scholar]

- Gao, J.D.; Kong, D.B.; Peng, Y.F.; Zhou, Y.Z.; Liu, Y.W.; Zhu, W.Y. Pore-scale mechanisms and hysteresis effect during multi-cycle injection and production process in underground hydrogen storage reservoir. Energy 2023, 283, 129007. [Google Scholar] [CrossRef]

- Fang, H.H.; Wang, Z.F.; Sang, S.X.; Liu, S.Q.; Gu, C.C.; Yang, J.; Huang, Y.H. Correlation Evaluation and Schematic Analysis of Influencing Factors Affecting Pore and Fracture Connectivity on the Microscale and Their Application Discussion in Coal Reservoir Based on X-ray CT Data. ACS Omega 2023, 8, 11852–11867. [Google Scholar] [CrossRef]

- Liu, X.; Rao, L.; Zhuang, T. Characterization of Micro-nano pore structure of tight sandstone based on nuclear magnetic resonance experiments (NMR). In Proceedings of the International Field Exploration and Development Conference, Wuhan, China, 20–22 September 2023; Springer Nature: Singapore, 2023; pp. 208–224. [Google Scholar]

- Yao, Y.B.; Liu, D.M.; Che, Y.; Tang, D.Z.; Tang, S.H.; Huang, W.H. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2009, 89, 1371–1380. [Google Scholar] [CrossRef]

- Coates, G.R.; Xiao, L.Z.; Prammer, M.G. NMR Logging Principles and Applications; Gulf Publishing Company: Houston, TX, USA, 1999; in press. [Google Scholar]

- Wen, X.; Chen, Y.; Pu, R. Analysis of the factors influencing movable fluid in shale oil reservoirs: A case study of Chang 7 in the Ordos Basin, China. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 177. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M. Physical properties and fluid characterization of shale reservoirs based on nuclear magnetic resonance relaxation spectroscopy. J. Coal 2018, 43, 181–189. [Google Scholar]

- Li, A.; Ding, W.L.; Wang, R.Y. Petrophysical characterization of shale reservoir based on nuclear magnetic resonance (NMR) experiment: A case study of Lower Cambrian Qiongzhusi Formation in eastern Yunnan Province, South China. J. Nat. Gas Sci. Eng. 2016, 37, 29–38. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Y.B.; Liu, D.M.; Zheng, S.J.; Sun, G.X.; Chang, Y.H. Shale pore size classification: An NMR fluid typing method. Mar. Pet. Geol. 2018, 96, 591–601. [Google Scholar] [CrossRef]

- Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural studies of gas shales. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. Paper SPE-131771 MS. [Google Scholar]

- Curtis, J.B. Fractured shale-gas system. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Qin, L.; Li, S.G.; Zhai, C.; Lin, H.F.; Zhao, P.X.; Yan, M.; Shi, Y. Joint analysis of pores in low, intermediate, and high rank coals using mercury intrusion, nitrogen adsorption, and nuclear magnetic resonance. Powder Technol. 2020, 362, 615–627. [Google Scholar] [CrossRef]

- Li, K.; Jia, Y.; Han, Y.L.; Lei, F.; Lin, F.H.; Wang, T.; Chen, W. Quantitative characterisation of microstructure of coal carbonate rocks in tectonic regions based on MIP and SEM. China Coal 2025, 51, 204–214. [Google Scholar]

- Wang, J.; Zhang, J.; Xiao, X.; Chen, Y.N.; Han, D. Pore Structure and Fractal Characteristics of Inter-Layer Sandstone in Marine–Continental Transitional Shale: A Case Study of the Upper Permian Longtan Formation in Southern Sichuan Basin, South China. Fractal Frac. 2025, 9, 11. [Google Scholar] [CrossRef]

- Shen, Y.J.; Wang, X.; Zhao, X.; Zhao, C.H.; Wang, S.Q.; Guo, C.; Shi, Q.M.; Ma, W. Characteristics of multiscale pore structure of oil-rich coal in Yushenfu mining area. Coalf. Geol. Explor. 2021, 49, 33–41. [Google Scholar]

- Li, J.; Liu, D.; Yao, Y.; Cai, Y.; Qiu, Y. Evaluation of the reservoir permeability of anthracite coals by geophysical logging data. Int. J. Coal Geol. 2011, 87, 121–127. [Google Scholar] [CrossRef]

- Liu, L.H.; Hu, H.Y.; Zhan, X.F.; Wang, T.; Tang, T.; Lei, L. Pore structure and NMR fractal characteristics of deep shale in Longmaxi Formation, Luzhou Block. Chin. Sci. Technol. Pap. 2023, 18, 501–511. [Google Scholar]

| Sample Number | Porosity (%) | DP (Mpa) | AMPTR (μm) | RSC (D) | UC (α) | PTD (Skp) | MMS (Smax) | RMS (%) | MRE (%) |

|---|---|---|---|---|---|---|---|---|---|

| L1 | 0.98 | 20.66 | 0.012 | 89.85 | 0.325 | −0.287 | 76.53 | 25.72 | 66.40 |

| L2 | 1.20 | 20.66 | 0.009 | 98.05 | 0.266 | −0.504 | 78.46 | 28.46 | 63.73 |

| L3 | 1.33 | 13.78 | 0.015 | 73.32 | 0.294 | −0.131 | 86.29 | 31.39 | 63.62 |

| L4 | 0.94 | 13.78 | 0.016 | 74.56 | 0.299 | −0.099 | 85.02 | 40.46 | 52.41 |

| L5 | 1.11 | 17.22 | 0.013 | 83.94 | 0.310 | −0.255 | 81.57 | 31.51 | 61.54 |

| Average | 1.11 | 17.22 | 0.013 | 83.94 | 0.291 | −0.255 | 81.57 | 31.51 | 61.54 |

| SD | 0.18 | 3.98 | 0.003 | 12.04 | 0.249 | 0.185 | 4.80 | 6.41 | 6.22 |

| S1 | 2.09 | 13.78 | 0.015 | 77.32 | 0.286 | −0.289 | 90.07 | 27.28 | 69.71 |

| S2 | 2.37 | 5.50 | 0.033 | 52.08 | 0.250 | −0.244 | 88.25 | 33.55 | 61.99 |

| S3 | 3.26 | 5.50 | 0.027 | 67.21 | 0.201 | −0.422 | 90.59 | 26.32 | 70.95 |

| S4 | 3.93 | 5.51 | 0.024 | 61.31 | 0.183 | −0.265 | 95.26 | 42.73 | 55.14 |

| Average | 2.91 | 7.57 | 0.025 | 64.48 | 0.230 | −0.305 | 91.04 | 32.47 | 64.45 |

| SD | 0.84 | 4.14 | 0.008 | 10.58 | 0.047 | 0.080 | 2.98 | 7.55 | 7.36 |

| M1 | 1.91 | 13.78 | 0.013 | 82.62 | 0.235 | −0.345 | 89.00 | 13.29 | 85.07 |

| M2 | 1.51 | 11.26 | 0.012 | 79.51 | 0.221 | −0.247 | 79.15 | 15.41 | 69.26 |

| M3 | 1.21 | 16.34 | 0.015 | 80.55 | 0.261 | −0.441 | 90.13 | 27.15 | 84.69 |

| M4 | 2.05 | 13.73 | 0.012 | 88.46 | 0.241 | −0.353 | 89.42 | 12.64 | 82.46 |

| M5 | 2.49 | 13.78 | 0.014 | 76.86 | 0.260 | −0.275 | 88.78 | 28.54 | 67.85 |

| M6 | 2.33 | 13.78 | 0.012 | 89.04 | 0.228 | −0.420 | 80.92 | 13.36 | 83.49 |

| Average | 1.83 | 13.78 | 0.013 | 82.84 | 0.241 | −0.347 | 86.23 | 18.40 | 78.80 |

| SD | 0.30 | 0.00 | 0.001 | 6.09 | 0.017 | 0.073 | 4.60 | 8.79 | 9.52 |

| Sample Number | Porosity (%) | Average Porosity (%) |

|---|---|---|

| L1 | 1.81 | 1.88 (n = 5) |

| L2 | 1.55 | |

| L3 | 2.19 | |

| L4 | 2.11 | |

| L5 | 1.76 | |

| S1 | 1.92 | 3.02 (n = 4) |

| S2 | 2.61 | |

| S3 | 3.32 | |

| S4 | 4.21 | |

| M1 | 1.99 | 2.01 (n = 6) |

| M2 | 1.03 | |

| M3 | 1.39 | |

| M4 | 2.42 | |

| M5 | 2.77 | |

| M6 | 2.50 |

| Sample Number | Fitting Formula | R2 | D |

|---|---|---|---|

| L1 | y = −1.944x + 12.199 | 0.9991 | 1.944 |

| L2 | y = −1.985x + 14.178 | 0.9938 | 1.985 |

| L3 | y = −1.851x + 11.647 | 0.9971 | 1.851 |

| L4 | y = −1.796x + 15.318 | 0.9956 | 1.796 |

| L5 | y = −1.990x + 12.211 | 0.9994 | 1.990 |

| S1 | y = −1.769x + 13.094 | 0.9934 | 1.769 |

| S2 | y = −1.341x + 11.681 | 0.9929 | 1.341 |

| S3 | y = −1.351x + 14.163 | 0.9983 | 1.351 |

| S4 | y = −1.405x + 10.168 | 0.9975 | 1.405 |

| M1 | y = −1.821x + 10.927 | 0.9919 | 1.821 |

| M2 | y = −1.568x + 12.981 | 0.9907 | 1.568 |

| M3 | y = −1.972x + 13.144 | 0.9964 | 1.972 |

| M4 | y = −1.895x + 12.657 | 0.9951 | 1.895 |

| M5 | y = −1.746x + 11.434 | 0.9982 | 1.746 |

| M6 | y = −1.789x + 14.212 | 0.9937 | 1.789 |

| Sample Number | MICP Porosity (%) | LFNMR Porosity (%) | Geometric Mean Porosity % |

|---|---|---|---|

| L1 | 0.98 | 1.81 | 1.33 |

| L2 | 1.20 | 1.55 | 1.36 |

| L3 | 1.33 | 2.19 | 1.70 |

| L4 | 0.94 | 2.11 | 1.41 |

| L5 | 1.11 | 1.76 | 1.40 |

| S1 | 2.09 | 1.92 | 2.00 |

| S2 | 2.37 | 2.61 | 2.49 |

| S3 | 3.26 | 3.32 | 3.29 |

| S4 | 3.93 | 4.21 | 4.07 |

| M1 | 1.91 | 1.99 | 1.95 |

| M2 | 1.51 | 1.03 | 1.25 |

| M3 | 1.21 | 1.39 | 1.30 |

| M4 | 2.05 | 2.42 | 2.23 |

| M5 | 2.49 | 2.77 | 2.63 |

| M6 | 2.33 | 2.50 | 2.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Zhao, L.; Hu, G.; Zhang, W. Pore–Fracture Structure and Fractal Features of Carboniferous Taiyuan Formation Hydrocarbon Source Rocks as Investigated Using MICP, LFNMR, and FESEM. Fractal Fract. 2025, 9, 263. https://doi.org/10.3390/fractalfract9040263

Wu D, Zhao L, Hu G, Zhang W. Pore–Fracture Structure and Fractal Features of Carboniferous Taiyuan Formation Hydrocarbon Source Rocks as Investigated Using MICP, LFNMR, and FESEM. Fractal and Fractional. 2025; 9(4):263. https://doi.org/10.3390/fractalfract9040263

Chicago/Turabian StyleWu, Dun, Liu Zhao, Guangqing Hu, and Wenyong Zhang. 2025. "Pore–Fracture Structure and Fractal Features of Carboniferous Taiyuan Formation Hydrocarbon Source Rocks as Investigated Using MICP, LFNMR, and FESEM" Fractal and Fractional 9, no. 4: 263. https://doi.org/10.3390/fractalfract9040263

APA StyleWu, D., Zhao, L., Hu, G., & Zhang, W. (2025). Pore–Fracture Structure and Fractal Features of Carboniferous Taiyuan Formation Hydrocarbon Source Rocks as Investigated Using MICP, LFNMR, and FESEM. Fractal and Fractional, 9(4), 263. https://doi.org/10.3390/fractalfract9040263