Fractal Analysis of Organic Matter Nanopore Structure in Tectonically Deformed Shales

Abstract

1. Introduction

2. Samples and Methods

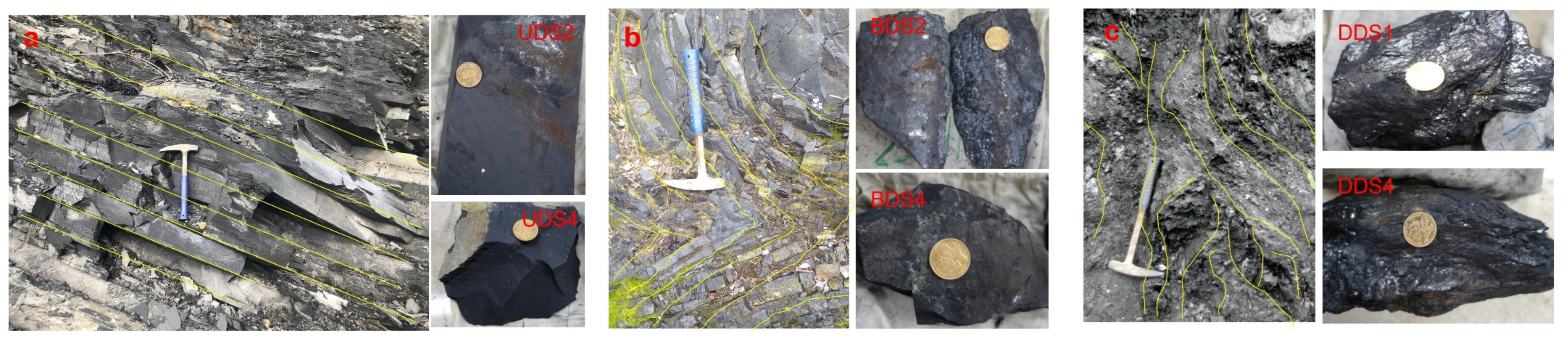

2.1. Sample Collection

2.2. Experimental and Methods

2.2.1. Geochemical and Mineralogical

2.2.2. Low-Temperature Gas Adsorption (LTGA)

2.2.3. Scanning Electron Microscopy (SEM)

2.2.4. ImageJ Analysis

2.2.5. Fractal Dimension

3. Results

3.1. Geochemical and Mineralogical Characteristics

3.2. Pore Morphology by SEM

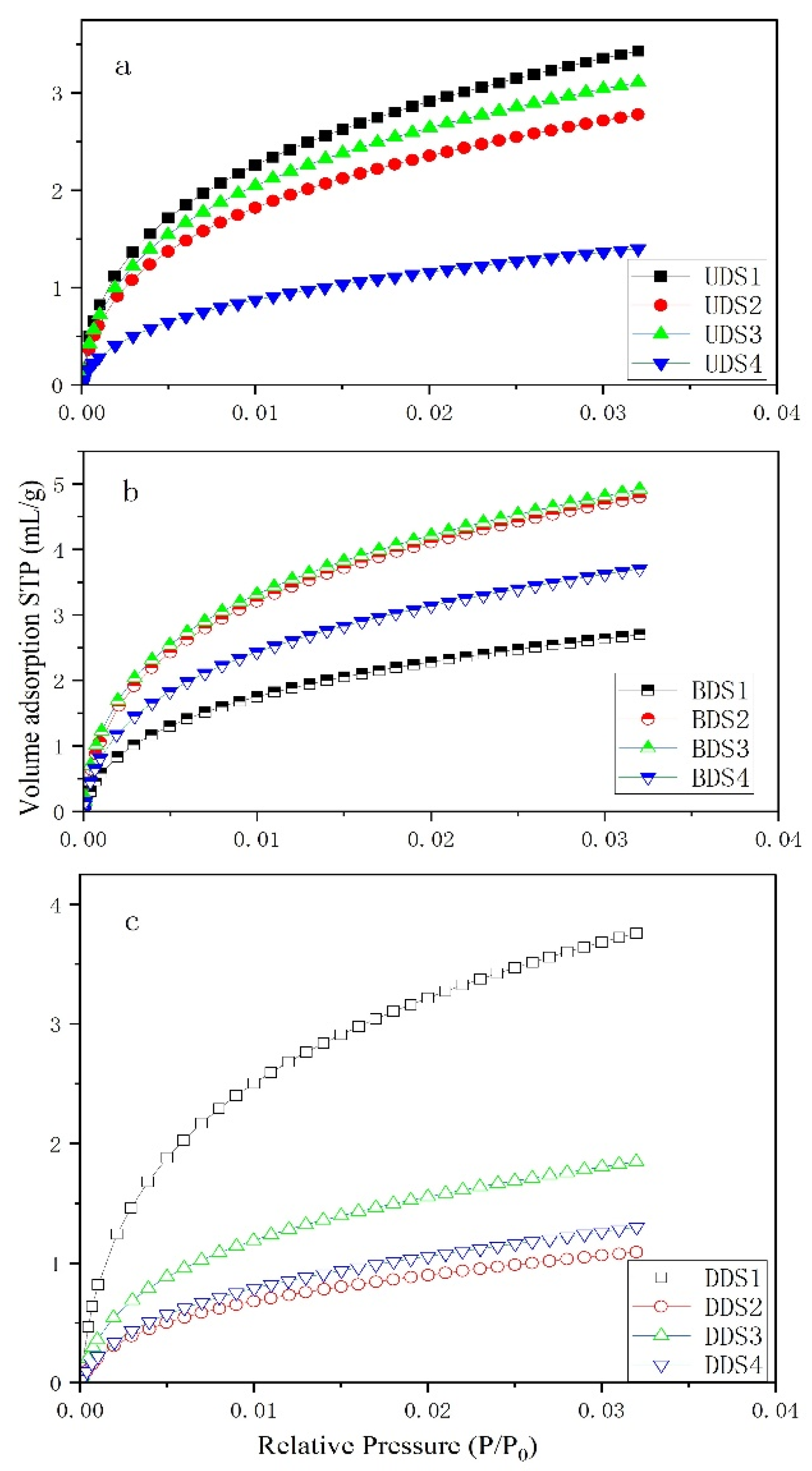

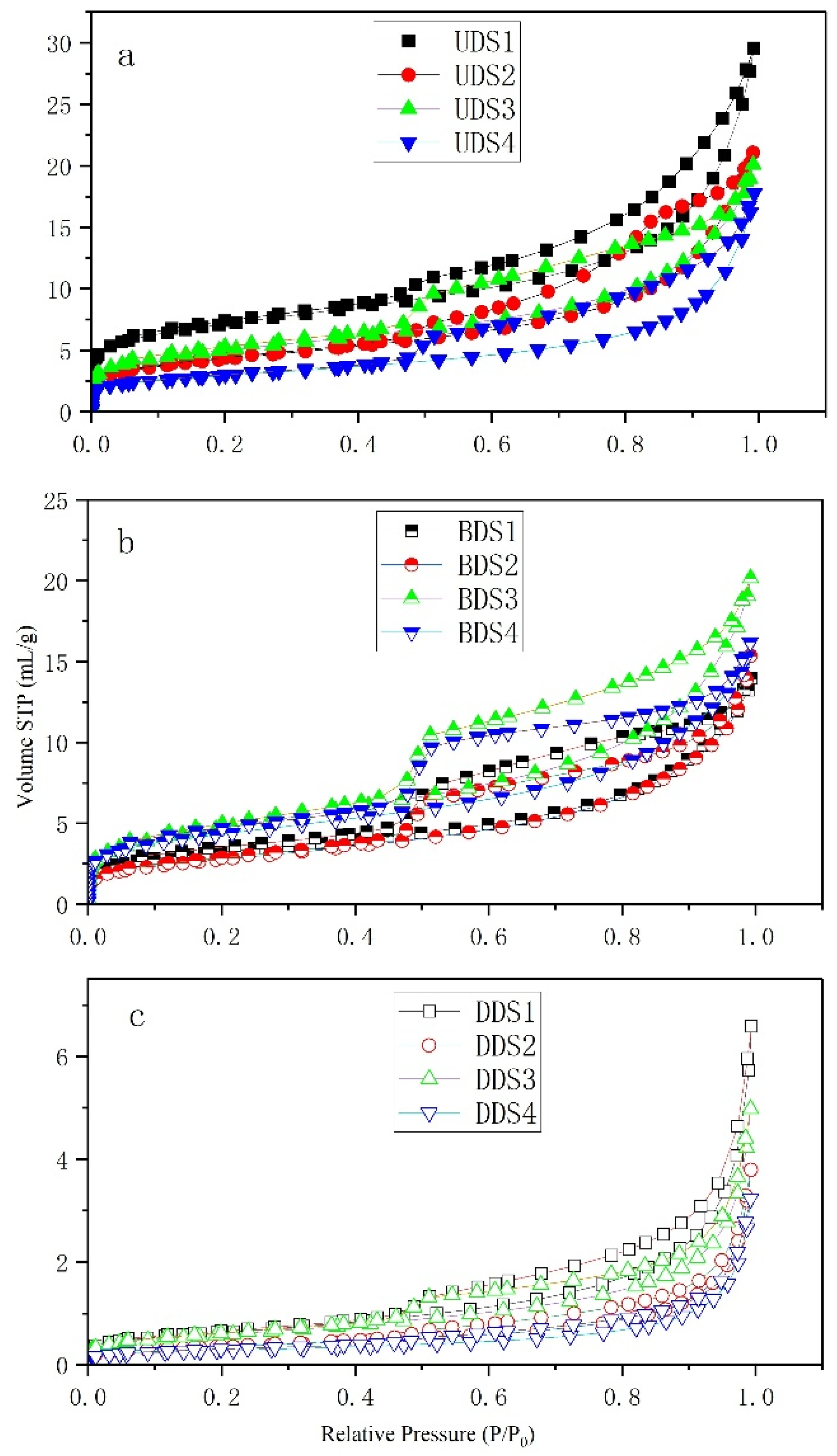

3.3. Gas Adsorption Isotherms from LTGA

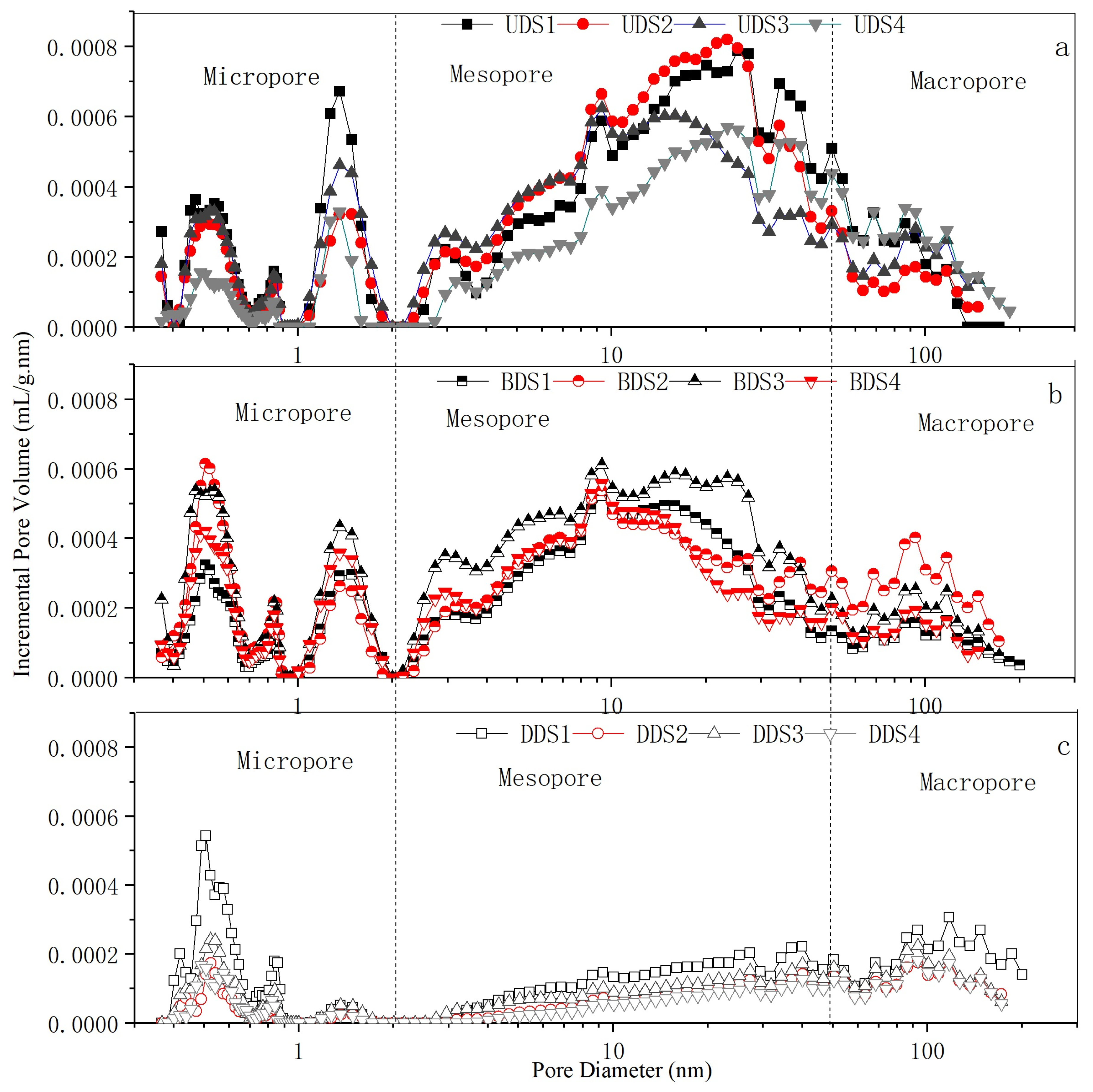

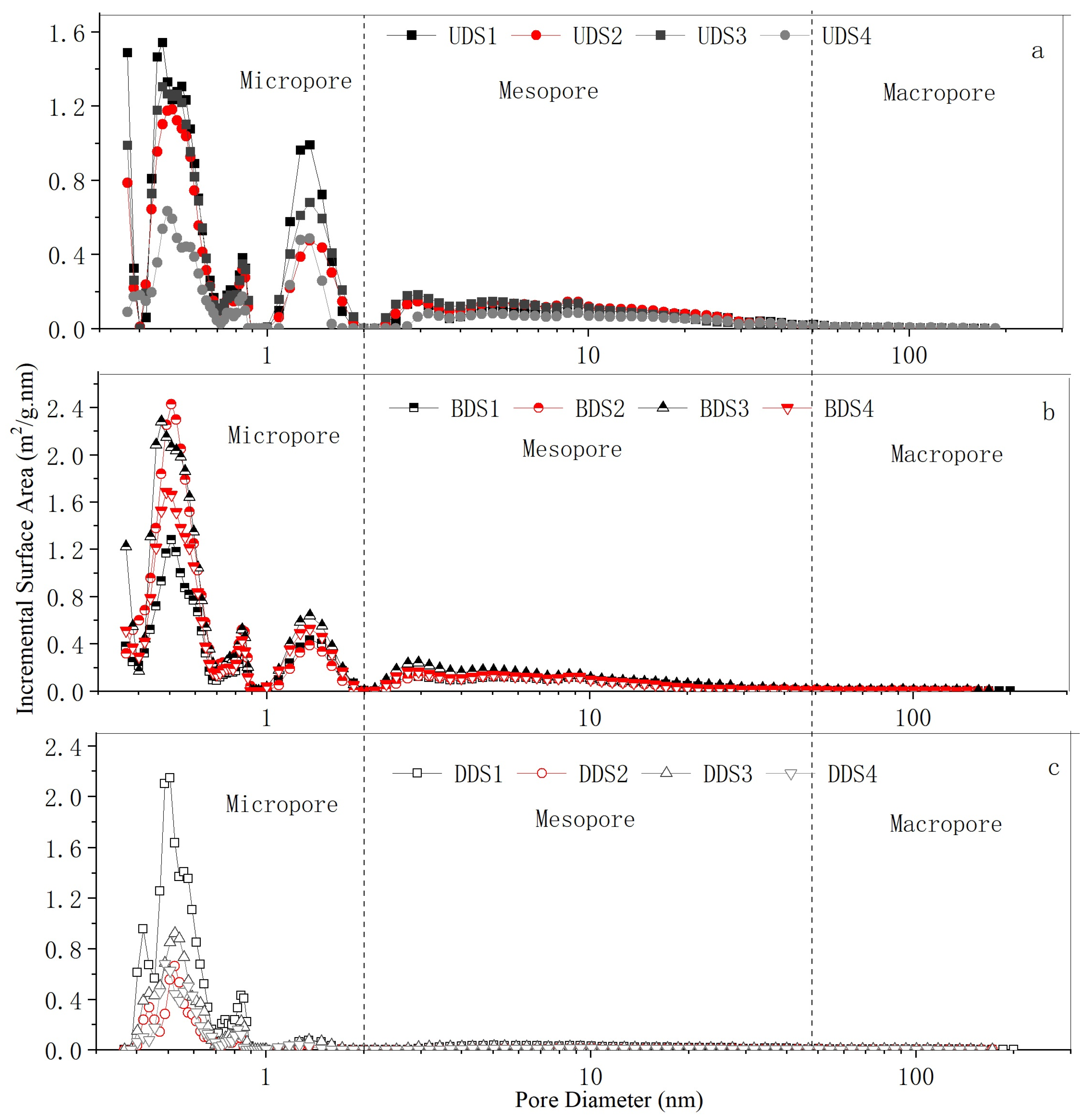

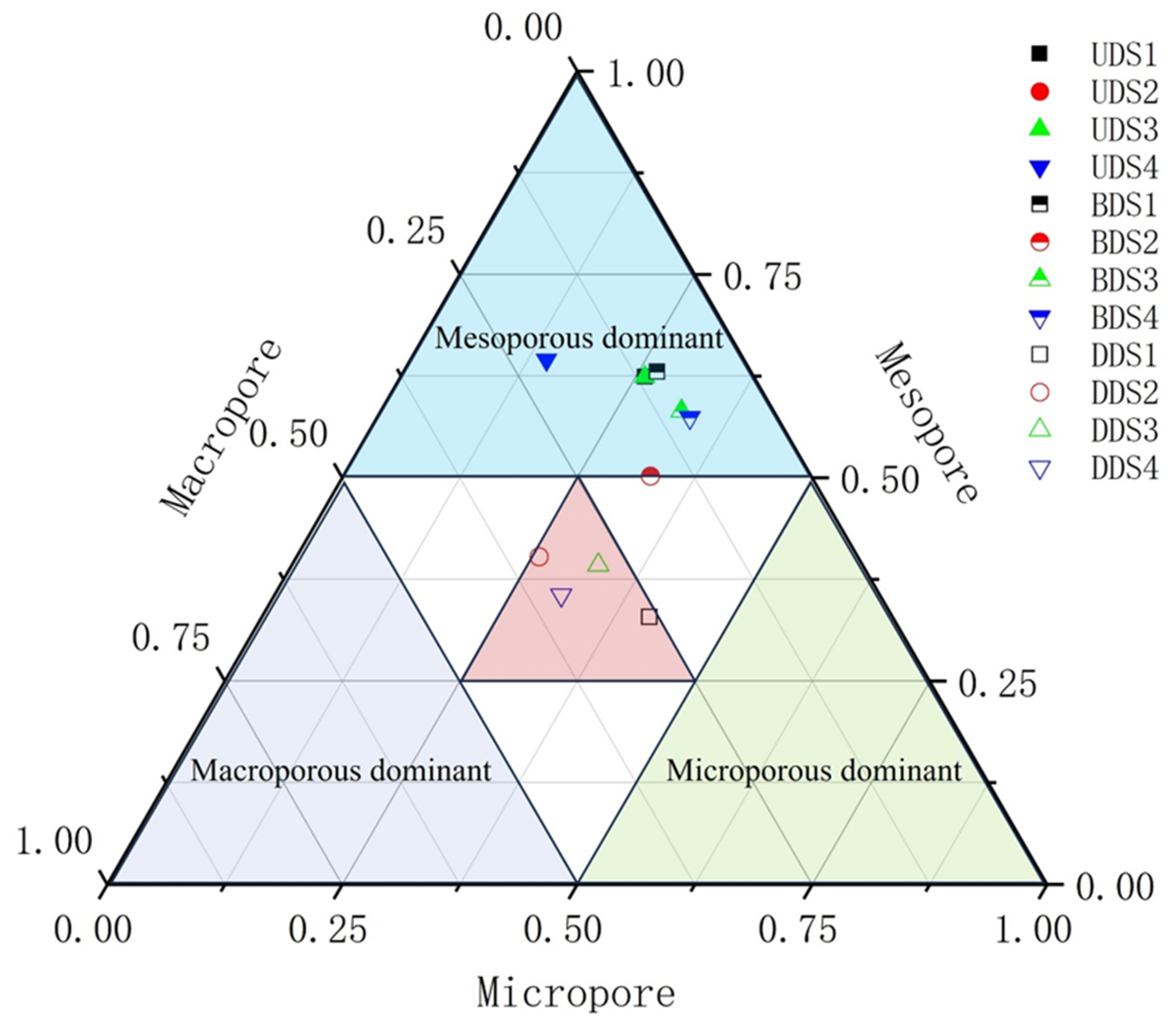

3.4. Pore Structure from LTGA

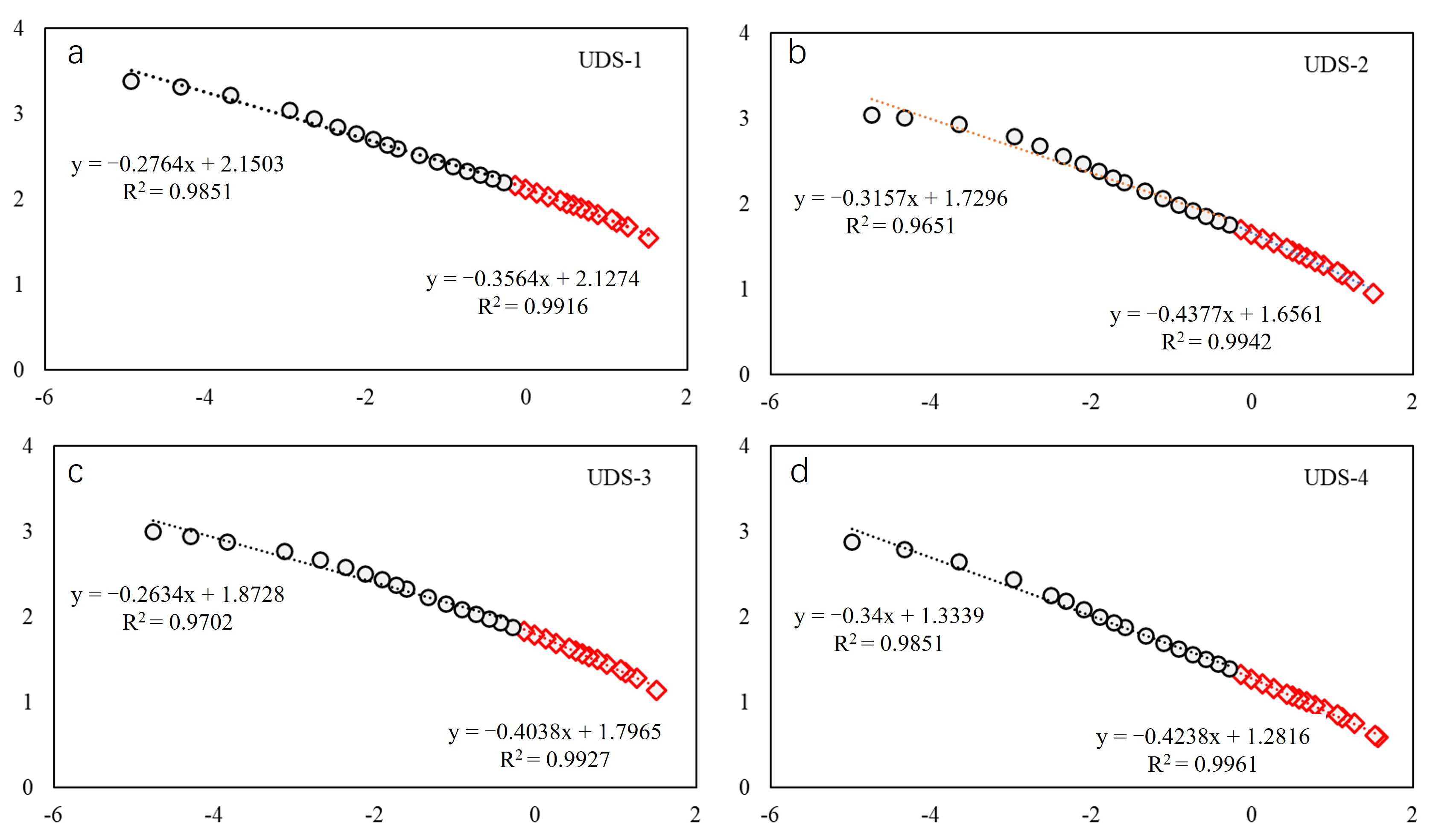

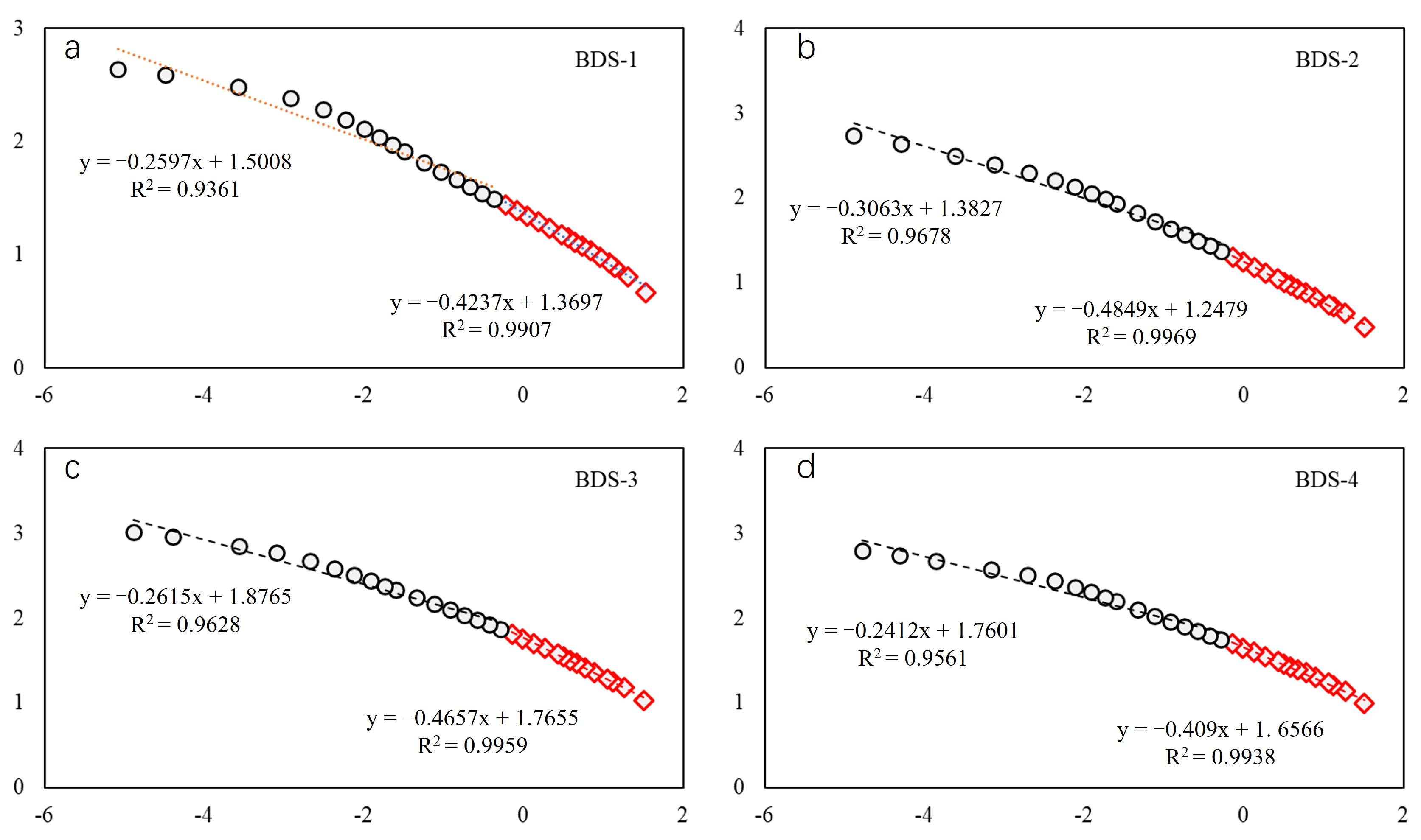

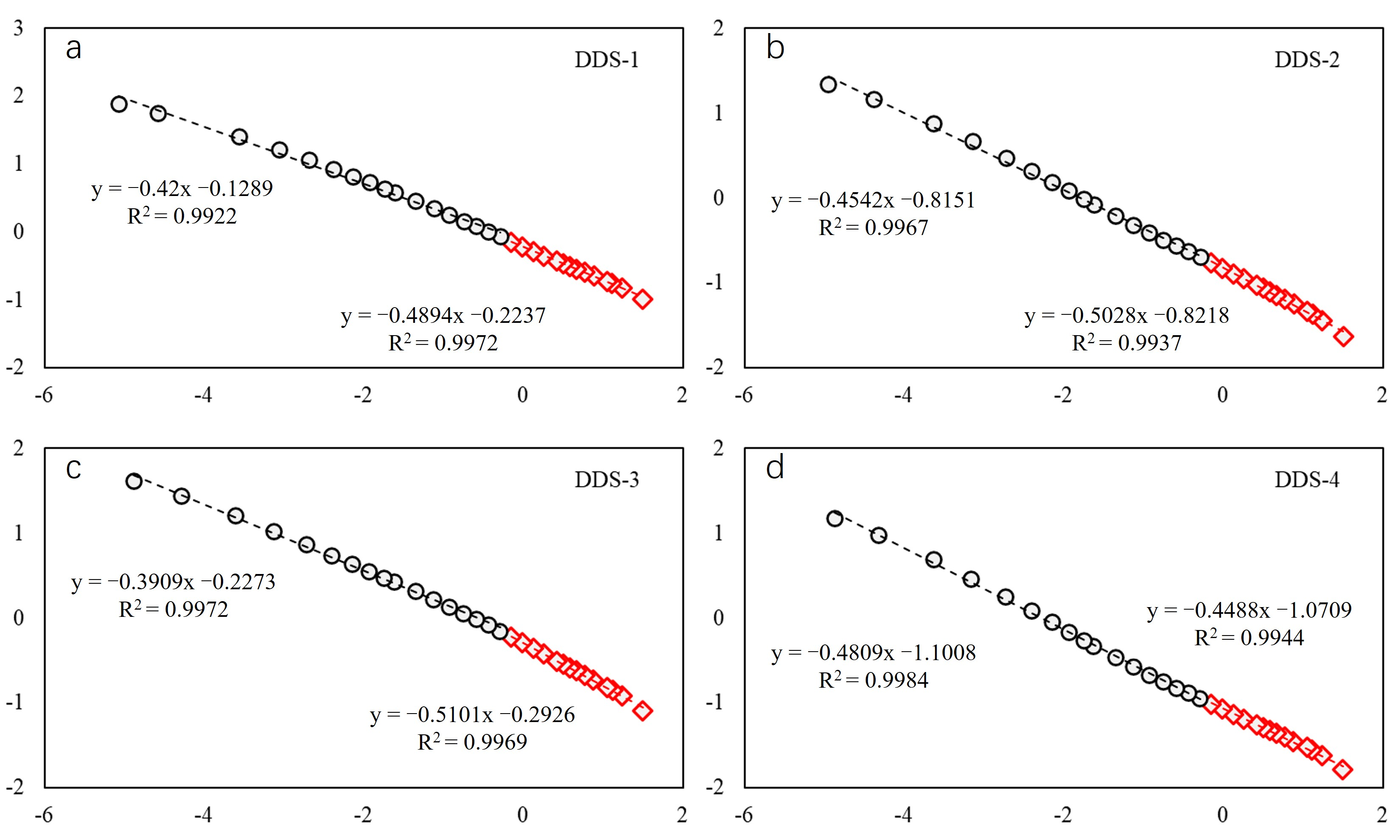

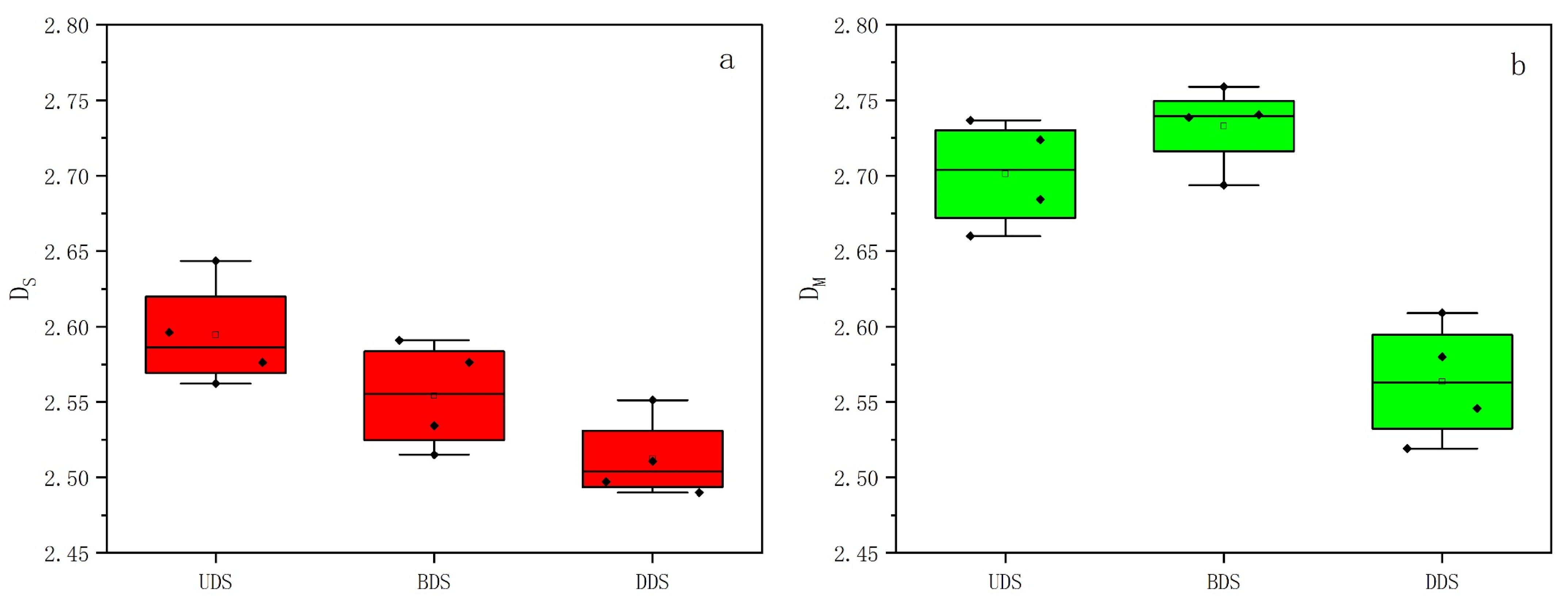

3.5. Fractal Dimensions from the N2 Adsorption

4. Discussion

4.1. Comparison of Pore Structure Fractal Characteristics Between Brittle and Ductile Deformation Shales

4.1.1. Differences in Fractal Dimensions

4.1.2. Impact of Deformation Type on Pore Structure Complexity

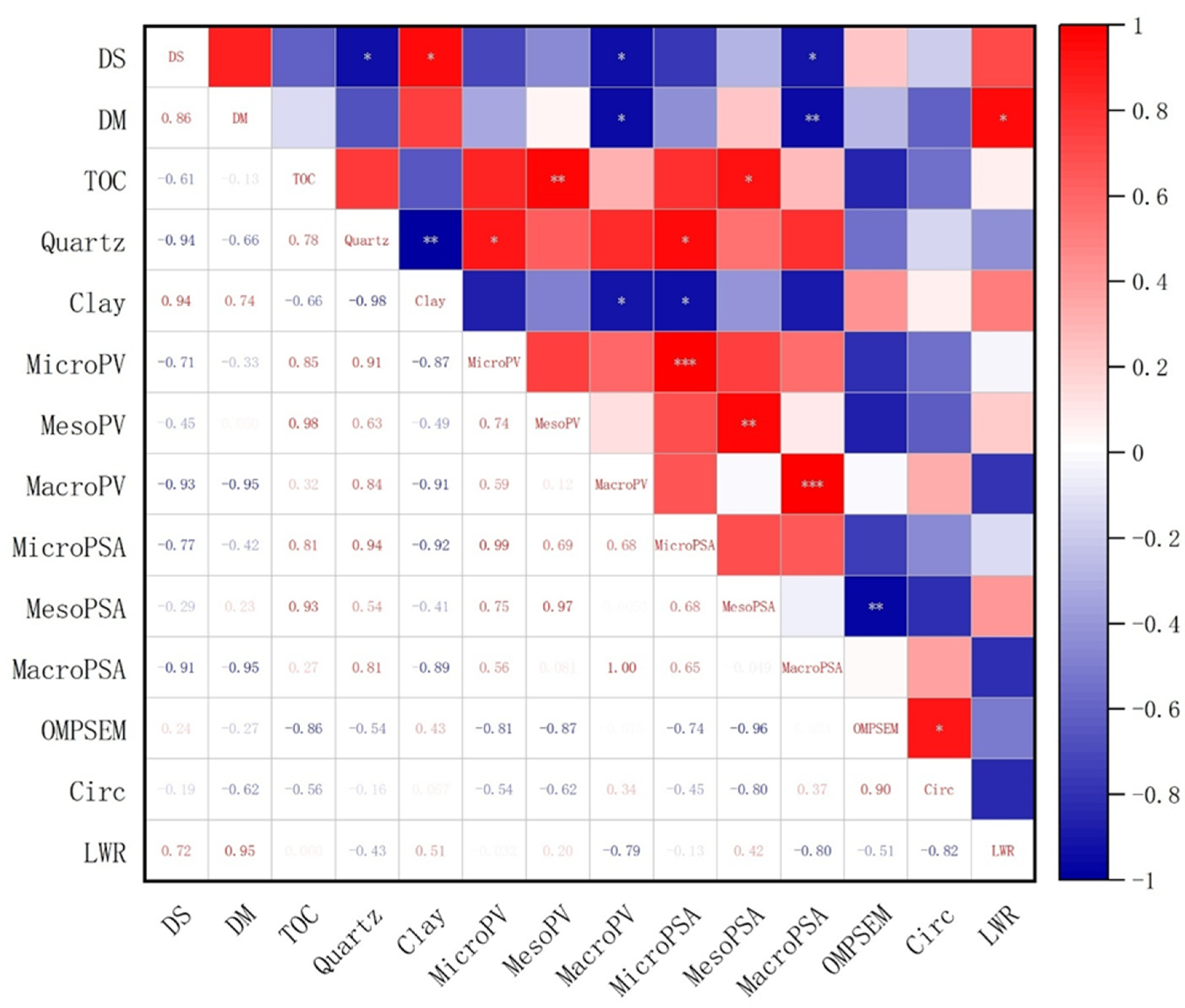

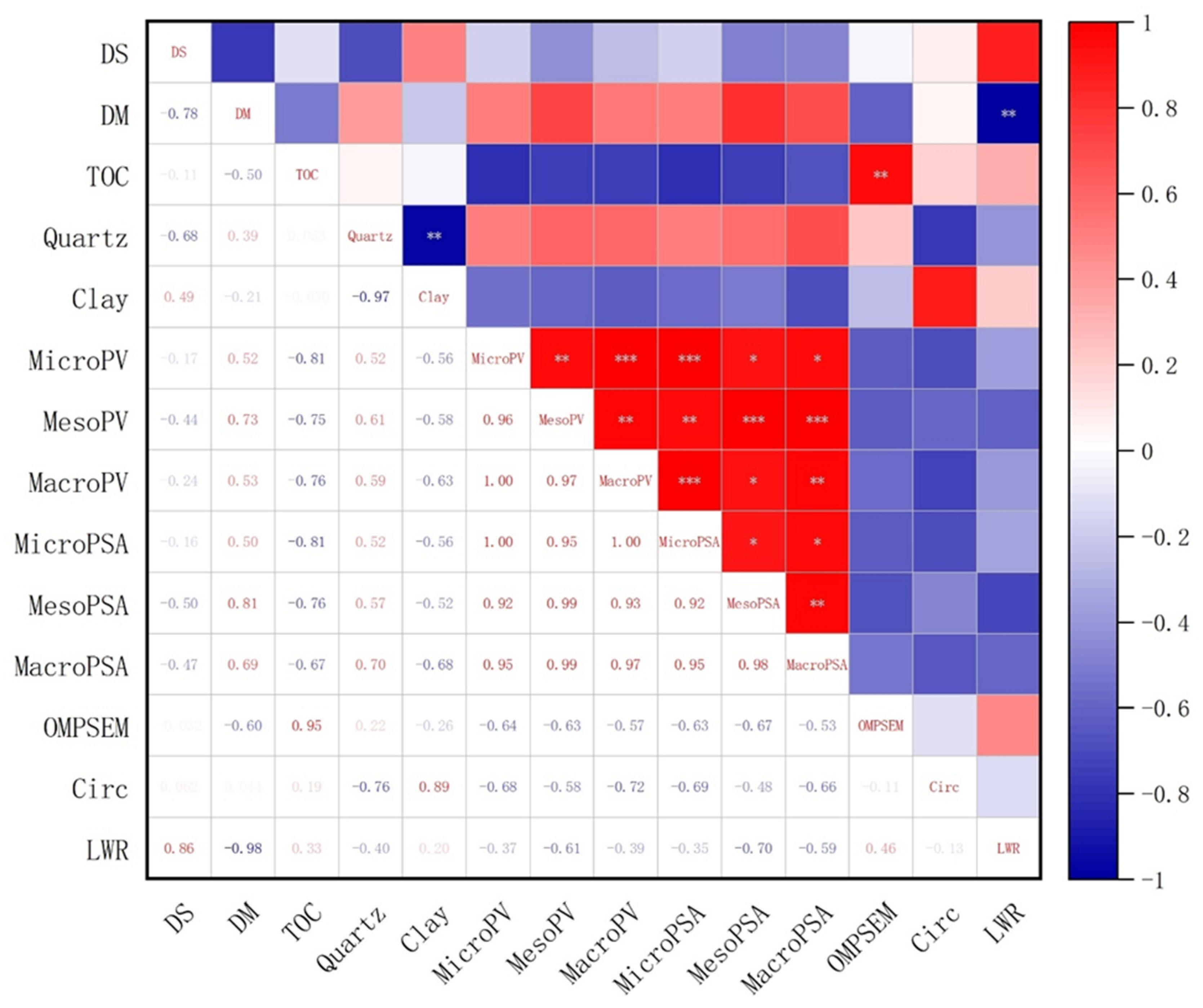

4.2. Factors Affecting the Fractal Characteristics of Shale Organic Pore Structure in Different Tectonic Deformation

4.3. Geological Significance of Shale Organic Nanopore Fractal Characters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Curtis, J.B. Fractured shale-gas systems. Aapg Bull. 2002, 86, 1921–1938. [Google Scholar]

- Zou, C.; Yang, Z.; Dong, D.; Zhao, Q.; Chen, Z.; Feng, Y.; Li, J.; Wang, X. Formation, Distribution and Prospect of Unconventional Hydrocarbons in Source Rock Strata in China. Earth Sci. 2022, 47, 1517–1533. [Google Scholar]

- Dong, D.; Zou, C.; Dai, J.; Huang, S.; Zheng, J.; Wang, Y.; Li, X.; Guan, Q.; Zhang, C.; Huang, J. Suggestions on the development strategy of shale gas in China. Nat. Gas Geosci. 2016, 27, 397–406. [Google Scholar] [CrossRef]

- Sun, C.; Nie, H.; Dang, W.; Chen, Q.; Zhang, G.; Li, W.; Lu, Z. Shale gas exploration and development in China: Current status, geological challenges, and future directions. Energy Fuels 2021, 35, 6359–6379. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. Shale gas potential of the Lower Jurassic Gordondale member, Northeastern British Columbia, Canada. Bull. Can. Pet. Geol. 2007, 55, 51–75. [Google Scholar] [CrossRef]

- Hu, Q.; Ewing, R.P.; Rowe, H.D. Low nanopore connectivity limits gas production in Barnett formation. J. Geophys. Res. Solid Earth 2015, 120, 8073–8087. [Google Scholar] [CrossRef]

- Tian, H.; Pan, L.; Zhang, T.; Xiao, X.; Meng, Z.; Huang, B. Pore characterization of organic-rich Lower Cambrian shales in Qiannan Depression of Guizhou Province, Southwestern China. Mar. Pet. Geol. 2015, 62, 28–43. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- English, J.M.; English, K.L.; Corcoran, D.V.; Toussaint, F. Exhumation charge: The last gasp of a petroleum source rock and implications for unconventional shale resources. AAPG Bull. 2016, 100, 1–16. [Google Scholar] [CrossRef]

- He, S.; Li, H.; Qin, Q.R.; Long, S.X. Influence of mineral compositions on shale pore development of Longmaxi Formation in the Dingshan area, southeastern Sichuan Basin, China. Energy Fuels 2021, 35, 10551–10561. [Google Scholar] [CrossRef]

- Cao, T.; Song, Z.; Wang, S.; Cao, X.; Li, Y.; Xia, J. Characterizing the pore structure in the Silurian and Permian shales of the Sichuan Basin, China. Mar. Pet. Geol. 2015, 61, 140–150. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity, IUPAC. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, H. Advances in microscopic pore structure characterization of fine-grained mudrocks. Energy Fuels 2023, 37, 1495–1510. [Google Scholar] [CrossRef]

- Liu, B.; Mastalerz, M.; Schieber, J. SEM Petrography of Dispersed Organic Matter in Black Shales: A Review. Earth Sci. Rev. 2022, 224, 103874. [Google Scholar] [CrossRef]

- Bakshi, T.; Vishal, V. A review on the role of organic matter in gas adsorption in shale. Energy Fuels 2021, 35, 15249–15264. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Yan, F.; Si, G.; Lin, B. Evolution characteristics of coal microstructure and its influence on methane adsorption capacity under high temperature pyrolysis. Energy 2022, 254, 124262. [Google Scholar] [CrossRef]

- Awan, R.S.; Liu, C.; Yasin, Q.; Liu, B.; Wood, D.A.; Feng, D.; Iltaf, K.H. Geologic characterization of the Lower Paleozoic black shale of the Niutitang Formation: Implications for a shale gas potential in western Hunan, China. Mar. Pet. Geol. 2024, 163, 106756. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Ko, L.T.; Loucks, R.G.; Zhang, T.W. Pore and pore network evolution of upper cretaceous boquillas (Eagle Ford-equivalent) mudrocks: Results from gold tube pyrolysis experiments. AAPG Bull. 2016, 100, 1693–1722. [Google Scholar] [CrossRef]

- Chen, J.; Xiao, X. Evolution of nanoporosity in organic-rich shales during thermal maturation. Fuel 2014, 129, 173–181. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Z.; Jiang, S.; Lu, S.; Xiao, D.; Chen, G.; Zhao, J. Factors affecting shale gas accumulation in overmature shales case study from lower Cambrian shale in western Sichuan Basin, South China. Energy Fuels 2018, 32, 3003–3012. [Google Scholar] [CrossRef]

- Ning, S.; Xia, P.; Hao, F.; Tian, J.; Fu, Y.; Wang, K. Pore Fractal Characteristics between Marine and Marine–Continental Transitional Black Shales: A Case Study of Niutitang Formation and Longtan Formation. Fractal Fract. 2024, 8, 288. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Brunauner, S.; Emmett, S.P.H.; Teller, E.J. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Klimakow, M.; Klobes, P.; Rademann, K.; Emmerling, F. Characterization of mechanochemically synthesized MOFs. Microporous Mesoporous Mater. 2012, 154, 113–118. [Google Scholar] [CrossRef]

- Han, H.; Cao, Y.; Chen, S.; Lu, J.; Huang, C.; Zhu, H.; Zhan, P.; Gao, Y. Influence of particle size on gas-adsorption experiments of shales: An example from a Longmaxi Shale sample from the Sichuan Basin, China. Fuel 2016, 186, 750–757. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Z.; Zhang, K.; Feng, X.; Cheng, M. Effects of shear on development characteristics of organic matter pores in shale: A case study of shale in the Niutitang Formation of the well XAD1. J. Petr. Sci. Eng. 2022, 211, 110166. [Google Scholar] [CrossRef]

- Tang, L.; Song, Y.; Jiang, Z.; Jiang, S.; Li, Q. Pore Structure and Fractal Characteristics of Distinct Thermally Mature Shales. Energy Fuels 2019, 33, 5116–5128. [Google Scholar] [CrossRef]

- Wang, Y.; Han, D.; Lin, W.; Jia, Y.; Zhang, J.; Wang, C.; Ma, B. Factors Controlling Differences in Morphology and Fractal Characteristics of Organic Pores of Longmaxi Shale in Southern Sichuan Basin, China. Fractal Fract. 2024, 8, 555. [Google Scholar] [CrossRef]

- Guan, D.Z.; Dong, D.Z.; Sun, S.S.; Hu, L.X.; Qi, L.; Li, C.D.; Chen, C.; Chen, X. Fractal characteristics of organic-rich shale pore structure and its geological implications: A case study of the Lower Silurian Longmaxi Formation in the Weiyuan block, Sichuan Basin. Nat. Gas Ind. 2024, 44, 108–118. [Google Scholar]

- Liang, M.; Wang, Z.; Gao, L.; Li, C.; Li, H. Evolution of pore structure in gas shale related to structural deformation. Fuel 2017, 197, 310–319. [Google Scholar] [CrossRef]

- Zhu, H.; Ju, Y.; Qi, Y.; Huang, C.; Zhang, L. Impact of tectonism on pore type and pore structure evolution in organic-rich shale: Implications for gas storage and migration pathways in naturally deformed rocks. Fuel 2018, 228, 272–289. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Li, Z.; Zhang, K.; Feng, X.; Wang, Z. Impact of brittle deformation on pore structure evolution in shale: Samples collected from different fault positions. Energy Fuels 2022, 36, 1441–1456. [Google Scholar] [CrossRef]

- Hu, J.; Tang, S.; Zhang, S. Investigation of pore structure and fractal characteristics of the Lower Silurian Longmaxi shales in western Hunan and Hubei Provinces in China. J. Nat. Gas. Sci. Eng. 2016, 28, 522–535. [Google Scholar] [CrossRef]

- Ma, Y.; Zhong, N.; Han, H. Definition and sturcture characteristics of pores in mylonitized organic-rich. Shales Earth Sci. 2014, 44, 2202–2210. [Google Scholar] [CrossRef]

- Zhan, H.M.; Li, X.Z.; Hu, Z.M.; Duan, X.G.; Wu, W.; Guo, W.; Lin, W. Fractal Characteristics of Deep Shales in Southern China by Small-Angle Neutron Scattering and Low-Pressure Nitrogen Adsorption. Fractal Fract. 2022, 6, 484. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Yi, J.; Hu, Q. Nano-scale pore structure and fractal dimension of organic-rich Wufeng-Longmaxi shale from Jiaoshiba area, Sichuan Basin: Investigations using FE-SEM, gas adsorption and helium pycnometry. Mar. Pet. Geol. 2016, 70, 27–45. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Thommes, M.; Cychosz, K.A. Physical adsorption characterization of nanoporous materials: Progress and challenges. Adsorption 2014, 20, 233–250. [Google Scholar] [CrossRef]

- Landers, J.; Gor, A.G.A.; Neimark, V. Density functional theory methods for characterization of porous materials. Chem. Inf. 2014, 437, 3–32. [Google Scholar] [CrossRef]

- Groen, J.C.; Peffer, L.A.A.; Perez-Ramírez, J. Pore size determination in modified micro- and mesoporous materials. Pitfalls and limitations in gas adsorption data analysis. Microporous Mesoporous Mater. 2003, 60, 1–17. [Google Scholar] [CrossRef]

- Klaver, J.; Desbois, G.; Urai, J.L.; Littke, R. BIB-SEM study of the pore space morphology in early mature Posidonia Shale from the Hils area, Germany. Int. J. Coal Geol. 2012, 103, 12–25. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Xie, Z.; Li, J.; Zhang, X.; Sun, K.; Wang, F. Characterization of microscopic pore types and structures in marine shale: Examples from the Upper Permian Dalong formation, Northern Sichuan Basin, South China. J. Nat. Gas Sci. Eng. 2018, 59, 326–342. [Google Scholar] [CrossRef]

- Lin, W.; Zhao, X.; Li, M.; Zhuang, Y. Pore Structure Characterization and Fractal Characteristics of Tight Limestone Based on Low-Temperature Nitrogen Adsorption and Nuclear Magnetic Resonance. Fractal Fract. 2024, 8, 371. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Pan, J.N.; Zhu, H.T.; Hou, Q.L. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Lewan, M.D. Stable carbon isotopes of amorphous kerogens from Phanerozoic sedimentary-rocks. Geochim. Cosmochim. Acta 1986, 50, 1583–1591. [Google Scholar] [CrossRef]

- Liang, Z.; Jiang, Z.; Han, Y.; Wang, B.; Wu, W.; Li, Z.; Li, Y.; Xue, Z. A modified dent-fractal mathematical model to investigate the water vapor adsorption on nanopore structure heterogeneity from the Longmaxi shale, Sichuan Basin, China. Energy Fuels 2023, 37, 9131–9150. [Google Scholar] [CrossRef]

- Zou, J.; Chen, W.; Yang, D.; Yuan, J.; Jiao, Y.Y. Fractal characteristics of the anisotropic microstructure and pore distribution of low-rank coal. AAPG Bull. 2019, 103, 1297–1319. [Google Scholar] [CrossRef]

- Jiang, W.; Zhang, Y.; Ma, T.; Chen, S.; Hu, Y.; Wei, Q.; Zhuang, D. Pore Structure and Its Fractal Dimension: A Case Study of the Marine Shales of the Niutitang Formation in Northwest Hunan, South China. Fractal Fract. 2025, 9, 49. [Google Scholar] [CrossRef]

| Sample ID | TOC (%) | VRb (%) | δC13 ‰ (PDB) | Quartz (%) | Clay (%) | Other Minerals (%) | Texture and Fabric Feature of Macroscopic Hand Specimens |

|---|---|---|---|---|---|---|---|

| UDS1 | 6.38 | 3.12 | −34.2 | 80 | 16 | 4 | Shale primary structure can be observed. Shale has original parallel bedding. |

| UDS2 | 8.44 | 3.15 | −33.7 | 77 | 14 | 9 | |

| UDS3 | 8.12 | 3.15 | −33.6 | 66 | 27 | 7 | |

| UDS4 | 3.57 | 3.13 | −34.2 | 66 | 33 | 1 | |

| BDS1 | 8.95 | 3.12 | −34.3 | 57 | 36 | 7 | Shale has original parallel bedding. Shale shows cleavage structure and cleavage surface is smooth with fine-grained powder coatings. Fractures and mineral filling development. |

| BDS2 | 11.5 | 3.19 | −33.5 | 85 | 10 | 5 | |

| BDS3 | 18 | 3.28 | −33.7 | 85 | 15 | - | |

| BDS4 | 9.11 | 3.30 | −32.5 | 61 | 31 | 8 | |

| DDS1 | 11.9 | 3.89 | −32.8 | 80 | 15 | 5 | The primary structure of shale is damaged and the parallel bedding has disappeared due to mylonitization. The plastic deformation of shale is obvious. Shale structure is loose and fragile. Shale shows cleavage structure and cleavage surface is smooth with fine-grained powder coatings. |

| DDS2 | 20.7 | 3.48 | −32.7 | 79 | 17 | 4 | |

| DDS3 | 14.3 | 3.39 | −32.8 | 72 | 25 | 3 | |

| DDS4 | 15.8 | 3.37 | −32.8 | 65 | 28 | 7 |

| Sample ID | Pore Volume | Adsorption Capacity | Relative Content * (%) | Pore Parameters from SEM | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Micropore(μL/g) | Mesopore(μL/g) | Macropore(μL/g) | Total Pore (μL/g) | CO2 (ml/g) | N2 (ml/g) | Micropore(%) | Mesopore(%) | Macropore(%) | OMP(%) | Circ.(0–1) | LWR | |

| UDS1 | 7.59 | 18.18 | 3.38 | 29.15 | 3.43 | 29.59 | 26.04 | 62.37 | 11.60 | 8.47 | 0.72 | 1.85 |

| UDS2 | 5.52 | 19.26 | 2.17 | 26.95 | 2.78 | 21.05 | 20.48 | 71.47 | 8.05 | 7.73 | 0.69 | 1.79 |

| UDS3 | 6.76 | 16.10 | 3.02 | 25.88 | 3.11 | 20.10 | 26.12 | 62.21 | 11.67 | 9.56 | 0.64 | 1.86 |

| UDS4 | 2.87 | 12.90 | 4.26 | 20.01 | 1.40 | 17.75 | 14.34 | 64.47 | 21.29 | 7.57 | 0.67 | 1.75 |

| BDS1 | 5.42 | 12.61 | 2.00 | 20.03 | 2.70 | 13.95 | 27.06 | 62.96 | 9.99 | 7.77 | 0.77 | 1.93 |

| BDS2 | 8.45 | 12.92 | 4.44 | 25.81 | 4.80 | 15.35 | 32.74 | 50.06 | 17.20 | 6.99 | 0.77 | 1.88 |

| BDS3 | 9.52 | 17.31 | 2.90 | 29.73 | 4.92 | 20.15 | 32.02 | 58.22 | 9.75 | 4.16 | 0.71 | 1.96 |

| BDS4 | 7.22 | 12.38 | 2.05 | 21.65 | 3.71 | 16.20 | 33.35 | 57.18 | 9.47 | 6.05 | 0.72 | 1.99 |

| DDS1 | 5.93 | 4.75 | 3.72 | 14.4 | 3.76 | 6.58 | 41.18 | 32.99 | 25.83 | 2.47 | 0.45 | 2.81 |

| DDS2 | 1.56 | 2.56 | 2.09 | 6.21 | 1.09 | 3.79 | 25.12 | 41.22 | 33.66 | 3.82 | 0.56 | 3.00 |

| DDS3 | 2.88 | 3.52 | 2.45 | 8.85 | 1.85 | 4.98 | 32.54 | 39.77 | 27.68 | 2.39 | 0.70 | 2.34 |

| DDS4 | 1.79 | 2.12 | 2.01 | 5.92 | 1.30 | 3.23 | 30.24 | 35.81 | 33.95 | 2.90 | 0.65 | 3.45 |

| Sample ID | Total SA of Gas Absorption by Different Model | SA of Gas Absorption by Same Model (DFT) | Relative Content * (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2 (DR) (m2/g) | CO2(DFT) (m2/g) | N2(BET) (m2/g) | N2(DFT) (m2/g) | Micropore (m2/g) | Mesopore (m2/g) | Macropore (m2/g) | Total pore (m2/g) | Micropore (%) | Mesopore (%) | Macropore (%) | |

| UDS1 | 25.77 | 26.74 | 25.54 | 18.00 | 22.10 | 3.17 | 0.10 | 25.37 | 87.11 | 12.50 | 0.39 |

| UDS2 | 21.20 | 21.54 | 15.36 | 10.23 | 16.77 | 3.66 | 0.06 | 20.49 | 81.84 | 17.86 | 0.29 |

| UDS3 | 23.54 | 24.11 | 17.94 | 12.02 | 19.71 | 3.64 | 0.08 | 23.43 | 84.12 | 15.54 | 0.34 |

| UDS4 | 10.52 | 10.94 | 10.51 | 6.77 | 8.27 | 2.12 | 0.11 | 10.5 | 78.76 | 20.19 | 1.05 |

| BDS1 | 21.44 | 20.77 | 11.67 | 7.81 | 16.20 | 2.84 | 0.05 | 19.09 | 84.86 | 14.88 | 0.26 |

| BDS2 | 37.15 | 36.96 | 10.03 | 6.05 | 27.89 | 2.92 | 0.11 | 30.92 | 90.20 | 9.44 | 0.36 |

| BDS3 | 36.36 | 38.25 | 17.04 | 10.15 | 30.31 | 4.20 | 0.07 | 34.58 | 87.65 | 12.15 | 0.20 |

| BDS4 | 28.06 | 28.77 | 15.57 | 10.30 | 22.21 | 3.13 | 0.05 | 25.39 | 87.48 | 12.33 | 0.20 |

| DDS1 | 29.47 | 28.83 | 2.26 | 1.50 | 20.68 | 0.78 | 0.08 | 21.54 | 96.01 | 3.62 | 0.37 |

| DDS2 | 8.89 | 8.53 | 1.25 | 0.82 | 5.37 | 0.36 | 0.05 | 5.78 | 92.91 | 6.23 | 0.87 |

| DDS3 | 14.70 | 14.22 | 2.12 | 1.36 | 9.77 | 0.61 | 0.06 | 10.44 | 93.58 | 5.84 | 0.57 |

| DDS4 | 10.92 | 10.09 | 1.00 | 0.66 | 6.10 | 0.28 | 0.04 | 6.42 | 95.02 | 4.36 | 0.62 |

| Sample ID | P/P0 = 0–0.45 | P/P0 = 0.45–1 | ||||

|---|---|---|---|---|---|---|

| Fitting Equation | R2 | DS | Fitting Equation | R2 | DM | |

| UDS1 | y = −0.3564x + 2.1274 | 0.9916 | 2.6436 | y = −0.2764x + 2.1503 | 0.9851 | 2.7236 |

| UDS2 | y = −0.4377x + 1.6561 | 0.9942 | 2.5623 | y = −0.3157x + 1.7296 | 0.9651 | 2.6843 |

| UDS3 | y = −0.4038x + 1.7965 | 0.9927 | 2.5962 | y = −0.2634x + 1.8728 | 0.9702 | 2.7366 |

| UDS4 | y = −0.4238x + 1.2816 | 0.9961 | 2.5762 | y = −0.34x + 1.3339 | 0.9851 | 2.66 |

| BDS1 | y = −0.4237x + 1.3697 | 0.9907 | 2.5763 | y = −0.2597x + 1.5008 | 0.9361 | 2.7403 |

| BDS2 | y = −0.4849x + 1.2479 | 0.9969 | 2.5151 | y = −0.3063x + 1.3827 | 0.9678 | 2.6937 |

| BDS3 | y = −0.4657x + 1.7655 | 0.9959 | 2.5343 | y = −0.2615x + 1.8765 | 0.9628 | 2.7385 |

| BDS4 | y = −0.409x + 1.6566 | 0.9938 | 2.5910 | y = −0.2412x + 1.7601 | 0.9561 | 2.7588 |

| DDS1 | y = −0.4894x − 0.2237 | 0.9972 | 2.5106 | y = −0.42x − 0.1289 | 0.9922 | 2.58 |

| DDS2 | y = −0.5028x − 0.8218 | 0.9937 | 2.4972 | y = −0.4542x − 0.8151 | 0.9967 | 2.5458 |

| DDS3 | y = −0.5101x − 0.2926 | 0.9969 | 2.4899 | y = −0.3909x − 0.2273 | 0.9972 | 2.6091 |

| DDS4 | y = −0.4488x − 1.0709 | 0.9944 | 2.5512 | y = −0.4809x − 1.1008 | 0.9984 | 2.5191 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, M.; Dong, M.; Wang, Z.; Zhang, K.; Li, X.; Feng, X. Fractal Analysis of Organic Matter Nanopore Structure in Tectonically Deformed Shales. Fractal Fract. 2025, 9, 257. https://doi.org/10.3390/fractalfract9040257

Liang M, Dong M, Wang Z, Zhang K, Li X, Feng X. Fractal Analysis of Organic Matter Nanopore Structure in Tectonically Deformed Shales. Fractal and Fractional. 2025; 9(4):257. https://doi.org/10.3390/fractalfract9040257

Chicago/Turabian StyleLiang, Mingliang, Min Dong, Zongxiu Wang, Kaixun Zhang, Xiaoshi Li, and Xingqiang Feng. 2025. "Fractal Analysis of Organic Matter Nanopore Structure in Tectonically Deformed Shales" Fractal and Fractional 9, no. 4: 257. https://doi.org/10.3390/fractalfract9040257

APA StyleLiang, M., Dong, M., Wang, Z., Zhang, K., Li, X., & Feng, X. (2025). Fractal Analysis of Organic Matter Nanopore Structure in Tectonically Deformed Shales. Fractal and Fractional, 9(4), 257. https://doi.org/10.3390/fractalfract9040257