A Novel Contact Stiffness Model for Grinding Joint Surface Based on the Generalized Ubiquitiformal Sierpinski Carpet Theory

Abstract

1. Introduction

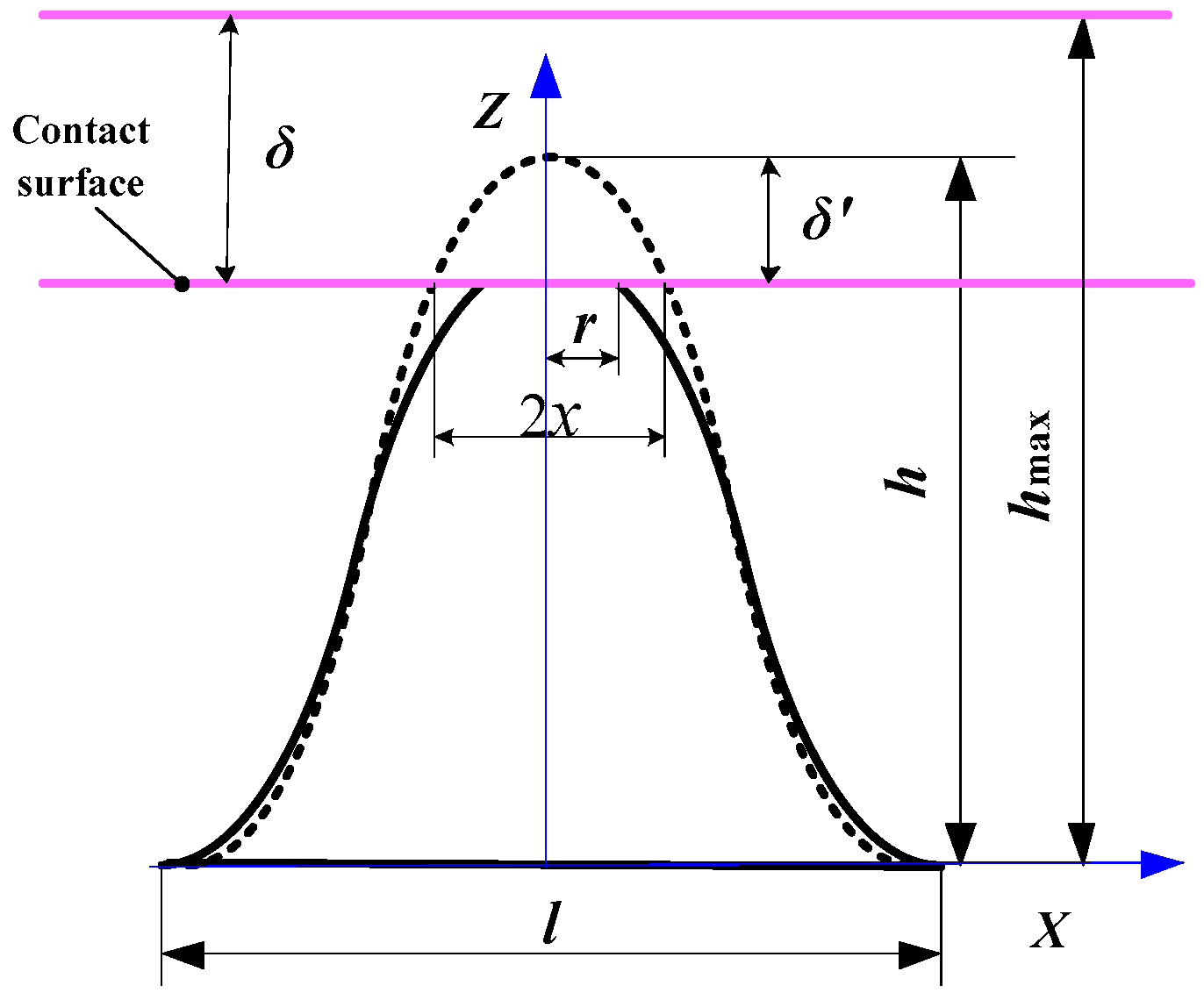

2. Characterization of the Grinding Surface

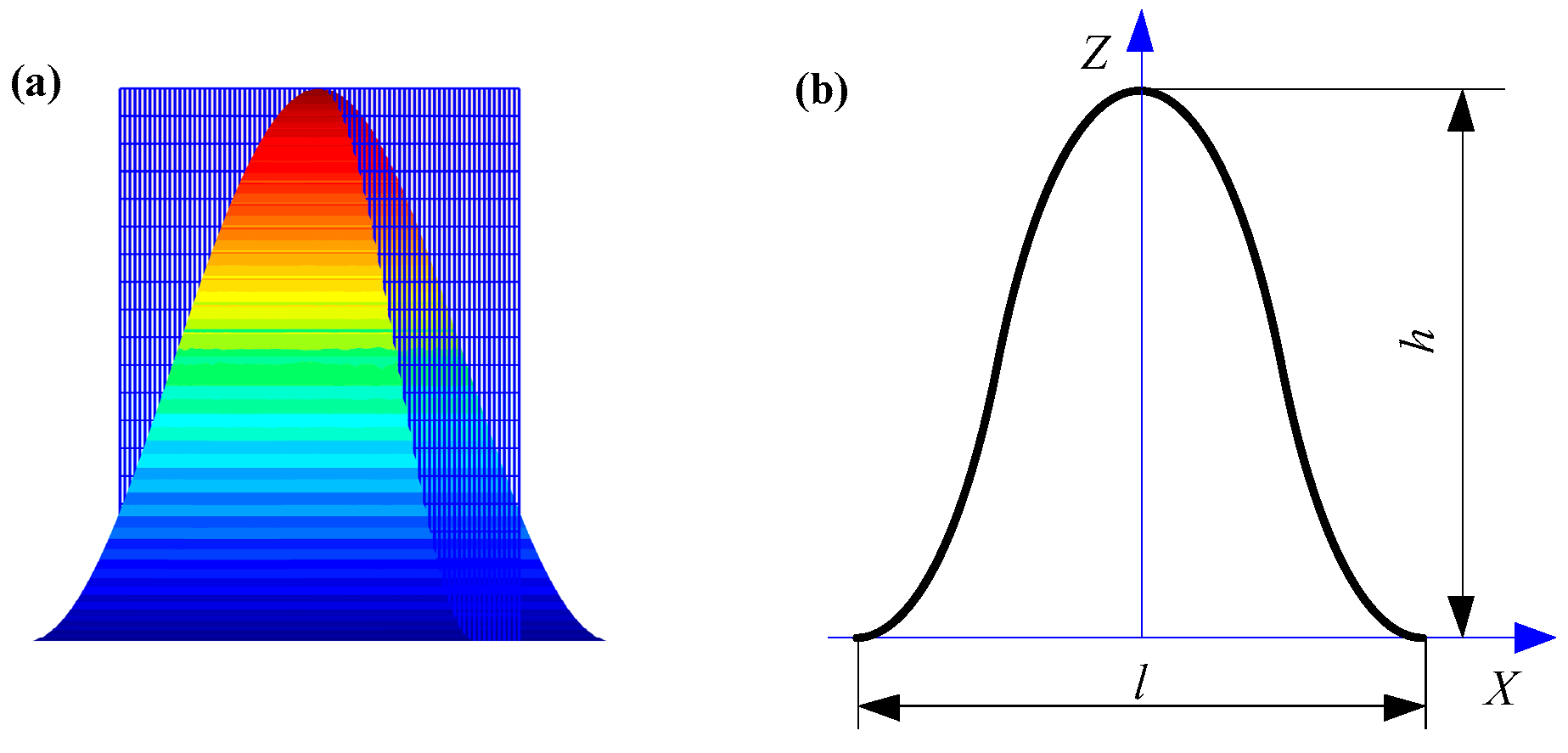

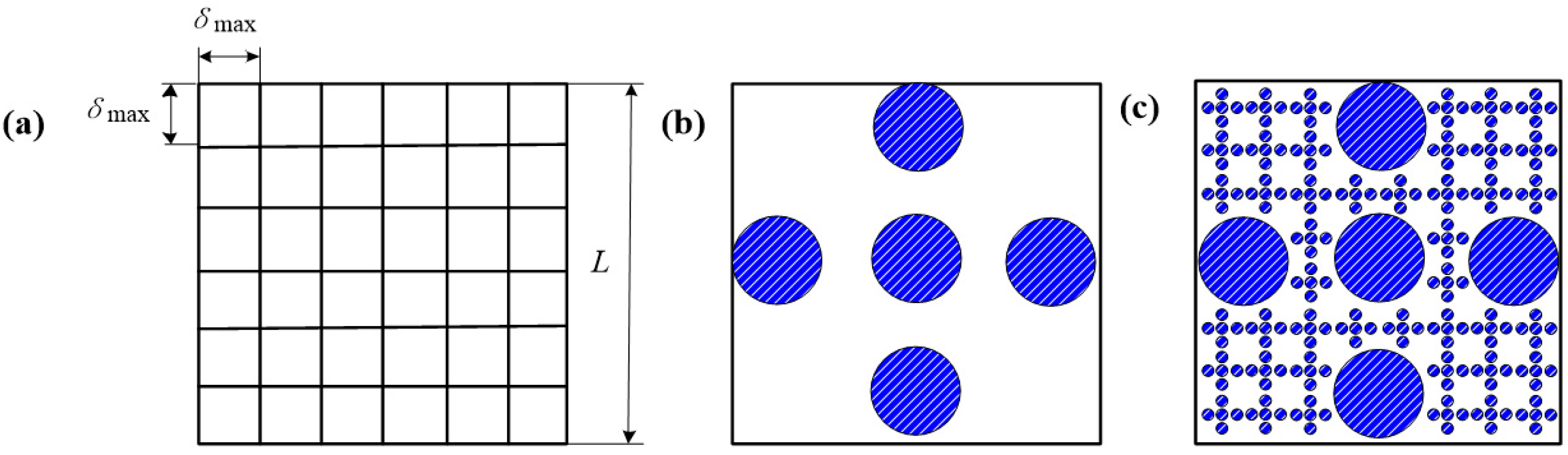

2.1. Characterization of Simulated Surface

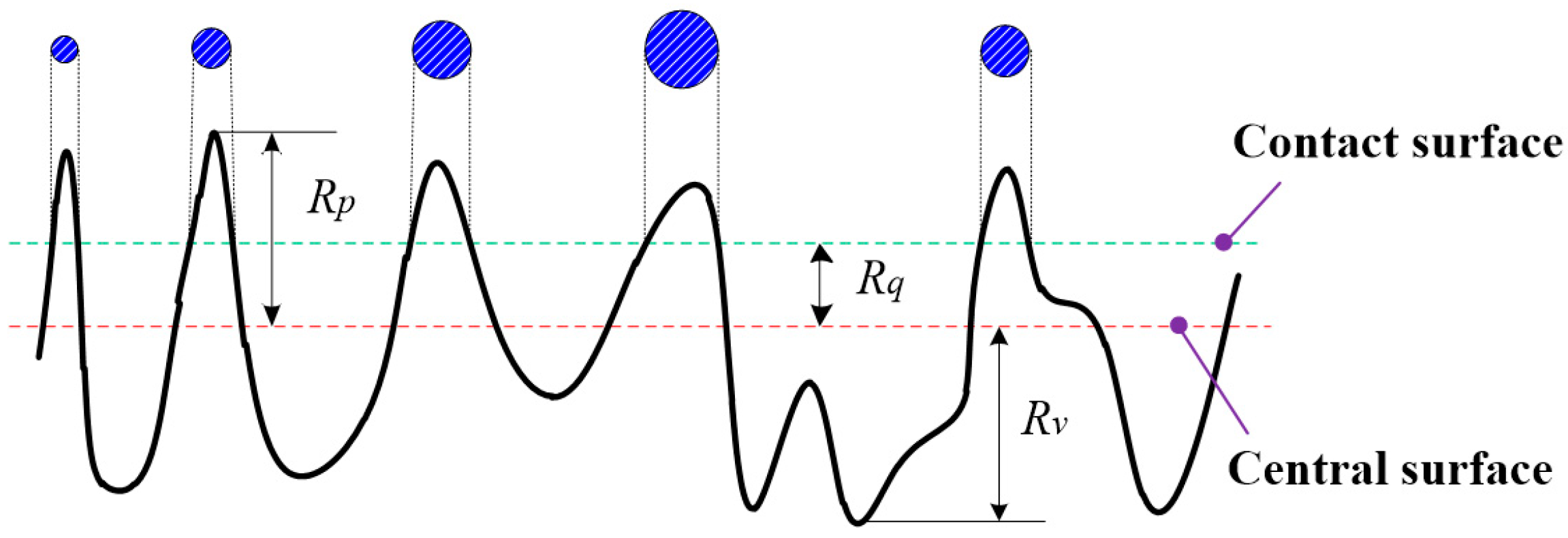

2.2. Contact Characterization of the Grinding Joint Surface

3. Contact Analysis

3.1. Contact Analysis of a Single Asperity

- (1)

- Elastic deformation stage

- (2)

- Plastic deformation stage

- (3)

- Elastic–plastic deformation stage

3.2. Contact Analysis of the Joint Surface

- (1)

- Elastic deformation stage

- (2)

- Plastic deformation stage

- (3)

- Elastic–plastic deformation stage

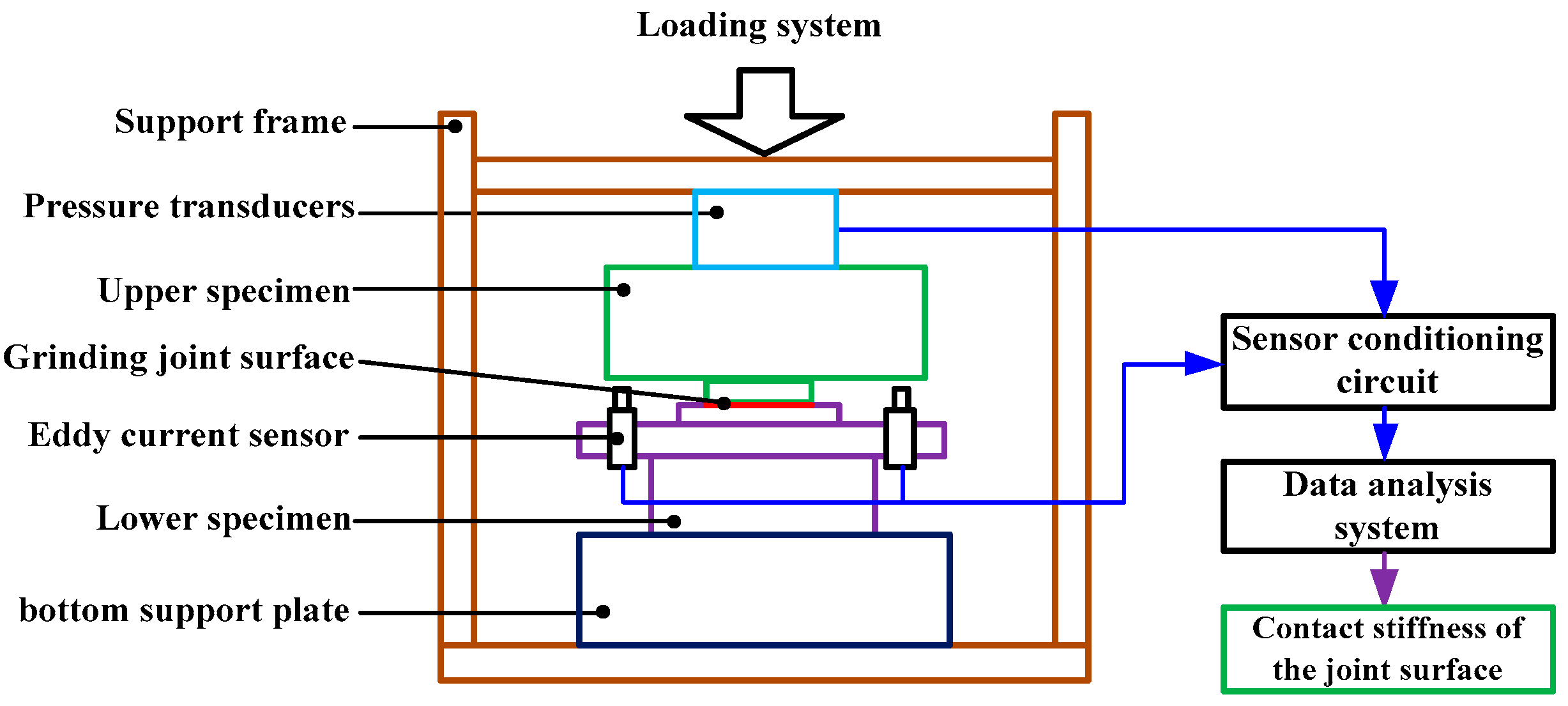

4. Experiment

4.1. Specimen Preparation

4.2. Test Rig

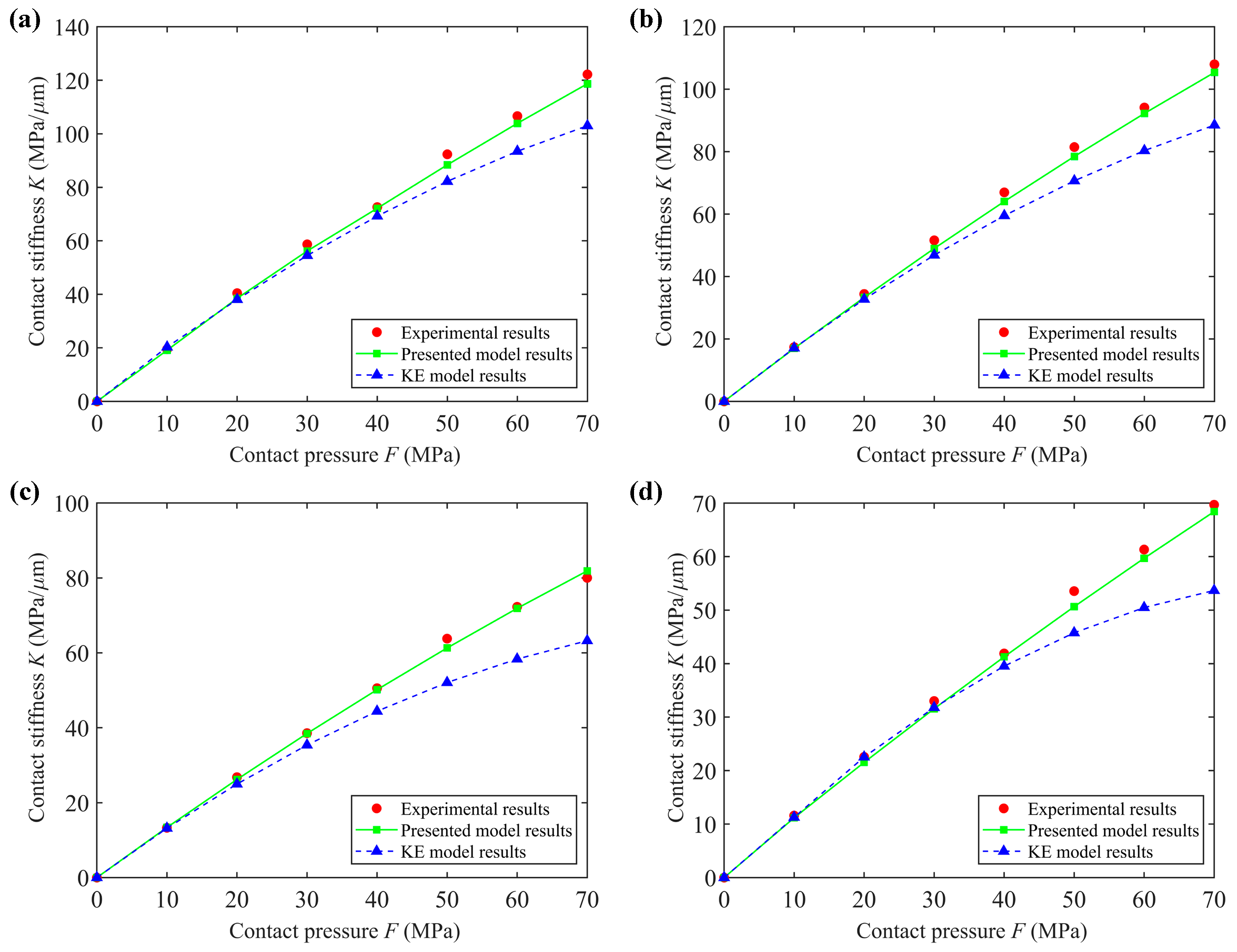

5. Results and Analysis

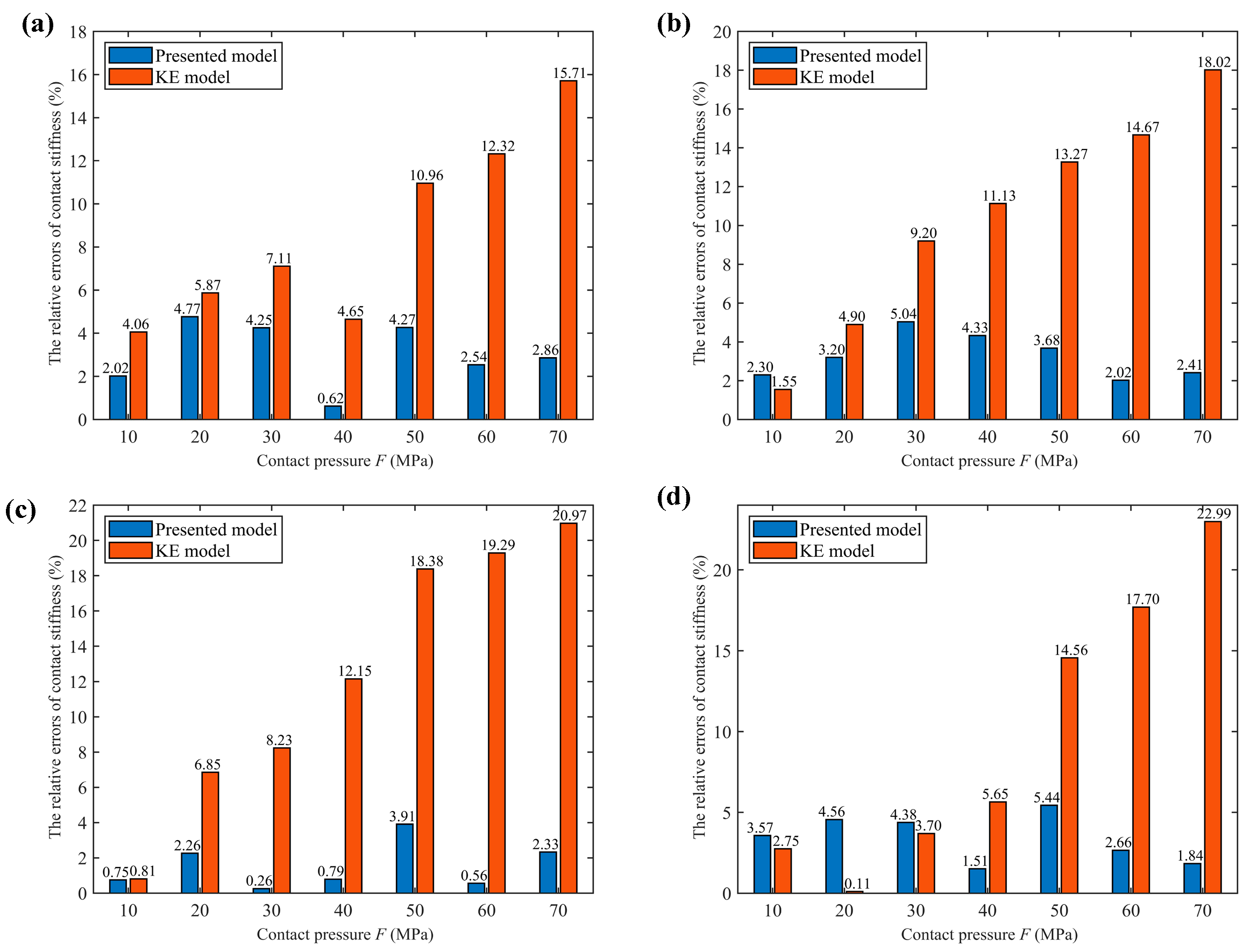

6. Conclusions

- (1)

- Combined with generalized ubiquitiformal Sierpinski carpet, the characterization of the grinding surface is realized. The profile of a single asperity is simulated using an axisymmetric sinusoid, while the distribution of asperities is represented using a Gaussian distribution. Based on the generalized ubiquitiformal Sierpinski carpet, the contact characterization of the grinding joint surface is realized. Then, a simulated surface which is more similar to the measured grinding surface is established, which provides the surface basis for the construction of the analytical model of normal contact stiffness.

- (2)

- A novel contact stiffness model for the grinding joint surface is proposed. Based on the simulated surface and contact mechanics analysis, the analytical expressions of contact stiffness in elastic deformation stage, elastic–plastic deformation stage, and plastic deformation stage are deduced, and the analytical model of contact stiffness for the grinding joint surface is eventually established.

- (3)

- The accuracy of the presented model is verified well. The results of the presented model, the KE model, and the experimental test are compared. The comparison results show that under the same contact pressure, the presented model is closer to the experimental results than the KE model. The rationality of the results is explained based on the distribution of the asperities and the contact deformation law of the asperities on the grinding surface.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; An, Q.; Suo, S.; Meng, G.; Yu, Y.; Bai, Y. A novel three-dimensional fractal model for the normal contact stiffness of mechanical interface based on axisymmetric cosinusoidal asperity. Fractal Fract. 2023, 7, 279. [Google Scholar] [CrossRef]

- Tian, J.Y.; Su, H.; Wang, Z.J.; Zuo, K.C.; Wang, D.F.; Guo, D. Comparative analysis of angular contact bearing stiffness calculated by Hertz contact and thermo-elastohydrodynamic lubrication. Tribol. Int. 2024, 192, 109251. [Google Scholar] [CrossRef]

- Zhou, H.; Long, X.H.; Meng, G.; Liu, X.B. A stiffness model for bolted joints considering asperity interactions of rough surface contact. J. Tribol. 2022, 144, 011501. [Google Scholar] [CrossRef]

- Yu, X.; Sun, Y.Y.; Zhao, D.; Wu, S.J. A revised contact stiffness model of rough curved surfaces based on the length scale. Tribol. Int. 2021, 164, 107206. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.; Gong, J.Z.; Zhang, M. Normal contact stiffness of rough surfaces considering oblique asperity contact. Adv. Mech. Eng. 2019, 11, 1–14. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.J.; Shi, X.H.; Ma, S.L.; Cai, A.J. Contact stiffness model of joint surface considering continuous smooth characteristics and asperity interaction. Tribol. Lett. 2021, 69, 43. [Google Scholar] [CrossRef]

- Ghaednia, H.; Wang, X.; Saha, S.; Xu, Y.; Sharma, A.; Jackson, R.L. A review of elastic-plastic contact mechanics. Appl. Mech. Rev. 2017, 69, 060804. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Bush, A.W.; Gibson, R.D.; Thomas, T.R. The elastic contact of a rough surface. Wear 1975, 35, 87–111. [Google Scholar] [CrossRef]

- Komvopoulos, K.; Choi, D.H. Elastic finite element analysis of multi-asperity contacts. J. Tribol. 1992, 114, 823–831. [Google Scholar] [CrossRef]

- Horng, J.-H. An elliptic elastic-plastic asperity microcontact model for rough surfaces. J. Tribol. 1998, 120, 82–88. [Google Scholar] [CrossRef]

- An, Q.; Suo, S.F.; Lin, F.Y.; Shi, J.W. A novel micro-contact stiffness model for the grinding surfaces of steel materials based on cosine curve-shaped asperities. Materials 2019, 12, 3561. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.R.; Etsion, I.; Bogy, D.B. An elastic-plastic model for the contact of rough surfaces. J. Tribol. 1987, 109, 257–263. [Google Scholar] [CrossRef]

- Zhao, Y.; Maietta, D.M.; Chang, L. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J. Tribol. 2000, 122, 86–93. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, L. A model of asperity interactions in elastic-plastic contact of rough surfaces. J. Tribol. 2001, 123, 857–864. [Google Scholar] [CrossRef]

- Ciavarella, M.; Greenwood, J.A.; Paggi, M. Inclusion of “interaction” in the Greenwood and Williamson contact theory. Wear 2008, 265, 729–734. [Google Scholar] [CrossRef]

- Sayles, R.S.; Thomas, T.R. Surface topography as a nonstationary random process. Nature 1978, 271, 431–434. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal model of elastic-plastic contact between rough surfaces. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Ausloos, M.; Berman, D.H. A multivariate Weierstrass–Mandelbrot function. Proc. R. Soc. Lond. A Math. Phys. Sci. 1997, 400, 331–350. [Google Scholar] [CrossRef]

- Yan, W.; Komvopoulos, K. Contact analysis of elastic-plastic fractal surfaces. J. Appl. Phys. 1998, 84, 3617–3624. [Google Scholar] [CrossRef]

- Shi, W.B.; Zhang, Z.S. Contact characteristic parameters modeling for the assembled structure with bolted joints. Tribol. Int. 2022, 165, 107272. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Wu, H.C.; Liu, Z.F.; Cheng, Q.; Yang, C.B. A novel nonlinear contact stiffness model of concrete-steel joint based on the fractal contact theory. Nonlinear Dyn. 2018, 94, 151–164. [Google Scholar] [CrossRef]

- Zheng, J.L.; Liu, X.K.; Jin, Y.; Dong, J.B.; Wang, Q.Q. Effects of surface geometry on advection-diffusion process in rough fractures. Chem. Eng. J. 2021, 414, 128745. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.S.; Chen, X.; Yu, H.C. A spherical conformal contact model considering frictional and microscopic factors based on fractal theory. Chaos Solitons Fractals 2018, 111, 96–107. [Google Scholar] [CrossRef]

- Jiang, K.; Liu, Z.F.; Yang, C.B.; Zhang, C.X.; Tian, Y.; Zhang, T. Effects of the joint surface considering asperity interaction on the bolted joint performance in the bolt tightening process. Tribol. Int. 2022, 167, 107408. [Google Scholar] [CrossRef]

- Magsipoc, E.; Zhao, Q.; Grasselli, G. 2D and 3D roughness characterization. Rock Mech. Rock Eng. 2020, 53, 1495–1519. [Google Scholar] [CrossRef]

- Li, L.; Yun, Q.Q.; Li, Z.Q.; Liu, Y.; Cao, C.Y. A new contact model of joint surfaces accounting for surface waviness and substrate deformation. Int. J. Appl. Mech. 2019, 11, 1950079. [Google Scholar] [CrossRef]

- Ou, Z.C.; Li, G.Y.; Duan, Z.P.; Huang, F.L. Ubiquitiform in applied mechanics. J. Theor. Appl. Mech. 2014, 52, 37–46. [Google Scholar] [CrossRef]

- Li, G.-Y.; Ou, Z.C.; Xie, R.; Duan, Z.-P.; Huang, F.-L. A ubiquitiformal one-dimensional steady-state conduction model for a cellular material rod. Int. J. Thermophys. 2016, 37, 41. [Google Scholar] [CrossRef]

- Min, Y.; Zhuo-Cheng, O.; Zhuo-Ping, D.; Feng-Lei, H. Research on one-dimensional ubiquitiformal constitutive relations for a bimaterial bar. J. Theor. Appl. Mech. 2019, 57, 291–301. [Google Scholar] [CrossRef]

- Ma, Z.; Shi, C.-Z.; Wu, H.-G. Numerical cracking analysis of steel-lined reinforced concrete penstock based on cohesive crack model. Structures 2021, 34, 4694–4703. [Google Scholar] [CrossRef]

- Ou, Z.C.; Li, C.Y.; Duan, Z.P.; Huang, F.L. A stereological ubiquitiformal softening model for concrete. J. Theor. Appl. Mech. 2019, 57, 27–35. [Google Scholar] [CrossRef]

- Ou, Z.C.; Yang, M.; Li, G.Y.; Duan, Z.P.; Huang, F.L. Ubiquitiformal fracture energy. J. Theor. Appl. Mech. 2017, 55, 1101–1108. [Google Scholar] [CrossRef][Green Version]

- Ou, Z.C.; Ju, Y.B.; Li, J.Y.; Duan, Z.P.; Huang, F.L. Ubiquitiformal crack extension in quasi-brittle materials. Acta Mech. Solida Sin. 2020, 33, 674–691. [Google Scholar] [CrossRef]

- Ju, Y.B.; Ou, Z.C.; Duan, Z.P.; Huang, F.L. The ubiquitiformal characterization of the mesostructures of polymer-bonded explosives. Materials 2019, 12, 3763. [Google Scholar] [CrossRef] [PubMed]

- Shang, S.; Cao, X.; Liu, Z.; Shi, J.P. Analysis of normal elastic contact stiffness of rough surfaces based on ubiquitiform theory. J. Tribol. 2019, 141, 111401. [Google Scholar] [CrossRef]

- Koumi, K.E.; Zhao, L.; Leroux, J.; Chaise, T.; Nelias, D. Contact analysis in the presence of an ellipsoidal inhomogeneity within a half space. Int. J. Solids Struct. 2014, 51, 1390–1402. [Google Scholar] [CrossRef]

- Khezrzadeh, H.; Mofid, M. Tensile fracture behavior of heterogeneous materials based on fractal geometry. Theor. Appl. Fract. Mech. 2006, 46, 46–56. [Google Scholar] [CrossRef]

- Freiberg, U.; Kohl, S. Box dimension of fractal attractors and their numerical computation. Commun. Nonlinear Sci. Numer. Simul. 2021, 95, 105615. [Google Scholar] [CrossRef]

- Denniston, J.T.; Solovyov, S.A. Sierpinski object for composite affine spaces. Fuzzy Sets Syst. 2021, 420, 157–168. [Google Scholar] [CrossRef]

| Ubiquitiformal Dimension | Grinding Joint Surface 1 | Grinding Joint Surface 2 | Grinding Joint Surface 3 | Grinding Joint Surface 4 |

|---|---|---|---|---|

| D1 | 2.553 | 2.517 | 2.497 | 2.491 |

| D2 | 2.536 | 2.522 | 2.501 | 2.496 |

| Roughness Parameters | Grinding Joint Surface 1 | Grinding Joint Surface 2 | Grinding Joint Surface 3 | Grinding Joint Surface 4 |

|---|---|---|---|---|

| Rp1/μm | 0.540 | 2.532 | 3.508 | 8.895 |

| Rv1/μm | 0.375 | 1.796 | 3.082 | 7.847 |

| Rq1/μm | 0.132 | 0.288 | 0.441 | 0.733 |

| Rp2/μm | 0.574 | 2.519 | 3.582 | 8.884 |

| Rv2/μm | 0.388 | 1.758 | 3.134 | 7.766 |

| Rq2/μm | 0.144 | 0.279 | 0.459 | 0.731 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, Q.; Liu, Y.; Huang, M.; Suo, S. A Novel Contact Stiffness Model for Grinding Joint Surface Based on the Generalized Ubiquitiformal Sierpinski Carpet Theory. Fractal Fract. 2024, 8, 351. https://doi.org/10.3390/fractalfract8060351

An Q, Liu Y, Huang M, Suo S. A Novel Contact Stiffness Model for Grinding Joint Surface Based on the Generalized Ubiquitiformal Sierpinski Carpet Theory. Fractal and Fractional. 2024; 8(6):351. https://doi.org/10.3390/fractalfract8060351

Chicago/Turabian StyleAn, Qi, Yue Liu, Min Huang, and Shuangfu Suo. 2024. "A Novel Contact Stiffness Model for Grinding Joint Surface Based on the Generalized Ubiquitiformal Sierpinski Carpet Theory" Fractal and Fractional 8, no. 6: 351. https://doi.org/10.3390/fractalfract8060351

APA StyleAn, Q., Liu, Y., Huang, M., & Suo, S. (2024). A Novel Contact Stiffness Model for Grinding Joint Surface Based on the Generalized Ubiquitiformal Sierpinski Carpet Theory. Fractal and Fractional, 8(6), 351. https://doi.org/10.3390/fractalfract8060351