1. Introduction

A sustainable future depends on wind energy, which offers a clean, abundant, renewable energy source that lowers greenhouse gas emissions and lessens our reliance on fossil fuels. Air wind speed at certain locations is the main factor influencing the amount of electrical active power generated by wind turbine generators, the wind turbine generator’s tower height, and the power curve’s characterization of the turbine’s power response to variations in wind speed [

1,

2,

3]. The manufacturers of wind turbines use field data of wind speed to capture the power produced by the turbine at each wind speed [

4]. Power curves for wind turbine generators vary; even turbines with identical ratings may produce power at various wind speeds. The crucial characteristic is the rated power, cut-in, rated, and cut-out speeds of a wind turbine, as shown in

Figure 1 [

5]. The turbine begins to produce electricity at cut-in speed. The turbine generates electricity that meets the relevant output at rated speed. The turbine stops producing power at cut-out speed.

Regarding power curve modelling for wind turbines, several studies have been conducted. The authors in [

6] provided a comparison of different wind turbine power curve models with respect to thirty-two commercial wind turbines, with ratings ranging between 330 and 7580 kW. The evaluated performance of the selected models for power curve modelling using statistical indicators such as correlation coefficient (

R), the Mean Absolute Percentage Error (

MAPE), and Relative Error (

RE) is used to evaluate the performance of capacity factor (

CF) model by comparing 12-month wind speed data at the Misrata location, located in northern Libya, with the Weibull and Gamma distributions during the whole year. Their results indicated that the general model gave the best accuracy for power curve modelling, the approximated power coefficient-based model was the least accurate when it comes to capacity factor estimation, and the most accurate model was the power-coefficient-based model, which was developed based on Weibull and gamma distributions, while the polynomial model was the least accurate. The four models are as follows: exponential, cubic, polynomial, and approximated cubic. These are most frequently used to represent the nonlinear part of a power curve between cut-in and rated speed and were contrasted by the results in [

7]. Utilizing data from manufacturer power curves from around 200 turbines with 225–7500 kW of capacity, they assessed the model’s accuracy using the coefficient of determination (

R2) as a statistical indicator. According to their findings, the cubic and exponential approximations result in reduced energy estimation errors and higher

R2, which makes this methodology appropriate given its simplicity. As a result of the polynomial model’s highly sensitive response to the manufacturer’s data, on the other hand, it produces the worst results.

Power curve modelling accurately gives the relationship between wind speed and power output, which is essential for wind turbines. Optimizing turbine performance, forecasting energy production, planning wind farms, and carrying out feasibility studies depend on accurate WTPC modelling. Precise power curve models facilitate the optimal penetration of wind energy into the electrical grid, boosting the dependability of wind power projections and supporting the economical operation and upkeep of wind turbines, all of which ultimately improve wind energy initiatives’ comprehensive efficacy and durability [

8].

The modelling of the WTPC is essential to account for these issues. 1. Evaluation of the possibilities for wind power since the wind turbine’s power curve can be utilized for evaluating wind power. It illustrates how wind speed and turbine output power are related to each other. Power curves are provided by manufacturers in tabular or graphical form. However, a mathematical model that precisely calculates the output power from the turbine at any wind speed is necessary for addressing several wind energy system issues, including determining the wind energy potential [

9]. 2. Estimation of capacity factor (CF): the capacity factor of the wind turbine can be defined as the ratio of a wind turbine’s actual power output over time to the energy it could have produced, regardless of its location. A wind turbine’s efficiency is reflected in its capacity factor, which shows how well the machine can use the wind’s energy. A wind turbine’s capacity factor is estimated using its power curve. The turbine will be more suitable for the site as the capacity factor value increases. As the capacity factor increases, the wind turbine utilizes more energy from the wind [

10]. 3. Wind turbine selection: the power curve can be used to determine if a certain wind turbine is suitable for this site or not according to the output power produced at each wind speed [

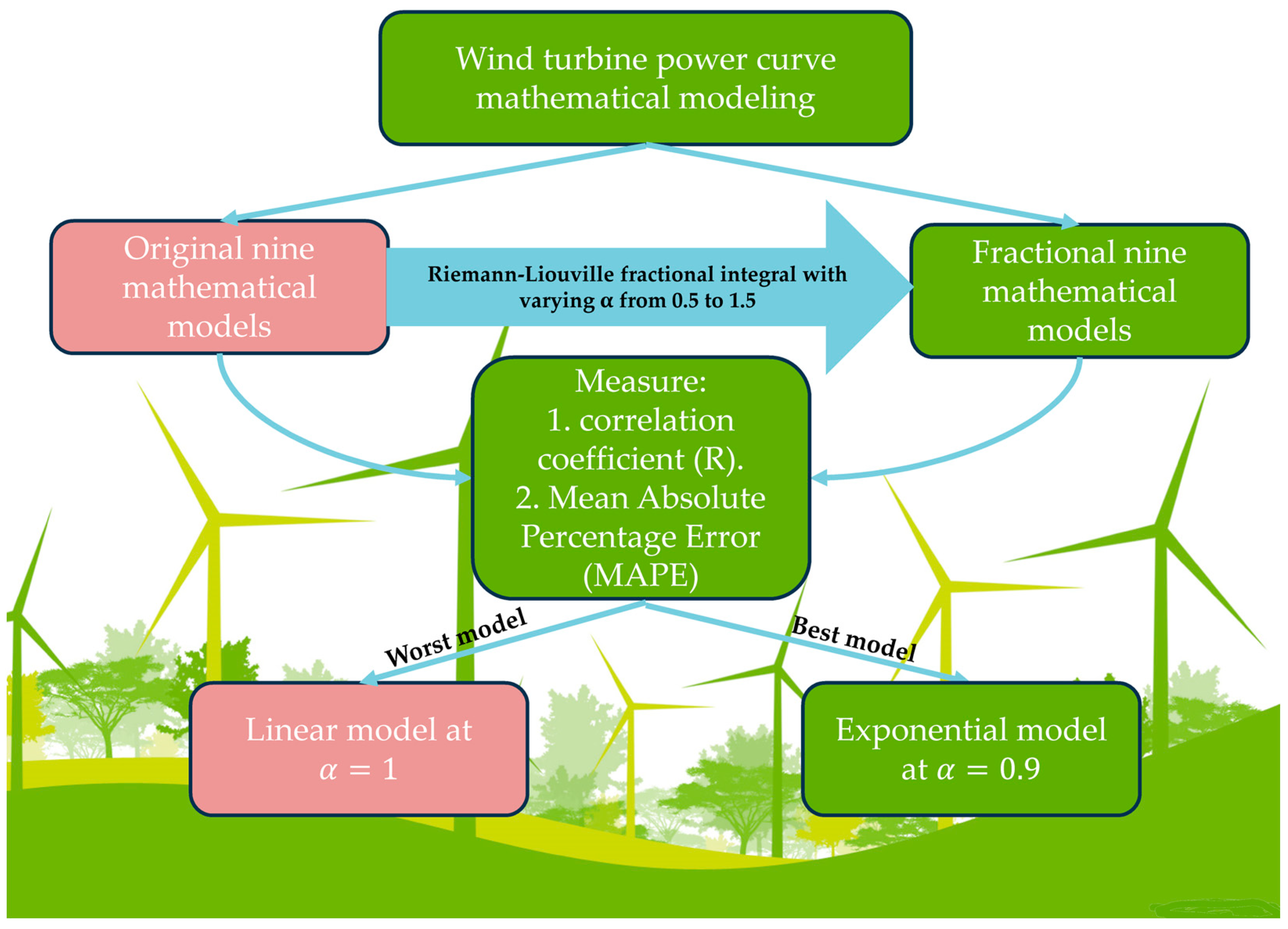

11]. A graphical abstract of the research can be illustrated in

Figure 2.

The flexibility needed to effectively describe complicated meteorological dynamics is frequently limited by integer-order differentiation in standard WTPC models, particularly in areas with changeable wind conditions. The complicated dynamics of wind power generation across various turbine configurations and weather patterns may be overlooked by traditional models based on classical derivatives, which may oversimplify real-world situations. To improve the representation of P-V curves and better match real-world data, fractional generalization aims to address the drawbacks of conventional WTPC models. To maximize wind energy output and guarantee the accuracy of turbine performance evaluations under various circumstances, this improved modelling capability is essential. By introducing FDE, fractional calculus makes it possible to represent the underlying system dynamics more precisely. Memory effects and non-local behaviour, which are frequently seen in wind turbine systems but are not well captured by integer-order models, can be considered by these models by utilizing the fractional derivative. By changing the α from 0.5 to 1.5, these models can be more flexible to accommodate varied turbine capacity and site-specific wind conditions, which improves the accuracy of turbine performance predictions.

The main contributions of the paper can be summarized as follows:

- •

We present nine novel fractional order differential and integral mathematical models, tested on various wind turbines across a wide range of ratings to validate the modelling of different 36 WTPCs.

- •

We solve FDE using an analytical form for the Riemann–Liouville fractional integral—which will be explained later in

Section 4—that is implemented on the model.

- •

We study the effect of changing the differentiation order () for nine mathematical models on the accuracy of WTPC modelling and CF.

- •

We utilize a decision-making technique, namely the analytical hierarchy process (AHP), to determine the best model for both WTPCs and CF and the order in which differentiation occurs.

The paper is organized as follows. In

Section 3, the system description is discussed in detail.

Section 4 focuses on wind turbine power curve mathematical modelling. In

Section 5, the results and discussion are presented and analysed.

Section 6 provides concluding remarks and summarizes the main findings of this study.

5. Results and Discussion

The above proposed fractional mathematical models were analysed to determine which

gives the best accuracy for each one. The first step was to collect the the power curves for manufacturer data. The models were then ranked according to their accuracy to determine which provided the best representation for the power curves. Consequently, a database of 36 WTPCs from three different manufacturers with ratings ranging between 150 kW and 3400 kW and their data is illustrated in

Appendix A [

42,

43,

44]. As an example,

Table 1 demonstrates how to calculate the wind turbine’s capacity factor of type “Nordex: N43/600”, which is the main wind turbine used in Zafarana wind station, which consists of 105 turbines of this type according to NREA, using measured time series for the wind speed, which is given in Equation (19). From

Table 1, the AEO described in Equation (20) for the site under study equals 1570.92 MWh/year; accordingly, the capacity factor equals 29.89%.

The histogram of the 36 selected wind turbines’ output rated power, cut-in, rated, and cut-out wind speeds, respectively, are shown in

Figure 3. It is evident from the wind turbine dataset that the rated power of turbines spans 150 kW to 3400 kW, but the rated power of most turbines is between 1 and 2 MW. The cut-in wind speeds vary between 2 and 4.5 m/s, with the majority between 3 and 3.5 m/s. The rated wind speeds range from 10 to 19 m/s, with the majority between 12 and 14 m/s. The cut-out wind speeds vary between 17 and 25 m/s, with the majority being 25 m/s.

The suggested models differ in

MAPE and

R. Every manufacturer power curve in the database was applied to each one of these models. The

MAPE and

R were used in the range

to assess the models’ performance and determine how well the models matched the power curve data from the manufacturers. The relationship between the instantaneous power and the manufacturer’s power curve values anticipated by each model is described by

MAPE and

R in the range

. The model that performs the best has the lowest

MAPE and the highest

R values. A representation of the original nine mathematical models for two wind turbines is shown in

Figure 4 as an example of WTPCs that give the best and worst accuracy results; the fractional exponential model provides the best results among all nine mathematical models. These models are (N100/3300), which is the best wind turbine that gives the lowest

MAPE, where

Pr = 3300 kW,

vci = 3.5 m/s,

vr = 14 m/s, and

vco = 25 m/s, and where

MAPE is calculated and found to be 8.68%; and (N29/250), which is the worst wind turbine that gives the highest

MAPE, where Pr = 250 kW,

vci = 2.5 m/s,

vr = 19 m/s, and

vco = 25 m/s, and where

MAPE is calculated and found to be 66.68%. The

MAPE and

R of the nine original mathematical models radar charts, respectively, are shown in

Figure 5, where the following models have identical

R values—cubic type I and type II, power coefficient and approximated power coefficient—but differ from each other in

MAPE, where the exponential model has the lowest

MAPE, while the polynomial model has the highest one among them. The outcomes of the original models’ performance assessment are illustrated in

Table 2, where the best model is determined using the AHP, as it is a structured decision-making technique that helps solve complex problems involving multiple criteria, where the model ranking is determined based on two criteria,

MAPE and

R, where the superior model is determined to be the exponential model with the greatest AHP score compared to the rest of the models, and the worst one is the polynomial model.

The following algorithm was utilized to determine the ranking of the mathematical models using the AHP illustrated in [

45,

46]:

Assuming that

MAPE is more significant than

R,

MAPE has a weight of 2 and

R a weight of 1.

- 3.

Normalize matrix and weights.

- •

Normalize the matrix

by dividing each element by the sum of its column.

- •

Calculate the priority vector by taking the average of each row in the normalized matrix.

- 3.

Score computation

- •

For each mathematical model, calculate the weighted sum based on Equations (56) and (57), respectively, for

MAPE and

R, where

Table 3 shows the score for each model and its rank, where the best model has the lowest rank value, i.e., exponential model has the highest rank.

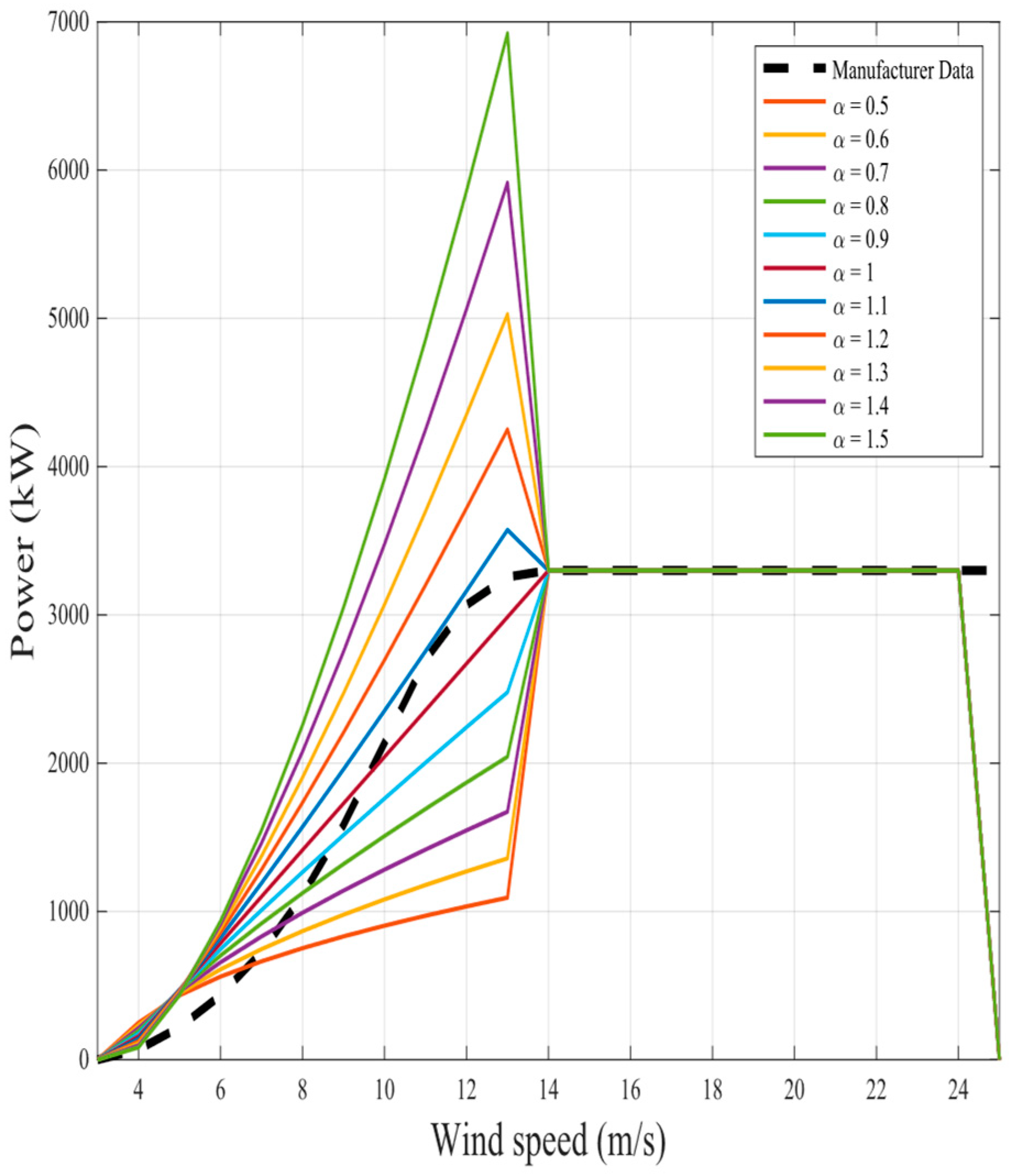

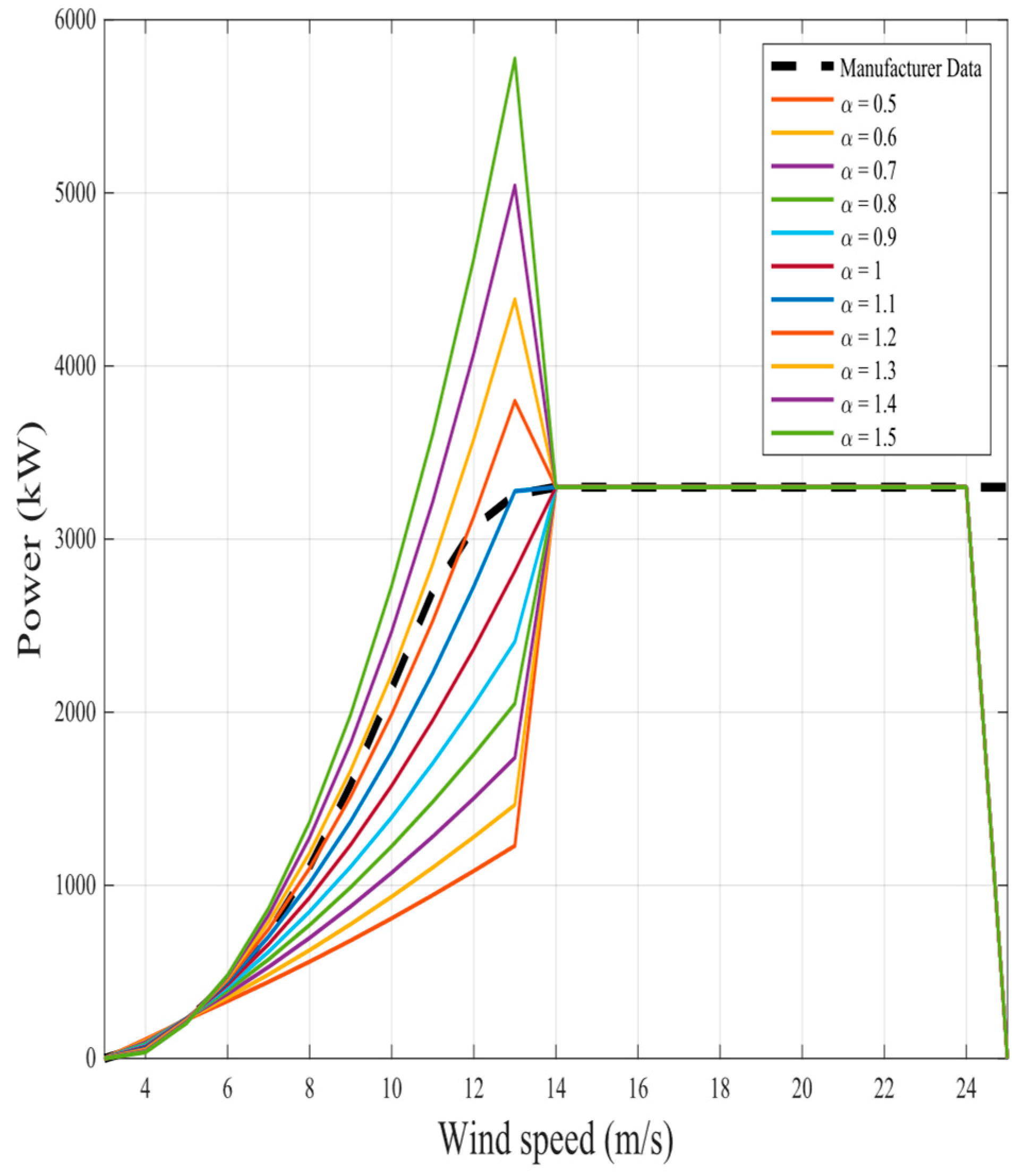

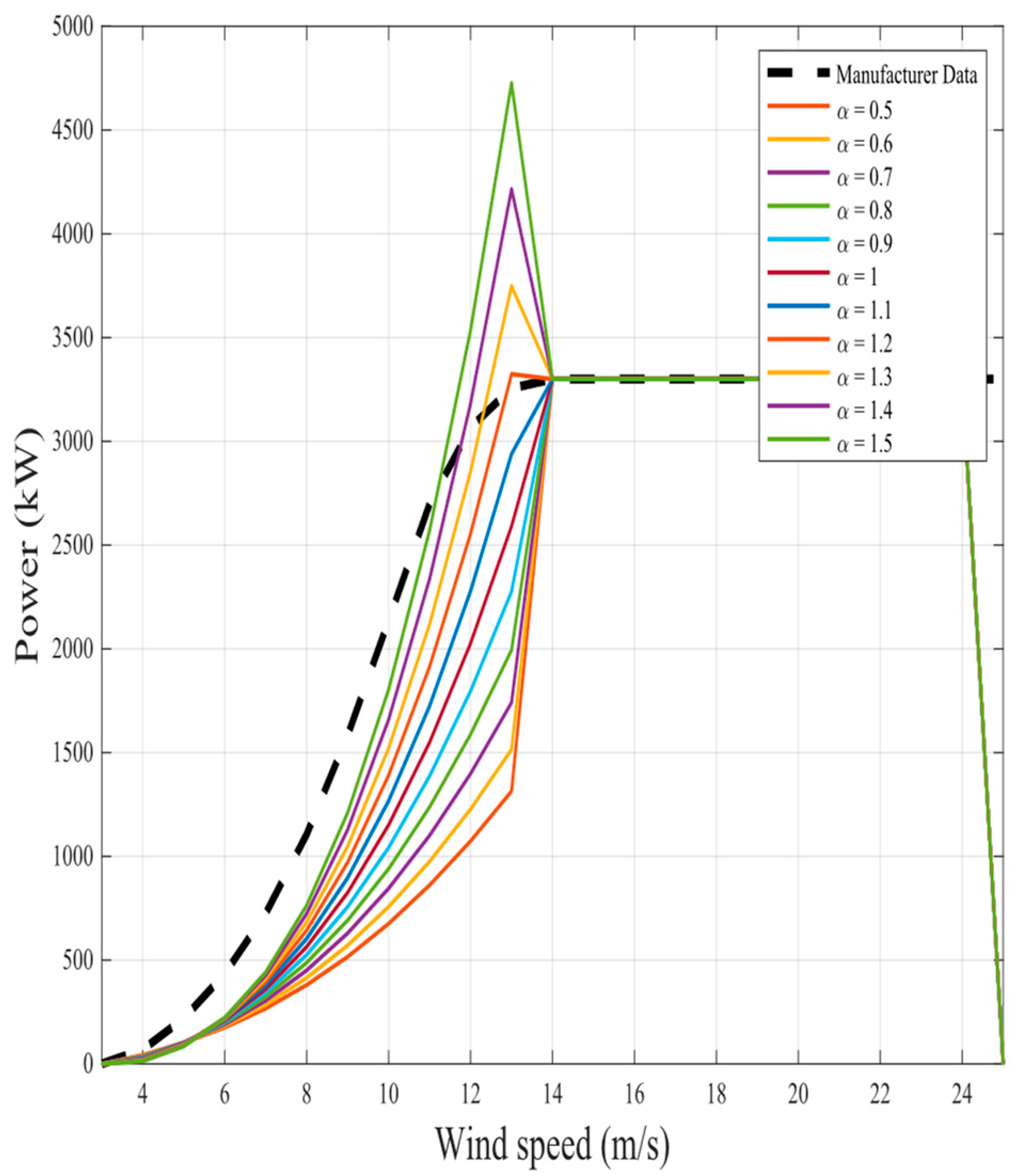

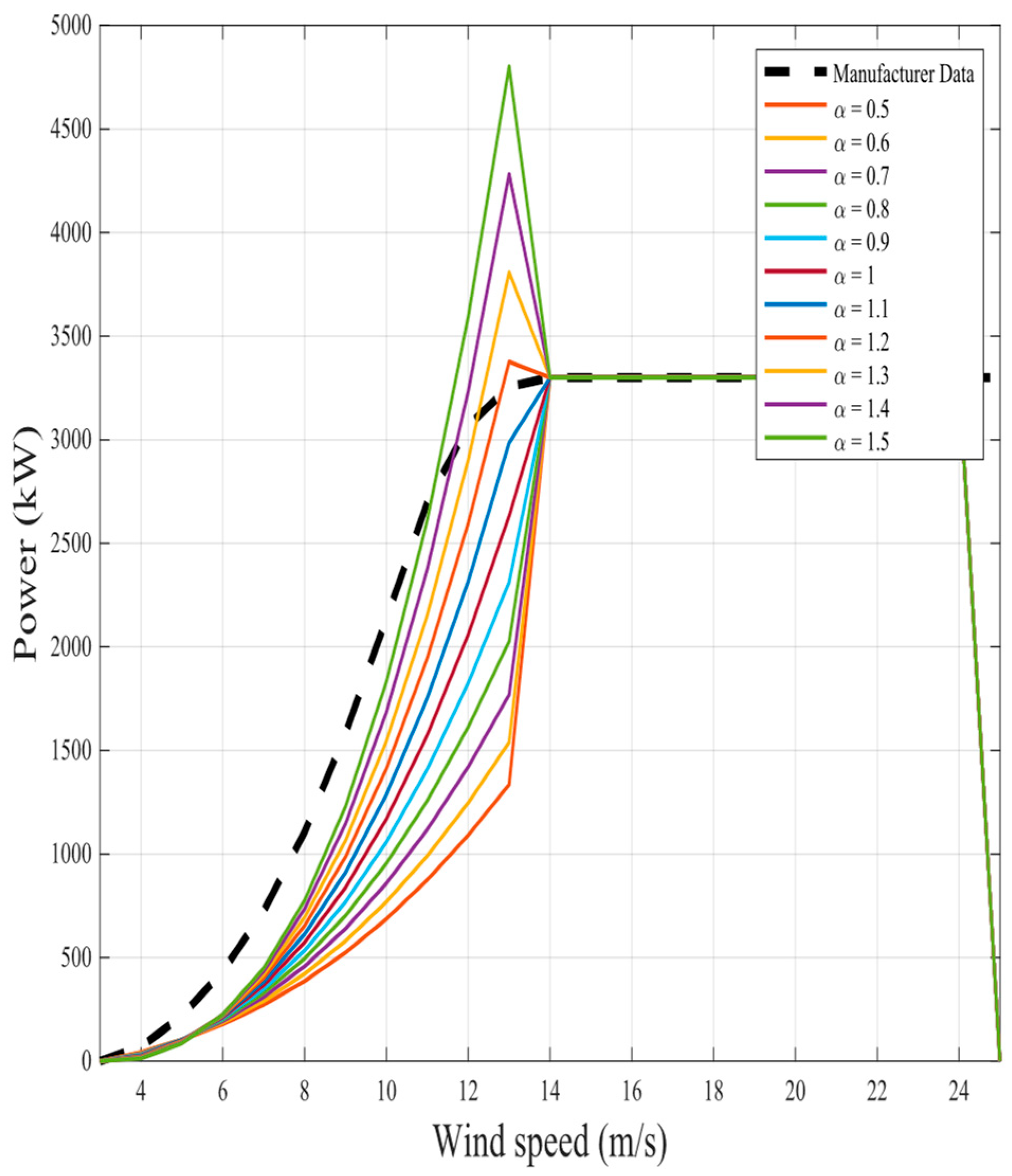

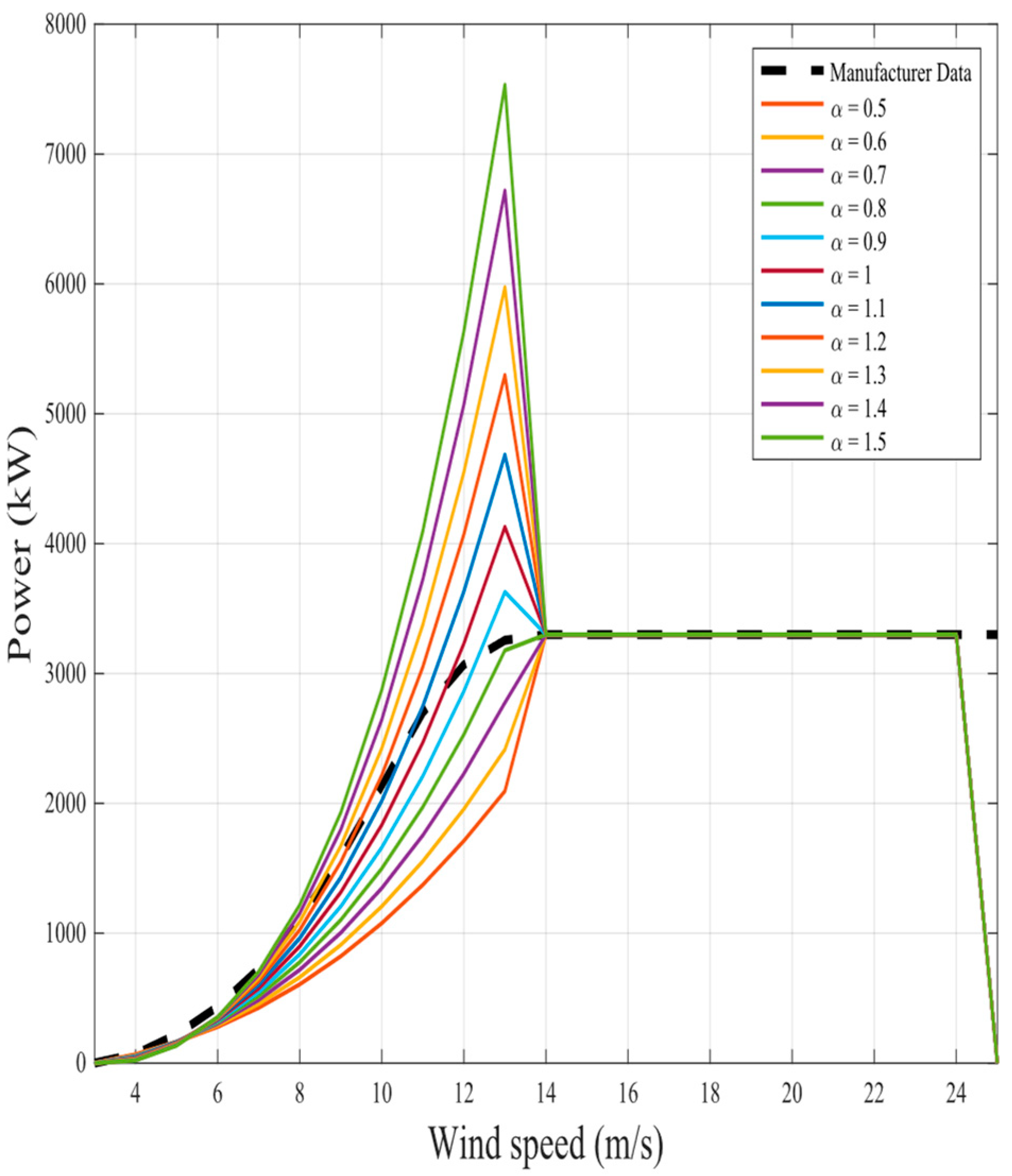

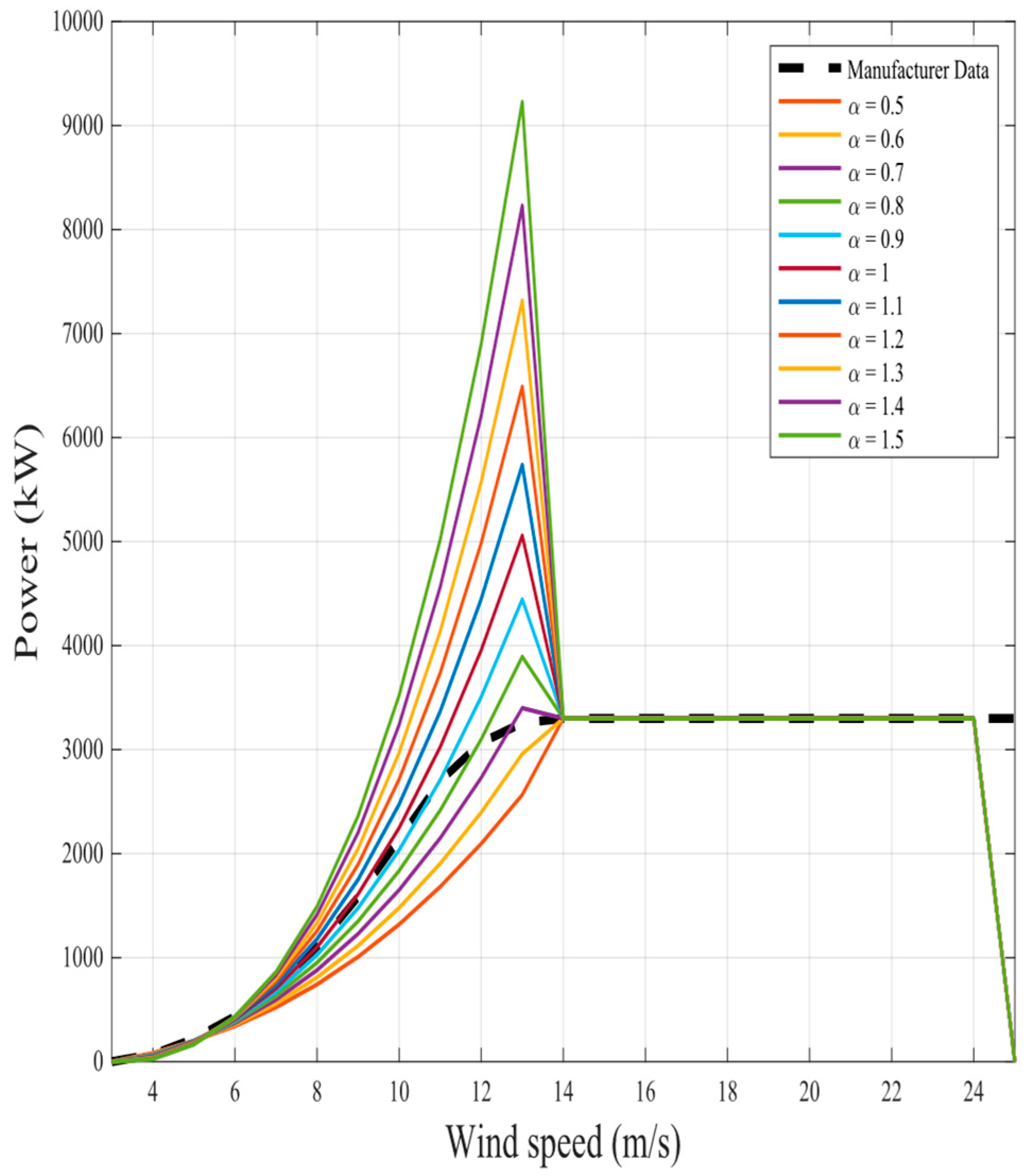

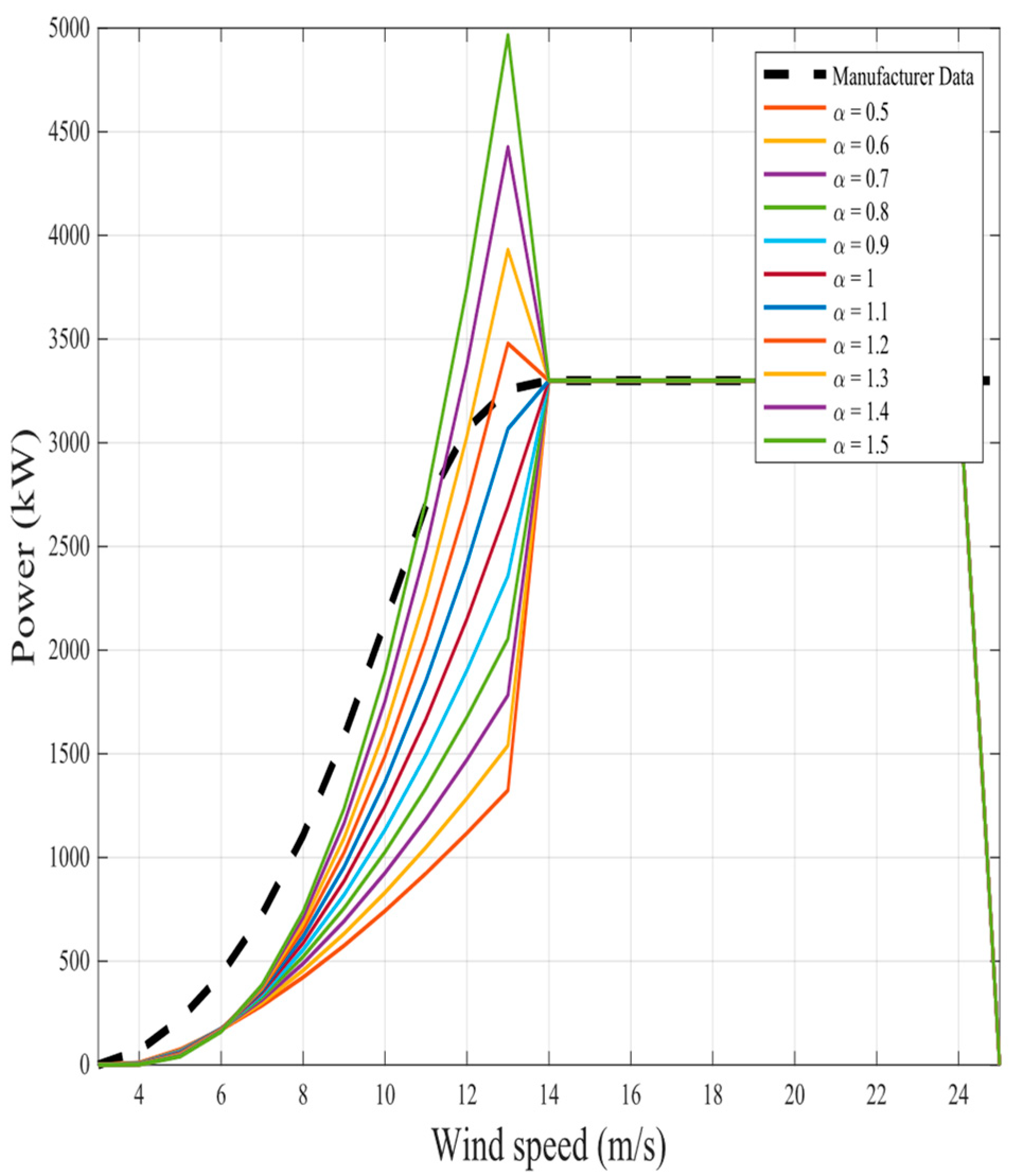

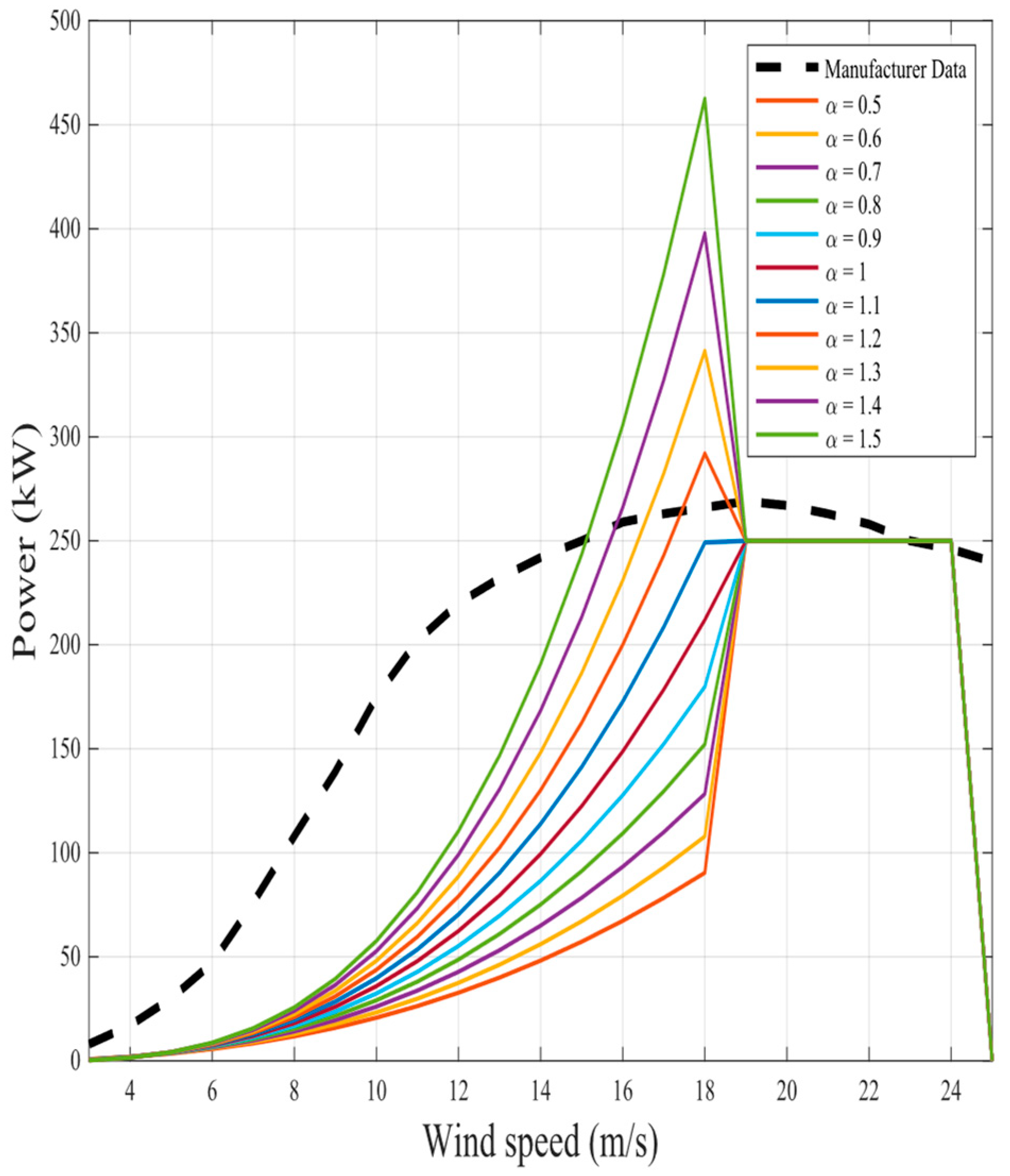

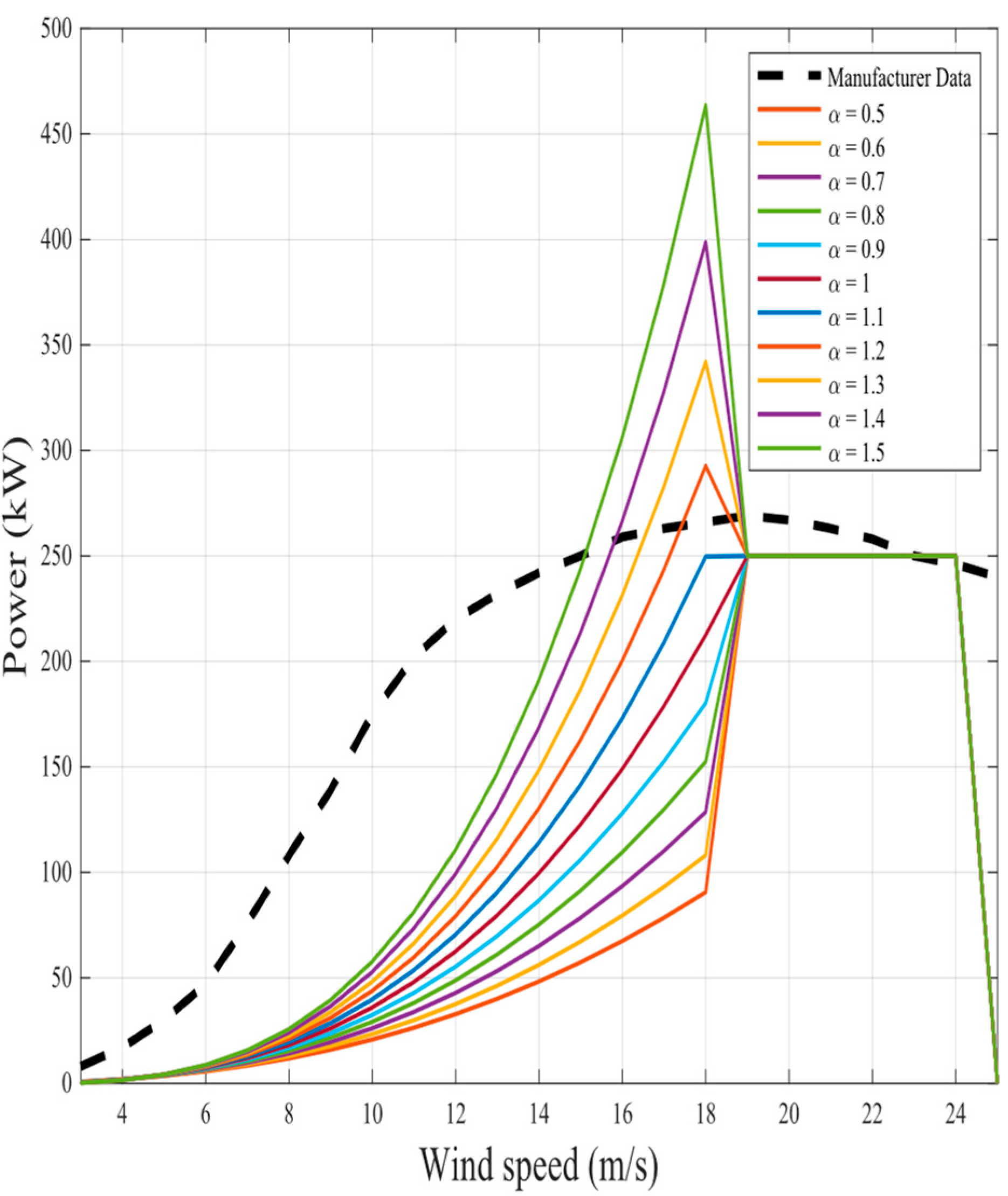

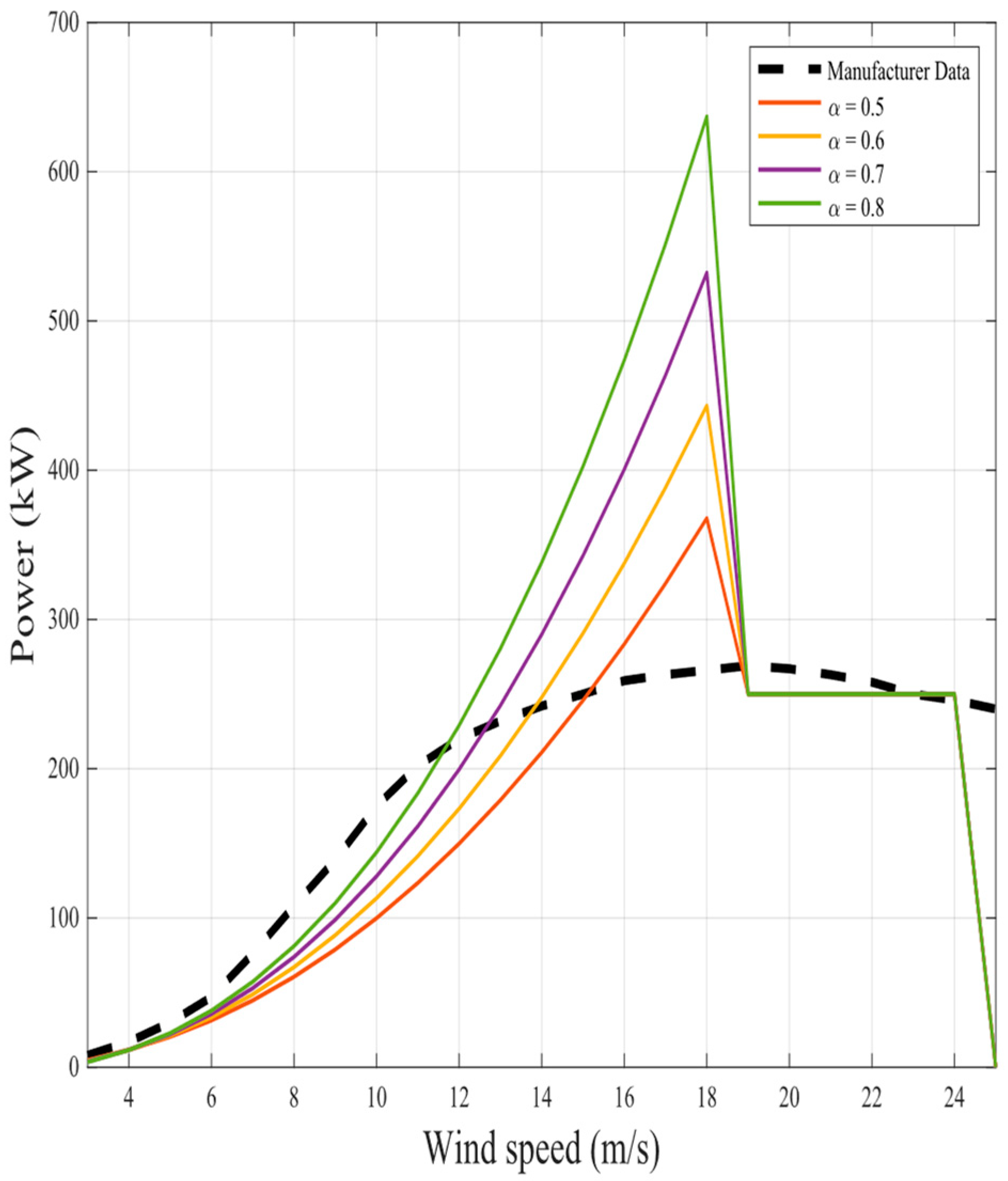

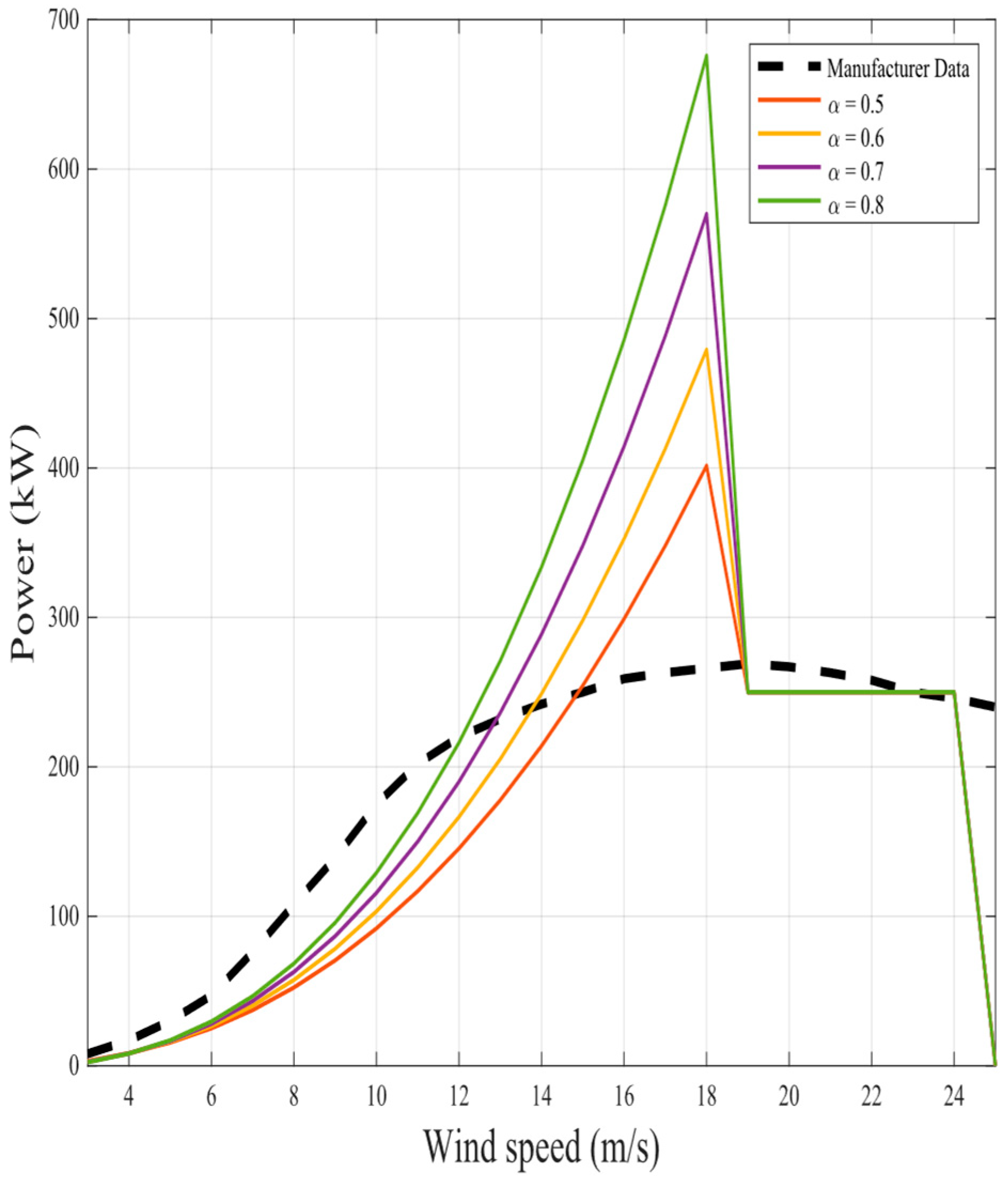

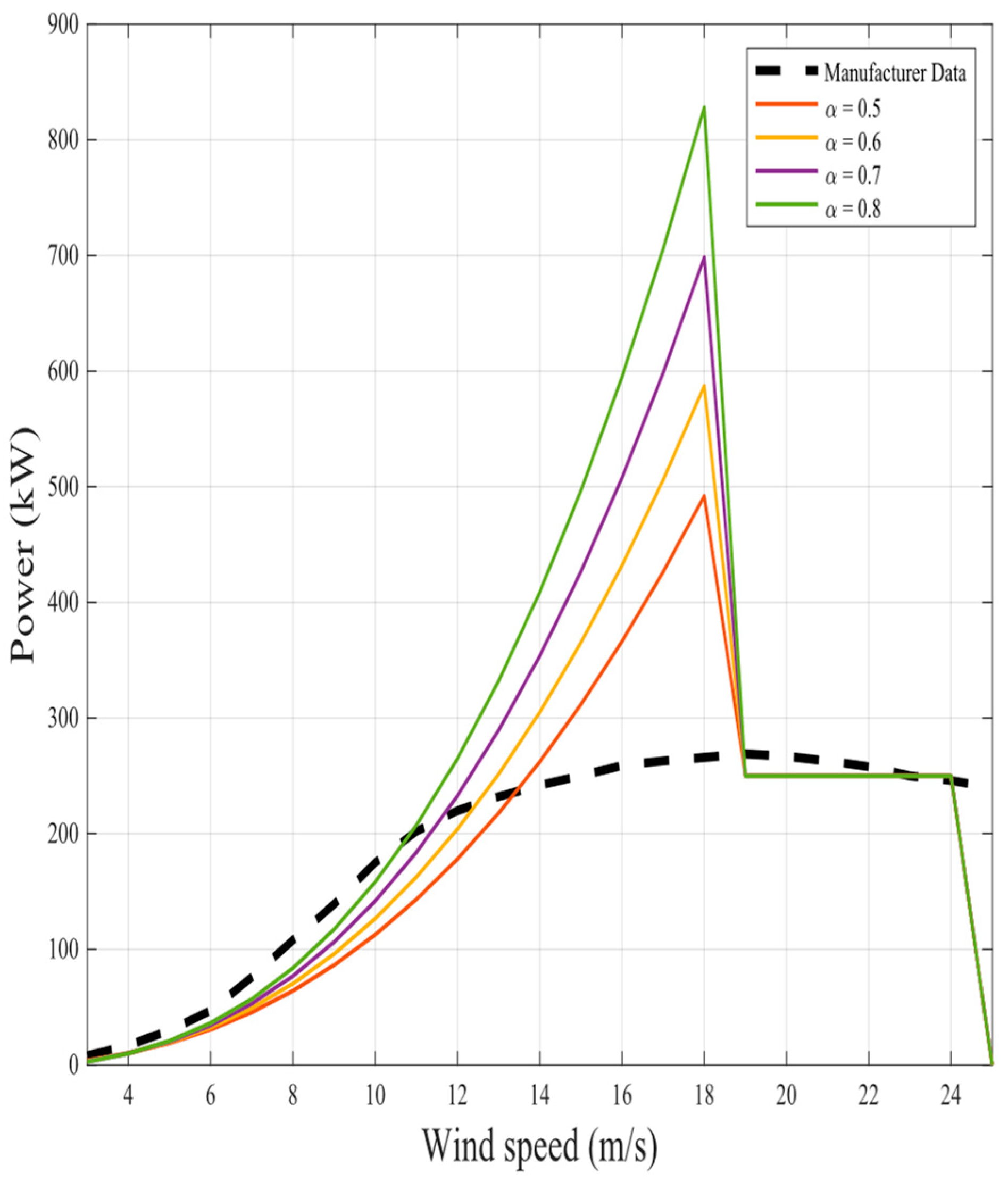

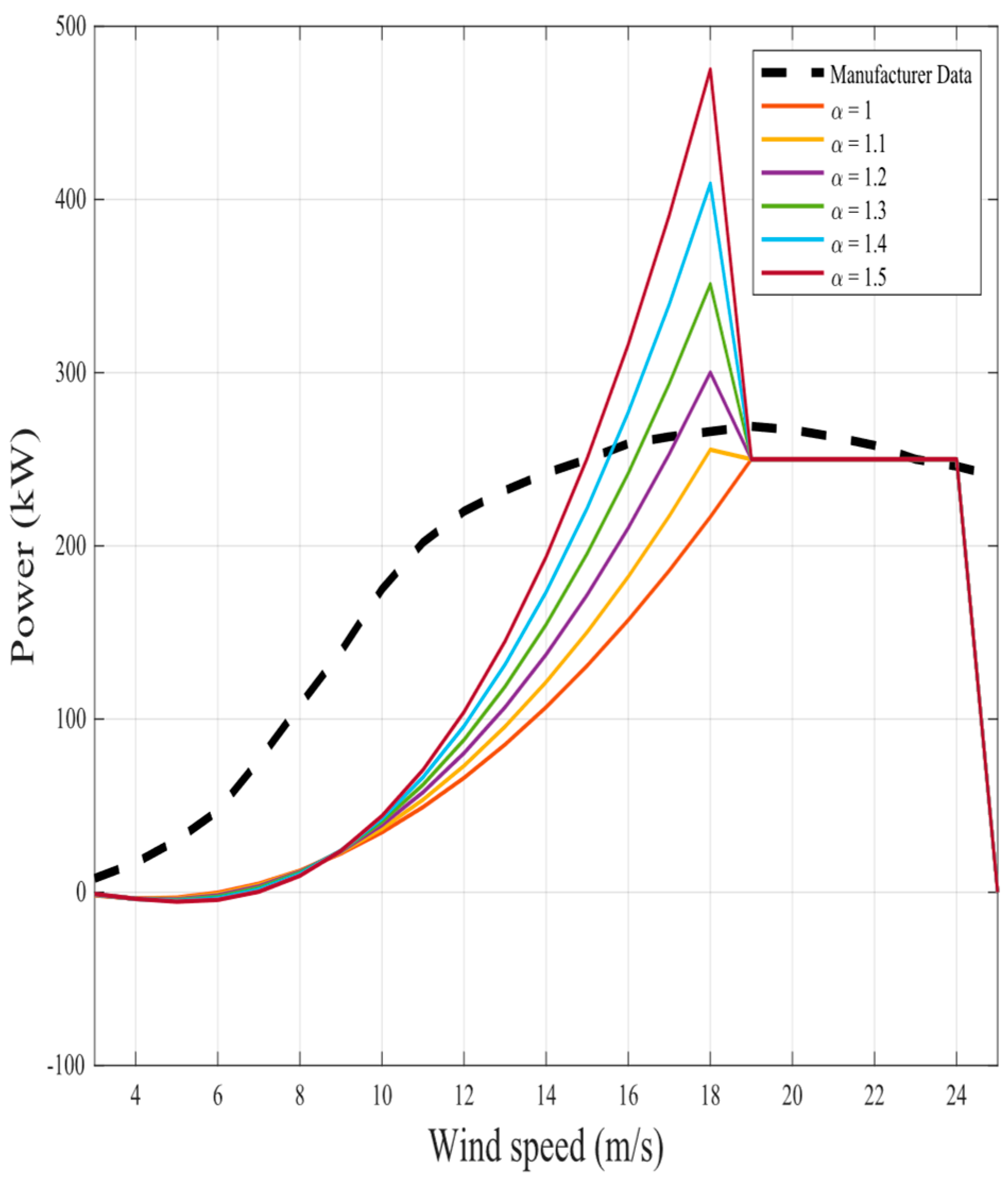

The representation of the proposed nine fractional mathematical models at different

for the same two wind turbines in original models is shown in

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22 and

Figure 23. The results illustrate as the

value increases in each model, more overshoot happens from the rated power. The nearest curves to the manufacturer power curve occur at around

.

Table 4 presents a comparative summary of

MAPE for the proposed fractional models used to estimate the P-V characteristics of the N100/3300 wind turbine as an example. The table demonstrates the performance of nine different models with varying α, ranging from 0.5 to 1.5. As shown, the MAPE values reflect the accuracy of each model at different fractional orders, with lower values indicating better performance. Notably, the exponential model at α = 1 (integer order) yields the lowest

MAPE (8.68%), signifying the highest accuracy among the models evaluated. In contrast, the linear model at α = 1.5 exhibits the highest

MAPE (91.21%), marking the least accurate result. Overall, the table provides insight into how varying the α affects the predictive accuracy of each model, enabling a nuanced understanding of their behaviour in wind turbine power curve modelling.

Table 5 provides a detailed summary of the correlation coefficients for the proposed fractional models used to estimate the P-V characteristics of the N100/3300 wind turbine as an example. The correlation coefficient values presented in the table correspond to different α values ranging from 0.5 to 1.5. A higher correlation coefficient reflects a stronger linear relationship between the predicted and actual data. As observed in the table, the linear model consistently exhibits one of the highest R values across various fractional orders, reaching up to 0.9945 at α = 1.3. In contrast, the cubic models show slightly lower correlation values, particularly as α increases beyond 1.1. Notably, the general model maintains a high level of accuracy, with

R = 0.9929 at α = 0.5, further validating the effectiveness of fractional differentiation in enhancing the model’s performance.

The results of the proposed fractional models’ performance evaluation are illustrated in

Table 6, where for each model, the

at which the model gives the best performance is stated, and also the percentage improvement compared to the original model for

MAPE is calculated. The score for each model and its rank are shown in

Table 7. The results show that the best model is the exponential model at

, with a percentage improvement in

MAPE compared to the original exponential model by

, and the worst model is the linear model

(the original linear model). The rank of models differs from original models to fractional models. The fractional model obtains improvements in

MAPE that reach around 44% in the approximated power coefficient model; however, it fails to give better results than the original linear model.

The

R and

MAPE values of the nine fractional mathematical models radar charts, respectively, are shown in

Figure 24, where the linear model has the highest correlation coefficient at

, while cubic type I, power coefficient, and approximated power coefficient models have the lowest R at

. The

MAPE is the lowest value for the exponential model at

and the highest value for the linear model at

(original linear model).

Based on the Weibull and gamma distributions, the values of

RE’s mean and standard deviation are calculated. The value of

at which each model gives the best accuracy, determined as

RE, is to be minimized. These results are illustrated in

Table 8. It is evident that the cubic type-I model at

has the smallest values of mean

RE; consequently, it is regarded as the most accurate mathematical model for estimating capacity factor. In contrast, the exponential model at

has the highest values of mean

RE; thus, it can be considered the worst model for estimating capacity factor. The gamma distribution gives lower

RE than the Weibull distribution, which means it is more suitable for capacity factor estimation at this site.