A Nonlinear Fractional BEM Model for Magneto-Thermo-Visco-Elastic Ultrasound Waves in Temperature-Dependent FGA Rotating Granular Plates

Abstract

1. Introduction

2. Formulation of the Problem

3. BEM Solution of Temperature-Dependent Heat Conduction Equation

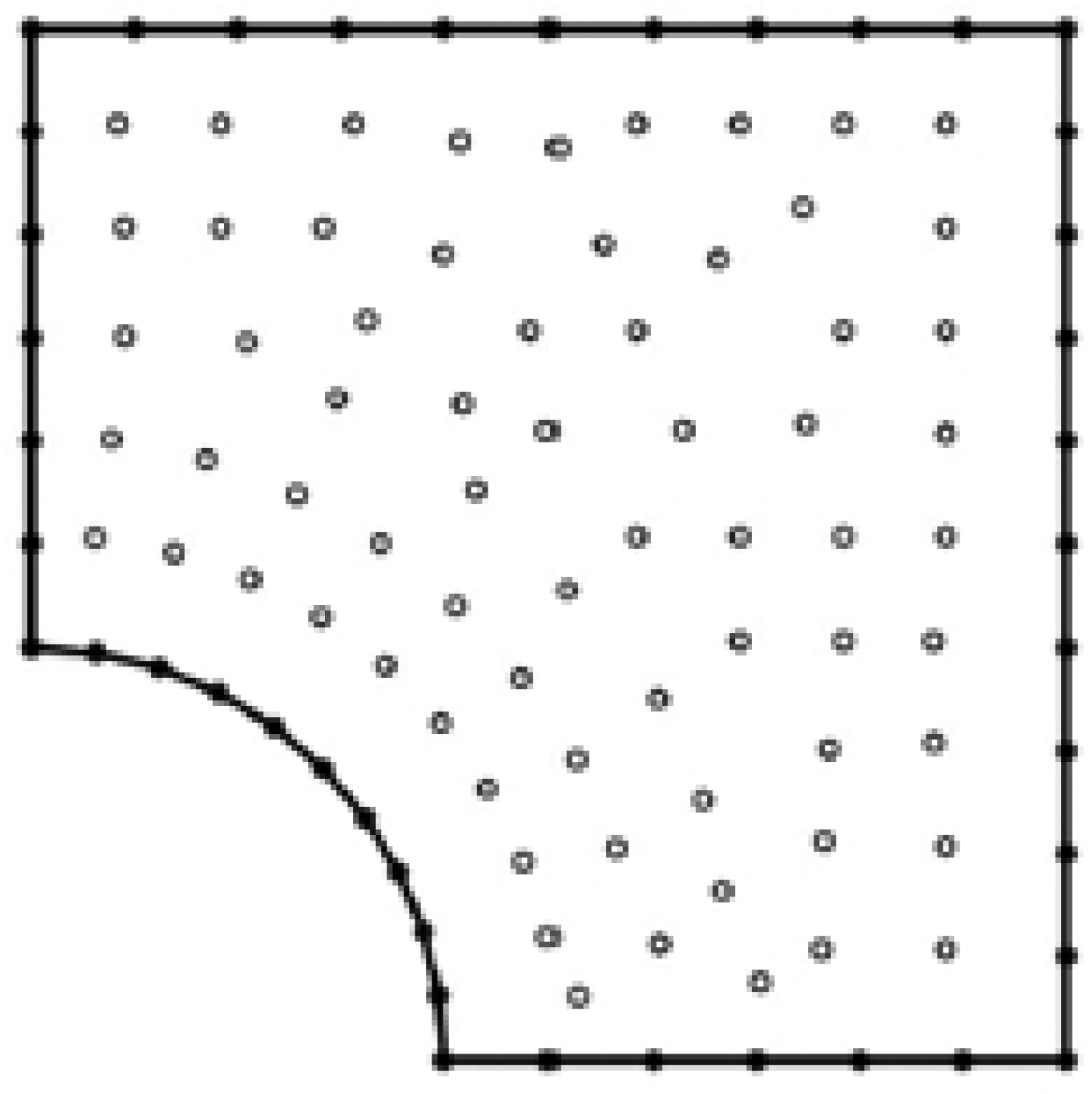

4. BEM Solution of Displacement Field

- (I)

- To resolve the system (55), we use successive over-relaxation (SOR), as outlined in Golub and Van Loan [38].

- (II)

- The values of are determined for each time step .

- (III)

- The values can then be used to calculate the unknowns and from (53) and (54), respectively.

- (IV)

- The method given in Bathe [39] is utilized along with the initial conditions for the scenario where to calculate and .

- (V)

- The traction vector is then calculated using (50).

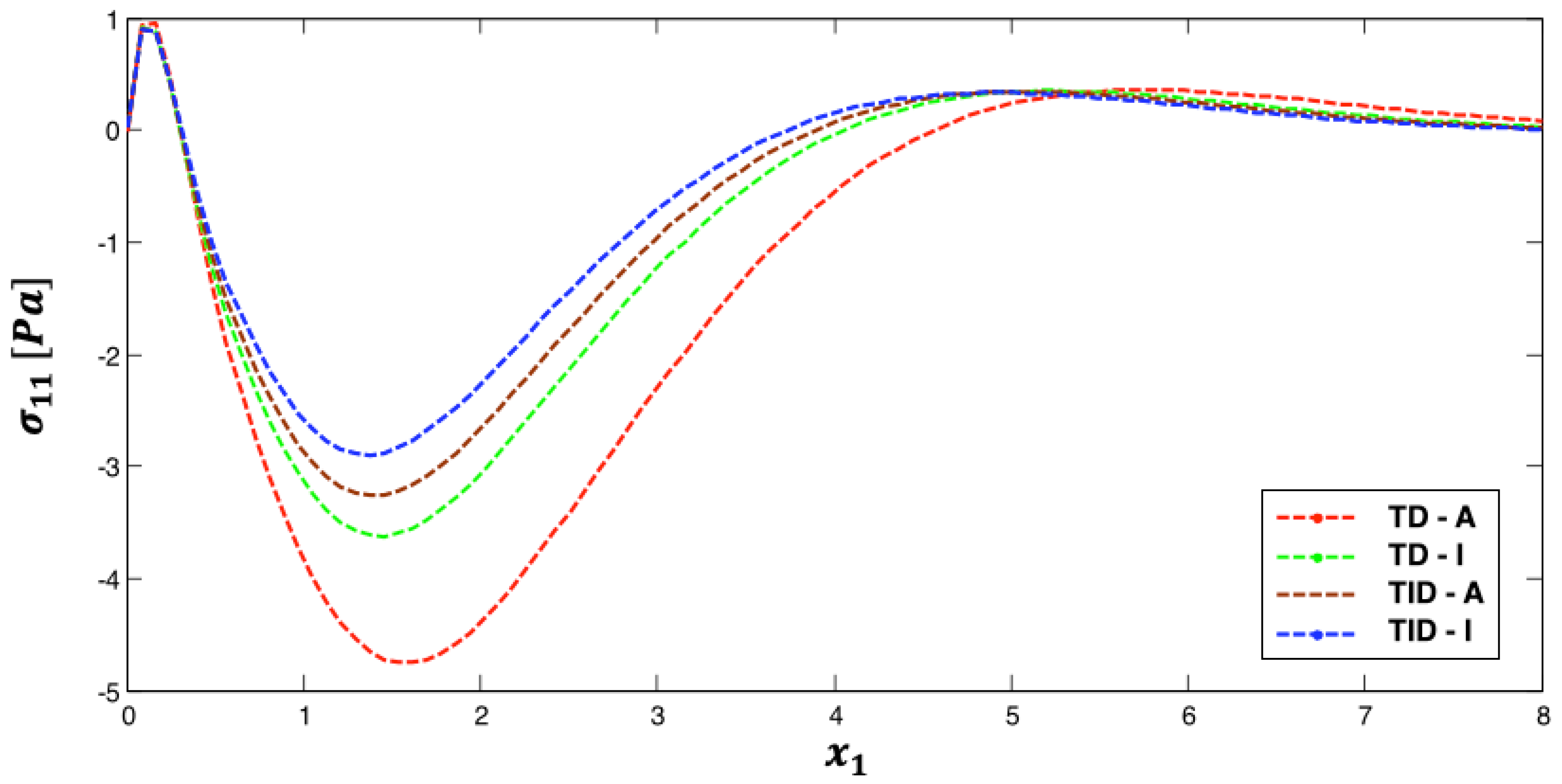

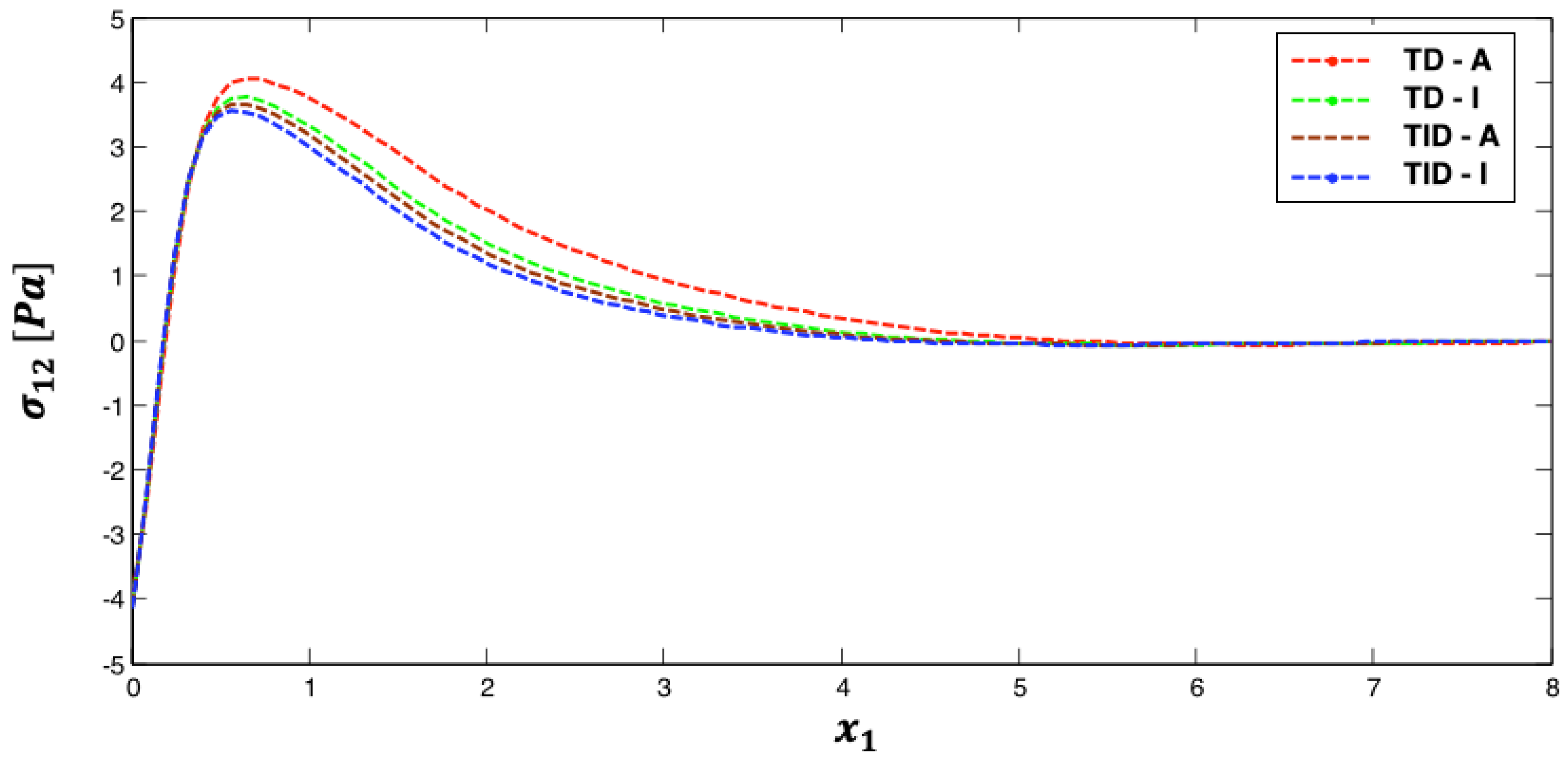

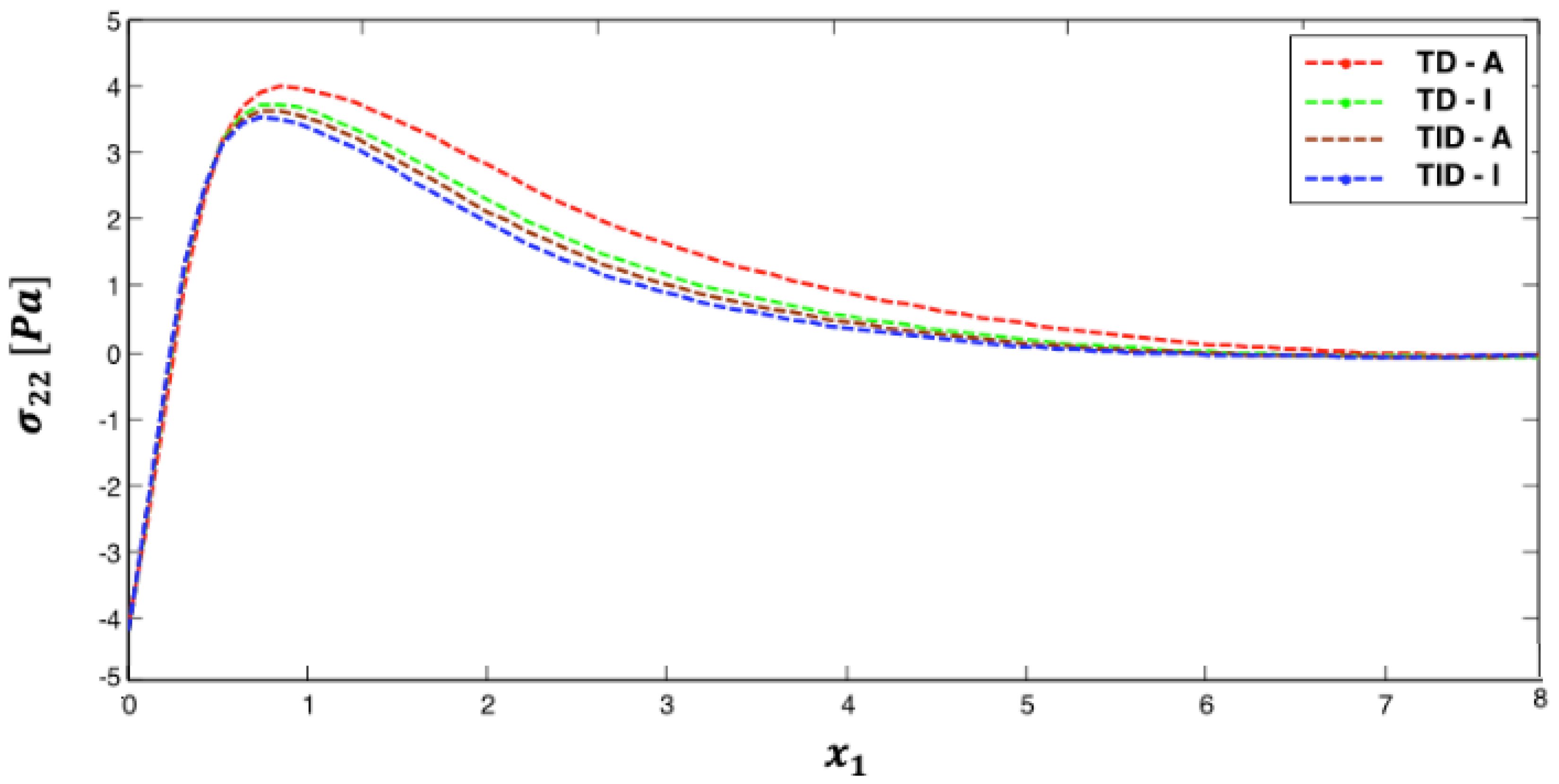

5. Numerical Results and Discussion

6. Conclusions

- A numerical BEM scheme is applied to a nonlinear fractional boundary element model for magneto-thermo-visco-elastic ultrasound wave problems in temperature-dependent FGA rotating granular plates.

- The BEM-based coupling scheme that is both reliable and efficient was proposed, with the Cartesian transformation method (CTM) used to compute domain integrals.

- The generalized modified shift-splitting (GMSS) method was used to solve the BEM-derived linear systems.

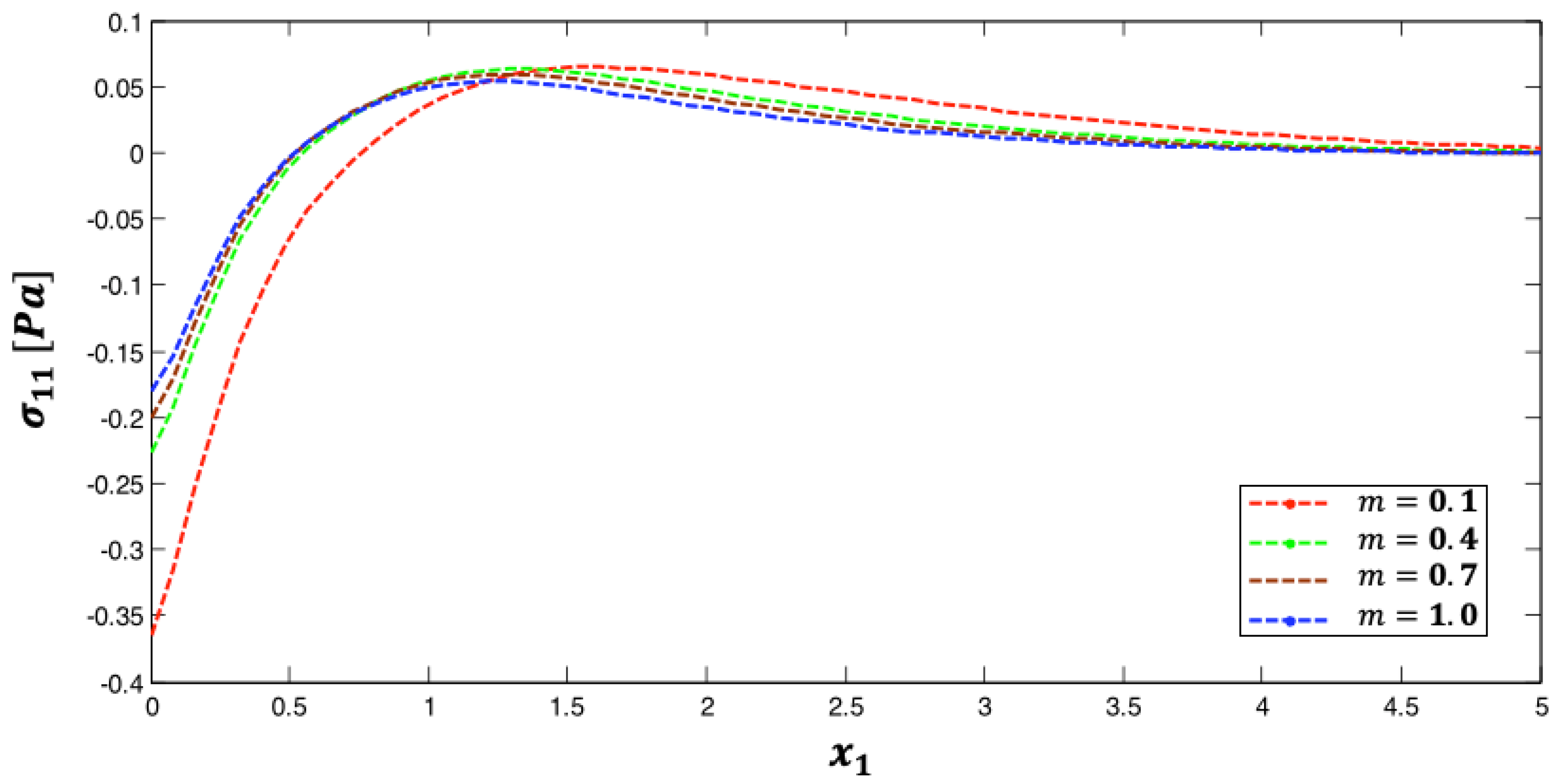

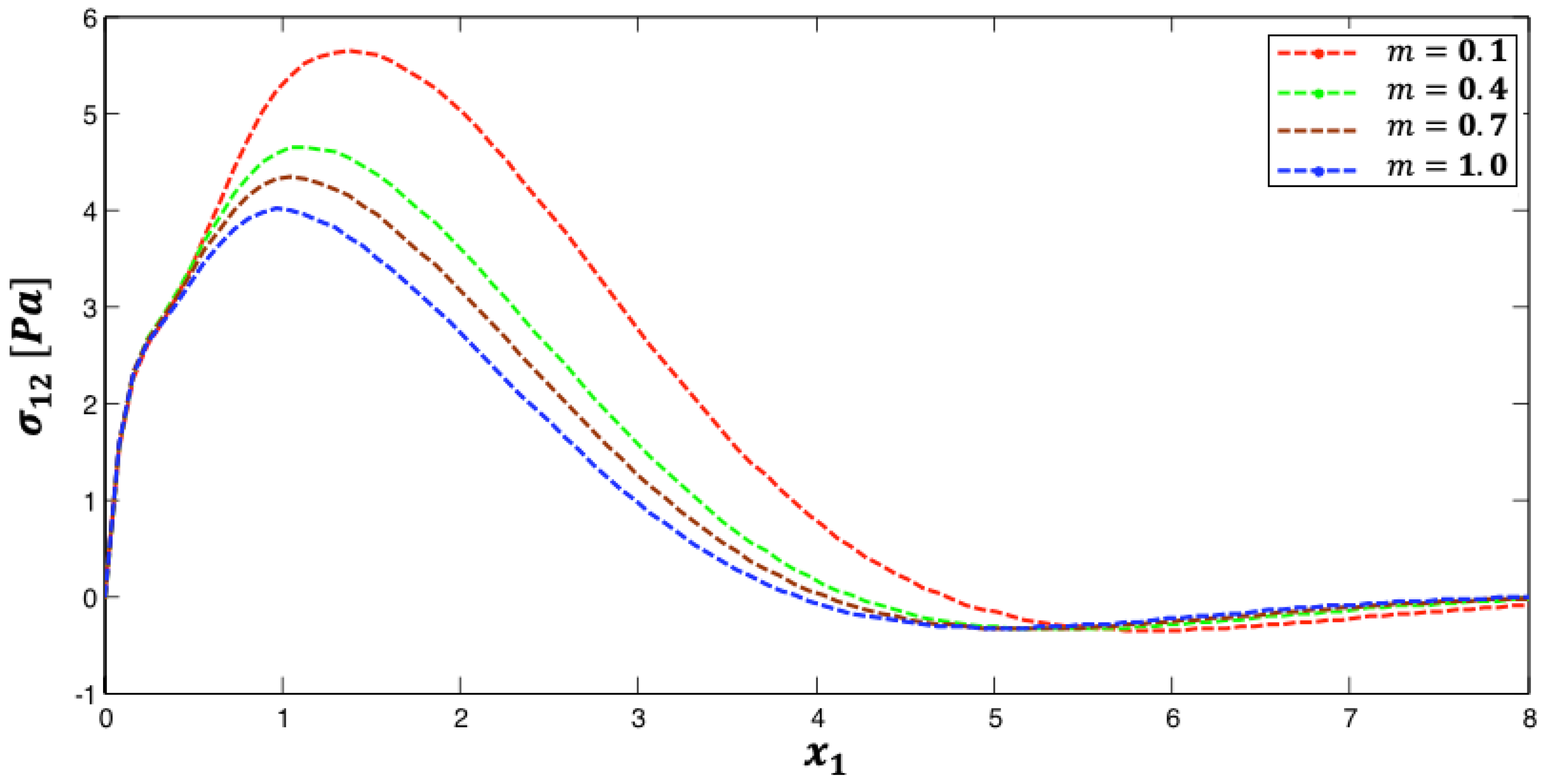

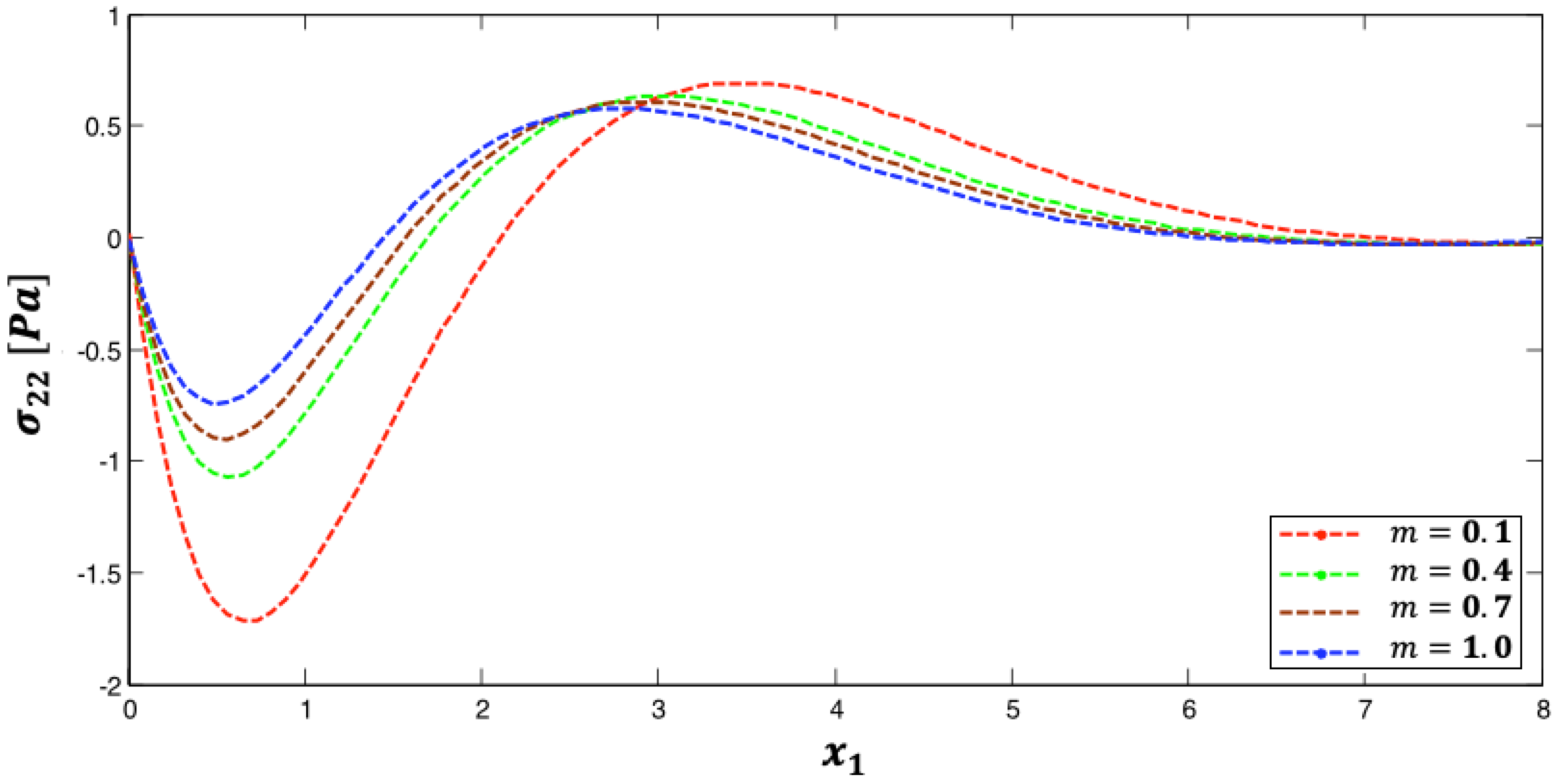

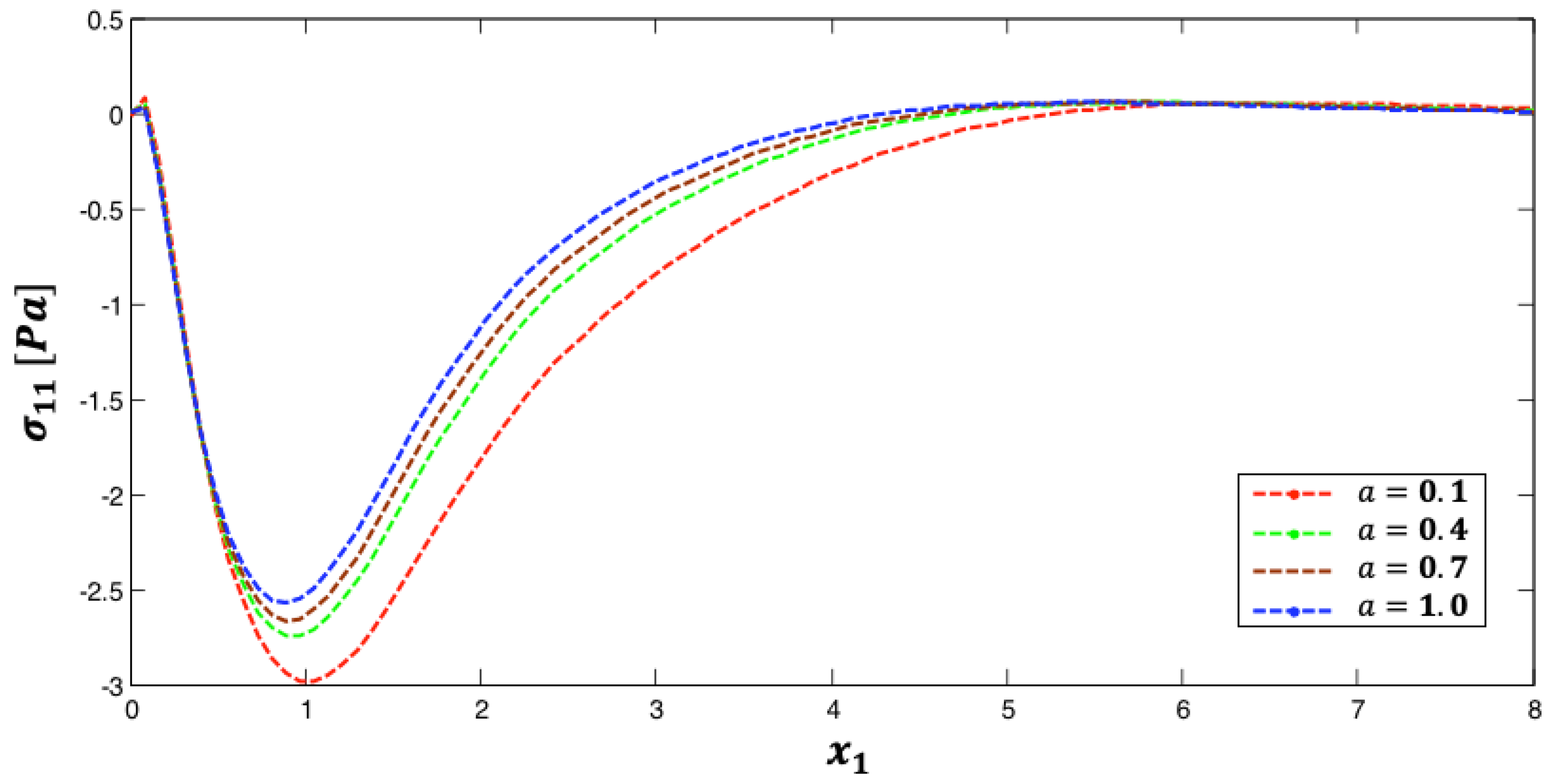

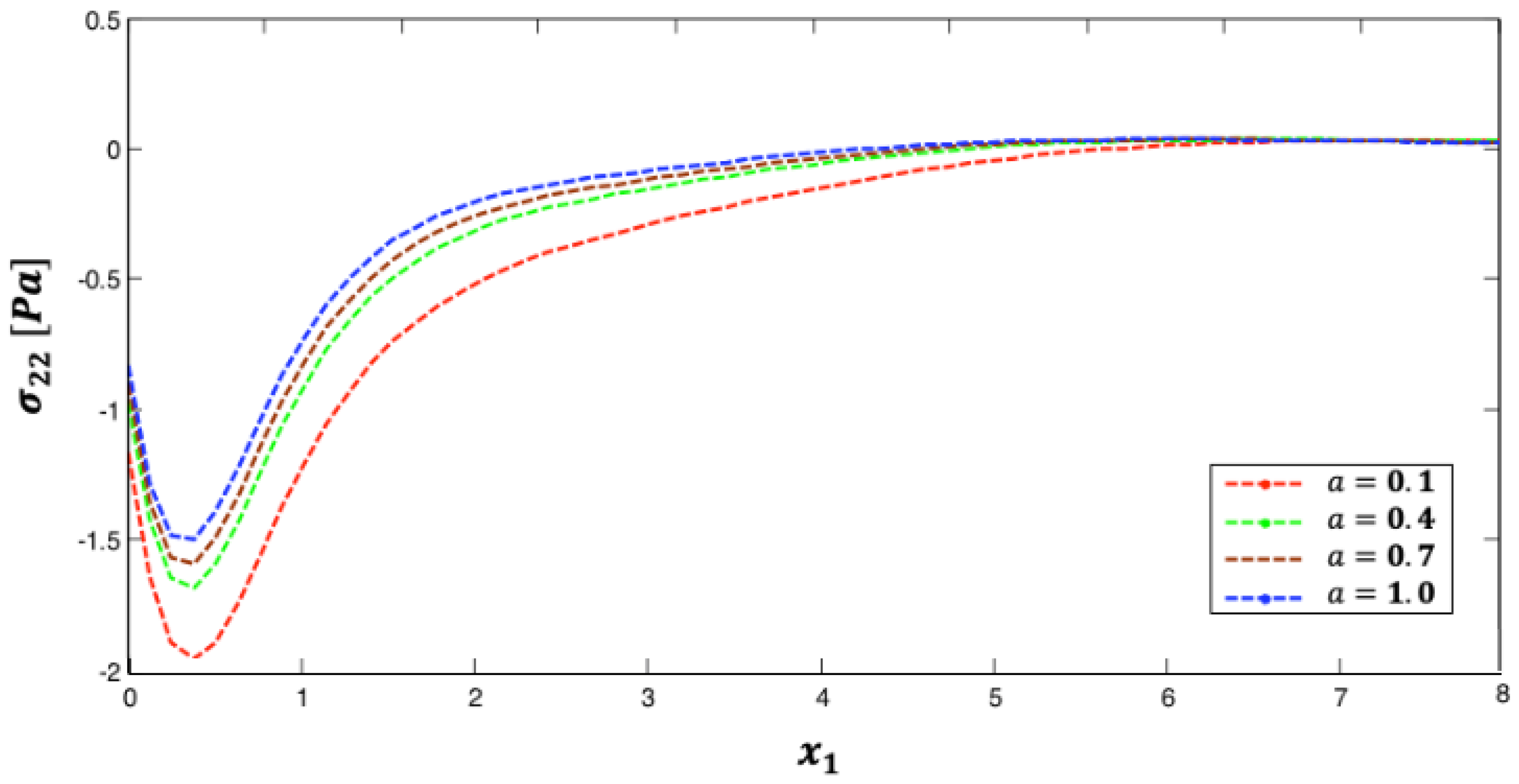

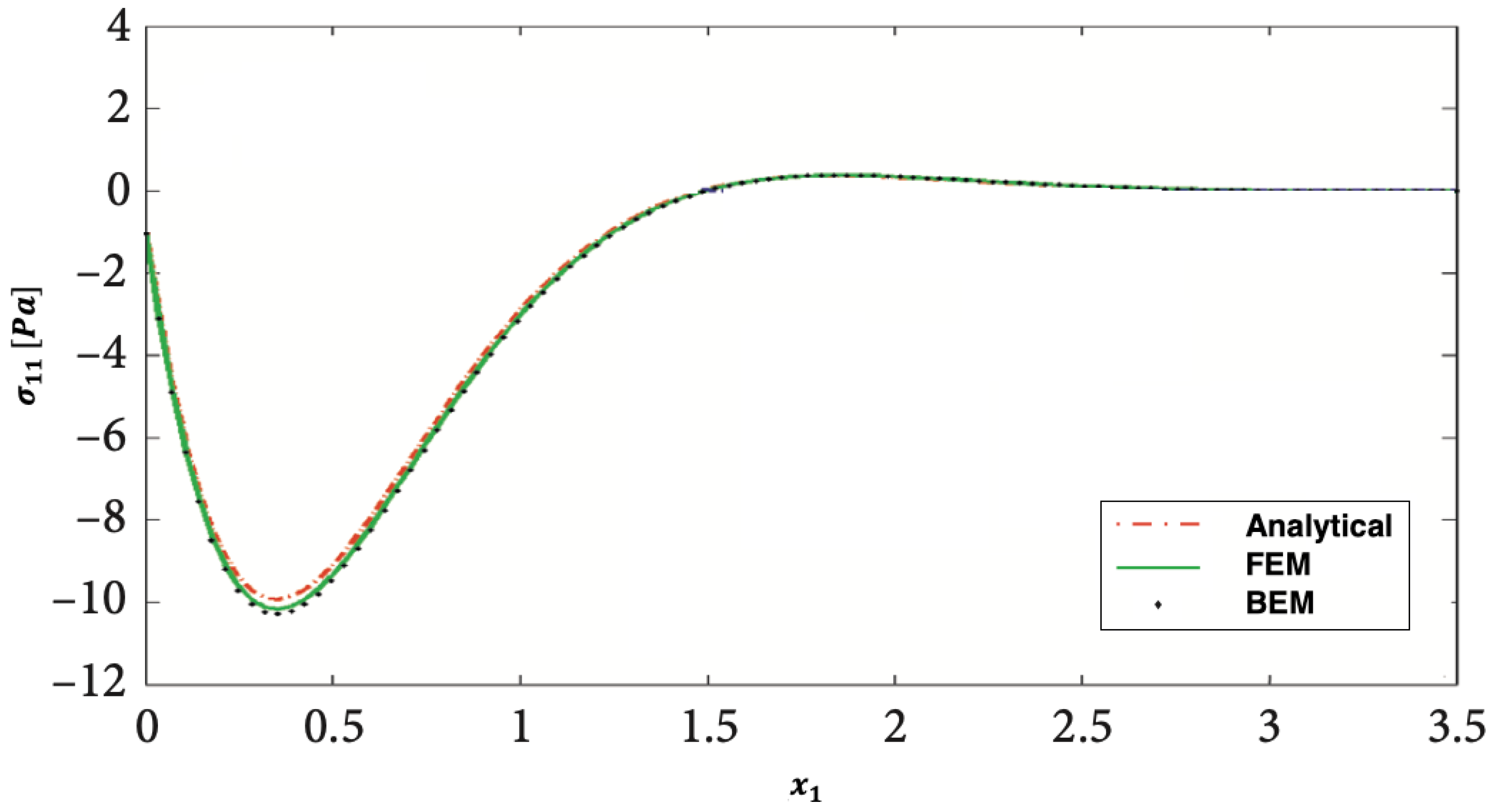

- Effects of temperature dependence, anisotropy, graded parameter, and fractional parameter on nonlinear thermal stress in the investigated plates are established.

- The numerical results validate the consistency and effectiveness of the developed modeling methodology.

- The results presented in this paper can be used in a variety of commercial applications, including the pharmaceutical industry, agriculture, and energy production.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Stress–temperature coefficients | |

| Gravity field tensor | |

| Magnetic permeability | |

| Visco-elastic material constant | |

| Density | |

| Mechanical stress tensor | |

| Electro-magnetic stress tensor | |

| Time | |

| & | Relaxation times |

| Laser pulse time characteristic | |

| Uniform angular velocity | |

| Specific heat of the plate | |

| Constant elastic moduli | |

| Earth gravity | |

| Perturbed magnetic field | |

| Non-Gaussian temporal profile | |

| Total energy intensity | |

| Thermal conductivity coefficients | |

| Graded parameter | |

| Irradiated surface absorptivity | |

| Irradiated surface absorptivity | |

| Tractions | |

| Temperature | |

| Displacement |

Appendix A

Appendix B

References

- Aragh, B.S.; Hedayati, H.; Farahani, E.B.; Hedayati, M. A novel 2-D six-parameter power-law distribution for free vibration and vibrational displacements of two-dimensional functionally graded fiber-reinforced curved panels. Eur. J. Mech. A 2011, 30, 865–883. [Google Scholar] [CrossRef]

- Alshabatat, N.T.; Naghshineh, K. Optimization of Natural Frequencies and Sound Power of Beams Using Functionally Graded Material. Adv. Acoust. Vib. 2014, 2014, 752361. [Google Scholar] [CrossRef]

- Majak, J.; Mikola, M.; Pohlak, M.; Eerme, M.; Karunanidhi, R. Modelling FGM materials. An accurate function approximation algorithms. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Modern Materials and Manufacturing (MMM 2021), Tallinn, Estonia, 27–29 April 2021; Volume 1140. [Google Scholar] [CrossRef]

- Abd-Elaziz, E.; Othman, M.I.A. Effect of rotation on a micropolar magnetothermo-elastic medium with dual-phase-lag model under gravitational field. Microsyst. Technol. 2017, 23, 4979–4987. [Google Scholar]

- Othman, M.I.A.; Eraki, E.E.M. Effect of gravity on generalized thermoelastic diffusion due to laser pulse using dual-phase-lag model. Multi. Model. Mater. Struct. 2018, 14, 457–481. [Google Scholar] [CrossRef]

- Othman, M.I.A.; Abd-Elaziz, E.M. Dual-phase-lag model on micropolar thermoelastic rotating medium under the effect of thermal load due to laser pulse. Indian J. Phys. 2020, 94, 999–1008. [Google Scholar] [CrossRef]

- Othman, M.I.A.; Zidan, M.E.M.; Mohamed, I.E.A. Dual-phase-lag model on thermo-microstretch elastic solid under the effect of initial stress and temperature-dependent. Steel Compos. Struct 2021, 38, 355–363. [Google Scholar]

- Fahmy, M.A. Boundary Element Algorithm for Modeling and Simulation of Dual Phase Lag Bioheat Transfer and Biomechanics of Anisotropic Soft Tissues. Int. J. Appl. Mech. 2018, 10, 1850108. [Google Scholar] [CrossRef]

- Oldham, K.B.; Spanier, J. The Fractional Calculus: Theory and Applications of Differentiation and Integration to Arbitrary Order; Dover Publication: Mineola, NY, USA, 2006. [Google Scholar]

- Bagley, R.L.; Torvik, P.J. On the fractional calculus model of viscoelastic behavior. J. Rheol. 1986, 30, 133. [Google Scholar] [CrossRef]

- Ozaktas, H.M.; Arikan, O.; Kutay, M.A.; Bozdagi, G. Digital computation of the fractional Fourier transform. IEEE Trans. Signal Process. 1996, 44, 2141–2150. [Google Scholar] [CrossRef]

- Machado, J.A.T. Analysis and design of fractional-order digital control systerns. SAMS J. Syst. Anal. Model. Simul. 1997, 27, 107–122. [Google Scholar]

- Wang, J.; Huang, M. Boundary element method for orthotropic thick plates. Acta Mech. Sin. 1991, 7, 258–266. [Google Scholar]

- Belytschko, T.; Krogauz, Y.; Organ, D.; Fleming, M.; Krysl, P. Meshless methods; an overview and recent developments. Comput. Methods Appl. Mech. Eng. 1996, 139, 3–47. [Google Scholar] [CrossRef]

- Donning, B.M.; Liu, W.K. Meshless methods for shear-deformable beams and plates. Comput. Methods Appl. Mech. Eng. 1998, 152, 47–71. [Google Scholar] [CrossRef]

- Krysl, P.; Belytschko, T. Analysis of thin shells by the element-free Galerkin method. Int. J. Solids Struct. 1996, 33, 3057–3080. [Google Scholar] [CrossRef]

- Fahmy, M.A. A new boundary element formulation for modeling and simulation of three-temperature distributions in carbon nanotube fiber reinforced composites with inclusions. Math. Methods Appl. Sci. 2021. [Google Scholar] [CrossRef]

- Fahmy, M.A.; Alsulami, M.O. Boundary element and sensitivity analysis of anisotropic thermoelastic metal and alloy discs with holes. Materials 2022, 15, 1828. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.D.; Ge, T.; Liu, J. Experimental and theoretical study of high energy dissipation viscoelastic dampers based on acrylate rubber matrix. ASCE J. Eng. Mech. 2020, 146, 04020057. [Google Scholar] [CrossRef]

- Abouelregal, A.E.; Mohammed, W.W. Effects of nonlocal thermoelasticity on nanoscale beams based on couple stress theory. Math. Methods Appl. Sci. 2020. [Google Scholar] [CrossRef]

- Fahmy, M.A.; Shaw, S.; Mondal, S.; Abouelregal, A.E.; Lotfy, K.; Kudinov, I.A.; Soliman, A.H. Boundary element modeling for simulation and optimization of three-temperature anisotropic micropolar magneto-thermoviscoelastic problems in porous smart structures using NURBS and genetic algorithm. Int. J. Thermophys. 2021, 42, 29. [Google Scholar] [CrossRef]

- Fahmy, M.A.; Almehmadi, M.M.; Al Subhi, F.M.; Sohail, A. Fractional boundary element solution of three-temperature thermoelectric problems. Sci. Rep. 2022, 12, 6760. [Google Scholar] [CrossRef]

- Fahmy, M.A. Boundary element modeling of fractional nonlinear generalized photothermal stress wave propagation problems in FG anisotropic smart semiconductors. Eng. Anal. Bound. Elem. 2022, 134, 665–679. [Google Scholar] [CrossRef]

- Fahmy, M.A. Boundary element modeling of 3T nonlinear transient magneto-thermoviscoelastic wave propagation problems in anisotropic circular cylindrical shells. Compos. Struct. 2021, 277, 114655. [Google Scholar] [CrossRef]

- Atluri, S.N. The Meshless Method (MLPG) for Domain & BIE Discretizations; Tech Science Press: Norcross, GA, USA, 2004. [Google Scholar]

- Sladek, J.; Sladek, V.; Mang, H.A. Meshless formulations for simply supported and clamped plate problems. International J. Numer. Methods Eng. 2002, 55, 359–375. [Google Scholar] [CrossRef]

- Sladek, J.; Sladek, V.; Mang, H.A. Meshless LBIE formulations for simply supported and clamped plates under dynamic load. Comput. Struct. 2003, 81, 1643–1651. [Google Scholar] [CrossRef]

- Soric, J.; Li, Q.; Jarak, T.; Atluri, S.N. Meshless Local Petrov-Galerkin (MLPG) Formulation for Analysis of Thick Plates. CMES Comput. Model. Eng. Sci. 2004, 6, 349–358. [Google Scholar]

- Fahmy, M.A. A time-stepping DRBEM for magneto-thermo-viscoelastic interactions in a rotatin nonhomogeneous anisotropic solid. Int. J. Appl. Mech. 2011, 3, 711–734. [Google Scholar] [CrossRef]

- Fahmy, M.A. 3D Boundary Element Model for Ultrasonic Wave Propagation Fractional Order Boundary Value Problems of Functionally Graded Anisotropic Fiber Reinforced Plates. Fractal Fract. 2022, 6, 247. [Google Scholar] [CrossRef]

- Cattaneo, C. Sur une forme de I’equation de la Chaleur Elinant le Paradox d’une Propagation Instantanc. Comptes Rendus de l’Académie des Sciences; Gauthier-Villars: Paris, France, 1958; Volume 247, pp. 431–433. [Google Scholar]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Clarendon Press: Oxford, UK, 1959. [Google Scholar]

- Wrobel, L.C. The Boundary Element Method: Applications in Thermo-Fluids and Acoustics; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Hematiyan, M.R. Exact transformation of a wide variety of domain integrals into boundary integrals in boundary element method. Commun. Numer. Methods Eng. 2008, 24, 1497–1521. [Google Scholar] [CrossRef]

- Hematiyan, M.R. A general method for evaluation of 2D and 3D domain integrals without domain discretization and its application in BEM. Comput. Mech. 2007, 39, 509–520. [Google Scholar] [CrossRef]

- Khosravifard, A.; Hematiyan, M.R. A new method for meshless integration in 2D and 3D Galerkin meshfree methods. Eng. Anal. Bound. Elem. 2010, 34, 30–40. [Google Scholar] [CrossRef]

- Liu, G.R.; Gu, Y.T. An Introduction to Meshfree Methods and Their Programming; Springer: New York, NY, USA, 2005. [Google Scholar]

- Golub, G.H.; Van Loan, C.F. Matrix Computations; North Oxford Academic: Oxford, UK, 1983. [Google Scholar]

- Bathe, K.J. Finite element Procedures; Prentice-Hall: Englewood Cliffs, NJ, USA, 1996. [Google Scholar]

- Breuer, M.; De Nayer, G.; Muüsch, M.; Gallinger, T.; Wuüuchner, R. Fluid–structure interaction using a partitioned semi–implicit predictor–corrector coupling scheme for the application of large–eddy simulation. J. Fluids Struct. 2012, 29, 107–130. [Google Scholar] [CrossRef]

- Huang, Z.G.; Wang, L.G.; Xu, Z.; Cui, J.J. The generalized modified shift-splitting preconditioners for nonsymmetric saddle point problems. Appl. Math. Comput. 2017, 299, 95–118. [Google Scholar] [CrossRef]

- Al-Basyouni, K.S.; Ghandourah, E.; Mostafa, H.M.; Algarni, A. Effect of the rotation on the thermal stress wave propagation in non-homogeneous viscoelastic body. Geomech. Eng. 2020, 2, 1–9. [Google Scholar]

- Pettermann, H.E.; DeSimone, A. An anisotropic linear thermo-viscoelastic constitutive law Elastic relaxation and thermal expansion creep in the time domain. Mech. Time-Depend. Mater. 2018, 22, 421–433. [Google Scholar] [CrossRef] [PubMed]

- Hoemmen, M. Communication-Avoiding Krylov Subspace Methods. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2010. [Google Scholar]

- Dehdezi, E.K.; Karimi, S. A rapid and powerful iterative method for computing inverses of sparse tensors with applications. Appl. Math. Comput. 2022, 415, 126720. [Google Scholar]

- Oshtorjani, M.K.; Oshtorjani, M.K.; Mikkola, A.; Jalali, P. Conjugate heat transfer in isolated granular clusters with interstitial fluid using lattice Boltzmann method. Int. J. Heat Mass Transf. 2022, 187, 122539. [Google Scholar] [CrossRef]

| Discretization | Preconditioning | CA-Arnoldi [44] | D-K [45] | GMSS [41] | |||

|---|---|---|---|---|---|---|---|

| Level | Level | CPU Time | Iteration Number | CPU Time | Iteration Number | CPU Time | Iteration Number |

| 1 (32) | 0 | 0.06 | 6 | 0.07 | 6 | 0.04 | 6 |

| 2 (56) | 0 | 0.18 | 8 | 0.22 | 8 | 0.14 | 7 |

| 1 | 0.14 | 6 | 0.18 | 6 | 0.1 | 5 | |

| 3 (104) | 0 | 0.54 | 10 | 0.6 | 11 | 0.4 | 9 |

| 1 | 0.48 | 8 | 0.54 | 9 | 0.32 | 5 | |

| 2 | 0.42 | 5 | 0.46 | 7 | 0.24 | 3 | |

| 4 (200) | 0 | 2.42 | 13 | 2.52 | 17 | 1.86 | 11 |

| 1 | 1.88 | 11 | 2.1 | 15 | 1.56 | 7 | |

| 2 | 1.65 | 7 | 1.82 | 10 | 1.4 | 5 | |

| 3 | 1.4 | 6 | 1.52 | 7 | 1.36 | 3 | |

| 5 (392) | 0 | 10.01 | 15 | 12.02 | 19 | 7.88 | 13 |

| 1 | 9.09 | 10 | 10.16 | 17 | 6.87 | 9 | |

| 2 | 8.19 | 9 | 9.29 | 15 | 6.09 | 7 | |

| 3 | 7.24 | 7 | 8.48 | 11 | 5.82 | 5 | |

| 4 | 6.6 | 5 | 7 | 7 | 5.18 | 3 | |

| 6 (776) | 0 | 42 | 19 | 48.3 | 21 | 35.9 | 15 |

| 1 | 36.9 | 17 | 43.5 | 19 | 33.9 | 11 | |

| 2 | 34.5 | 15 | 41.6 | 17 | 30.1 | 9 | |

| 3 | 29.6 | 11 | 37.7 | 13 | 25.7 | 7 | |

| 4 | 27.4 | 9 | 33.4 | 11 | 21.7 | 5 | |

| 5 | 25.5 | 7 | 29.6 | 9 | 19.6 | 3 | |

| LBM | FEM | BEM | |

|---|---|---|---|

| Number of nodes | 52,000 | 50,000 | 50 |

| Number of elements | 11,000 | 10,000 | 15 |

| CPU time (min) | 170 | 180 | 2 |

| Memory (MB) | 120 | 130 | 1 |

| Disc space (MB) | 250 | 270 | 0 |

| Accuracy of results (%) | 2.2 | 2.0 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fahmy, M.A. A Nonlinear Fractional BEM Model for Magneto-Thermo-Visco-Elastic Ultrasound Waves in Temperature-Dependent FGA Rotating Granular Plates. Fractal Fract. 2023, 7, 214. https://doi.org/10.3390/fractalfract7030214

Fahmy MA. A Nonlinear Fractional BEM Model for Magneto-Thermo-Visco-Elastic Ultrasound Waves in Temperature-Dependent FGA Rotating Granular Plates. Fractal and Fractional. 2023; 7(3):214. https://doi.org/10.3390/fractalfract7030214

Chicago/Turabian StyleFahmy, Mohamed Abdelsabour. 2023. "A Nonlinear Fractional BEM Model for Magneto-Thermo-Visco-Elastic Ultrasound Waves in Temperature-Dependent FGA Rotating Granular Plates" Fractal and Fractional 7, no. 3: 214. https://doi.org/10.3390/fractalfract7030214

APA StyleFahmy, M. A. (2023). A Nonlinear Fractional BEM Model for Magneto-Thermo-Visco-Elastic Ultrasound Waves in Temperature-Dependent FGA Rotating Granular Plates. Fractal and Fractional, 7(3), 214. https://doi.org/10.3390/fractalfract7030214