Virtual Reality-Based Digital Twins: A Case Study on Pharmaceutical Cannabis

Abstract

1. Introduction

2. Background

2.1. Pharmaceutical Cannabis Production

2.2. Virtual, Augmented and Mixed Reality (XR) in Agriculture

2.3. Digital Twins in Agriculture

3. Methodology

3.1. Schematic Design Approach

3.2. Survey Process

4. Architecture Design

4.1. Design Requirements

- R1: The architecture must present the interaction between the elements of the physical and the corresponding Digital Twin in the virtual environment.

- R2: The architecture must support the processes and activities regarding the implementation of DT/XR smart IoT remote monitoring management systems applied in modern or future pharmaceutical cannabis production.

- R3: The architecture must provide concise information and representation of activities, processes and features enabled by the organisation’s designed system.

- R4: The architecture must provide precise information regarding data acquisition, management integration and augmentation processes of the physical twin in real time.

- R5: The architecture should provide concise information about systems and functionalities provided regarding the overall control physical twin’s future or current state and behaviour.

- R6: The architecture should provide information about the integration of Digital Twins with the ERPs of pharmaceutical cannabis production farms.

4.2. Viewpoint Definition

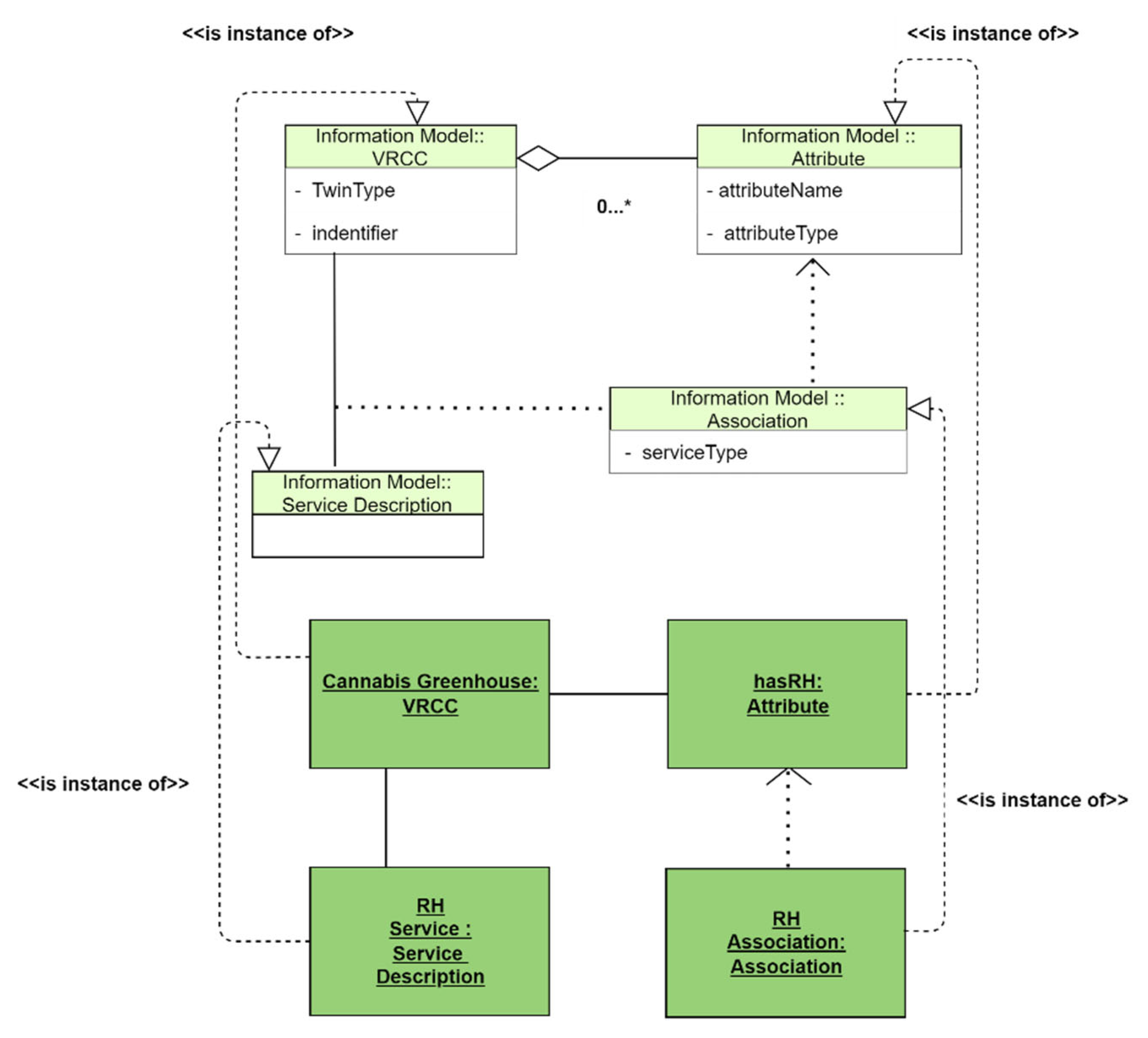

4.3. Information Model

5. Results

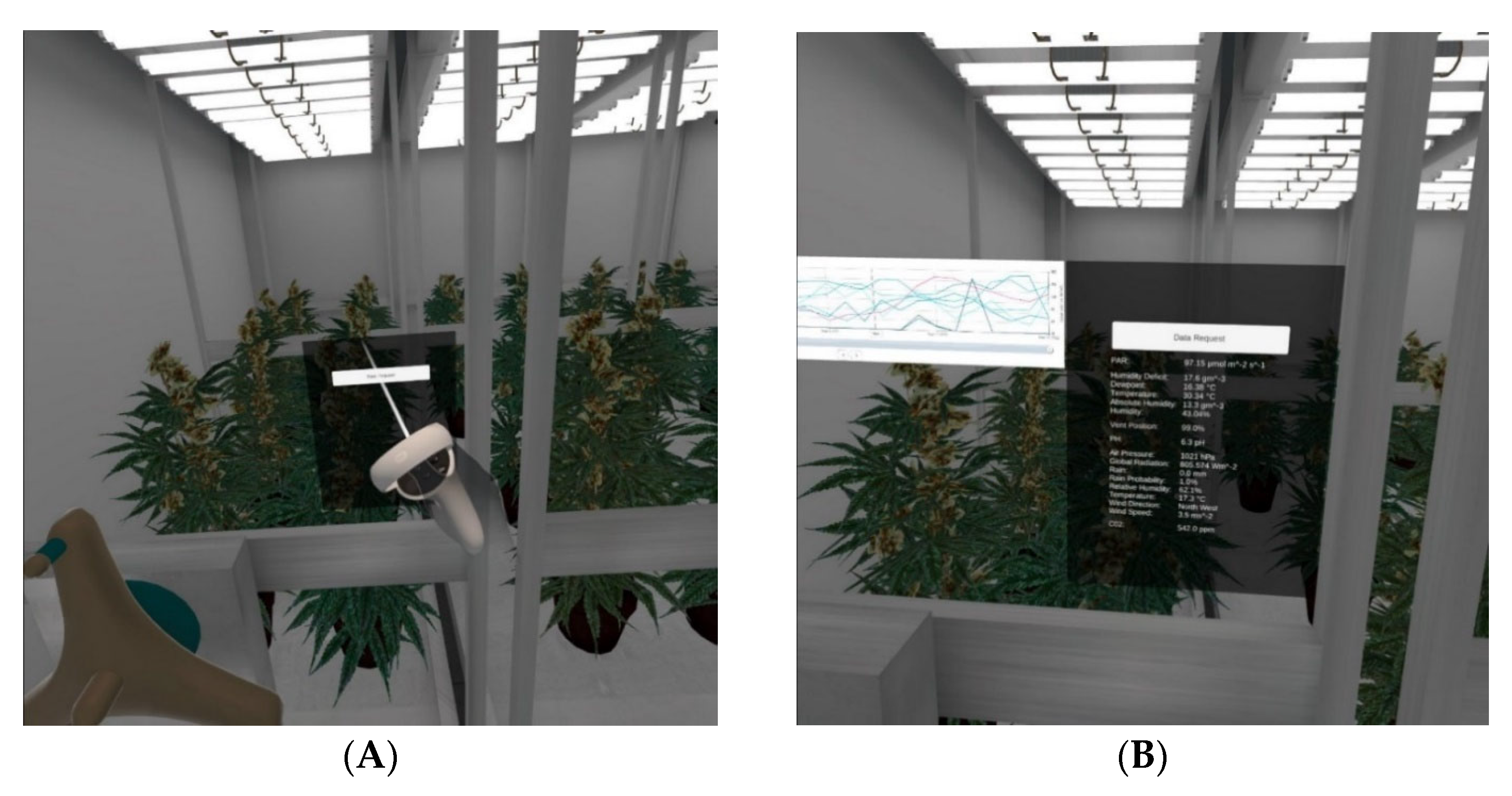

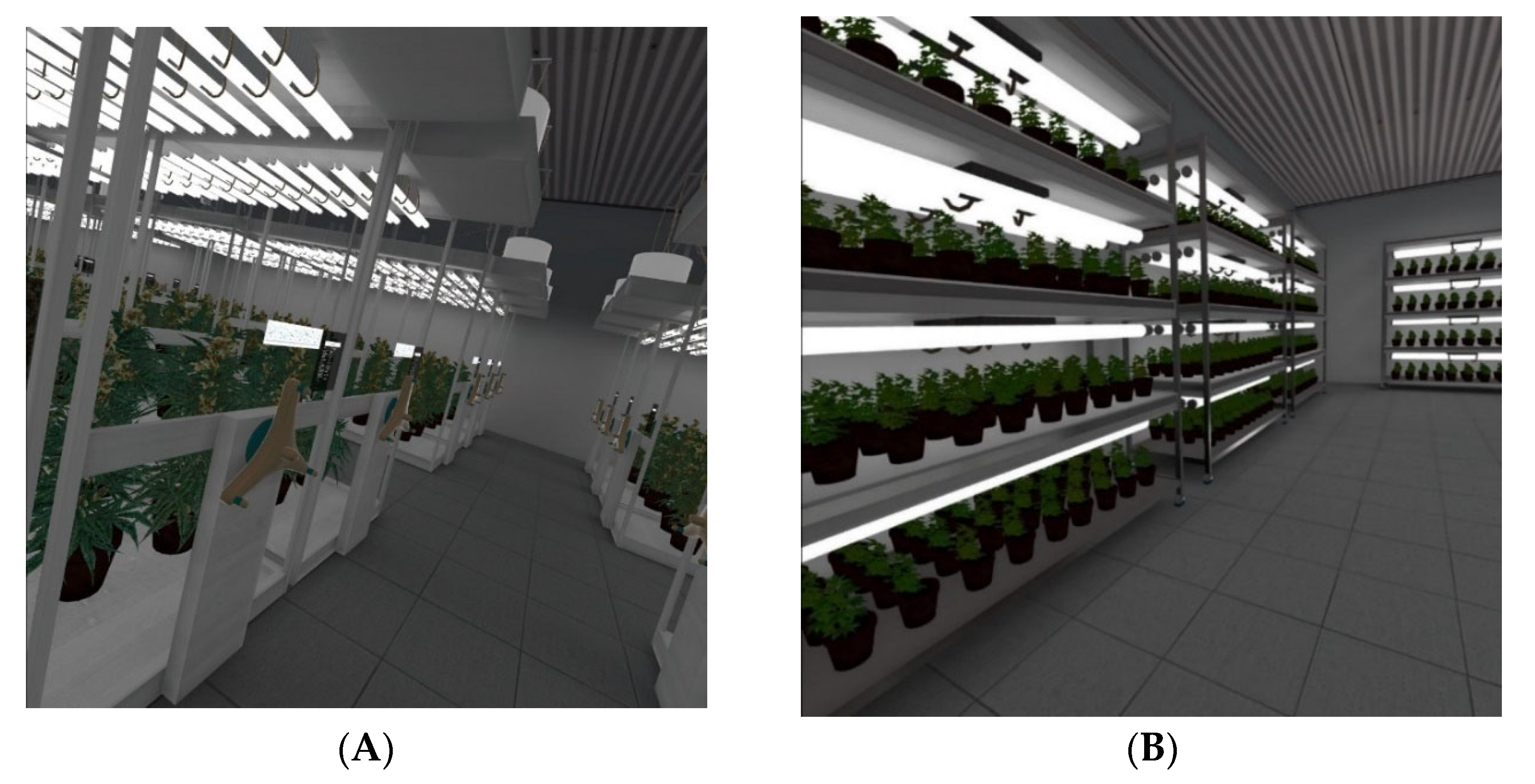

5.1. Development and Sensor Output Display

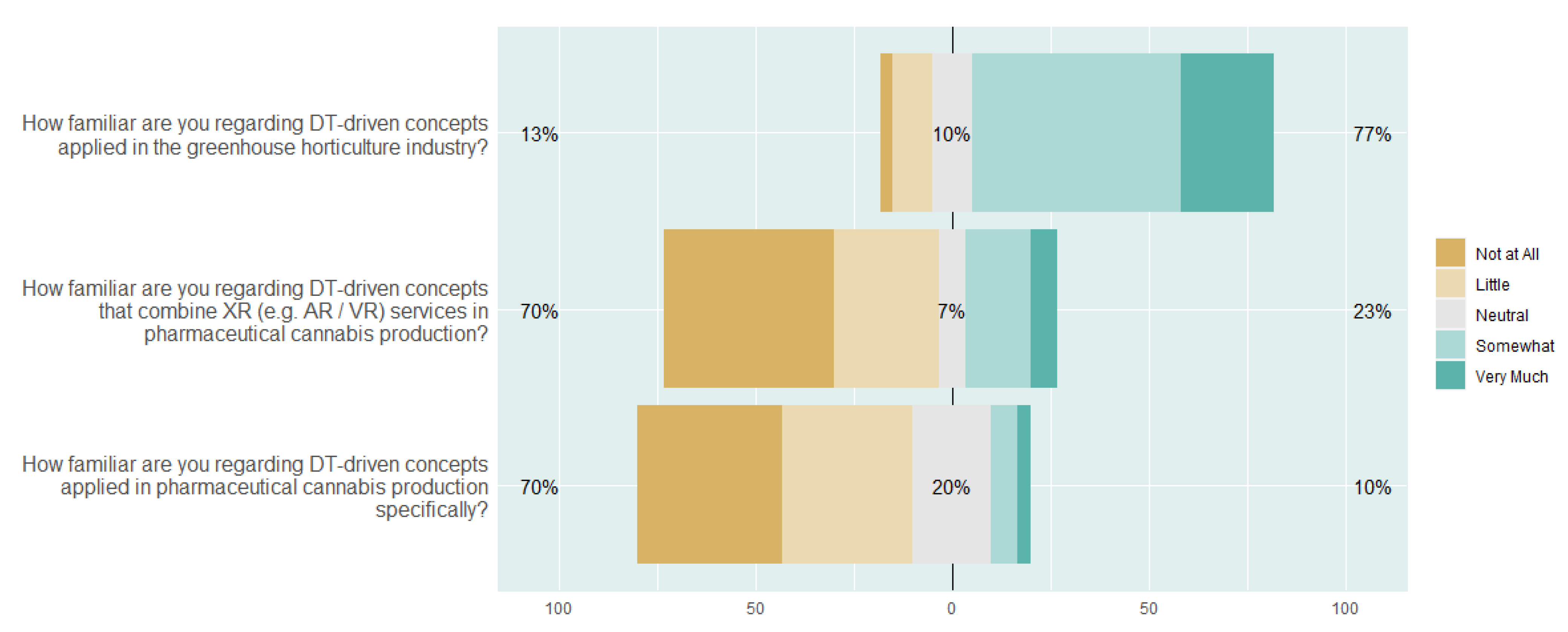

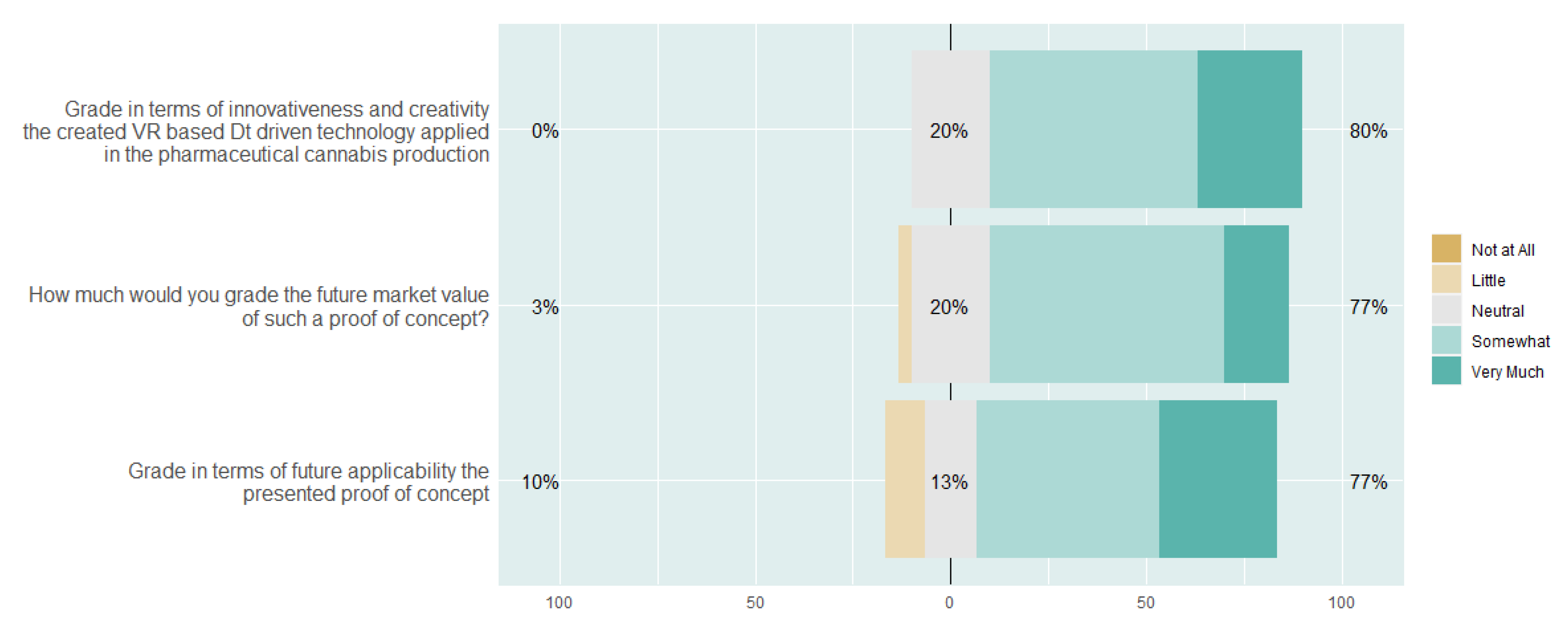

5.2. Survey Outcomes

6. Discussion

6.1. Reflection on Research Questions

- A.

- RQ1 How can an XR-based Digital Twin for pharmaceutical cannabis production be implemented?

- B.

- RQ2 What are the future possibilities of the integration of XR with Digital Twin models?

6.2. Practical Relevance

6.3. Limitations and Future Work

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D | Two Dimensional |

| 3D | Three Dimensional |

| APK | Android Application Package |

| API | Application Programming Interface |

| AR | Augmented Reality |

| BPMN | Business Process Model and Notation |

| CO2 | Carbon dioxide |

| DT | Digital Twin |

| IoT | Internet of Things |

| KPI | Key Performance Indicators |

| MR | Mixed Reality |

| PAR | Photosynthetic active radiation |

| Ph | Potential of hydrogen |

| SDK | Software development kit |

| Temp. | Temperature and Humidity Dewpoint |

| UML | Unified Modelling Language |

| VR | Virtual Reality |

| VRCC | Virtual Reality Cannabis Crops |

| XR | eXtended Reality |

References

- Hartmann, D.; Van der Auweraer, H. Digital twins. In Progress in Industrial Mathematics: Success Stories; Springer: Cham, Switzerland, 2021; pp. 3–17. [Google Scholar]

- Rosen, R.; Boschert, S.; Sohr, A. Next Generation Digital Twin. ATP Mag. 2018, 60, 86–96. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Gartner Survey Reveals Digital Twins Are Entering Mainstream Use. (20 February 2019). Gartner. Available online: https://www.gartner.com/en/newsroom/press-releases/2019-02-20-gartner-survey-reveals-digital-twins-are-entering-mai (accessed on 27 February 2023).

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Tebaldi, L.; Vignali, G.; Bottani, E. Digital twin in the agri-food supply chain: A literature review. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Nantes, France, 5–9 September 2021; Springer: Cham, Switzerland, 2021; pp. 276–283. [Google Scholar]

- Bewley-Taylor, D.; Jelsma, M.; Kay, S. Cannabis Regulation and Development: Fair (er) Trade Options for Emerging Legal Markets. In Drug Policies and Development; Brill Nijhoff: Leiden, The Netherlands, 2020; pp. 106–124. [Google Scholar]

- Potter, D.J. A review of the cultivation and processing of cannabis (Cannabis sativa L.) for production of prescription medicines in the UK. Drug Test. Anal. 2014, 6, 31–38. [Google Scholar] [CrossRef]

- Lemphane, N.J.; Kotze, B.; Kuriakose, R.B. A review on current IoT-based pasture management systems and applications of digital twins in farming. In Proceedings of the Third International Conference on Sustainable Computing, Jaipur, India, 19–20 March 2021; Springer: Singapore, 2022; pp. 173–180. [Google Scholar]

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef]

- Kim, R.W.; Kim, J.G.; Lee, I.B.; Yeo, U.H.; Lee, S.Y.; Decano-Valentin, C. Development of three-dimensional visualisation technology of the aerodynamic environment in a greenhouse using CFD and VR technology, part 1: Development of VR a database using CFD. Biosyst. Eng. 2021, 207, 33–58. [Google Scholar] [CrossRef]

- Dawood, N.; Pour Rahimian, F.; Seyedzadeh, S.; Sheikhkhoshkar, M. Enabling the Development and Implementation of Digital Twins. In Proceedings of the 20th International Conference on Construction Applications of Virtual Reality, London, UK, 30–31 October 2013. [Google Scholar]

- Ariesen-Verschuur, N.; Verdouw, C.; Tekinerdogan, B. Digital Twins in greenhouse horticulture: A review. Comput. Electron. Agric. 2022, 199, 107183. [Google Scholar] [CrossRef]

- Wang, K.; Xie, W.; Wu, W.; Wang, B.; Pei, J.; Baker, M.; Zhou, Q. Simulation-Based Digital Twin Development for Blockchain Enabled End-to-End Industrial Hemp Supply Chain Risk Management. arXiv 2020, arXiv:2006.10915. [Google Scholar]

- Chandra, S.; Lata, H.; ElSohly, M.A.; Walker, L.A.; Potter, D. Cannabis cultivation: Methodological issues for obtaining medical-grade product. Epilepsy Behav. 2017, 70, 302–312. [Google Scholar] [CrossRef]

- Veit, M. Quality Requirements for Medicinal Cannabis and Respective Products in the European Union–Status Quo. Planta Med. 2022, in press. [Google Scholar] [CrossRef]

- Zheng, Y. (Ed.) Handbook of Cannabis Production in Controlled Environments; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Rovetto, L.J.; Aieta, N.V. Supercritical carbon dioxide extraction of cannabinoids from Cannabis sativa L. J. Supercrit. Fluids 2017, 129, 16–27. [Google Scholar] [CrossRef]

- Blake, A.; Nahtigal, I. The evolving landscape of cannabis edibles. Curr. Opin. Food Sci. 2019, 28, 25–31. [Google Scholar] [CrossRef]

- Gallo-Molina, A.C.; Castro-Vargas, H.I.; Garzón-Méndez, W.F.; Ramírez, J.A.M.; Monroy, Z.J.R.; King, J.W.; Parada-Alfonso, F. Extraction, isolation and purification of tetrahydrocannabinol from the Cannabis sativa L. plant using supercritical fluid extraction and solid phase extraction. J. Supercrit. Fluids 2019, 146, 208–216. [Google Scholar] [CrossRef]

- De Paolis, L.T.; Bourdot, P.; Mongelli, A. (Eds.) Augmented Reality, Virtual Reality, and Computer Graphics. In Proceedings of the 4th International Conference, AVR 2017, Ugento, Italy, 12–15 June 2017; Part I. Springer: Berlin/Heidelberg, Germany, 2017; Volume 10324. [Google Scholar]

- Taheri, A.; Aguayo, C. XR technologies and experience-based learning: A new tech for education? Pac. J. Technol. Enhanc. Learn. 2022, 4, 44–45. [Google Scholar] [CrossRef]

- Phupattanasilp, P.; Tong, S.R. Augmented reality in the integrative internet of things (AR-IoT): Application for precision farming. Sustainability 2019, 11, 2658. [Google Scholar] [CrossRef]

- Sari, A.C.; Setiawan, H.; Adiputra, T.W.; Widyananda, J. Fruit classification quality using convolutional neural network and augmented reality. J. Theor. Appl. Inf. Technol. 2021, 99, 012015. [Google Scholar]

- Hurst, W.; Mendoza, F.R.; Tekinerdogan, B. Augmented Reality in Precision Farming: Concepts and Applications. Smart Cities 2021, 4, 1454–1468. [Google Scholar] [CrossRef]

- Aiswarya, S.; Rakshit, S.; Chandrakumar, A. Internet of Things (IoT): Smarter Agriculture for a Smarter Future. Food Sci. Rep. 2020, 1, 26. [Google Scholar]

- Garg, S.; Sinha, P.; Singh, A. Overview of Augmented Reality and Its Trends in Agriculture Industry. In IOT with Smart Systems; Springer: Singapore, 2022; pp. 627–636. [Google Scholar]

- Azuma, R.; Baillot, Y.; Behringer, R.; Feiner, S.; Julier, S.; MacIntyre, B. Recent advances in augmented reality. IEEE Comput. Graph. Appl. 2001, 21, 34–47. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From smart farming towards agriculture 5.0: A review on crop data management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Dadi, V.; Nikhil, S.R.; Mor, R.S.; Agarwal, T.; Arora, S. Agri-food 4.0 and innovations: Revamping the supply chain operations. Prod. Eng. Arch. 2021, 27, 75–89. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G. Augmented reality technology in the manufacturing industry: A review of the last decade. IISE Trans. 2019, 51, 284–310. [Google Scholar] [CrossRef]

- Yu, F.; Zhang, J.F.; Zhao, Y.; Zhao, J.C.; Tan, C.; Luan, R.P. The research and application of virtual reality (VR) technology in agriculture science. In Proceedings of the International Conference on Computer and Computing Technologies in Agriculture, Beijing, China, 14–17 October 2009; Springer: Berlin/Heidelberg, Germany, 2009; pp. 546–550. [Google Scholar]

- Hu, W.; Pan, Z.; Guo, X.; Zhao, C. Virtual reality application in agriculture field. In Proceedings of the Fourth International Conference on Virtual Reality and Its Applications in Industry, Tianjin, China, 23–25 October 2003; International Society for Optics and Photonics: Washington, DC, USA, 2004; Volume 5444, pp. 510–513. [Google Scholar]

- de Castro Neto, M.; Cardoso, P. Augmented reality greenhouse. In Proceedings of the EFITA-WCCA-CIGR Conference “Sustainable Agriculture through ICT Innovation”, Turin, Italy, 24–27 June 2013; pp. 24–27. [Google Scholar]

- Zhang, X.; Blaise, F. Interactive Visualization of Virtual Orchard. In Proceedings of the Second International Symposium on Intelligent Information Technology in Agriculture-ISIITA 2003, Beijing, China; 2003; pp. 454–461. Available online: https://inria.hal.science/inria-00107689/document (accessed on 27 February 2023).

- Pan, Z.; Cheok, A.D.; Müller, W.; Iurgel, I.; Petta, P.; Urban, B. Transactions on Edutainment X; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Clements, P.; Bachmann, F.; Bass, L.; Garlan, D.; Ivers, J.; Little, R.; Merson, P.; Nord, R.; Stafford, J. Documenting Software Architectures: Views and Beyond, 2nd ed.; Addison-Wesley: London, UK, 2010. [Google Scholar]

- Thomas, O. Understanding the Term Reference Model in Information Systems Research: History, Literature Analysis and Explanation. In Proceedings of the Satellite Workshop of BPM 2005, Nancy, France, 5 September 2005; Springer: Nancy, France, 2006; pp. 484–496. [Google Scholar]

- Verdouw, C.; Sundmaeker, H.; Tekinerdogan, B.; Conzon, D.; Montanaro, T. Architecture Framework of IoT-Based Food and Farm Systems: A Multiple Case Study. Comput. Electron. Agric. 2019, 165, 104939. [Google Scholar] [CrossRef]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design Science Research in Information Systems. In Design Research in Information Systems; Springer: Boston, MA, USA, 2010; pp. 9–22. [Google Scholar]

- Eisenhardt, K.M. Building Theories from Case Study Research. The Academy of Management Review. JSTOR 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V.; Boulton, E.; Davey, L.; McEvoy, C. The online survey as a qualitative research tool. Int. J. Soc. Res. Methodol. 2021, 24, 641–654. [Google Scholar] [CrossRef]

- Joshi, S.; Hamilton, M.; Warren, R.; Faucett, D.; Tian, W.; Wang, Y.; Ma, J. Implementing Virtual Reality technology for safety training in the precast/ prestressed concrete industry. Appl. Ergon. 2021, 90, 103286. [Google Scholar] [CrossRef]

- Verdouw, C.N. Business Process Modelling in Demand-Driven Supply Chains: A Reference Framework. Ph.D. Thesis, Information Technology Group, Wageningen University, Wageningen, The Netherlands, 2010. [Google Scholar]

- Bauer, M.; Bui, N.; Loof, J.D.; Magerkurth, C.; Nettsträter, A.; Stefa, J.; Walewski, J.W. IoT reference model. In Enabling Things to Talk; Springer: Berlin/Heidelberg, Germany, 2013; pp. 113–162. [Google Scholar]

- ANSI/ISA-95.00.01-2010 (IEC 62264-1 Mod); Enterprise-Control System Integration—Part 1: Models and Terminology. ISA: Haryana, India, 2010.

- Carruth, D.W.; Hudson, C.; Fox, A.A.; Deb, S. User interface for an immersive virtual reality greenhouse for training precision agriculture. In Proceedings of the International Conference on Human-Computer Interaction, Copenhagen, Denmark, 19–24 July 2020; Springer: Cham, Switzerland, 2020; pp. 35–46. [Google Scholar]

| Number | Question | Type |

|---|---|---|

| 1 | Age | Check box |

| 2 | Gender | Check box |

| 3 | Profession | Open Response |

| 4 | How familiar are you regarding DT-driven concepts applied in the greenhouse horticulture industry? | Likert |

| 5 | How familiar are you regarding DT-driven concepts applied in pharmaceutical cannabis production specifically? | Likert |

| 6 | How familiar are you regarding DT-driven concepts that combine XR (e.g., AR/VR) services in pharmaceutical cannabis production? | Likert |

| 7 | Grade in terms of innovativeness and creativity the created VR based Dt driven technology applied in the pharmaceutical cannabis production | Likert |

| 8 | Grade in terms of future applicability the presented proof of concept | Likert |

| 9 | In your opinion, can the presented DT driven concept, if further modified, be used for monitoring pharmaceutical cannabis production by augmenting all the cultivation information? | Open Response |

| 10 | How much would you grade the future market value of such a proof of concept? | Likert |

| 11 | If possible, could you provide some brief thoughts about the future of VR-based DTs | Open Response |

| View | Definition | Viewpoint | Reference Architecture |

|---|---|---|---|

| Context Diagram | Depicts the interconnected entities’ relations and interactions within the boundaries of the systems. | IDEF0 | TOGAF |

| Domain Model | Generic view of essential functionality aspects of the system in scope, including relationships and interactions between system objects and with the outside world. | UML | IoT-A |

| Information Model | Depicts the data entities and their relations, including the usage of data for virtual entities in a conceptualized manner. | UML | IoT-A |

| Functional Decomposition Model | Decomposes the complexity of a DT-based system into a layered form with numerous technical layers, ranging from security layer to device layer. | OSI | IoT-A |

| Business Process Model | Provides an overview of all business processes and activities of the product life cycle, ranging from managerial to operational control. | BPMN 2.0 | ISA-95 |

| Sensor Type | Description |

|---|---|

| PAR | Photosynthetic active radiation |

| CO2 | Carbon dioxide |

| Temp. | Temperature and Humidity Dewpoint |

| Ph | Potential of hydrogen |

| Weather Data | Live data from weather station |

| Vent Position | Position of greenhouse vent according with sensors readings |

| Profession | Count |

|---|---|

| Msc Student | 1 |

| PhD student | 2 |

| Assistant prof | 2 |

| Public relations | 1 |

| Researcher | 6 |

| Engineer | 2 |

| Climate control greenhouses | 1 |

| Intern | 1 |

| Lecturer | 1 |

| Author | 1 |

| Professor | 1 |

| Statistician/Modeler | 1 |

| Indoor farming specialist | 1 |

| Data Scientist | 1 |

| 3D Content Creator or XR developer | 2 |

| Bioinformatics | 1 |

| Sr advisor Corporate strategy and accounts | 1 |

| Question | Response | Count |

|---|---|---|

| In your opinion, can the presented DT driven concept, if further modified, be used for monitoring pharmaceutical cannabis production by augmenting all the cultivation information? | “Yes” | 13 |

| “Don’t know” | 4 | |

| “Blockchain for tracking tracing” | 1 | |

| No answer | 7 | |

| “I think so” | 3 | |

| “It depends how accurate it is.” | 1 | |

| “I think this app has a lot of potential … after explanation it seems really interesting” | 1 |

| Theme | Quote |

|---|---|

| Positive | “As VR is very immersive, you see and remember the data much better. Therefore I see a lot of potential” |

| “This is the future” × 2 | |

| “It could be applied in a wide variety of field” | |

| Negative | “I see them as potentially useful in a number of application settings, but not all.” |

| “Why VR instead of real-time video that can be steered in a similar way (e.g., webcam on robot)” | |

| Interaction | “Useful for training people, production efficiency gain TBC” |

| Future Directions | “Only with the ability to simulate different emergency scenarios for training, VR based dt might provide big value to production.” |

| “I think that the more detailed and advanced the visualisation, the more accurate information on flowers might be extrapolated from VR visualisation and simulation” |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spyrou, O.; Hurst, W.; Verdouw, C. Virtual Reality-Based Digital Twins: A Case Study on Pharmaceutical Cannabis. Big Data Cogn. Comput. 2023, 7, 95. https://doi.org/10.3390/bdcc7020095

Spyrou O, Hurst W, Verdouw C. Virtual Reality-Based Digital Twins: A Case Study on Pharmaceutical Cannabis. Big Data and Cognitive Computing. 2023; 7(2):95. https://doi.org/10.3390/bdcc7020095

Chicago/Turabian StyleSpyrou, Orestis, William Hurst, and Cor Verdouw. 2023. "Virtual Reality-Based Digital Twins: A Case Study on Pharmaceutical Cannabis" Big Data and Cognitive Computing 7, no. 2: 95. https://doi.org/10.3390/bdcc7020095

APA StyleSpyrou, O., Hurst, W., & Verdouw, C. (2023). Virtual Reality-Based Digital Twins: A Case Study on Pharmaceutical Cannabis. Big Data and Cognitive Computing, 7(2), 95. https://doi.org/10.3390/bdcc7020095