Abstract

Digitalisation has enjoyed rapid acceleration during the COVID-19 pandemic on top of the already fast-paced expansion impacting almost every aspect of daily life. Digital twin technology, which is considered a building block of Metaverse and an important pillar of Industrial revolution 4.0, has also received growing interest. Apart from its significant contribution to intelligent manufacturing, there has been considerable discussion on its implementation and the as yet undiscovered potential. This paper reviews the current trajectory of digital twin applications in supporting general sustainability, in the context of the 17 UN SDGs. Furthermore, it connects researchers and readers from different fields with the aim of achieving a better understanding of emerging digital twin technologies, the current values this technology has brought to support UN SDGs, and identify areas with potential for future research to better contribute to achieving the remaining tasks of Agenda 2030.

1. Introduction

With the growing severity of climate events, erosion of multilateralism, and persistence of economic crises, sustainable development is a well-known and well understood concept, receiving growing attention worldwide. In 2015, the 17 United Nations Sustainable Development Goals (UN SDGs) were adopted to replace the eight Millennium Development Goals (MDGs), which had guided global development since 2000. This new and ambitious plan aims to complete the remaining targets of the MDGs and strike a better balance between prosperity for people while at the same time protecting the planet. Although the concept of sustainable development originated back in the late 1980s [1], it has attracted a significant public attention in recent years, most especially since 2015 [2,3], and it remains a top trending term across sectors globally.

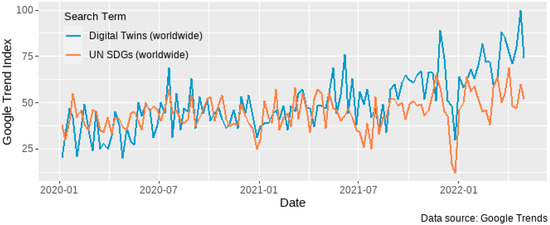

In recent decades, we have witnessed a dramatic technological revolution in almost every aspect of human life [4]; rapid technological advancements and digital transformation have the potential to make a more significant contribution to sustainable development than at any period in the past [2]. One of the tech buzzwords that has featured in the Gartner top 10 strategic technology trends every year since 2017 is “digital twin”. It is also considered a building block of the Metaverse, another fast-emerging topic that represents an immersive digital world that allows real-life-like experiences and interactions. As can be seen in Figure 1, Google Trends indices for the two terms are listed—digital twins and UN SDGs since 2020, the data were extracted from the Google Trends website. The Google search interest in both of these terms showed a growing trend over the last two years. The index for the UN SDGs showed a steady rise, from about 40 to nearly 70 with some fluctuations, whilst global interest in digital twins has increased from about 25 to 100 (where 100 indicates the highest possible interest worldwide). It is interesting to note the steady and growing interest in sustainable development as it permeates every aspect of our lives. Meanwhile, the public interest in digital twins is more recent and dramatic, arising from the boost in digital transformation owing to the COVID pandemic, the enormous investment plans announced by some tech giants and the enabling environment of expanding digital infrastructure and advancing technology. Examining these two issues together and investigating their valuable interactions will bring insightful contributions to both sustainable development in general and the scaling up of digital twin implementations in supporting sustainability.

Figure 1.

Worldwide Google Trends for UN SDGs and digital twins since 2020.

Digital twins have been predominantly implemented in manufacturing. To the best of our knowledge, there has been no research that has solely investigated the value of digital twin technology in supporting the general UN SDGs. This paper aims to systematically review the applications of digital-twin-related technologies in supporting the UN SDGs and identify areas of popular interest, as well as those with apparent potentials that are still being explored. It is hoped that this paper can help bring together researchers and practitioners from diverse backgrounds to promote insightful future research on the implementation of digital twins to achieve the UN SDGs. The remainder of the paper is organised as follows: Section 2 clarifies the emerging concept of the digital twin; the general implementation of digital twins in support of the UN SDGs is summarised in Section 3; finally, Section 4 concludes with insights emerging from the research and discusses existing challenges, potential concerns, and avenues for future research.

2. Understanding the Trending Buzzword-Digital Twin

Although, the concept of digital twin was originated back in the 1960s by NASA, using it to simulate spacecraft for the Apollo projects, Michael Grieves is acknowledged as having coined the term “digital twin” in a presentation in 2003. The now, widely accepted, formal definition of digital twin was proposed by NASA at a conference in 2012, during which, Glaessgen and Stargel (2012) [5] defined a digital twin as “an integrated multi-physics, multi-scale, probabilistic simulation of an as-built vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to mirror the life of its corresponding flying twin”. As the first sector where digital twin technology originated, general manufacturing industries also experienced the very first boost by widely applying digital twin technology at every step of production. This led to an updated definition of the digital twin by Grieves (2017) [6] in the context of product lifecycle management (PLM). It is noteworthy that, up until now, manufacturing and general industrial companies are still the key players and main users of digital twin technology. The successes achieved with digital twins in the industrial sector are also reflected by the dominant amount of literature in that field, where digital twins are frequently referred to as the most important pillar of the Industrial Revolution 4.0 [7].

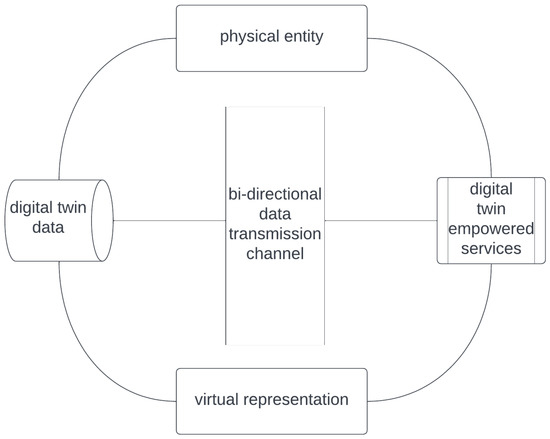

A digital twin system can firstly be decomposed into three main elements [8], which are the physical product, the corresponding virtual representation, and the bi-directional data transmission channel between them. This three-element model was subsequently extended to a five-dimensional model by Tao et al. (2018) [9] by adding two more elements: digital twin data and services. The importance of information collected by applying digital twin technology and the services involved were addressed in this extended model by systematically embedding them as essential components of the digital twin model (an illustrative figure can be found in Figure 2). This more sophisticated model of a digital twin clearly highlighted the key functionalities of this emerging technology; for instance, given the context of product lifecycle management (PLM), digital twin technology has been applied to simulate every element of the entire product lifecycle. Physical entities and operational processes are monitored in real time while data are simultaneously collected and digitally recorded. The corresponding virtual representation and associated data are adopted for simulation, validation, and optimisation of a specific process or across the entire product lifecycle. This real-time feedback and analytics can then assist physical entities and specific operational processes in achieving the best prediction, efficiency, and risk management outcomes. For those interested in having a comprehensive understanding of the technical aspects of applying a digital twin, systematic reviews of key technologies, software, and technical tools used can be found in [10,11].

Figure 2.

Five-dimensional digital twin model.

According to a collection of digital twin definitions in a recent paper by Liu et al. (2021) [11], the most important features of digital twin technology have been repeatedly highlighted: a dynamic system with real-time and bi-directional data transmission between the physical entity and its virtual representation. These also serve as the key features to distinguish digital twin technology from some of its closely related rooting technologies [12], i.e., modelling, simulation, validation, prototyping, etc., which are also the elements commonly confused with digital twin. Other common misconceptions or confusions arise in distinguishing digital twin from several similar concepts, such as, digital shadow, digital modelling, digital simulation, digital prototyping, digital thread, device shadow, and cyber twin. It is usually the case that similar terms represent only part or a certain step of digital twin technology, or are one of the rooting technologies of digital twin, or could be a term that represents one of the two scenarios above, but in the context of another domain/area. The technological revolution has led to a digital divide. An important first step in creating an equally accessible and understanding environment of these emerging technologies, will be to seek the best collaborative implementations that contribute to the general social good. In the next section of this paper, implementation of digital twin relevant technologies are systematically investigated, as are their associations with the 17 UN SDGs.

3. Digital Twin Implementations for Supporting UN SDGs

Although implementation of digital twin has made significant progress over recent years, it is evident that many areas of the UN SDGs have not benefited from this well-acknowledged technology. A comprehensive overview of digital twin applications that support or might support general sustainability are presented. Areas that use digital twin and those that do not are identified. Over 160 research articles relevant to digital twin and sustainable development were manually researched to provide readers with the current trajectory of interactions between digital twin technology and general sustainability. In doing so this paper aims to direct interested researchers and practitioners toward potentially beneficial avenues of research and contribute to achieving the UN SDGs. The figure below summarises key areas of digital twin implementation in support of sustainability. The associated UN SDGs are also listed for convenient reference as are the goals where there has been no adoption of digital twin technology. Readers should note that for many use cases it is difficult to clearly distinguish relevant UN SDGs as there are close connections and interlinkages between goals, as well as areas of application. Moreover, the influences of specific applications could lead to a wider scale of impact, making it challenging to draw a clear line between relevant goals. There are likely overlapping goals across different areas of application, and there are also very close and complex connections between many areas of application. In order to provide readers with a more specific segmentation, subsections are arranged to introduce each key area of digital twin application along with carefully selected relevant literature. Please note that the segmentation does not indicate absolute distinctions between domains, but rather our method of keeping track of applications in those areas.

3.1. Sustainable Production, Maintenance, Logistics and Circular Economy

Digital twin empowered PLM has become the essential requirement among industrial companies experiencing rapid changes in the era of industrial revolution 4.0 [7,10]. Managing and optimising production processes in a dynamic, intelligent and data-driven manner has made incalculable contributions to productivity, cost reduction, resource and risk management, as well as sustainable production [9,13,14]. Manufacturing is the sector where digital twin technology originated, and it is to date the sector which has benefited most from digital twin implementation. The contribution of this sector to digital twin literature dominates; even review articles concerning general digital twin applications typically have a significant proportion of content discussing its role in manufacturing. There are several systematic reviews that focus on digital twin in manufacturing only; some of the most up to date review papers can be found at [11,15,16,17] and thus are not reproduced here. In brief, studies approached this specific review task from different perspectives. From a technical perspective, some researchers focused on the technical architecture or specific tools/software/model of digital twin systems in manufacturing [9,16,17,18], and often the proposed architecture closely integrates IoT, cloud computing, data analytics, etc. Other research reviews the topic from a manufacturing perspective, where digital twin applications were organised by different stages of production [11,14], or added value/services where digital twin can contribute [15,19].

Considering the well-established literature on digital twin applications in manufacturing, many researchers have narrowed down the scope by targeting a more specific group of interested readers. Research focusing on one selected digital twin service has been identified, for instance, digital twin enabled design [20,21], logistics [22,23], maintenance [24,25] stage of the production. There are also papers discussing the production line of a specific industry/product/company [26,27,28]. Moreover, some research has reinforced interactions between industrial companies and sustainability, e.g., green material [29], resource management [30], recycle [31], circular economy [32]. Furthermore, circular economy literature also extended to the sustainable use of natural resources, green energy, smart energy/resource infrastructures, etc. Instead of further expanding this section concerning manufacturing and sustainable production, a separate Section 3.3, which focuses on energy and resource management, urban planning and infrastructure is presented. Please note that the segmentation does not indicate absolute distinctions between these two domains, but rather as a means of keeping track of applications in different areas. This provides interested readers with more specific segmentation across different areas of applications.

3.2. Smart Construction and Building Management

Given the impact of digital twin implementations in manufacturing and its immeasurable contributions to the industrial revolution 4.0, the construction sector could perhaps realise its potential by embracing digital twin technology. here digital twin could real show the benefits of the digital future, as construction, even general engineering and building management, are all significantly influencing the progress of several UN SDGs (as can be seen in Figure 3). There are a few recent review papers specifically investigating digital twin applications in construction [33,34,35,36] for interested readers. Rather than summarise these papers, the focus will be on the benefits that support sustainability.

Figure 3.

Digital twin implementations supporting UN SDGs.

In the context of construction, digital twin’s relevant and rooting technologies (i.e., modelling, simulation, analytics, etc.) have an emerging product, namely, building information modelling (BIM). It is common to mix BIM with digital twin. In fact, a large proportion of the identified literature has discussed BIM rather than digital twin. Although the technical difference is clear, as digital twin highlights real-time bidirectional data transmission between the physical object and its virtual representation, advancing BIM tools in the construction sector could be the closest form or partially established product of digital twin, subject to improved integration with newer technologies to achieve the outstanding features of digital twin that current BIM tools do not contain [35,37,38].

In accordance with the PLM concept in manufacturing, applications were also grouped into different lifecycle phases by Opoku et al. (2021) [33] in the context of the construction sector. The design and engineering stage accounts for the bulk of applications relevant to BIM, which contain all the digital project information that have been collectively shared by different stakeholders. Tools such as this can serve designers with convenient access to the most comprehensive project information [39], assist decision-making on the best workflow of project delivery within estimated project duration [38], monitoring built assets [40] and assessing sustainability [41,42,43]. Applications in the construction stage focus on progress monitoring, quality control as well as on site safety management [36]. Moreover, a great number of applications target the maintenance stage [40,44,45], partly due to its close connections with smart building [46], as well as intelligent building lifecycle management [47]. Digital twin has been implemented in this stage mainly for optimising predictive maintenance [48], enhancing building sustainability factors [49,50], as well as safety management [51]. There are also papers focusing on certain types of buildings/infrastructure (i.e., [52,53]), or integrating with smart building or/and its energy management [46].

3.3. Energy and Resource Management, Urban Planning and Smart Water Infrastructure

The optimisation of energy and other resources is not completely new territory for digital twin. Much of the implementation across manufacturing and construction (see sections above) has the shared aim of energy saving, together they have positively influenced the management of energy and resources while achieving more sustainable production. There are papers specifically focusing on digital twin applications in manufacturing or construction energy systems [54], for instance, industrial production lines [55,56] and building energy management [57,58,59,60]. In the energy industry, digital twin also plays an important role in promoting transformation to a more digitalised intelligent future.

From the supply side, digital twin applications to power plant systems have emerged in recent years, as can be seen in a recent review paper by Sleiti et al. (2022) [61]. Similar to how digital twin is applied in assisting PLM in manufacturing, the main aim of such applications is to improve energy system efficiency and optimisation of operations. The literature to date has focused mainly on system architecture design and planning stages with only a few incorporating case studies in practice [62,63,64,65]. Energy distribution and grid control have also embraced transformation towards smart grids, where digital twin technologies actively contribute to its advancement. Jiang et al. (2021) [66] proposed a new digital twin body model, which is compatible with complex systems such as smart grids. Mourtzis et al. (2022) [67] developed a framework for a digital twin enabled product service system to achieve optimal energy distribution. With cyber security a consideration, some researchers [68,69] have proposed digital twin empowered modules for identifying faults in smart grid infrastructure.

Concerning the demand side of digital twin applications [70], several papers focused on sustainable energy consumption via digital twin empowered platforms. Fathy et al. (2021) [71] proposed the energy system digital twin at the household level to promote effective energy planning and consumption. Similarly, a digital twin architecture model was developed in [72] for achieving better energy consumption prediction and providing personalised demand response suggestions on a residential-level energy system. A district-level energy management tool verified in a digital twin environment was proposed in [73], which integrated urban-level energy, transport energy and building energy systems. Another energy demand side topic joining forces with digital twin technology is smart electric vehicles [74], which also has a close connection with the general sustainability of transportation and logistics. Per the initial function of digital twin in simulating NASA spacecraft, digital twin technology has been embraced by electric vehicles in constructing smart vehicle systems [75]. The main functions identified from the literature include developing smart management systems for battery [76,77], propulsion systems [78,79], charging [80], maintenance training [81], as well as internet of vehicles [82].

Digital twin applications in energy and resource management also play significant roles in the areas of smart city, logistics, urban planning, civil engineering, water management, etc. [83,84]. Moreover, it is not only conceptual planning that were discovered in the literature, real life case studies were also identified [85,86,87]. A framework for digital twin cities was proposed in [88] detailing areas of applications, intelligent platforms and infrastructure. A recent review paper focused on interactions of digital twin and civil engineering can be found in [89]. Similarly, another recent review article by Callcut et al. (2021) [90] summarised digital twin use cases in civil infrastructure systems, i.e., transport, construction, telecommunication, water, energy, waste, etc. Better water management is another area where digital twin has contributed significantly. The literature showcase digital twin applications in water treatment [91], optimising water distribution [92,93], constructing urban water management system [94,95] and urban drainage system [96]. It is also noteworthy that the progression of smart cities supported by smart infrastructure/systems of almost every aspect also enables better disaster prevention and management [97], where decision-making and resource coordination is of crucial importance.

3.4. Agriculture, Livestock Farming, Fishery and the Earth

The establishment of digital twin in manufacturing and other sectors reveals an important part of its success - that is to enable environmentally sustainable production/operation. This transferable advantage is also the key to digital twin expansion to other fields, such as agriculture, livestock farming, etc., where concepts such as smart agriculture [98,99], smart farming [100,101] and smart fishery [102] have also emerged significantly in the last decade thanks to the digital revolution. Although these fields traditionally have fewer interactions with smart technologies and lack a data culture [103,104], insights and successes from other sectors suggest that embracing technological advancements such as digital twin could provide better solutions to the escalating climate and food challenges, and contribute to achieving the relevant UN SDGs [105,106].

A comprehensive review of digital twin applications in agriculture/smart farming up until 2020 can be found in [104,107], these papers are not reproduced here. Instead a focus on more recent literature, since 2021, presents a more up-to-date trajectory of digital twin applications, evidenced by the fact that a simple google scholar search of “digital twin” and “agriculture” since 2021 returned almost double the amount of literature results than the same search for the period 2015 to 2020. The domain functionality of digital twin applications in agriculture is sustainably improving productivity. For instance, Chaux et al. (2021) [108] proposed digital twin empowered architecture to modify existing controlled agriculture environment applications to be more energy efficient while achieving higher quality crops and yields. Digital twin has also been applied to advanced urban agriculture techniques such as aquaponics in [109] to combat growing food pressure arising from urbanisation, climate change and degradation. Technological advancements (i.e., smart sensors, IoT, machine learning, AI, as well as digital twin) in the context of smart agriculture have brought significant changes in different phases of crop production, from soil monitoring [110], soil mapping [111], agricultural machinery automation and cost efficiency [112], disease detection [113], post-harvest handling and management [114,115], quality control [116,117], food processing and supply chain [118,119,120].

Unlike the pathway of digital twin in manufacturing/construction, the implementation of digital twin in other fields (like agriculture, farming, and fishery) has specific challenges. Managing living physical entities can be far more complex than digital twining a product [121]. Only a few papers specifically target livestock farming rather than general agriculture. A recent review paper with a specific focus on the interactions between digital twin technology and livestock farming can be found in [122], where promising use case examples were proposed for different aspects of livestock farming, for instance, livestock real-time monitoring and management, farming property energy management, early livestock diseases detection, feed intake optimisation, etc. In the closely related aquaculture sector, digital twin enabled smart fishery and precision aquaculture have been emerging as well [123,124], promoting sustainable management of the underwater environment and aquaculture production.

Earth observation technology and its related big data systems played a crucial role in understanding the changes to the planet and the accelerating climate challenges [2,3,125]. Years of development, fast expansion of data infrastructure, advancements of data processing technologies and a shared vision for a greener future, have together led to the ambitious plan of developing a digital twin for the Earth [126]. Although this presents many challenges, this plan aims to capture comprehensive details of the planet, develop the ultimate tool of climate modelling and forecasting, and reveal the keys to managing interactions between human activities and climate [127].

3.5. Digital Twining Everything as Healthcare Service

Digital twin technology has contributed significantly to the digitalisation revolution in healthcare, which directly influences the progress of achieving UN SDG 3, good health and well-being, as well as reducing already existing inequalities in healthcare. As discussed in Section 2, the general five-dimensional digital twin model contains the physical entity, its digital representation, data transmission channels, digital twin data and services [9]. The physical entity of digital twin in the context of healthcare can be a diverse collection of objects/services. Digital twinning those physical entities creates an enormous Internet of Everything (IoE) such as architecture for providing improved healthcare services.

Thanks to the growing scope of Internet of Things (IoT), cloud computing and technological network infrastructure, a physical entity could be any smart device with healthcare functions. Smart devices could promote personalised healthcare knowledge and information sharing via multimedia channels. For instance, providing personalised precise nutrition advice [128,129], the Gabby preconception care system [130] and later the personal mHealth smart pregnancy programme [131] give personalised coaching and preconception care information in order to prevent adverse maternal and infant outcomes. Wearable devices are also extremely popular nowadays incorporating digital twin related technologies in a number of valuable functionalities: coaching physical activity [132], fitness management [133], managing ergonomic risks [134], real time health monitoring [135], even training athletes [132]. Moreover, smart medical devices empowered by digital twin technology can be used for timely diagnosis and early prevention. By detecting early signals of diseases/symptoms, implementations have been found in assisting the diagnosis of oncology patients [136], patients with multiple sclerosis [137], precision cardiology [138], lung cancer [139], as well as general elderly healthcare [140] and critical patient care in intensive care unit [141].

Advancing technologies have also expanded the horizon of possible physical entities for building up the digital twin model, from molecular or genome-level data to complex large scale systems/institutions/facilities. In the context of healthcare, the physical entity of a digital twin model could also be an actual patient, or a specific cell, DNA, organ, organ system, or even the whole human body [142,143,144,145,146]. There are some well known genome projects (i.e., the Human Genome Project, 100,000 Genomes Project, New Born Genomes Programme), where leading researchers and organisations join forces and continuously explore the genetic secrets of human beings. In practice, applications empowered by advancing virtual reality technology have already brought positive impacts to the healthcare experiences of patients. Immersive virtual reality technology helps IVF patients to ease negative emotional impacts prior to embryo transfer [147]. Much improved visualisation of embryonic and placental structures could assist in early diagnosis of complications during pregnancy [148].

Digital twin technologies can also apply to complex physical entities; in the context of healthcare, it could be complex surgery, professional or research facilities, or even an entire hospital. For instance, digital twin applications enable better immersive surgery simulation [149] for training, more accurate surgery planning and evaluation, development of less invasive surgery [150], a framework for remote surgery was also proposed in [151] which could significantly improve the accessibility of healthcare resources. Digital twinning an entire hospital was also identified in the literature [152,153,154], aiming at optimising patient pathways, improving hospital operational efficiency, achieving real-time hospital building management and general optimisation of healthcare resources.

3.6. Education and Research

Digital twin technology is bridging reality and the virtual world at an unprecedented speed. Another sector that has experienced a radical digitalisation revolution is education and research, especially since the COVID-19 pandemic. Education, training and research under virtual settings have fast emerged on a global scale, allowing the public to access a digitalised future which, until recently, had seemed far away and had not been expected anytime soon. Virtual/immersive reality is one of the key techniques in the process of digitalisation for education and research [155,156,157], helping to simulate real-life-like environments for assisting teaching and learning [158,159], especially for contents/subjects which would be difficult without practical settings. Although most of the existing use cases are not technically digital twin technologies as the physical and virtual objects should have dynamic real-time integration and data transmission, it is progressing in the same direction as if the aim is to make reality more immersive/responsive. Furthermore, most use cases have been accomplished using part or rooting technologies of digital twin. Applications have been identified in construction engineering education [160,161], safety training [162], military training [163], arts education [164], healthcare sector education and training [165,166]. These applications not only positively influenced the learning experience and outcomes, they also enabled more equal and sustainable access to learning/research resources without restrictions of location, language, and disability.

4. Conclusions

This paper aims to investigate the diverse roles of digital twin technology in supporting the UN SDGs; six domains with potential were identified. The associated list of UN SDG targets are also listed. The key areas of digital twin implementation where scholars and practitioners have focused are manufacturing, construction, urban planning, energy and resource management, agriculture, healthcare and education. These have contributed towards several UN SDGs as detailed in Figure 3. Although most implementations may have a wider impact on sustainability and bring positive effects to multiple UN SDGs, it is evident that economic growth, production, and infrastructure related UN SDGs are those most influenced by digital twin implementation. This may be due to the business/profit driven nature of most technical advancements, but it could also be a compatible tool to support social goods. We are already witnessing more governments, global institutions and research organisations joining forces to develop digital twin-related projects to better support sustainable development, for instance, the national digital twin programme in the UK, the joint project between the world economic forum and the China Academy of Information and Communication Technology on developing digital twins of cities, etc.

Some UN SDGs have received considerable attention, for instance, the UN SDGs concerning healthcare, climate and agriculture, whereas for others there is still very limited literature. The spillover or collateral impact on other sectors has been limited, most likely as those UN SDGs were not the intended target of digital twin applications. Following the big successes of digital twin in the key sectors, it should be a promising topic to investigate further in the context of applications in those overlooked UN SDGs. To date there is a lack of literature about digital twin and UN SDG 5 (gender equality), UN SDG 16 (peace, justice and strong institutions) and UN SDG 17 (partnerships). Regarding UN SDG 5 for instance, no literature discussing digital twin application for improving gender equality were identified. The close connection between digital twin and Metaverse could lead to fruitful discussions about digital avatar diversity, freedom and equality.

Digital twin has received considerable public attention, but its scalability is still questionable, as more and more complex physical entities would mean more challenging computational resource requirements for implementing digital twin technology. Further investigation on whether this large-scale digital infrastructure and consumption of computational resources would put more stress or bring more benefits for the UN SDGs is needed. There is still a long journey before we get to the dynamic, immersive, digital twinning everything future, but the path we now choose to progress towards that future is of crucial importance; sustainability, as one of the most vital global issues, could be better addressed by applying valuable technological advancements such as digital twin. For future research, we will continue monitoring the development of emerging technologies such as digital twin and their interactions with the 17 UN SDGs, especially in those areas that are currently overlooked by existing applications.

Author Contributions

All authors contributed equally to the work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lele, S.M. Sustainable development: A critical review. World Dev. 1991, 19, 607–621. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; MacFeely, S.; Entezarian, M.R. Big Data and the United Nations Sustainable Development Goals (UN SDGs) at a Glance. Big Data Cogn. Comput. 2021, 5, 28. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; Silva, E. Big data and climate change. Big Data Cogn. Comput. 2019, 3, 12. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; Silva, E. The human digitalisation journey: Technology first at the expense of humans? Information 2021, 12, 267. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; MacFeely, S. Impactful Digital Twin in the Healthcare Revolution. Big Data Cogn. Comput. 2022, 6, 83. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital twins in product lifecycle for sustainability in manufacturing and maintenance. Appl. Sci. 2020, 11, 31. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital twin as a service (DTaaS) in industry 4.0: An architecture reference model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot.-Comput.-Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Redelinghuys, A.J.H.; Basson, A.H.; Kruger, K. A six-layer architecture for the digital twin: A manufacturing case study implementation. J. Intell. Manuf. 2020, 31, 1383–1402. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Pan, Y.H.; Qu, T.; Wu, N.Q.; Khalgui, M.; Huang, G.Q. Digital twin based real-time production logistics synchronization system in a multi-level computing architecture. J. Manuf. Syst. 2021, 58, 246–260. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Sundram, V.P.K.; Pyeman, J.; Othman, A.K.; Sorooshian, S. Digital twin integrated reinforced learning in supply chain and logistics. Logistics 2021, 5, 84. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltran, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The use of Digital Twin for predictive maintenance in manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Wang, K.J.; Lee, Y.H.; Angelica, S. Digital twin design for real-time monitoring–a case study of die cutting machine. Int. J. Prod. Res. 2021, 59, 6471–6485. [Google Scholar] [CrossRef]

- Xiang, F.; Zhang, Z.; Zuo, Y.; Tao, F. Digital twin driven green material optimal-selection towards sustainable manufacturing. Procedia Cirp 2019, 81, 1290–1294. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, G.; Guo, X.; Zhang, Y. Digital twin-driven service model and optimal allocation of manufacturing resources in shared manufacturing. J. Manuf. Syst. 2021, 59, 165–179. [Google Scholar] [CrossRef]

- Wang, X.V.; Wang, L. Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0. Int. J. Prod. Res. 2019, 57, 3892–3902. [Google Scholar] [CrossRef]

- Rocca, R.; Rosa, P.; Sassanelli, C.; Fumagalli, L.; Terzi, S. Integrating virtual reality and digital twin in circular economy practices: A laboratory application case. Sustainability 2020, 12, 2286. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Meda, P.; Calvetti, D.; Hjelseth, E.; Sousa, H. Incremental digital twin conceptualisations targeting data-driven circular construction. Buildings 2021, 11, 554. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, E14. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Zhou, Z. Sustainability-based lifecycle management for bridge infrastructure using 6D BIM. Sustainability 2020, 12, 2436. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Z.; Chang, R.; Li, Y. Building Information Modeling (BIM) for green buildings: A critical review and future directions. Autom. Constr. 2017, 83, 134–148. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Seyis, S. Mixed method review for integrating building information modeling and life-cycle assessments. Build. Environ. 2020, 173, 106703. [Google Scholar] [CrossRef]

- Coupry, C.; Noblecourt, S.; Richard, P.; Baudry, D.; Bigaud, D. BIM-Based digital twin and XR devices to improve maintenance procedures in smart buildings: A literature review. Appl. Sci. 2021, 11, 6810. [Google Scholar] [CrossRef]

- Yitmen, I.; Alizadehsalehi, S.; Akıner, İ.; Akıner, M.E. An adapted model of cognitive digital twins for building lifecycle management. Appl. Sci. 2021, 11, 4276. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Ma, W.; Phil-Ebosie, O. Digital twin aided vulnerability assessment and risk-based maintenance planning of bridge infrastructures exposed to extreme conditions. Sustainability 2021, 13, 2051. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Cecconi, F.R.; Maltese, S.; Rinaldi, S.; Ciribini, A.L.C.; Flammini, A. Leveraging digital twin for sustainability assessment of an educational building. Sustainability 2021, 13, 480. [Google Scholar] [CrossRef]

- Sepasgozar, S.M. Differentiating digital twin from digital shadow: Elucidating a paradigm shift to expedite a smart, sustainable built environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, A.; Wang, W. A framework for an indoor safety management system based on digital twin. Sensors 2020, 20, 5771. [Google Scholar] [CrossRef]

- Shim, C.S.; Dang, N.S.; Lon, S.; Jeon, C.H. Development of a bridge maintenance system for prestressed concrete bridges using 3D digital twin model. Struct. Infrastruct. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Ranasinghe, G.D.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a Digital Twin at Building and City Levels: A Case Study of West Cambridge Campus. J. Manag. Eng.-ASCE 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic digital twin architecture for industrial energy systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Karanjkar, N.; Joglekar, A.; Mohanty, S.; Prabhu, V.; Raghunath, D.; Sundaresan, R. Digital twin for energy optimization in an SMT-PCB assembly line. In Proceedings of the 2018 IEEE International Conference on Internet of Things and Intelligence System (IOTAIS), Bali, Indonesia, 1–3 November 2018; pp. 85–89. [Google Scholar]

- Kaewunruen, S.; Rungskunroch, P.; Welsh, J. A digital-twin evaluation of net zero energy building for existing buildings. Sustainability 2018, 11, 159. [Google Scholar] [CrossRef]

- Francisco, A.; Mohammadi, N.; Taylor, J.E. Smart city digital twin–enabled energy management: Toward real-time urban building energy benchmarking. J. Manag. Eng. 2020, 36, 04019045. [Google Scholar] [CrossRef]

- Agouzoul, A.; Tabaa, M.; Chegari, B.; Simeu, E.; Dandache, A.; Alami, K. Towards a digital twin model for building energy management: Case of Morocco. Procedia Comput. Sci. 2021, 184, 404–410. [Google Scholar] [CrossRef]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-physical systems improving building energy management: Digital twin and artificial intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Granacher, J.; Nguyen, T.V.; Castro-Amoedo, R.; Marechal, F. Overcoming decision paralysis—A digital twin for decision making in energy system design. Appl. Energy 2022, 306, 117954. [Google Scholar] [CrossRef]

- Saad, A.; Faddel, S.; Mohammed, O. IoT-based digital twin for energy cyber-physical systems: Design and implementation. Energies 2020, 13, 4762. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Hu, W.; Liu, G.P.; Guan, S.; Feng, X. Toward a web-based digital twin thermal power plant. IEEE Trans. Ind. Inform. 2021, 18, 1716–1725. [Google Scholar] [CrossRef]

- Xu, B.; Wang, J.; Wang, X.; Liang, Z.; Cui, L.; Liu, X.; Ku, A.Y. A case study of digital-twin-modelling analysis on power-plant-performance optimizations. Clean Energy 2019, 3, 227–234. [Google Scholar] [CrossRef]

- Jiang, Z.; Lv, H.; Li, Y.; Guo, Y. A novel application architecture of digital twin in smart grid. J. Ambient. Intell. Humaniz. Comput. 2022, 13, 3819–3835. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Development of a PSS for Smart Grid Energy Distribution Optimization based on Digital Twin. Procedia CIRP 2022, 107, 1138–1143. [Google Scholar] [CrossRef]

- Tzanis, N.; Andriopoulos, N.; Magklaras, A.; Mylonas, E.; Birbas, M.; Birbas, A. A hybrid cyber physical digital twin approach for smart grid fault prediction. In Proceedings of the 2020 IEEE Conference on Industrial Cyberphysical Systems (ICPS), Tampere, Finland, 10–12 June 2020; Volume 1, pp. 393–397. [Google Scholar]

- Danilczyk, W.; Sun, Y.L.; He, H. Smart grid anomaly detection using a deep learning digital twin. In Proceedings of the 2020 52nd North American Power Symposium (NAPS), Tempe, AZ, USA, 11–13 April 2021; pp. 1–6. [Google Scholar]

- Onile, A.E.; Machlev, R.; Petlenkov, E.; Levron, Y.; Belikov, J. Uses of the digital twins concept for energy services, intelligent recommendation systems, and demand side management: A review. Energy Rep. 2021, 7, 997–1015. [Google Scholar] [CrossRef]

- Fathy, Y.; Jaber, M.; Nadeem, Z. Digital twin-driven decision making and planning for energy consumption. J. Sens. Actuator Netw. 2021, 10, 37. [Google Scholar] [CrossRef]

- Fujii, T.Y.; Hayashi, V.T.; Arakaki, R.; Ruggiero, W.V.; Bulla, R., Jr.; Hayashi, F.H.; Khalil, K.A. A Digital Twin Architecture Model Applied with MLOps Techniques to Improve Short-Term Energy Consumption Prediction. Machines 2021, 10, 23. [Google Scholar] [CrossRef]

- O’Dwyer, E.; Pan, I.; Charlesworth, R.; Butler, S.; Shah, N. Integration of an energy management tool and digital twin for coordination and control of multi-vector smart energy systems. Sustain. Cities Soc. 2020, 62, 102412. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Singh, R.R. Towards the future of smart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rassolkin, A.; Vaimann, T.; Kallaste, A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability 2022, 14, 601. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, R.; Zhou, C.; Kang, X.; Chen, Z. Digital twin and cloud-side-end collaboration for intelligent battery management system. J. Manuf. Syst. 2022, 62, 124–134. [Google Scholar] [CrossRef]

- Garg, A.; Panigrahi, B.K. Multi-dimensional digital twin of energy storage system for electric vehicles: A brief review. Energy Storage 2021, 3, e242. [Google Scholar]

- Venkatesan, S.; Manickavasagam, K.; Tengenkai, N.; Vijayalakshmi, N. Health monitoring and prognosis of electric vehicle motor using intelligent-digital twin. IET Electr. Power Appl. 2019, 13, 1328–1335. [Google Scholar] [CrossRef]

- Ruba, M.; Nemes, R.O.; Ciornei, S.M.; Martis, C.; Bouscayrol, A.; Hedesiu, H. Digital twin real-time FPGA implementation for light electric vehicle propulsion system using EMR organization. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–6. [Google Scholar]

- Yu, G.; Ye, X.; Xia, X.; Chen, Y. Towards Cognitive EV Charging Stations Enabled by Digital Twin and Parallel Intelligence. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2019; pp. 290–293. [Google Scholar]

- Lee, S.H.; Jung, B.S. Development of electric vehicle maintenance education ability using digital twin technology and VR. Int. J. Adv. Cult. Technol. 2020, 8, 58–67. [Google Scholar]

- Zhang, T.; Liu, X.; Luo, Z.; Dong, F.; Jiang, Y. Time series behavior modeling with digital twin for Internet of Vehicles. EURASIP J. Wirel. Commun. Netw. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Mylonas, G.; Kalogeras, A.; Kalogeras, G.; Anagnostopoulos, C.; Alexakos, C.; Munoz, L. Digital twins from smart manufacturing to smart cities: A survey. IEEE Access 2021, 9, 143222–143249. [Google Scholar] [CrossRef]

- Shahat, E.; Hyun, C.T.; Yeom, C. City digital twin potentials: A review and research agenda. Sustainability 2021, 13, 3386. [Google Scholar] [CrossRef]

- Wan, L.; Nochta, T.; Schooling, J.M. Developing a city-level digital twin–propositions and a case study. In International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making; ICE Publishing: Cambridge, UK, 2019; pp. 187–194. [Google Scholar]

- Dembski, F.; Wossner, U.; Letzgus, M.; Ruddat, M.; Yamu, C. Urban digital twins for smart cities and citizens: The case study of Herrenberg, Germany. Sustainability 2020, 12, 2307. [Google Scholar] [CrossRef]

- Major, P.; Li, G.; Hildre, H.P.; Zhang, H. The Use of a Data-Driven Digital Twin of a Smart City: A Case Study of Ålesund, Norway. IEEE Instrum. Meas. Mag. 2021, 24, 39–49. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, K.; Shen, Z.J.M. A systematic review of a digital twin city: A new pattern of urban governance toward smart cities. J. Manag. Sci. Eng. 2021, 6, 125–134. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Callcut, M.; Cerceau Agliozzo, J.-P.; Varga, L.; McMillan, L. Digital twins in civil infrastructure systems. Sustainability 2021, 13, 11549. [Google Scholar] [CrossRef]

- Curl, J.M.; Nading, T.; Hegger, K.; Barhoumi, A.; Smoczynski, M. Digital twins: The next generation of water treatment technology. J.-Am. Water Work. Assoc. 2019, 111, 44–50. [Google Scholar] [CrossRef]

- Conejos Fuertes, P.; Martinez Alzamora, F.; Hervas Carot, M.; Alonso Campos, J.C. Building and exploiting a Digital Twin for the management of drinking water distribution networks. Urban Water J. 2020, 17, 704–713. [Google Scholar] [CrossRef]

- Salomons, E.; Housh, M. Practical real-time optimization for energy efficient water distribution systems operation. J. Clean. Prod. 2020, 275, 124148. [Google Scholar] [CrossRef]

- Pedersen, A.N.; Borup, M.; Brink-Kjær, A.; Christiansen, L.E.; Mikkelsen, P.S. Living and prototyping digital twins for urban water systems: Towards multi-purpose value creation using models and sensors. Water 2021, 13, 592. [Google Scholar] [CrossRef]

- Ramos, H.M.; Morani, M.C.; Carravetta, A.; Fecarrotta, O.; Adeyeye, K.; Lopez-Jimenez, P.A.; Perez-Sanchez, M. New Challenges towards Smart Systems’ Efficiency by Digital Twin in Water Distribution Networks. Water 2022, 14, 1304. [Google Scholar] [CrossRef]

- Bartos, M.; Kerkez, B. Pipedream: An interactive digital twin model for natural and urban drainage systems. Environ. Model. Softw. 2021, 144, 105120. [Google Scholar] [CrossRef]

- Fan, C.; Zhang, C.; Yahja, A.; Mostafavi, A. Disaster City Digital Twin: A vision for integrating artificial and human intelligence for disaster management. Int. J. Inf. Manag. 2021, 56, 102049. [Google Scholar] [CrossRef]

- Ayaz, M.; Ammad-Uddin, M.; Sharif, Z.; Mansour, A.; Aggoune, E.H.M. Internet-of-Things (IoT)-based smart agriculture: Toward making the fields talk. IEEE Access 2019, 7, 129551–129583. [Google Scholar] [CrossRef]

- Sinha, B.B.; Dhanalakshmi, R. Recent advancements and challenges of Internet of Things in smart agriculture: A survey. Future Gener. Comput. Syst. 2022, 126, 169–184. [Google Scholar] [CrossRef]

- Navarro, E.; Costa, N.; Pereira, A. A systematic review of IoT solutions for smart farming. Sensors 2020, 20, 4231. [Google Scholar] [CrossRef] [PubMed]

- Saiz-Rubio, V.; Rovira-Más, F. From smart farming towards agriculture 5.0: A review on crop data management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Ebrahimi, S.H.; Ossewaarde, M.; Need, A. Smart fishery: A systematic review and research agenda for sustainable fisheries in the age of AI. Sustainability 2021, 13, 6037. [Google Scholar] [CrossRef]

- Zielinski, T.; Bolzacchini, E.; Evans, K.; Ferrero, L.; Gregorczyk, K.; Kijewski, T.; Kotynska-Zielinska, I.; Mrowiec, P.; Oleszczuk, B.; Pakszys, P.; et al. Abundance of Environmental Data vs. Low Public Interest in Climate and Ocean Issues. Where Is the Missing Link? Front. Mar. Sci. 2021, 51. [Google Scholar] [CrossRef]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Basso, B.; Antle, J. Digital agriculture to design sustainable agricultural systems. Nat. Sustain. 2020, 3, 254–256. [Google Scholar] [CrossRef]

- Garske, B.; Bau, A.; Ekardt, F. Digitalization and AI in European Agriculture: A Strategy for Achieving Climate and Biodiversity Targets? Sustainability 2021, 13, 4652. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Chaux, J.D.; Sanchez-Londono, D.; Barbieri, G. A digital twin architecture to optimize productivity within controlled environment agriculture. Appl. Sci. 2021, 11, 8875. [Google Scholar] [CrossRef]

- Ghandar, A.; Ahmed, A.; Zulfiqar, S.; Hua, Z.; Hanai, M.; Theodoropoulos, G. A decision support system for urban agriculture using digital twin: A case study with aquaponics. IEEE Access 2021, 9, 35691–35708. [Google Scholar] [CrossRef]

- Yin, H.; Cao, Y.; Marelli, B.; Zeng, X.; Mason, A.J.; Cao, C. Soil sensors and plant wearables for smart and precision agriculture. Adv. Mater. 2021, 33, 2007764. [Google Scholar] [CrossRef]

- Searle, R.; McBratney, A.; Grundy, M.; Kidd, D.; Malone, B.; Arrouays, D.; Stockman, U.; Zund, P.; Wilson, P.; Wilford, J.; et al. Digital soil mapping and assessment for Australia and beyond: A propitious future. Geoderma Reg. 2021, 24, e00359. [Google Scholar] [CrossRef]

- Reis, A.V.D.; Medeiros, F.A.; Ferreira, M.F.; Machado, R.L.T.; Romano, L.N.; Marini, V.K.; Francetto, T.R.; Machado, A.L.T. Technological trends in digital agriculture and their impact on agricultural machinery development practices. Revista Ciência Agronômica 2021, 51. [Google Scholar] [CrossRef]

- Gupta, M.; Kumari, M.; Ved, C. Digital Twin in Agriculture Sector: Detection of Disease Using Deep Learning. In Digital Twin Technology; CRC Press: Boca Raton, FL, USA, 2021; pp. 47–60. [Google Scholar]

- Hu, F. Mutual information-enhanced digital twin promotes vision-guided robotic grasping. Adv. Eng. Inform. 2022, 52, 101562. [Google Scholar] [CrossRef]

- Dyck, G.; Hawley, E.; Hildebrand, K.; Paliwal, J. Digital Twins: A Novel Traceability Concept for Post-Harvest Handling. Smart Agric. Technol. 2022, 3, 100079. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Bollo, M.; Di Pasquale, V.; Centro, F.; Riemma, S. Machine Learning-Based Digital Twin for Monitoring Fruit Quality Evolution. Procedia Comput. Sci. 2022, 200, 13–20. [Google Scholar] [CrossRef]

- Shrivastava, C.; Defraeye, T. Digital twins unveil trade-offs in maintaining citrus quality in the refrigerated supply chain. Nat. Food 2022, 3, 411–412. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef]

- Tebaldi, L.; Vignali, G.; Bottani, E. Digital twin in the agri-food supply chain: A literature review. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Switzerland, 2021; pp. 276–283. [Google Scholar]

- Koulouris, A.; Misailidis, N.; Petrides, D. Applications of process and digital twin models for production simulation and scheduling in the manufacturing of food ingredients and products. Food Bioprod. Process. 2021, 126, 317–333. [Google Scholar] [CrossRef]

- Smith, M.J. Getting value from artificial intelligence in agriculture. Anim. Prod. Sci. 2018, 60, 46–54. [Google Scholar] [CrossRef]

- Neethirajan, S.; Kemp, B. Digital twins in livestock farming. Animals 2021, 11, 1008. [Google Scholar] [CrossRef] [PubMed]

- Ko, E.; Raj, D.; Shin, S.Y.; Kim, S.G.; Park, S.H. International Standardization for Maritime, Underwater Internet of Things and Digital Twin Applications. In Proceedings of the 15th International Conference on Underwater Networks & Systems, Shenzhen, China, 22–24 November 2021; pp. 1–2. [Google Scholar]

- Teixeira, R.; Puccinelli, J.; de Vargas Guterres, B.; Pias, M.R.; Oliveira, V.M.; Botelho, S.S.D.C.; Poersch, L.; Filho, N.D.; Janati, A.; Paris, M. Planetary digital twin: A case study in aquaculture. In Proceedings of the 37th ACM/SIGAPP Symposium on Applied Computing, Virtual, 25–29 April 2022; pp. 191–197. [Google Scholar]

- Guo, H.D.; Zhang, L.; Zhu, L.W. Earth observation big data for climate change research. Adv. Clim. Chang. Res. 2015, 6, 108–117. [Google Scholar] [CrossRef]

- Bauer, P.; Stevens, B.; Hazeleger, W. A digital twin of Earth for the green transition. Nat. Clim. Chang. 2021, 11, 80–83. [Google Scholar] [CrossRef]

- Nativi, S.; Mazzetti, P.; Craglia, M. Digital ecosystems for developing digital twins of the earth: The destination earth case. Remote Sens. 2021, 13, 2119. [Google Scholar] [CrossRef]

- Gkouskou, K.; Vlastos, I.; Karkalousos, P.; Chaniotis, D.; Sanoudou, D.; Eliopoulos, A.G. The “Virtual Digital Twins” Concept in Precision Nutrition. Adv. Nutr. 2020, 11, 1405–1413. [Google Scholar] [CrossRef]

- Shamanna, P.; Saboo, B.; Damodharan, S.; Mohammed, J.; Mohamed, M.; Poon, T.; Kleinman, N.; Thajudeen, M. Reducing HbA1c in type 2 diabetes using digital twin technologyenabled precision nutrition: A retrospective analysis. Diabetes Ther. 2020, 11, 2703–2714. [Google Scholar] [CrossRef]

- Gardiner, P.; Hempstead, M.B.; Ring, L.; Bickmore, T.; Yinusa-Nyahkoon, L.; Tran, H.; Paasche-Orlow, M.; Damus, K.; Jack, B. Reaching women through health information technology: The Gabby preconception care system. Am. J. Health Promot. 2013, 27, eS11–eS20. [Google Scholar] [CrossRef]

- Van Dijk, M.R.; Oostingh, E.C.; Koster, M.P.; Willemsen, S.P.; Laven, J.S.; Steegers-Theunissen, R.P. The use of the mHealth program Smarter Pregnancy in preconception care: Rationale, study design and data collection of a randomized controlled trial. BMC Pregnancy Childbirth 2017, 17, 1–7. [Google Scholar] [CrossRef]

- Gamez Diaz, R.; Yu, Q.; Ding, Y.; Laamarti, F.; El Saddik, A. Digital twin coaching for physical activities: A survey. Sensors 2020, 20, 5936. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Gliozzo, J.; Petrini, A.; Valtolina, S. Human digital twin for fitness management. IEEE Access 2020, 8, 26637–26664. [Google Scholar] [CrossRef]

- Ogunseiju, O.R.; Olayiwola, J.; Akanmu, A.A.; Nnaji, C. Digital twin-driven framework for improving self-management of ergonomic risks. Smart Sustain. Built Environ. 2021, 10, 403–419. [Google Scholar] [CrossRef]

- Rivera, L.F.; Jimenez, M.; Angara, P.; Villegas, N.M.; Tamura, G.; Muller, H.A. Towards continuous monitoring in personalized healthcare through digital twins. In Proceedings of the 29th Annual International Conference on Computer Science and Software Engineering, Toronto, ON, Canada, 4–6 November 2019; pp. 329–335. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N.; Kardamakis, D. A Smart IoT Platform for Oncology Patient Diagnosis based on AI: Towards the Human Digital Twin. Procedia CIRP 2021, 104, 1686–1691. [Google Scholar] [CrossRef]

- Voigt, I.; Inojosa, H.; Dillenseger, A.; Haase, R.; Akgun, K.; Ziemssen, T. Digital twins for multiple sclerosis. Front. Immunol. 2021, 12, 1556. [Google Scholar] [CrossRef] [PubMed]

- Corral-Acero, J.; Margara, F.; Marciniak, M.; Rodero, C.; Loncaric, F.; Feng, Y.; Gilbert, A.; Fernandes, J.F.; Bukhari, H.A.; Wajdan, A.; et al. The ‘Digital Twin’ to enable the vision of precision cardiology. Eur. Heart J. 2020, 41, 4556–4564. [Google Scholar] [CrossRef]

- Zhang, J.; Li, L.; Lin, G.; Fang, D.; Tai, Y.; Huang, J. Cyber resilience in healthcare digital twin on lung cancer. IEEE Access 2020, 8, 201900–201913. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Yang, Y.; Zhou, L.; Ren, L.; Wang, F.; Liu, R.; Pang, Z.; Deen, M.J. A novel cloud-based framework for the elderly healthcare services using digital twin. IEEE Access 2019, 7, 49088–49101. [Google Scholar] [CrossRef]

- Zhong, X.; Sarijaloo, F.B.; Prakash, A.; Park, J.; Huang, C.; Barwise, A.; Herasevich, V.; Gajic, O.; Pickering, B.; Dong, Y. A multidisciplinary approach to the development of digital twin models of critical care delivery in intensive care units. Int. J. Prod. Res. 2022, 60, 4197–4213. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, J.; Wang, X.; Feng, L.; Wu, J.; Zhu, X.; Wen, W.; Gong, X. Organon-a-chip: Recent breakthroughs and future prospects. Biomed. Eng. Online 2020, 19, 1–19. [Google Scholar] [CrossRef]

- Baillargeon, B.; Rebelo, N.; Fox, D.D.; Taylor, R.L.; Kuhl, E. The living heart project: A robust and integrative simulator for human heart function. Eur. J. Mech.-A/Solids 2014, 48, 38–47. [Google Scholar] [CrossRef]

- Martinez-Velazquez, R.; Gamez, R.; El Saddik, A. Cardio Twin: A Digital Twin of the human heart running on the edge. In Proceedings of the 2019 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Istanbul, Turkey, 26–28 June 2019; pp. 1–6. [Google Scholar]

- Subramanian, K. Digital twin for drug discovery and development—The virtual liver. J. Indian -Stitute Sci. 2020, 100, 653–662. [Google Scholar] [CrossRef]

- Coorey, G.; Figtree, G.A.; Fletcher, D.F.; Redfern, J. The health digital twin: Advancing precision cardiovas-cular medicine. Nat. Rev. Cardiol. 2021, 18, 803–804. [Google Scholar] [CrossRef] [PubMed]

- Di Guardo, F.; Palumbo, M. Immersive virtual reality as tool to reduce anxiety during embryo transfer. J. Obstet. Gynaecol. 2022, 42, 802–808. [Google Scholar] [CrossRef] [PubMed]

- Rousian, M.; Schoenmakers, S.; Eggink, A.J.; Gootjes, D.V.; Koning, A.H.; Koster, M.P.; Mulders, A.G.M.G.J.; Baart, E.B.; Reiss, I.K.M.; Laven, J.S.E.; et al. Cohort Profile Update: The Rotterdam Periconceptional Cohort and embryonic and fetal measurements using 3D ultrasound and virtual reality techniques. Int. J. Epidemiol. 2021, 50, 1426–1427l. [Google Scholar] [CrossRef]

- Mao, R.Q.; Lan, L.; Kay, J.; Lohre, R.; Ayeni, O.R.; Goel, D.P. Immersive virtual reality for surgical training: A systematic review. J. Surg. Res. 2021, 268, 40–58. [Google Scholar] [CrossRef]

- Zinchenko, K.; Song, K.T. Autonomous Endoscope Robot Positioning Using Instrument Segmentation With Virtual Reality Visualization. IEEE Access 2021, 9, 72614–72623. [Google Scholar] [CrossRef]

- Laaki, H.; Miche, Y.; Tammi, K. Prototyping a digital twin for real time remote control over mobile networks: Application of remote surgery. IEEE Access 2019, 7, 20325–20336. [Google Scholar] [CrossRef]

- Karakra, A.; Fontanili, F.; Lamine, E.; Lamothe, J. HospiT’Win: A predictive simulation-based digital twin for patients pathways in hospital. In Proceedings of the 2019 IEEE EMBS International Conference on Biomedical & Health Informatics (BHI), Chicago, IL, USA, 19–22 May 2019; pp. 1–4. [Google Scholar]

- Lu, Q.; Xie, X.; Fang, Z.; Chen, L.; Ye, Z.; Pitt, M. An inter-hospital digital twin for response to COVID-19 pandemic based on blockchain—A proof of concept. Sustain. Cities Soc. 2021; in press. [Google Scholar]

- Peng, Y.; Zhang, M.; Yu, F.; Xu, J.; Gao, S. Digital twin hospital buildings: An exemplary case study through continuous lifecycle integration. Adv. Civ. Eng. 2020, 2020, 8846667. [Google Scholar] [CrossRef]

- Radianti, J.; Majchrzak, T.A.; Fromm, J.; Wohlgenannt, I. A systematic review of immersive virtual reality applications for higher education: Design elements, lessons learned, and research agenda. Comput. Educ. 2020, 147, 103778. [Google Scholar] [CrossRef]

- Luo, H.; Li, G.; Feng, Q.; Yang, Y.; Zuo, M. Virtual reality in K-12 and higher education: A systematic review of the literature from 2000 to 2019. J. Comput. Assist. Learn. 2021, 37, 887–901. [Google Scholar] [CrossRef]

- Makransky, G.; Petersen, G.B. The cognitive affective model of immersive learning (CAMIL): A theoretical research-based model of learning in immersive virtual reality. Educ. Psychol. Rev. 2021, 33, 937–958. [Google Scholar] [CrossRef]

- Kaminska, D.; Sapiński, T.; Wiak, S.; Tikk, T.; Haamer, R.E.; Avots, E.; Helmi, A.; Ozcinar, C.; Anbarjafari, G. Virtual reality and its applications in education: Survey. Information 2019, 10, 318. [Google Scholar] [CrossRef]

- Hamilton, D.; McKechnie, J.; Edgerton, E.; Wilson, C. Immersive virtual reality as a pedagogical tool in education: A systematic literature review of quantitative learning outcomes and experimental design. J. Comput. Educ. 2021, 8, 1–32. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Wang, J.; Chi, H.L.; Wang, X. A critical review of the use of virtual reality in construction engineering education and training. Int. J. Environ. Res. Public Health 2018, 15, 1204. [Google Scholar] [CrossRef] [PubMed]

- Sepasgozar, S.M. Digital twin and web-based virtual gaming technologies for online education: A case of construction management and engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Eiris, R.; Gheisari, M.; Esmaeili, B. Desktop-based safety training using 360-degree panorama and static virtual reality techniques: A comparative experimental study. Autom. Constr. 2020, 109, 102969. [Google Scholar] [CrossRef]

- Ahir, K.; Govani, K.; Gajera, R.; Shah, M. Application on virtual reality for enhanced education learning, military training and sports. Augment. Hum. Res. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Gonzalez-Zamar, M.D.; Abad-Segura, E. Implications of virtual reality in arts education: Research analysis in the context of higher education. Educ. Sci. 2020, 10, 225. [Google Scholar] [CrossRef]

- Pottle, J. Virtual reality and the transformation of medical education. Future Healthc. J. 2019, 6, 181. [Google Scholar] [CrossRef]

- Pears, M.; Yiasemidou, M.; Ismail, M.A.; Veneziano, D.; Biyani, C.S. Role of immersive technologies in healthcare education during the COVID-19 epidemic. Scott. Med. J. 2020, 65, 112–119. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).