Design of a 130 MW Axial Turbine Operating with a Supercritical Carbon Dioxide Mixture for the SCARABEUS Project †

Abstract

1. Introduction

2. Design Process

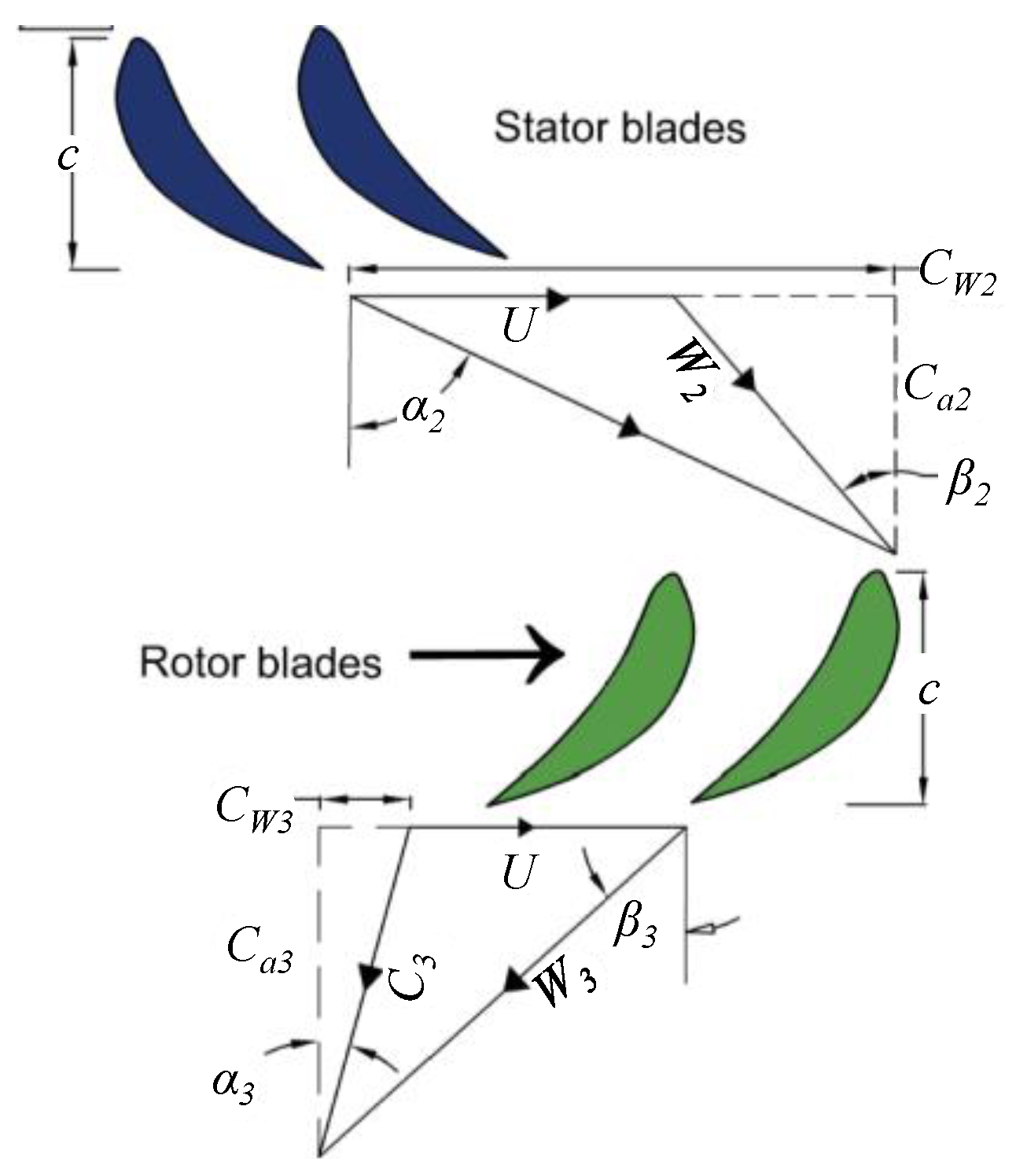

2.1. Meanline Design Model

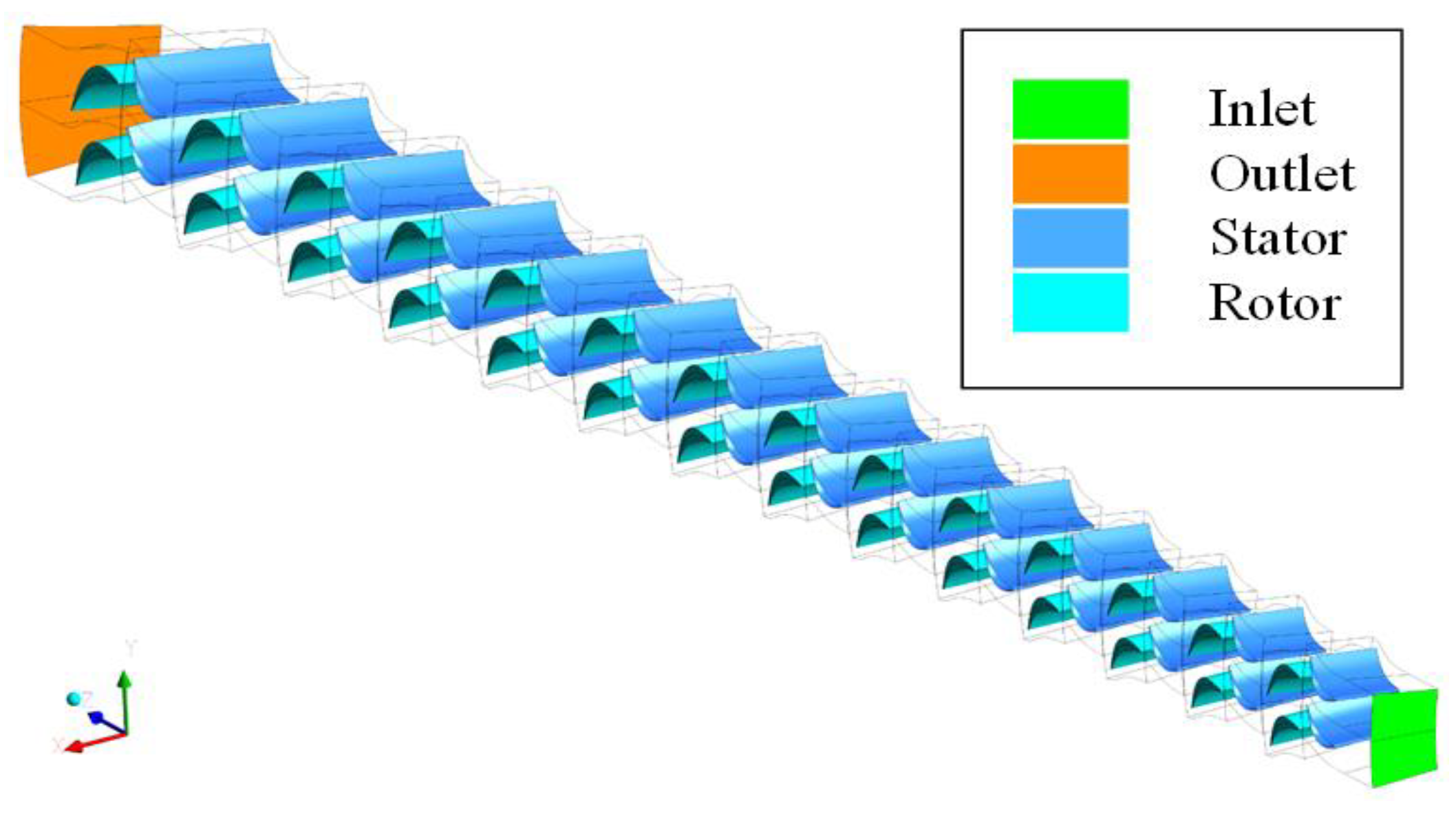

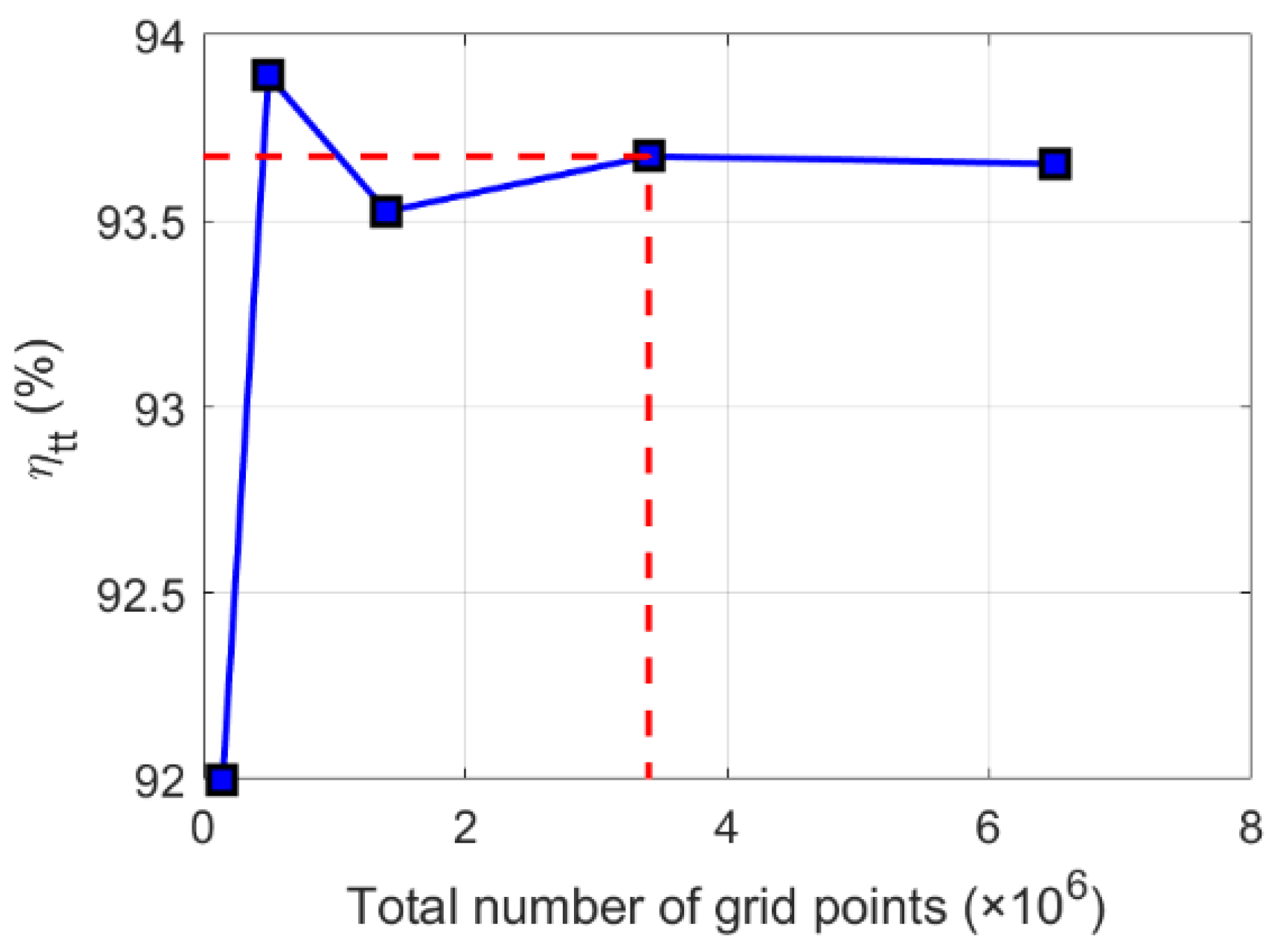

2.2. CFD Model Definition

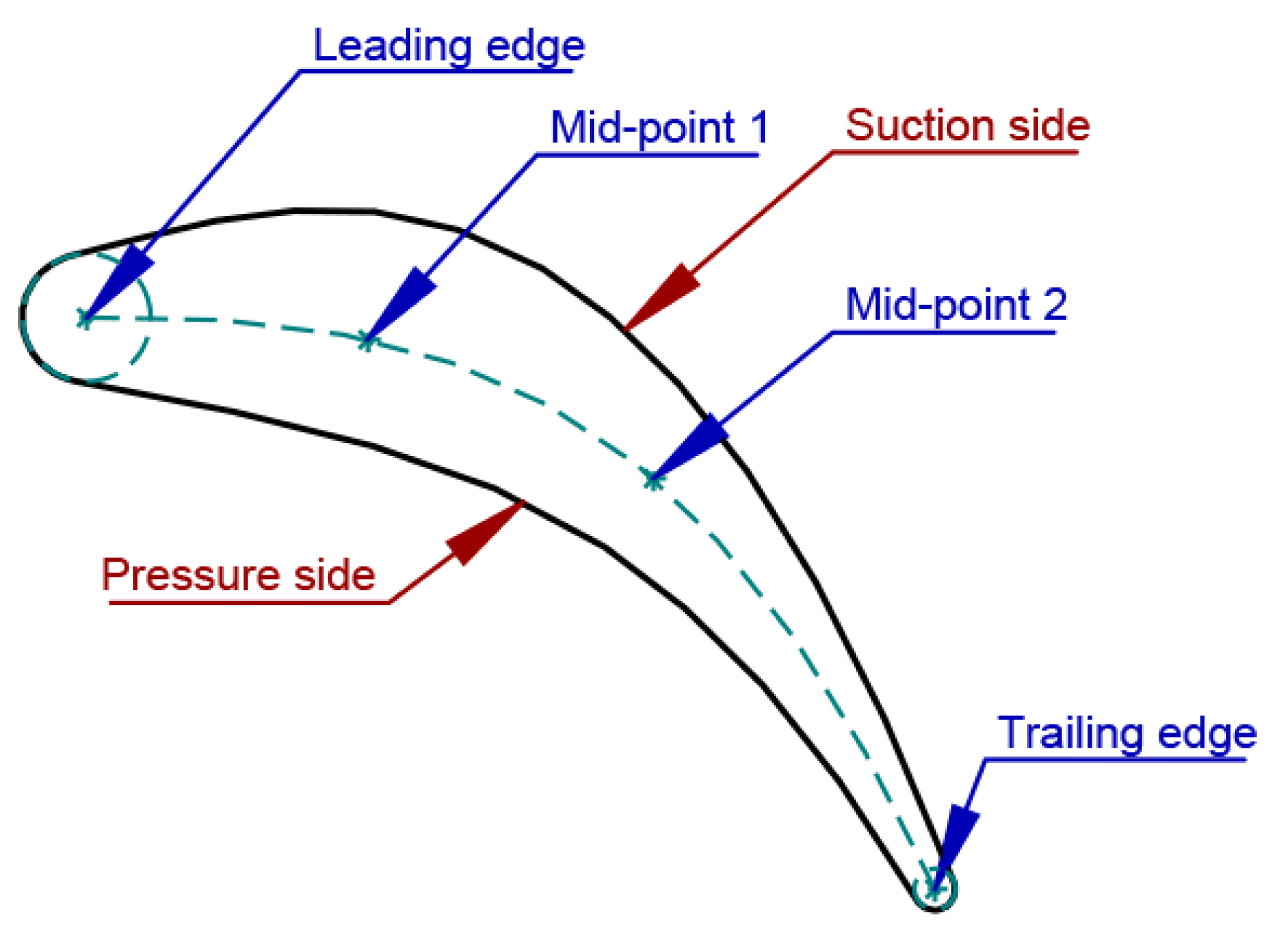

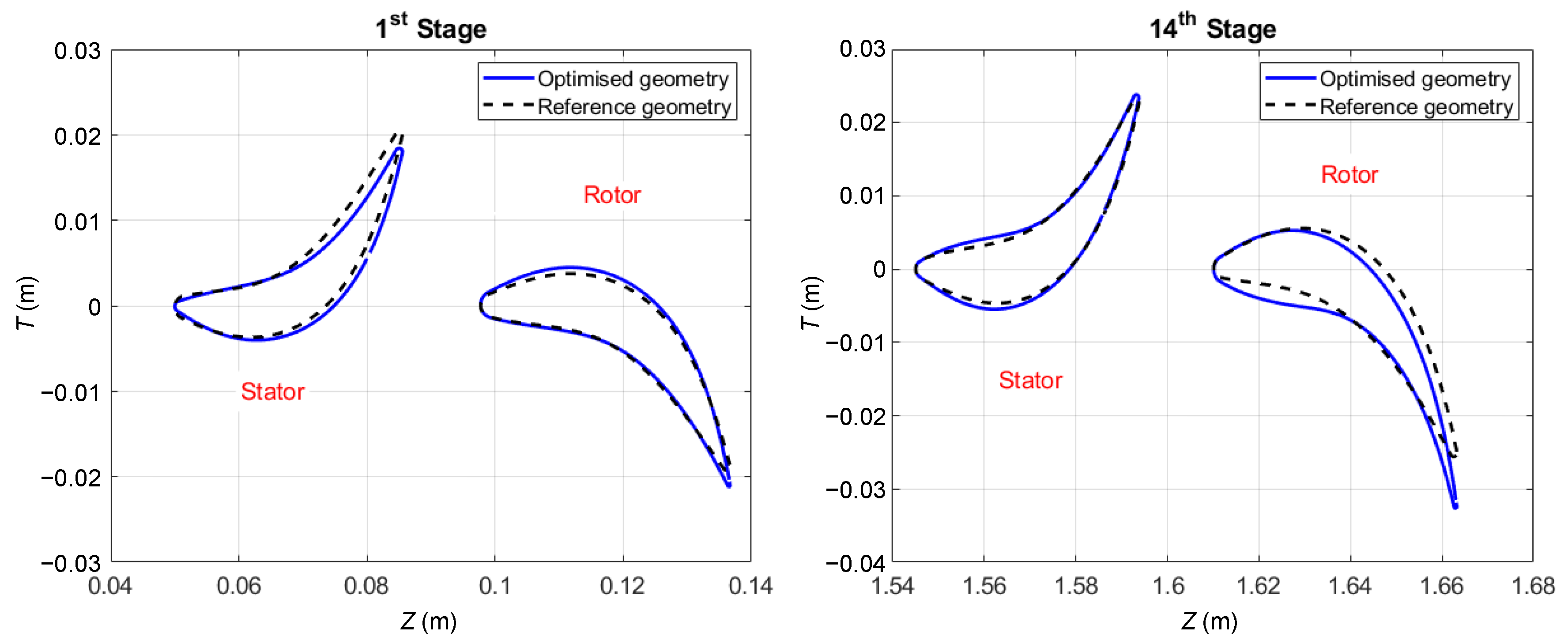

2.3. Blade Shape Optimisation

3. Results and Discussion

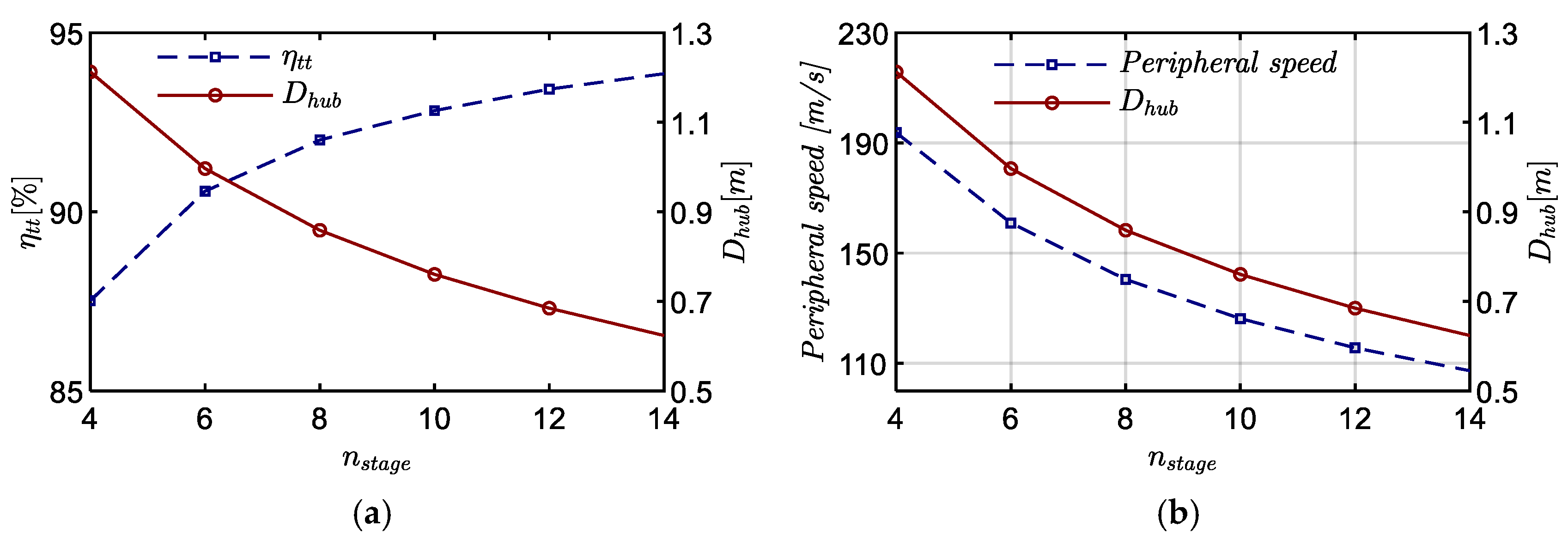

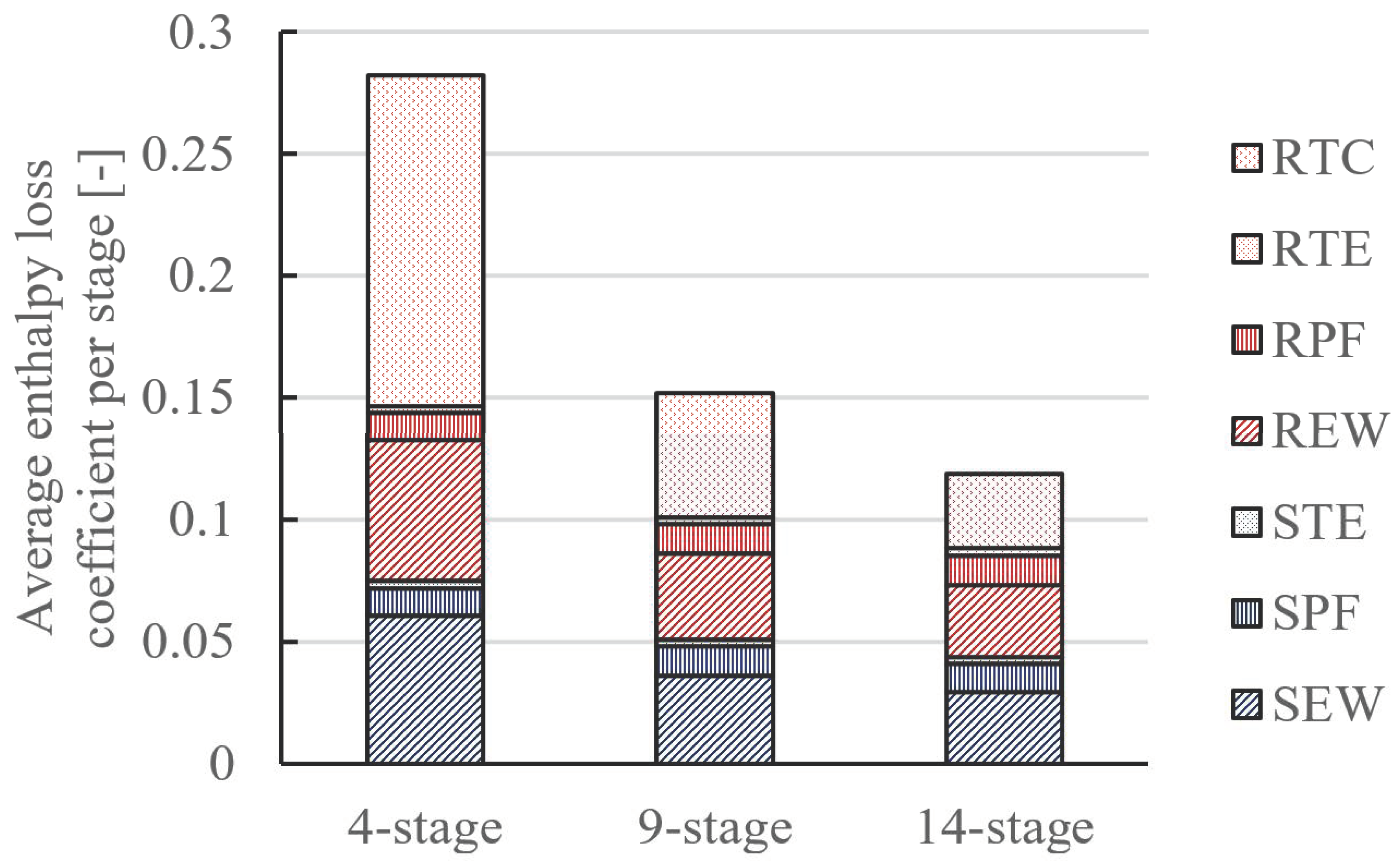

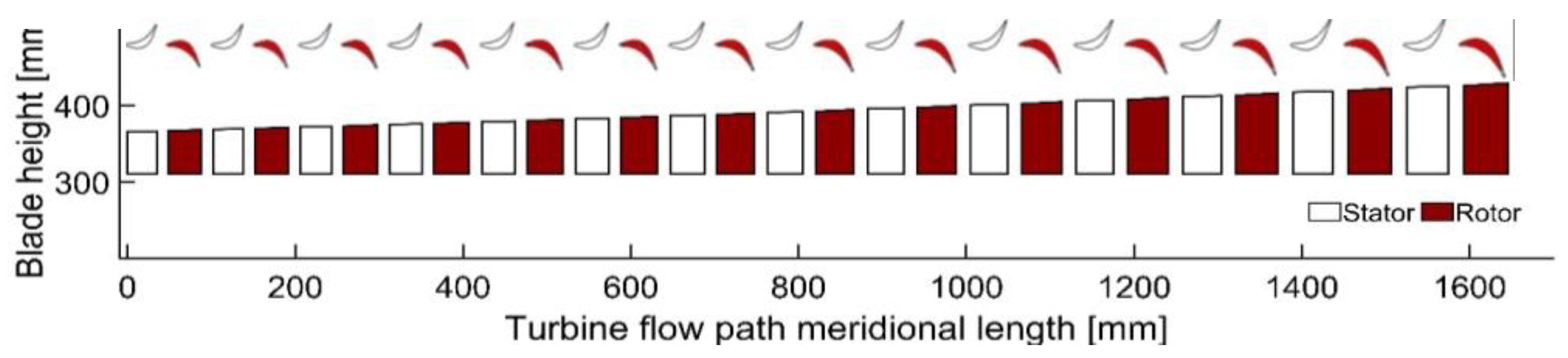

3.1. Flow Path Design

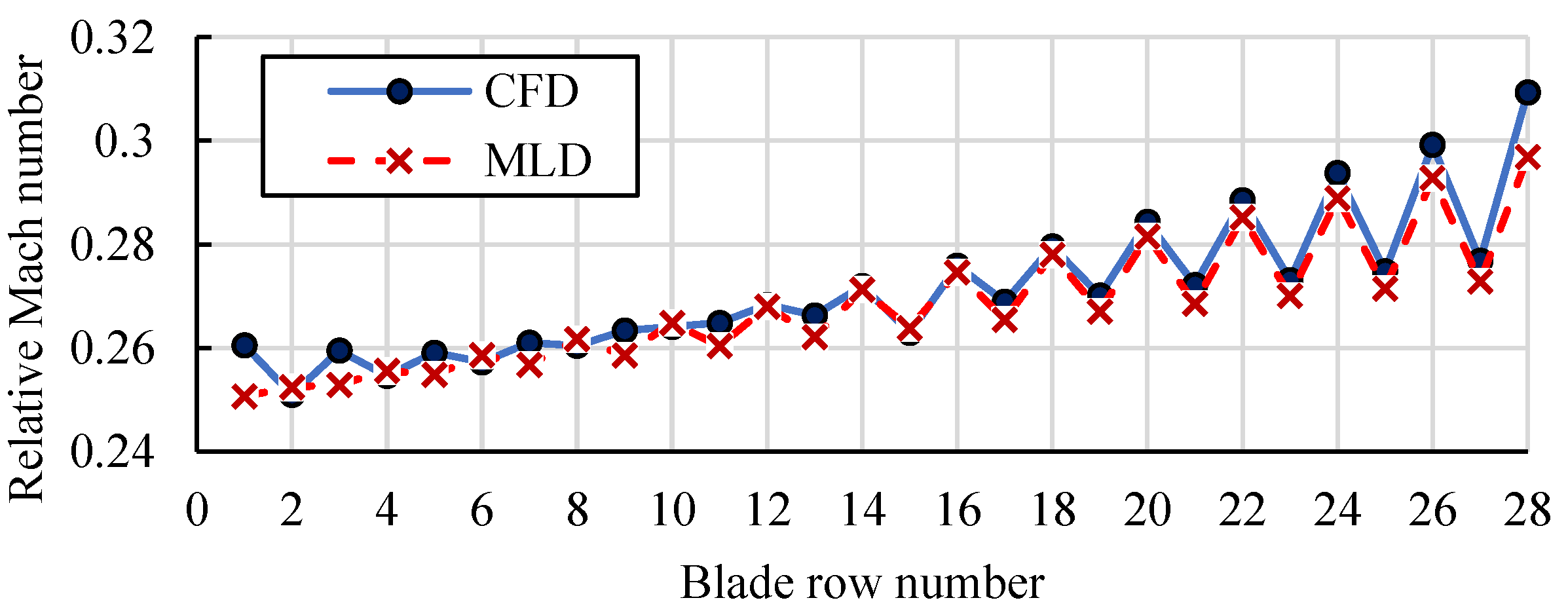

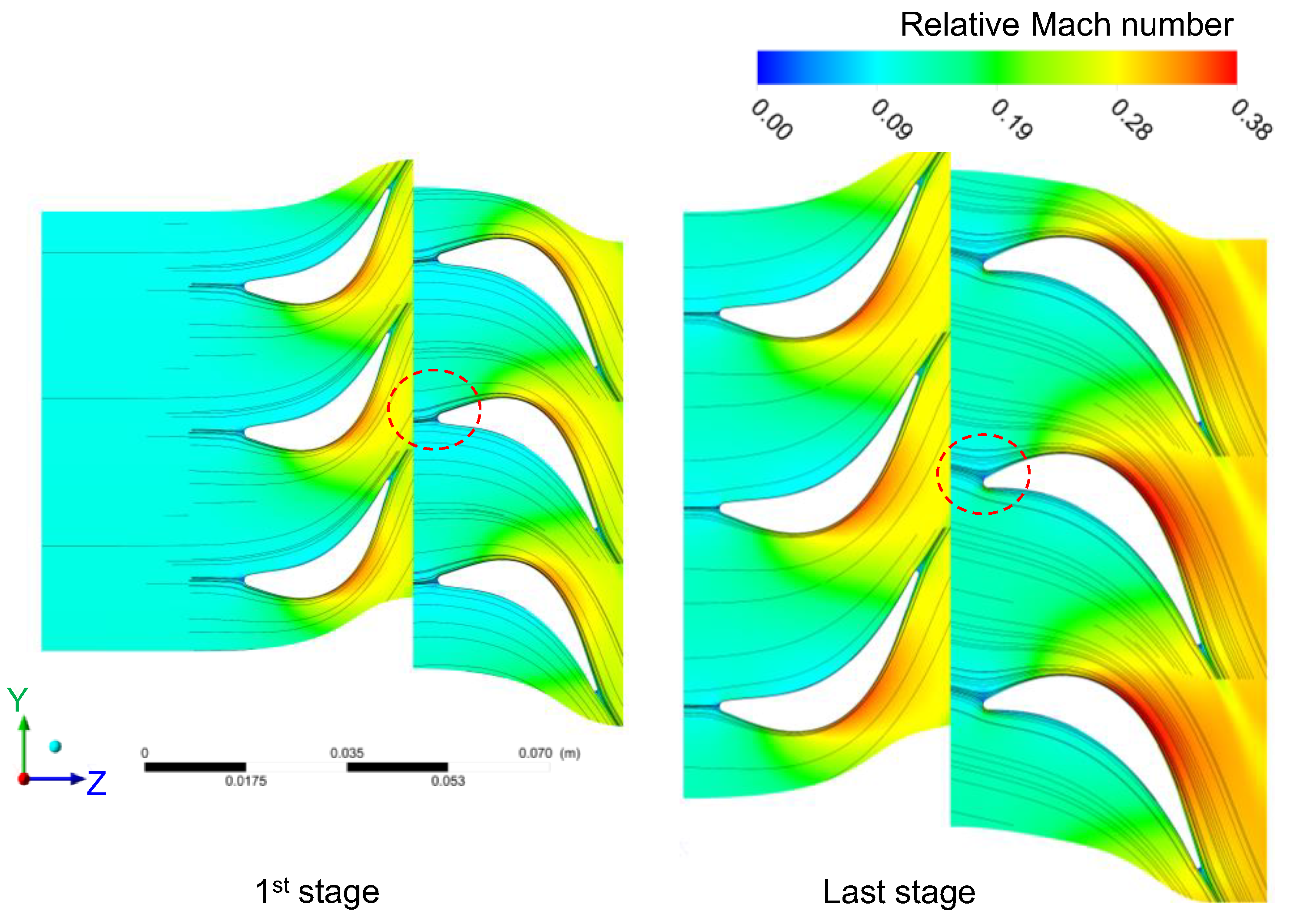

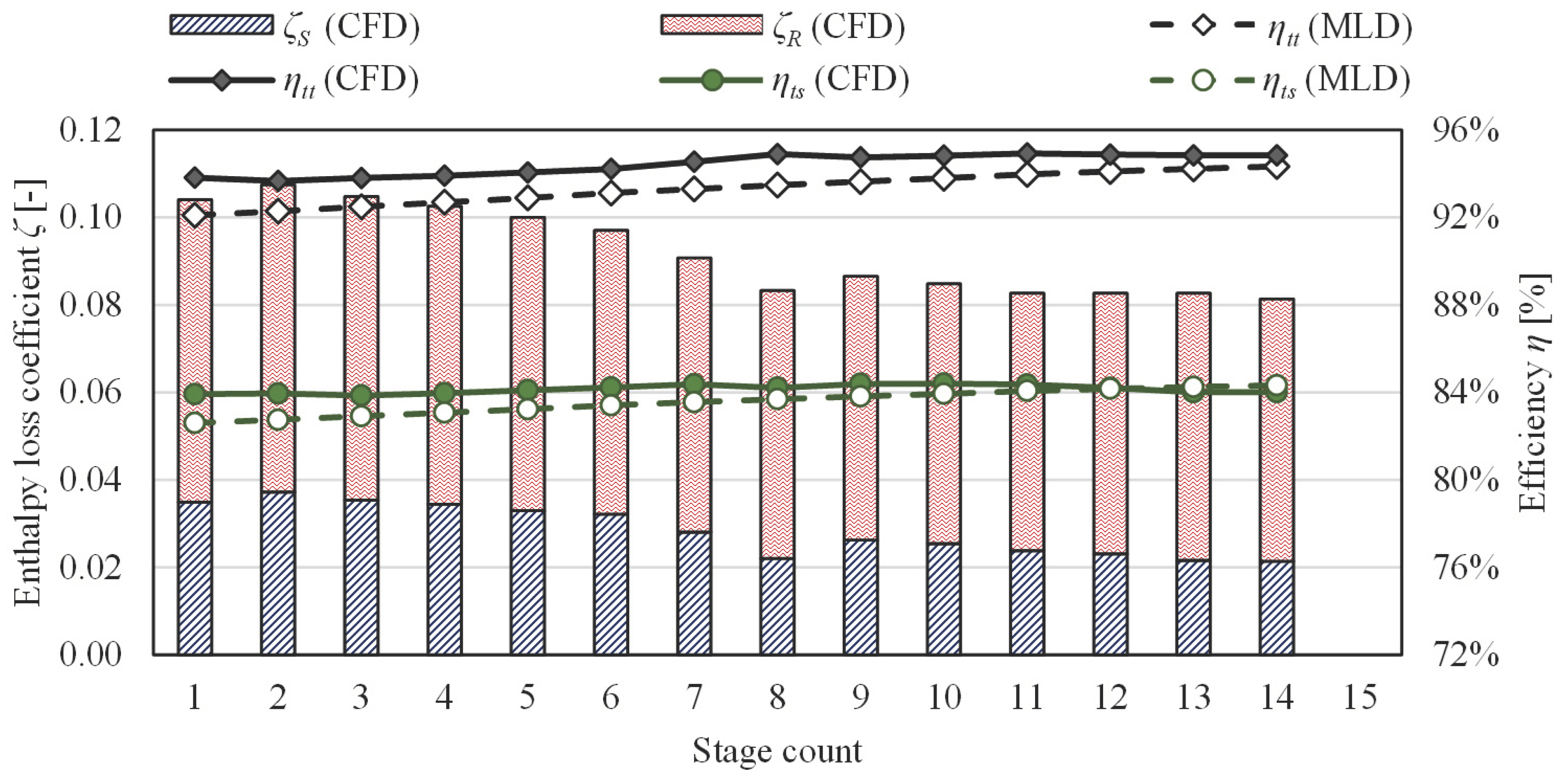

3.2. Evaluation of Design-Point Performance

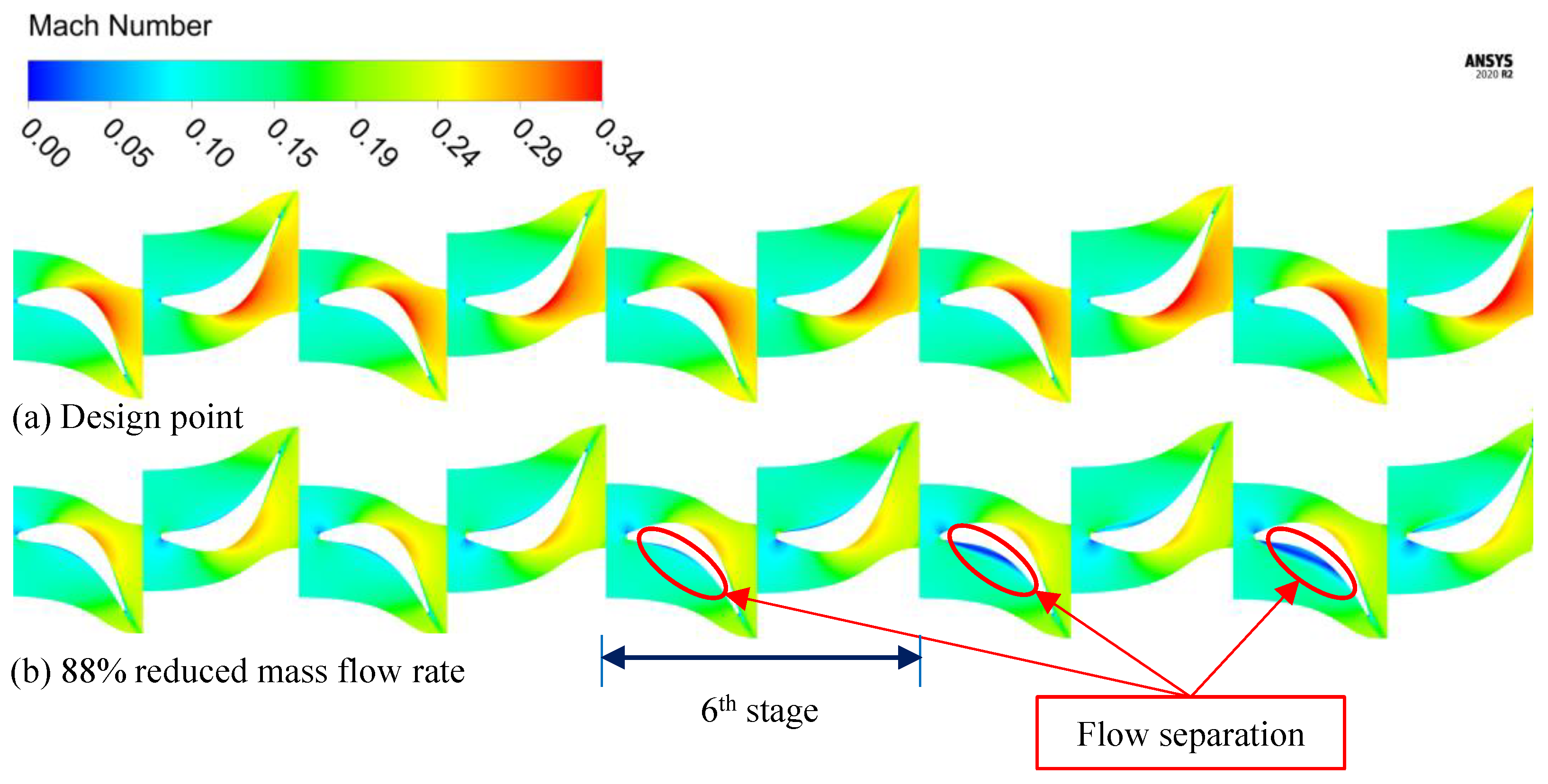

3.3. Off-Design Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abdeldayem, A.; Salah, S.; Aqel, O.; White, M.; Sayma, A. 2023 Design of a 130 MW axial turbine operating with a supercritical carbon dioxide mixture for the SCARABEUS project. In Proceeding of the 15th European Turbomachinery Conference, Budapest, Hungary, 24–28 April 2023; Paper n. ETC2023-133. Available online: https://www.euroturbo.eu/publications/conference-proceedingsrepository/ (accessed on 12 June 2023).

- White, M.T.; Bianchi, G.; Chai, L.; Tassou, S.A.; Sayma, A.I. Review of supercritical CO2 technologies and systems for power generation. Appl. Therm. Eng. 2021, 185, 116447. [Google Scholar] [CrossRef]

- Yin, J.M.; Zheng, Q.Y.; Peng, Z.R.; Zhang, X.R. Review of supercritical CO2 power cycles integrated with CSP. Int. J. Energy Res. 2020, 44, 1337–1369. [Google Scholar] [CrossRef]

- Binotti, M.; Marcoberardino, G.D.; Iora, P.; Invernizzi, C.; Manzolini, G. Scarabeus: Supercritical carbon dioxide/alternative fluid blends for efficiency upgrade of solar power plants. AIP Conf. Proc. 2020, 2303, 130002. [Google Scholar] [CrossRef]

- Meng, F.; Wang, E.; Zhang, B.; Zhang, F.; Zhao, C. Thermo-economic analysis of transcritical CO2 power cycle and comparison with Kalina cycle and ORC for a low-temperature heat source. Energy Convers. Manag. 2019, 195, 1295–1308. [Google Scholar] [CrossRef]

- Binotti, M.; Manzolini, G. Supercritical carbon dioxide/alternative fluids blends for efficiency upgrade of solar power plant. In Proceedings of the 3rd European Supercritical CO2 Conference, Paris, France, 19–20 September 2019; pp. 141–149. [Google Scholar] [CrossRef]

- Tafur-Escanta, P.; Valencia-Chapi, R.; López-Paniagua, I.; Coco-Enríquez, L.; Muñoz-Antón, J. Supercritical CO2 Binary Mixtures for Recompression Brayton s-CO2 Power Cycles Coupled to Solar Thermal Energy Plants. Energies 2021, 14, 4050. [Google Scholar] [CrossRef]

- Manzolini, G.; Binotti, M.; Morosini, E.; Sanchez, D.; Crespi, F.; Marcoberdino, G.D.; Iora, P.; Invernizzi, C. Adoption of CO2 blended with C6F6 as working fluid in CSP plants. AIP Conf. Proc. 2022, 2445, 090005. [Google Scholar] [CrossRef]

- Crespi, F.; de Arriba, P.R.; Sánchez, D.; Muñoz, A. Preliminary investigation on the adoption of CO2-SO2 working mixtures in a transcritical Recompression cycle. Appl. Therm. Eng. 2022, 211, 118384. [Google Scholar] [CrossRef]

- Crespi, F.; Martínez, G.; Rodriguez de Arriba, P.; Sánchez, D.; Jiménez-Espadafor, F. Influence of working fluid composition on the optimum characteristics of blended supercritical carbon dioxide cycles. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Virtual, Online, 7–11 June 2021; American Society of Mechanical Engineers: New York, NY, USA, 2021; p. V010T030A030. [Google Scholar] [CrossRef]

- Crespi, F.; de Arriba, P.R.; Sánchez, D.; Ayub, A.; Di Marcoberardino, G.; Invernizzi, C.M.; Martínez, G.; Iora, P.; Di Bona, D.; Binotti, M. Thermal efficiency gains enabled by using CO2 mixtures in supercritical power cycles. Energy 2022, 238, 121899. [Google Scholar] [CrossRef]

- Schubert, D. Boron oxides, boric acid, and borates. In Kirk-Othmer Encyclopedia of Chemical; Wiley: Hoboken, NJ, USA, 2000; Volume 4, pp. 1–68. [Google Scholar] [CrossRef]

- Novales, D.; Erkoreka, A.; De la Peña, V.; Herrazti, B. Sensitivity analysis of supercritical CO2 power cycle energy and exergy efficiencies regarding cycle component efficiencies for concentrating solar power. Energy Convers. Manag. 2019, 182, 430–450. [Google Scholar] [CrossRef]

- Dostal, V.; Driscoll, M.J.; Hejzlar, P. A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors. Ph.D. Thesis, Czech Technical University, Prague, Czech Republic, 2004. [Google Scholar]

- Brun, K.; Friedman, P.; Dennis, R. 7-Turbomachinery. In Fundamentals and Applications of Supercritical Carbon Dioxide (sCO2) Based Power Cycles, 1st ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 147–215. [Google Scholar]

- Zhang, H.; Zhao, H.; Deng, Q.; Feng, Z. Aerothermodynamic design and numerical investigation of supercritical carbon dioxide turbine. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Montreal, QC, Canada, 15–19 June 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; p. V009T036A007. [Google Scholar] [CrossRef]

- Shi, D.; Zhang, L.; Xie, Y.; Zhang, D. Aerodynamic design and off-design performance analysis of a multi-stage S-CO2 axial turbine based on solar power generation system. Appl. Sci. 2019, 9, 714. [Google Scholar] [CrossRef]

- Bidkar, R.A.; Mann, A.; Singh, R.; Sevincer, E.; Cich, S.; Day, M.; Kulhanek, C.D.; Thatte, A.M.; Peter, A.M.; Hofer, D.; et al. Conceptual designs of 50 MWe and 450 MWe supercritical CO2 turbomachinery trains for power generation from coal. Part 1: Cycle and turbine. In Proceedings of the 5th International Symposium-Supercritical CO2, San Antonio, TX, USA, 28–31 March 2016. [Google Scholar]

- Kalra, C.; Hofer, D.; Sevincer, E.; Moore, J.; Brun, K. Development of high efficiency hot gas turbo-expander for optimized CSP supercritical CO2 power block operation. In Proceedings of the Fourth International Symposium—Supercritical CO2 Power Cycles (sCO2), Pittsburgh, Pennsylvania, 9–10 September 2014; pp. 1–11. [Google Scholar]

- Schmitt, J.; Willis, R.; Amos, D.; Kapat, J.; Custer, C. Study of a supercritical CO2 turbine with TIT of 1350 K for Brayton cycle with 100 MW class output: Aerodynamic analysis of stage 1 vane. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Düsseldorf, Germany, 16–20 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V03BT36A019. [Google Scholar] [CrossRef]

- Aqel, O.; White, M.; Sayma, A. Binary interaction uncertainty in the optimisation of a transcritical cycle: Consequences on cycle and turbine design. In Proceedings of the 4th European sCO2 Conference for Energy Systems, Online Conference, 23–24 March 2021; pp. 164–176. [Google Scholar] [CrossRef]

- Abdeldayem, A.; White, M.; Paggini, A.; Ruggiero, M.; Sayma, A.I. Integrated Aerodynamic and Structural Blade Shape Optimisation of Axial Turbines Operating with Supercritical Carbon Dioxide Blended with Dopants. J. Eng. Gas Turbine Power 2022, 144, 101016. [Google Scholar] [CrossRef]

- Abdeldayem, A.; Paggini, A.; Diurno, T.; Orazi, C.; White, M.; Ruggiero, M.; Sayma, A. Integrated aerodynamic and mechanical design of a large-scale axial turbine operating with supercritical carbon dioxide mixtures. J. Eng. Gas Turbine Power 2023, 146, 021011. [Google Scholar] [CrossRef]

- Salah, S.I.; Khader, M.A.; White, M.T.; Sayma, A.I. Mean-line design of a supercritical CO2 micro axial turbine. Appl. Sci. 2020, 10, 5069. [Google Scholar] [CrossRef]

- Salah, S.I.; White, M.T.; Sayma, A.I. A comparison of axial turbine loss models for air, sCO2 and ORC turbines across a range of scales. Int. J. Thermofluids 2022, 15, 100156. [Google Scholar] [CrossRef]

- Smith, S. A simple correlation of turbine efficiency. Aeronaut. J. 1965, 69, 467–470. [Google Scholar] [CrossRef]

- Kacker, S.; Okapuu, U. A mean line prediction method for axial flow turbine efficiency. J. Eng. Power 1982, 104, 111–119. [Google Scholar] [CrossRef]

- Ainley, D.; Mathieson, G. A Method of Performance Estimation for Axial-Flow Turbines. Aeronautical Research Council. Reports and Memoranda; Her Majesty’s Stationery Office: London, UK, 1951; Available online: https://reports.aerade.cranfield.ac.uk/handle/1826.2/3538 (accessed on 11 June 2023).

- Aungier, R.H. Turbine Aerodynamics; American Society of Mechanical Engineers Press: New York, NY, USA, 2006. [Google Scholar]

- Salah, S.I.; Crespi, F.; White, M.T.; Muñoz, A.; Paggini, A.; Ruggiero, M.; Sánchez, D.; Sayma, A.I. Axial turbine flow path design for concentrated solar power plants operating with CO2 blends. Appl. Therm. Eng. 2023, 230, 120612. [Google Scholar] [CrossRef]

- Abdeldayem, A.; White, M.T.; Sayma, A.I. Comparison of CFD predictions of supercritical carbon dioxide axial flow turbines using a number of turbulence models. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Virtual, Online, 7–11 June 2021; American Society of Mechanical Engineers: New York, NY, USA, 2021; p. V010T030A010. [Google Scholar] [CrossRef]

- Touil, K.; Ghenaiet, A. Simulation and analysis of vane-blade interaction in a two-stage high-pressure axial turbine. Energy 2019, 172, 1291–1311. [Google Scholar] [CrossRef]

- Baudouin, O.; Dechelotte, S.; Guittard, P.; Vacher, A. Simulis® Thermodynamics: An open framework for users and developers. In Computer Aided Chemical Engineering; Braunschweig, B., Joulia, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 635–640. [Google Scholar]

- Morosini, E.; Ayub, A.; di Marcoberardino, G.; Invernizzi, C.M.; Iora, P.; Manzolini, G. Adoption of the CO2 + SO2 mixture as working fluid for transcritical cycles: A thermodynamic assessment with optimized equation of state. Energy Convers. Manag. 2022, 255, 115263. [Google Scholar] [CrossRef]

- Abdeldayem, A.; Salah, S.; White, M.; Sayma, A. A modified loss breakdown approach for axial turbines operating with blended supercritical carbon dioxide. J. Eng. Gas Turbine Power 2023, 145, 081002. [Google Scholar] [CrossRef]

- Coull, J.D. Endwall Loss in Turbine Cascades. J. Turbomach. 2017, 139, 081004. [Google Scholar] [CrossRef]

| Design Parameter | Value | Design Parameter | Value |

|---|---|---|---|

| Surface roughness (mm) | 0.002 | 0.5 | |

| 0.5 [26] | 0.05 [27] | ||

| 1 [26] | 0.85 [28] |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Dopant | SO2 | Outlet static pressure (bar) | 81.24 |

| Dopant molar fraction (%) | 20% | Mass flow rate (kg/s) | 827 |

| Turbine inlet total pressure (bar) | 239 | Rotational speed (RPM) | 3000 |

| Turbine inlet total temperature (K) | 973 |

| Parameter | S1 | R1 | S7 | R7 | S14 | R14 |

|---|---|---|---|---|---|---|

| Axial chord (mm) | 35.53 | 38.96 | 40.43 | 44.28 | 48.75 | 53.12 |

| Hub radius (mm) | 310.61 | |||||

| Inlet tip radius (mm) | 365.17 | 366.54 | 386.34 | 387.54 | 423.51 | 425.21 |

| Outlet tip radius (mm) | 366.17 | 368.04 | 387.21 | 389.81 | 424.74 | 428.99 |

| No. of blades | 58 | 53 | 53 | 48 | 47 | 42 |

| Tip gap (mm) | - | 0.515 | - | 0.546 | - | 0.601 |

| Parameter | Unit | MLD | CFD | Difference |

|---|---|---|---|---|

| kg/s | 827.06 | 822.9 | 0.51% | |

| MW | 131.9 | 130.1 | 1.38% | |

| % | 93.84 | 92.90 | 1.01% | |

| % | 93.06 | 91.95 | 1.21% |

| Model | (kg/s) | (%) | (MPa) | (MPa) | |

|---|---|---|---|---|---|

| Reference geometry | 898.22 | 10.07 | 93.15 | 445.70 | 310.64 |

| Increase outlet wedge angle (decrease throat opening 5%) | 846.46 | 9.60 | 92.98 | 333.28 | 258.38 |

| Increase the base aerofoil thickness (around 25%) | 873.38 | 9.76 | 92.77 | 272.13 | 237.99 |

| Increase the whole blade thickness (around 25%) | 848.72 | 9.46 | 92.19 | 269.86 | 223.97 |

| Increase base fillet radius from 1 mm to 2 mm | 890.15 | 9.85 | 92.86 | 238.36 | 264.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Abdeldayem, A.S.; Salah, S.I.; Aqel, O.A.; White, M.T.; Sayma, A.I. Design of a 130 MW Axial Turbine Operating with a Supercritical Carbon Dioxide Mixture for the SCARABEUS Project. Int. J. Turbomach. Propuls. Power 2024, 9, 5. https://doi.org/10.3390/ijtpp9010005

Abdeldayem AS, Salah SI, Aqel OA, White MT, Sayma AI. Design of a 130 MW Axial Turbine Operating with a Supercritical Carbon Dioxide Mixture for the SCARABEUS Project. International Journal of Turbomachinery, Propulsion and Power. 2024; 9(1):5. https://doi.org/10.3390/ijtpp9010005

Chicago/Turabian StyleAbdeldayem, Abdelrahman S., Salma I. Salah, Omar A. Aqel, Martin T. White, and Abdulnaser I. Sayma. 2024. "Design of a 130 MW Axial Turbine Operating with a Supercritical Carbon Dioxide Mixture for the SCARABEUS Project" International Journal of Turbomachinery, Propulsion and Power 9, no. 1: 5. https://doi.org/10.3390/ijtpp9010005

APA StyleAbdeldayem, A. S., Salah, S. I., Aqel, O. A., White, M. T., & Sayma, A. I. (2024). Design of a 130 MW Axial Turbine Operating with a Supercritical Carbon Dioxide Mixture for the SCARABEUS Project. International Journal of Turbomachinery, Propulsion and Power, 9(1), 5. https://doi.org/10.3390/ijtpp9010005