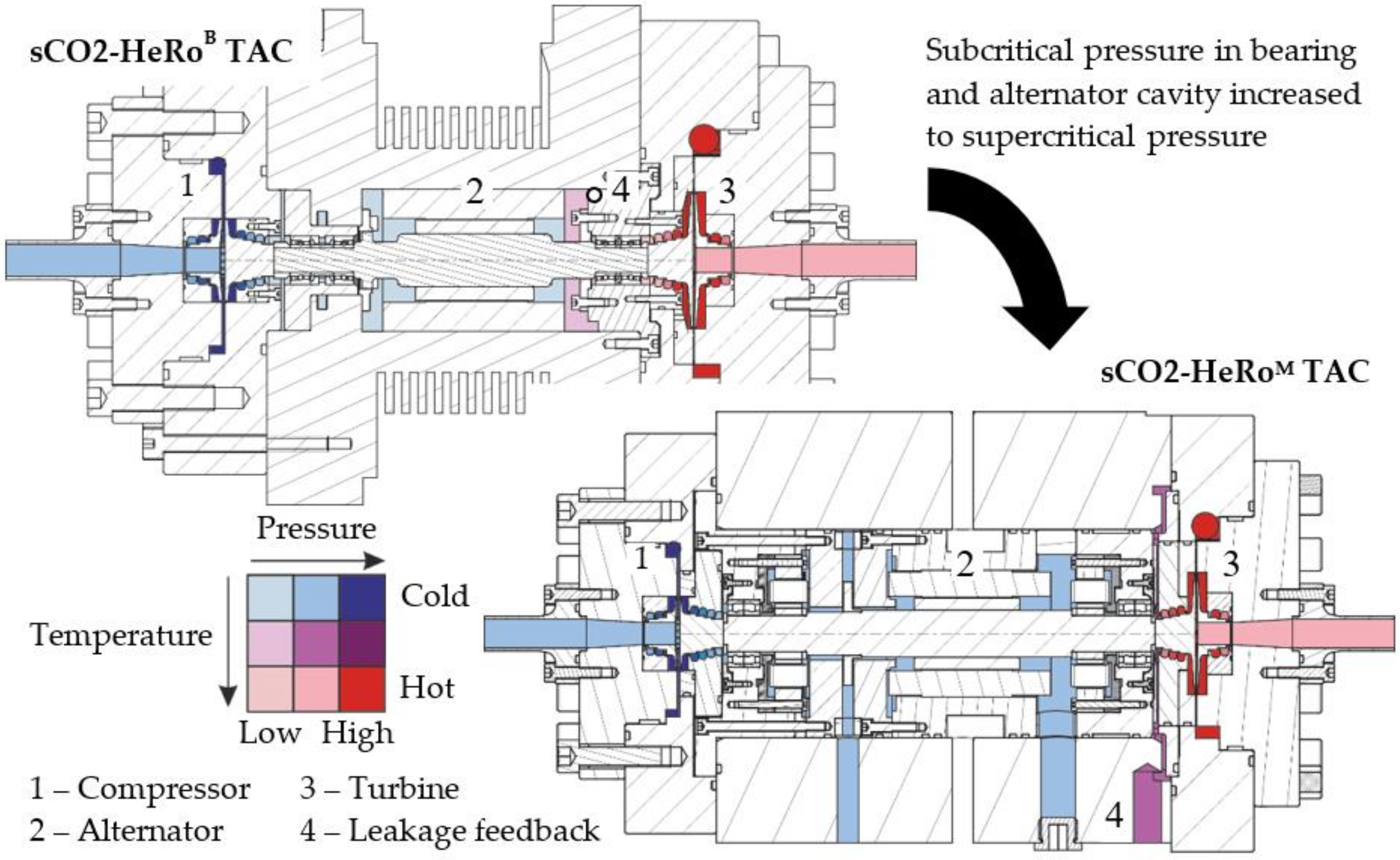

The goal of the initial operation of the sCO2-HeRo

M TAC is to prove its operability in the sCO2-HeRo cycle. It also aims to verify the concept of internal flow paths and improve understanding of the effects of rotational speed and density on the operation of the TAC in sCO

2. Based on findings of the previous chapter and the publications of Cha et al. [

4] and Kim et al. [

5], operation of a TAC with AMB becomes more difficult as density increases. Therefore, the tests start with operation in air at atmospheric pressure, considered as known conditions. Then, they proceed with CO

2 in gaseous conditions and low density. As shown in

Figure 6, the density at the compressor inlet, representing the highest density in the cycle, increased gradually starting from the gaseous state of CO

2 at 160 kg/m

3 in region I until reaching supercritical conditions for the first time in region III with a density above 300 kg/m

3. Finally, region V reached design density and design static inlet pressure of 566 kg/m

3 and 78.3 bar at the compressor inlet, respectively. Together with regions III, IV and VI, the tests covered the whole range of possible compressor inlet conditions. This includes higher static inlet pressures of up to 90 bar, maximum inlet density of 650 kg/m

3 and conditions around the critical point. During operation of the TAC in the different regions of compressor inlet conditions in

Figure 6, the deflection of the rotor and the radial, magnetic forces calculated for the bearings were monitored. Radial deflections are measured at the radial bearings with eddy current sensors monitoring the position of the rotor relative to the stator. At each bearing, four sensor pairs opposite to each other are employed. The increase of rotational speed in different regions of compressor inlet conditions is presented first. Afterwards, measurements at constant rotational speed are discussed with respect to the influence of density. Measurements are compared to obtain a qualitative understanding regarding the dependence of deflection and bearing forces on rotational speed and sCO

2 density.

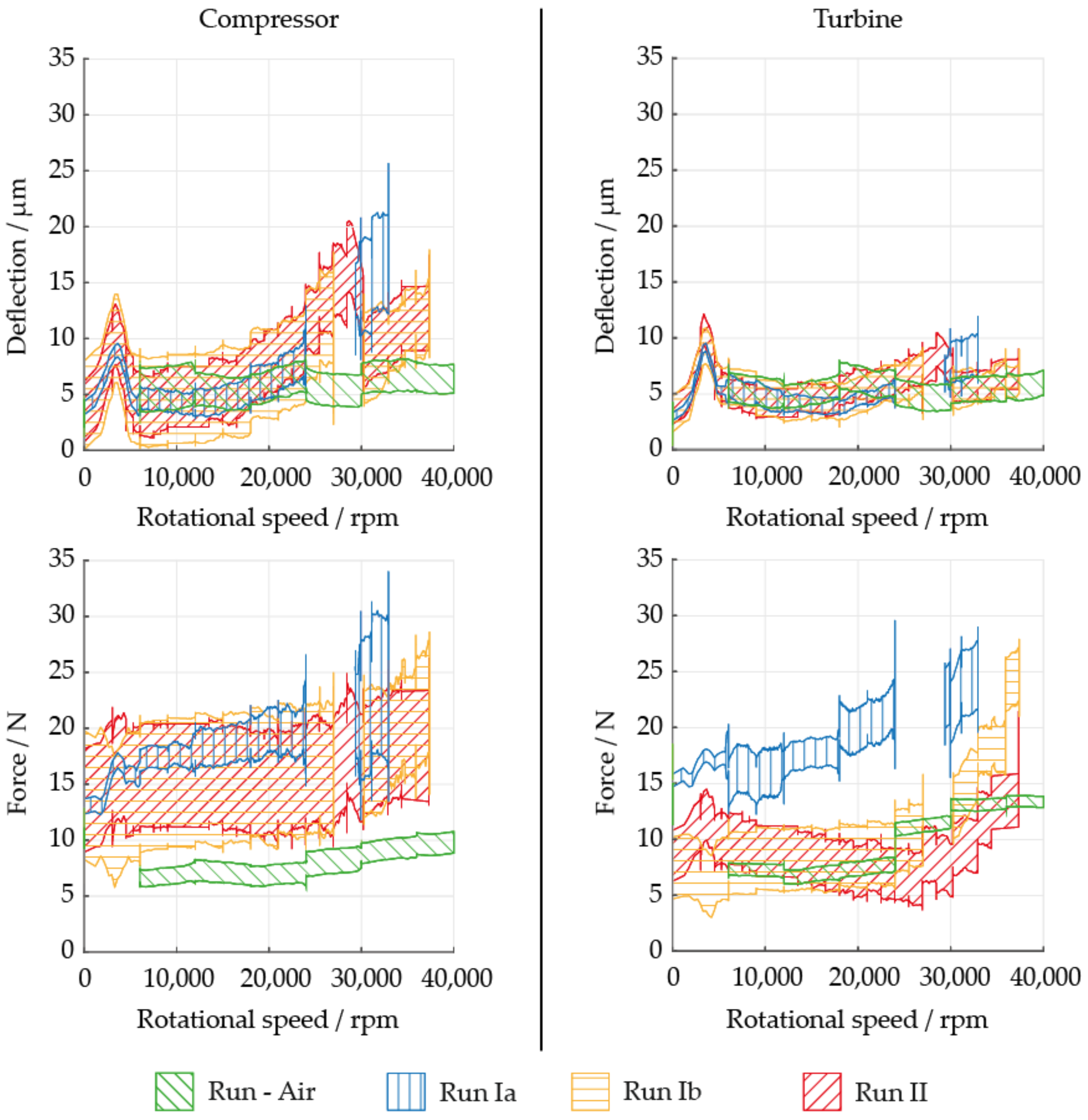

3.1. Increasing Rotational Speed

Here, a comparison between test runs in different regions of

Figure 6 is presented. Each test run also shows the effect of rotational speed on the radial deflection of the rotor and the radial forces in the bearings. From

Figure 5, the observation of an increase in force and/or deflection when increasing both rotational speed and density is expected. Whereby rotational speed is expected to demonstrate a larger effect. The analysis starts with a preliminary test conducted in air. The TAC reached a design rotational speed of 50,000 rpm as shown in

Figure 7. For readability, the (thousands) of measurement points are not depicted. Instead, the shaded areas represent the area where 90% of the measurement points are located. That means that for each rotational speed, the lower and upper bound of the shaded area are chosen in a way that 90% of measurements at the respective rotational speed are included. During air pre-tests, a basic AMB controller was used without considering rotordynamic coefficients of seals and cavities. Since air density represents only 1% of the density in region I of operation in CO

2 (see

Figure 7) and even less, only 0.3%, of the compressor design inlet density, forces due to fluid inside the impellers and cavities are considered negligible compared to operation in CO

2.

Figure 7 shows deflection of rotor at standstill to be on average 3 μm for the compressor bearing and 2 μm for the turbine bearing and to fluctuate in the same range. As speed increases, both deflection and forces increase slightly. At 50,000 rpm, the maximum deflection reached approximately 12 μm or 15% of the maximum clearance in the safety bearings. Forces remained well below 10% of the maximum bearing force.

In general, the preliminary air test reached 50,000 rpm and showed the rotor to be well-balanced and clearances to be as designed. It proved general operability of the TAC and provided the basis for further testing in CO2.

The next step included the first tests regions I–III in

Figure 6, where CO

2 was in a gaseous or gas-like state. From regions I–III, the density increases at the compressor inlet and in the whole cycle. Furthermore, the density difference between the turbine inlet and compressor inlet is small because the maximum temperature of CO

2 is kept well below 60 °C. Finally, the maximum speed during these tests is limited to 40,000 rpm because, unlike tests in air, the TAC relies on turbine power to reach maximum speed owing to the higher density at the compressor requiring more power. Due to low compressor inlet density and low turbine inlet temperature, this power cannot be provided.

Figure 8 presents a comparison of measurements for three test runs and the test run in air. Test run Ia and Ib are at the density in region I and run II is in region II. During run Ia, the initial controller design used for the air test was not modified. As in the air test, increased deflections and forces were observed as rotational speed increased. Moreover, the fluctuations in measurements (depicted as larger enclosed area) now seem to also increase. Above 20,000 rpm, the deflections are larger than for the test run with air, especially on the compressor side.

Figure 8 shows large deflections of about 25 μm or 31% of the clearance at the compressor bearing at a speed of 33,000 rpm or 66% of design rotational speed. This is already more than twice the deflection found in the air test at design rotational speed. Note the peak at approximately 5000 rpm, which indicates switching on the imbalance controller. It is active for larger rotational speeds and strongly reduces the deflection of the rotor. Similar action is taken again during test runs Ib and II. The controller parameters are changed so that the deflection of the rotor is reduced at speeds above 27,000 rpm. Therefore, there is drastically less deflection of the rotor for rotational speeds above 27,000 rpm compared to run Ia. For approximately 38,000 rpm, values are now 40–50% larger than values at design speed in the test run with air. Observing the radial force in both bearings, the forces in the compressor bearing are larger than for the air case. On the other hand, forces in the turbine bearing remain similar but for larger fluctuations (larger enclosed area). Run Ia is an exception, exhibiting a much larger force. It is interesting to note that changing the control parameters when exceeding 27,000 rpm leads to a steeper increase in the forces as a function of speed.

These observations suggest that conditions in CO2 indeed have an effect on operating the TAC with AMB. The reason for the observed behavior is likely due to the approximately 100-fold higher density. Furthermore, a change in control parameters is required to balance the effect of CO2 on the rotor.

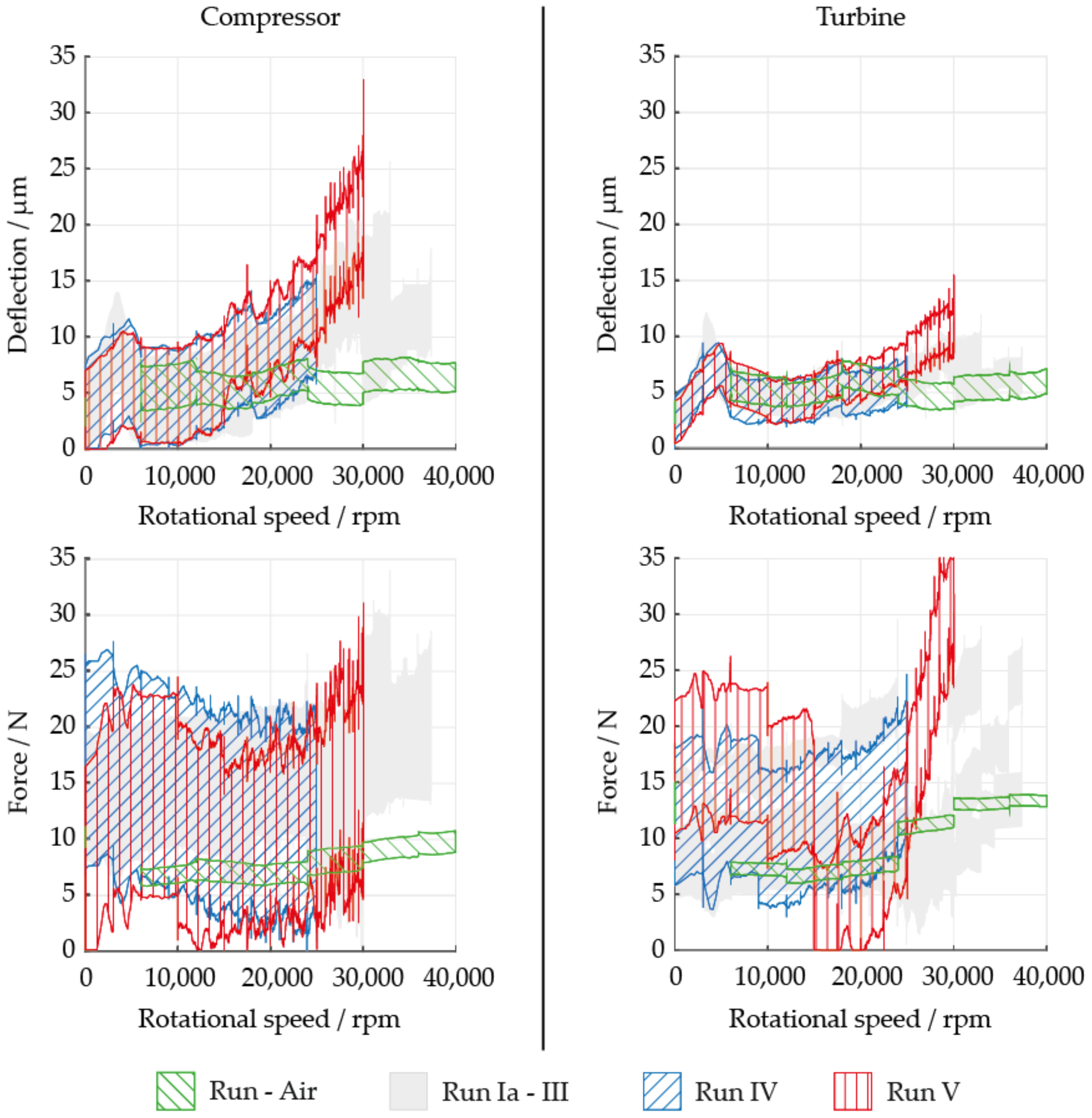

The next step is test run III, where CO

2 is in supercritical, gas-like conditions in region III right of the pseudocritical line (see

Figure 6). The density is now 150–200% of the density of run II, which was performed with a compressor inlet density of about 200 kg/m

3. Approaching 20,000 rpm, the deflection at both the turbine bearing and compressor increases more than previously observed (see

Figure 9). Therefore, the rotational speed for adjusting control parameters to limit deflections is reduced from 27,000 rpm to just above 18,000 rpm. This results in deflections at speeds greater than 18,000 rpm being in the same range as the previous test runs in CO

2. A change in forces similar to before is observed. However, the size of the enclosed area representing the scatter of radial forces of the bearings increases rather than the mean value. The fluctuations are approximately twice as large as previously measured. Again, it is assumed that this is related to the increasing interaction of CO

2 with the rotor due to greater density.

Finally, compressor inlet conditions for test run IV and V are brought to liquid-like sCO

2 conditions left of the pseudocritical line in regions III, IV and V. The test runs featured compressor inlet densities of about 450 kg/m

3 and 600 kg/m

3, respectively. Note that the density at the turbine inlet remains similar to test run III due to the elevated inlet temperature. As in the previous run, the maximum deflection increases mainly at the compressor bearing (see

Figure 10). The maximum deflection reaches 40% of the clearance height at approximately 30,000 rpm (60% of design speed). While maximum force in

Figure 10 and its fluctuation at the compressor are similar to previous tests, the scatter of measured values for deflection increases. For the turbine bearing, a reduction in force can be seen at 15,000 rpm when the turbine bypass valve that was previously completely open is closed to 30%. At 25,000 rpm, it is closed to 10%, resulting in an increase in force at the turbine bearing. Additionally, the force increases more rapidly as rotational speed rises. Between 11% and 30% opening of the turbine bypass marks the point at which the flow direction changes at the turbine. While the turbine impeller “pumps” sCO

2 due to e.g., friction at the disk when the pressure ratio across the turbine is low due to the open bypass valve, closing the valve means the pumping effect can no longer overcome the rising pressure ratio. Thus, a “wrong” flow direction at the turbine results in a larger force on the turbine bearing. In addition, deflections up to 15,000 rpm are in a similar range to the air tests, but become much larger at speeds near 30,000 rpm. Therefore, future test runs require further modification of the control parameters to achieve speeds above 30,000 rpm when the compressor is operated with high-density liquid-like CO

2.

The speed up tests showed that at low rotational speeds of up to 15,000 rpm, deflection is similar to the test run in air, regardless of density. It appears that the AMB is able to compensate the influence of sCO2, even though larger forces are required. At larger rotational speeds, radial deflections and forces remain almost constant in test run with air, while the values and scatter of the measurements increase significantly for test runs in CO2. The difference becomes larger when the density at the compressor inlet increases. As shown, a change of AMB control parameters can reduce deflections at the cost of larger forces. Therefore, AMBs are able to actively compensate the effect of sCO2 on the rotor in the speed and density range investigated.

3.2. Increasing Density

The previous section clearly shows that the radial deflection of the rotor and the radial forces in the bearings increase with speed. It also shows an increase in deflection and bearing forces for test runs in regions with higher compressor inlet density. A similar result is presented by Kim et al. [

6], who describe the effect of different sCO

2 conditions on radial force on the rotor for a cylindrical shell-type rotor–stator cavity. They show that an increase in density can also increase forces of sCO

2 on the rotor. To investigate the effect more closely, measurements at a constant rational speed are presented.

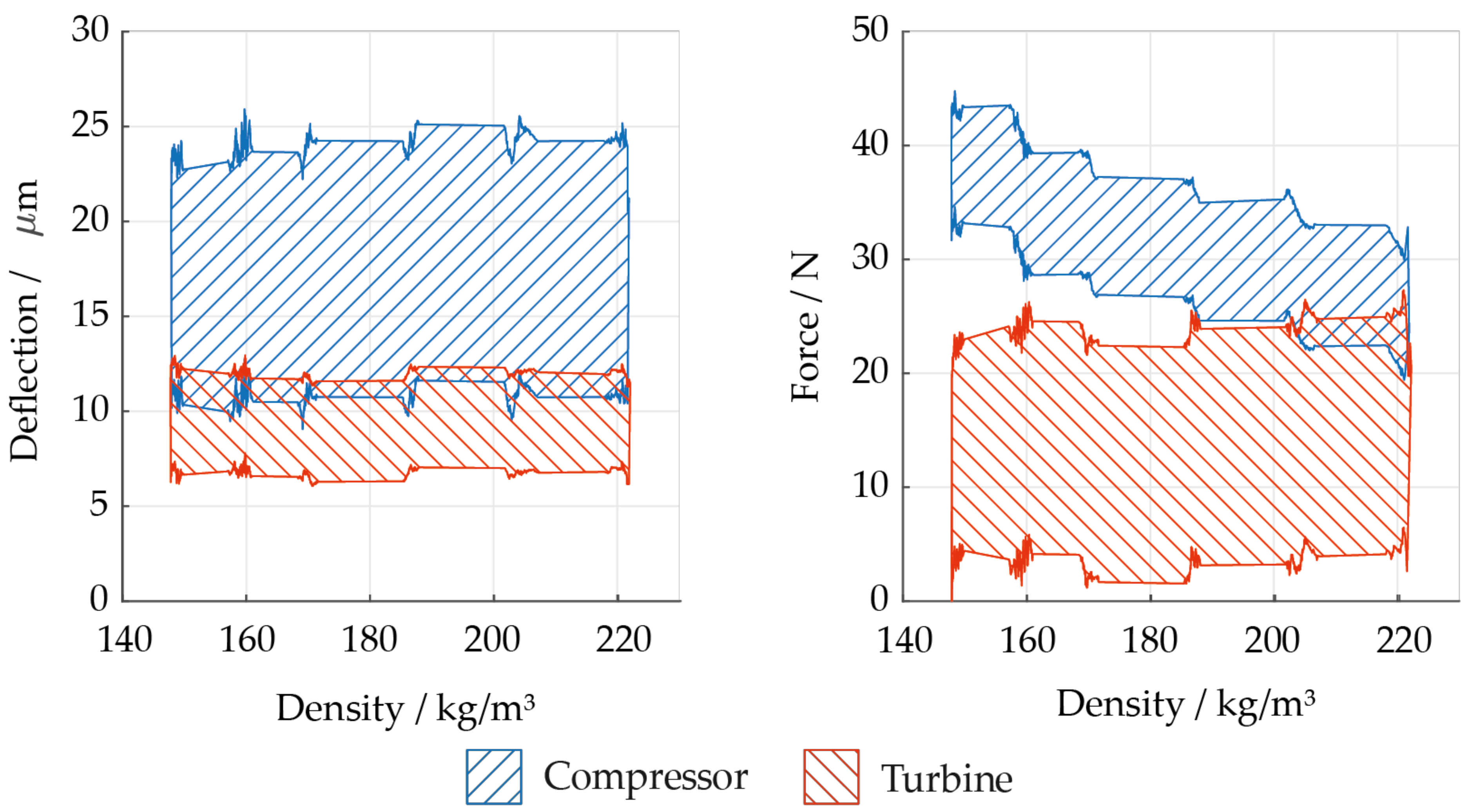

Figure 11 shows that an increase in compressor inlet density indeed increases radial deflection of the rotor and radial forces inside the bearings. However, it should be noted that the increase of compressor inlet density has several effects. For example, it leads to an increase in the pressure ratio and thus in the force acting on the blades of the impeller.

To separate the different effects of increases in density, the pressure ratio is more closely examined. The pressure ratio can usually be changed by altering the flow rate of the compressor. The sCO2-HeRo cycle features a compressor bypass valve for this purpose. However, the change in pressure ratio due to closure of the bypass valve is small and no effect on deflection or radial bearing forces was observed. This is due to flat curves of constant speed in the compressor performance map (compare Hacks et al. [

3]). However, the pressure rise in the compressor is strongly dependent on its inlet density (compare Hacks et al. [

9,

10]). In the case of

Figure 11, it doubles as inlet density increases from 325 kg/m³ to 580 kg/m³. Therefore, it can be concluded that a change of flow rate at the compressor inlet is not responsible for the increase in bearing forces and radial deflection of the rotor but the direct effect of density on pressure rise might be.

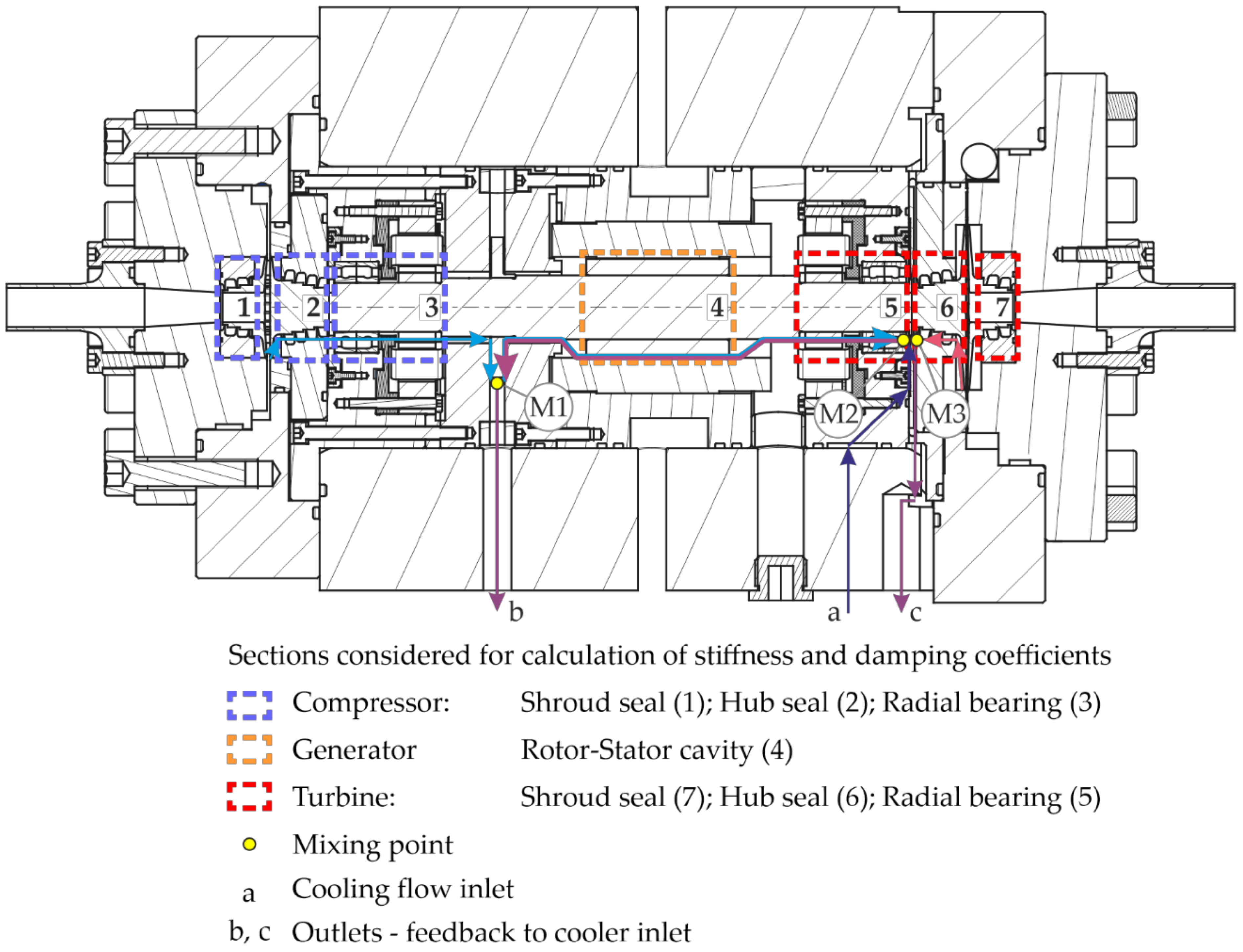

Second, the effect of density inside the rotor–stator cavities is analyzed. As

Figure 5 indicates, fluid forces inside rotor–stator cavities increase with local density, which was also reported by Kim et al. [

6]. Here, only the effect of changing the density in the generator cavity is considered, because design calculations indicated the largest destabilizing forces to be caused by CO

2 inside the cavity (see

Figure 4).

Figure 12 presents the radial deflection of the rotor and radial bearing forces for one set of measurements when the valve controlling the cooling flow rate (a) was throttled. The further this valve is throttled, the lower the density inside the generator cavity becomes. The expectation is that lower density reduces the deflection of the rotor and radial force in the AMB due to smaller destabilizing forces. However,

Figure 12 shows no considerable change of deflection and larger forces for smaller density inside the cavity (contrary to expectations). The behavior was also checked for other series of measurements. While the change in radial force is often less pronounced than in

Figure 12, no definite increase in deflection or radial force is observed with density. The reason behind this is uncertain, but might be related to one of the following reasons. Leakage flow over the hub seal of the turbine impeller mixes with the cooling flow rate (a) inside the TAC (see

Figure 3). Neither of the two mass flows can be measured directly, but must be calculated. Since the mixing with the leakage flow occurs inside the TAC, only the density inside the cavity is calculated and thus subject to uncertainties in calculating mass flow over the seal and valve. Another reason could be that according to the model used for

Figure 5, the direct stiffness coefficient has a quadratic dependency on rotational speed. Therefore, radial forces in the cavity might only be significant at higher rotational speeds.

Finally, it was discovered that an increase in density at the compressor inlet does not lead to an increase in density in the generator cavity, even though the cooling flow rate rises and the temperature drops. Instead, the density remains almost constant because the pressure inside the cavity decreases. This also hints that forces acting on the compressor impeller dominate the fluid forces that originated in the generator cavity. Therefore, the effects on the compressor impeller dominate the increase in radial deflection of the rotor and the increase in radial bearing forces, at least in the speed and density range studied.