Thermal Performance Evaluation in Gas Turbine Aero Engines Accessory Gearbox

Abstract

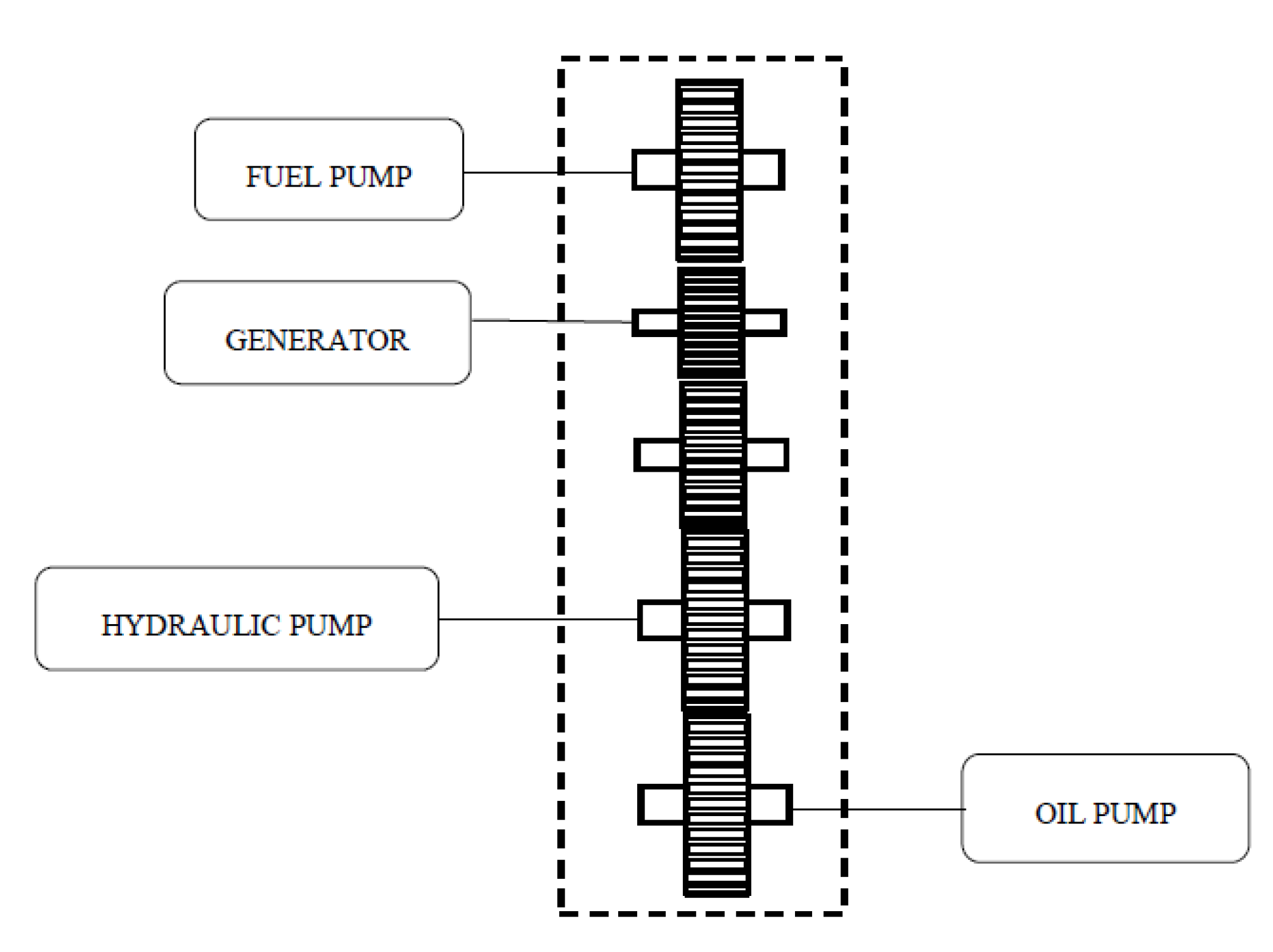

1. Introduction

2. Accessory Gearbox Heat Loss Mechanisms

3. Mathematical Modelling of Heat Losses

3.1. No-Load Dependent Losses

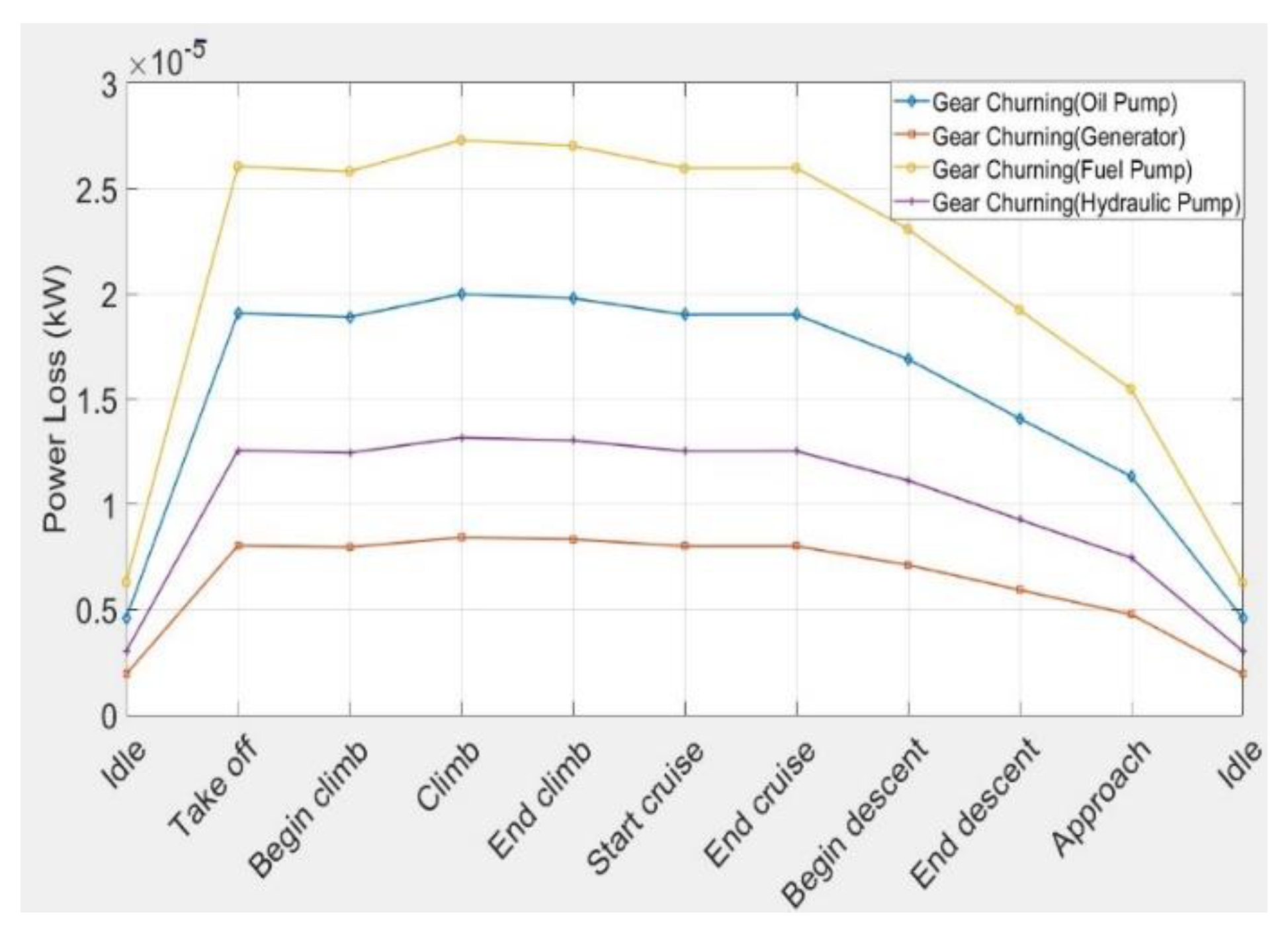

3.1.1. Gears Churning Loss

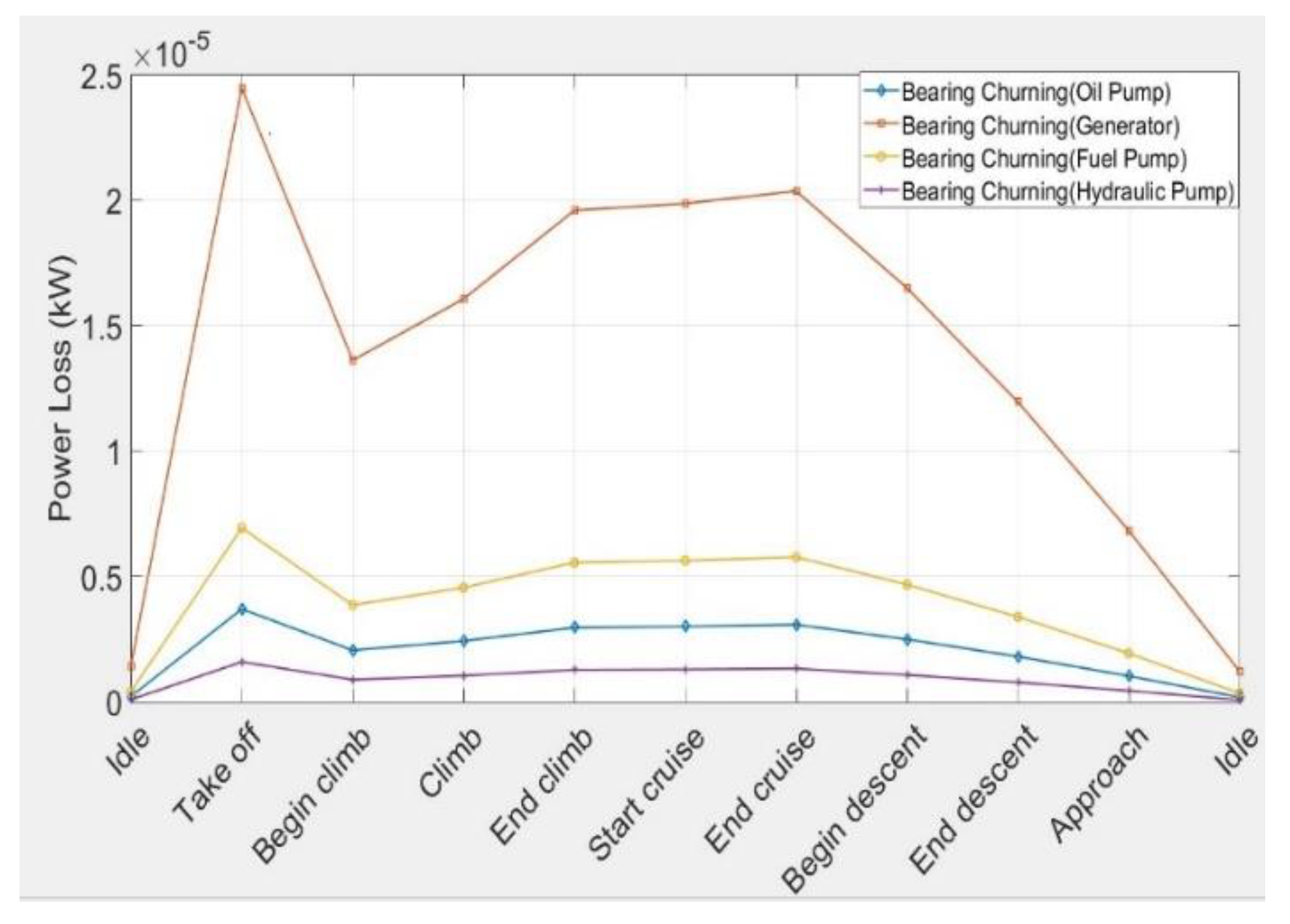

3.1.2. Bearings Churning Loss

3.1.3. Seals Churning Loss

3.2. Load Dependent Losses

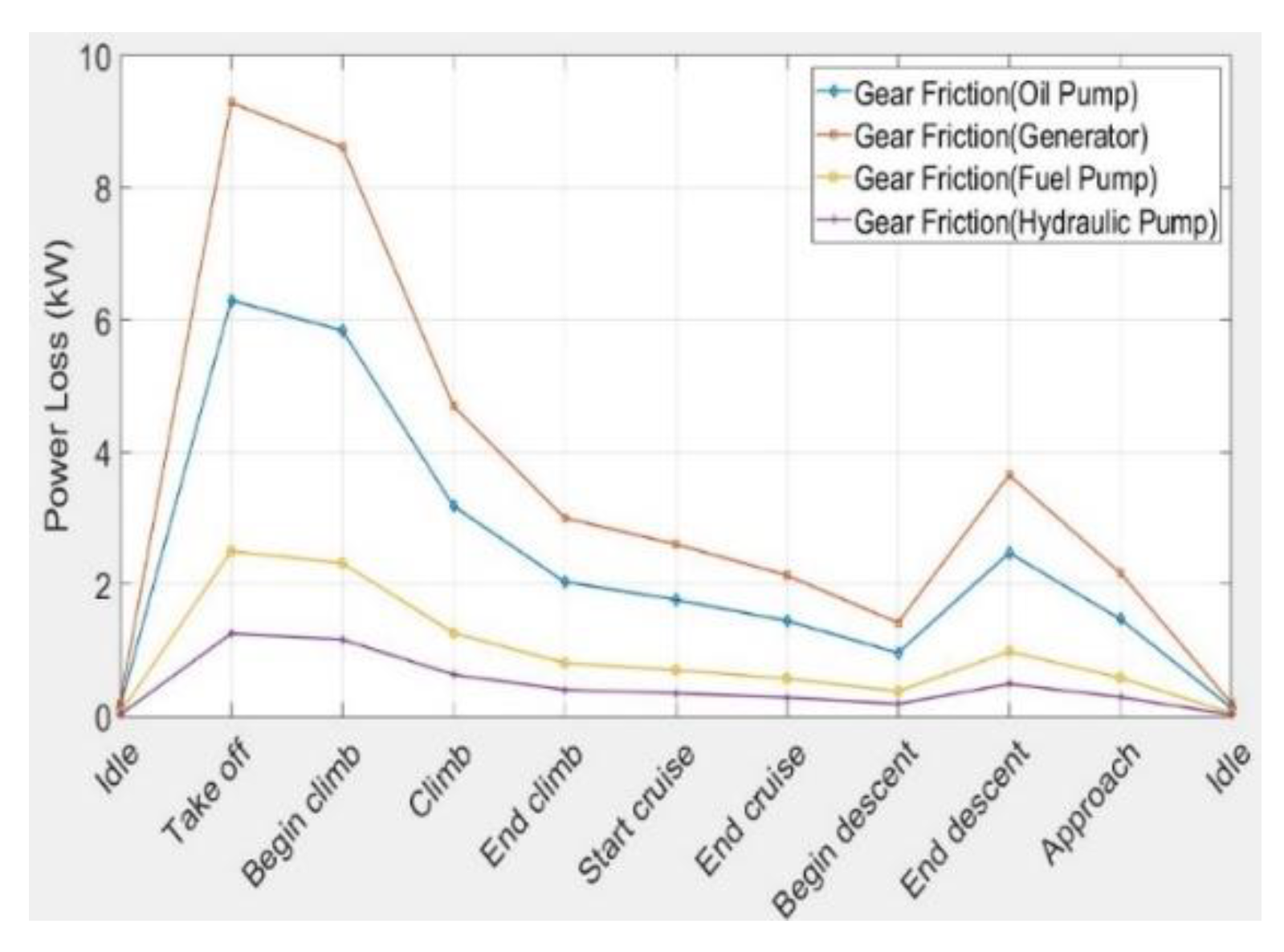

3.2.1. Power Loss in Meshing Gears

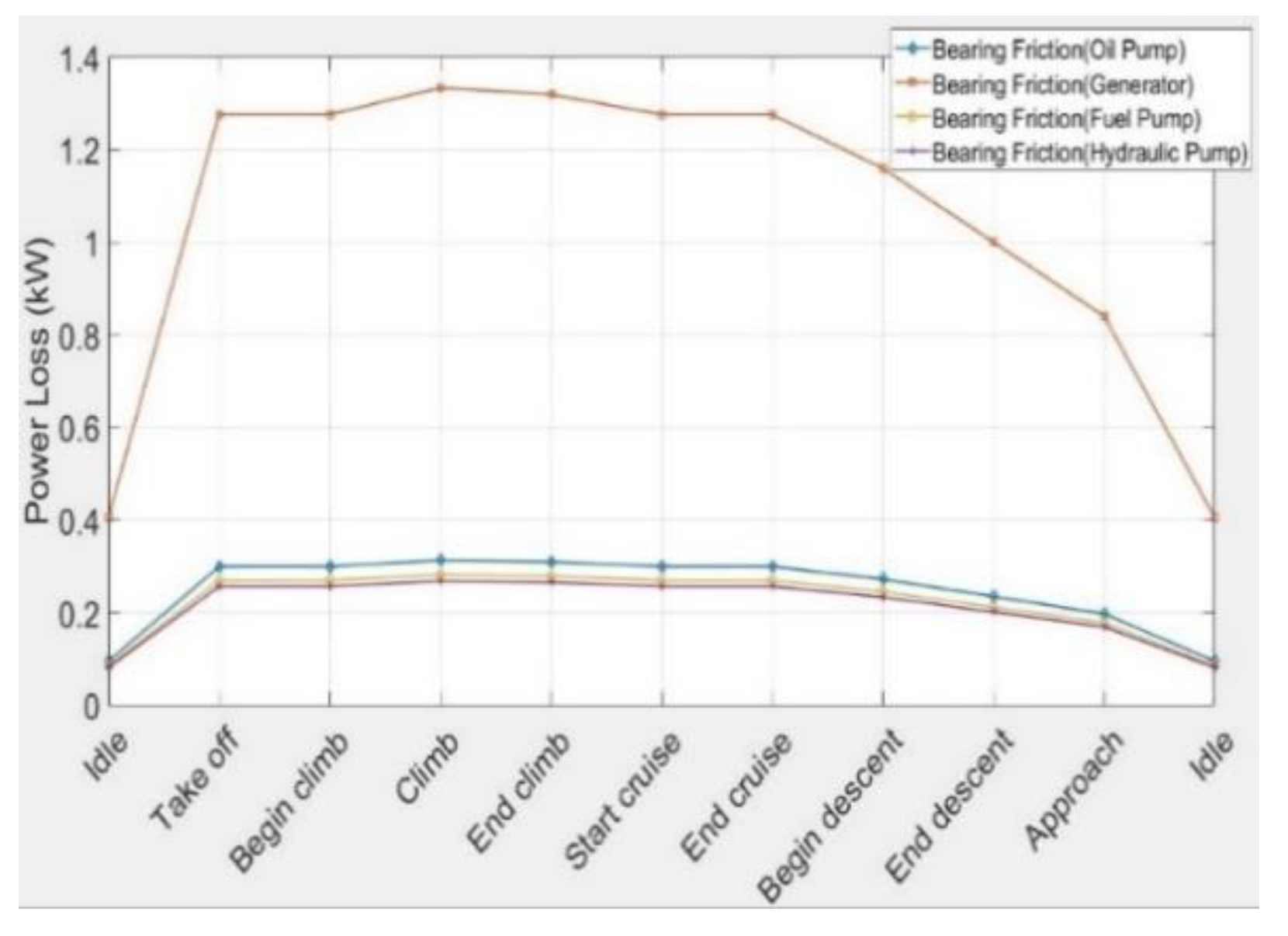

3.2.2. Power Loss in Bearings

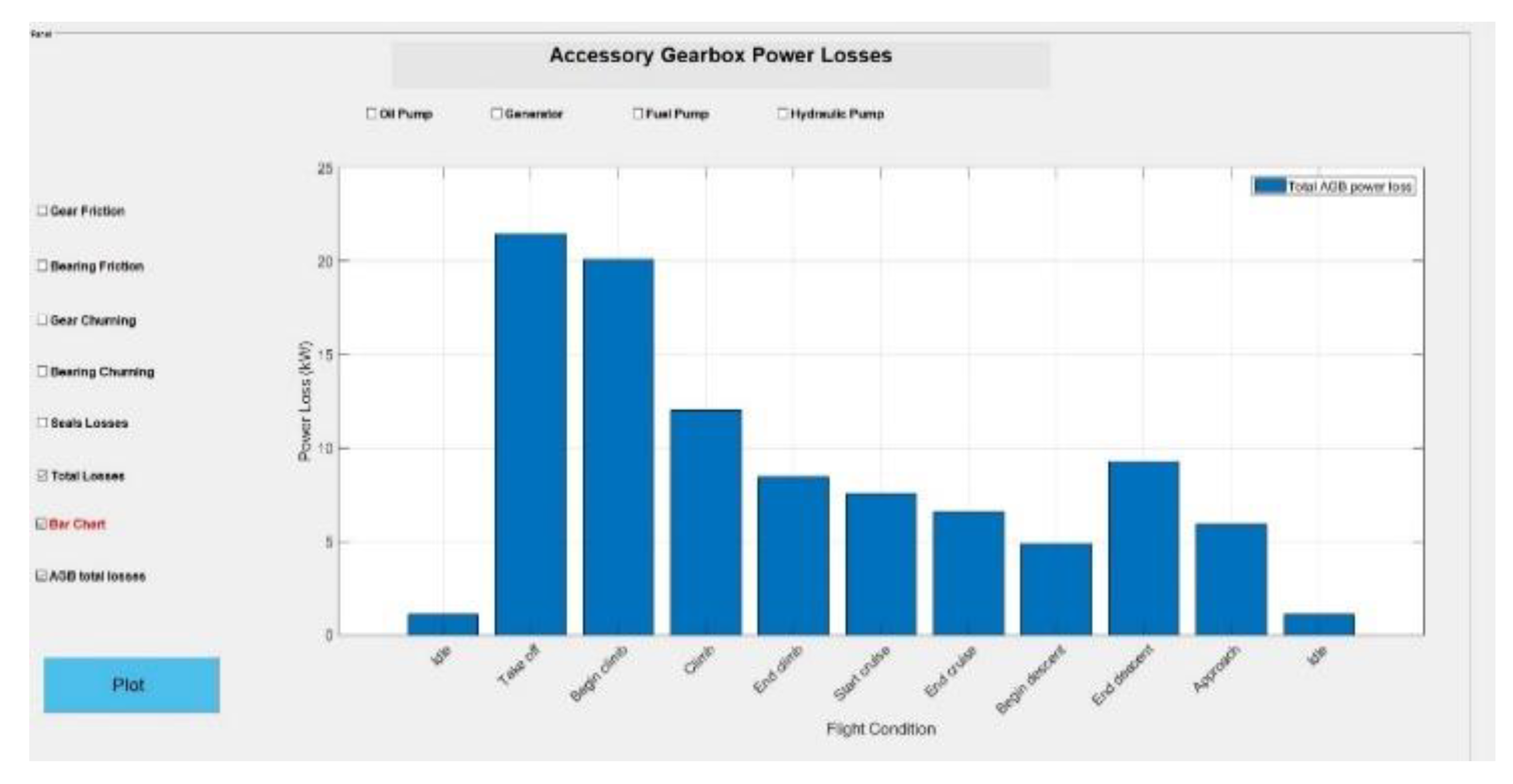

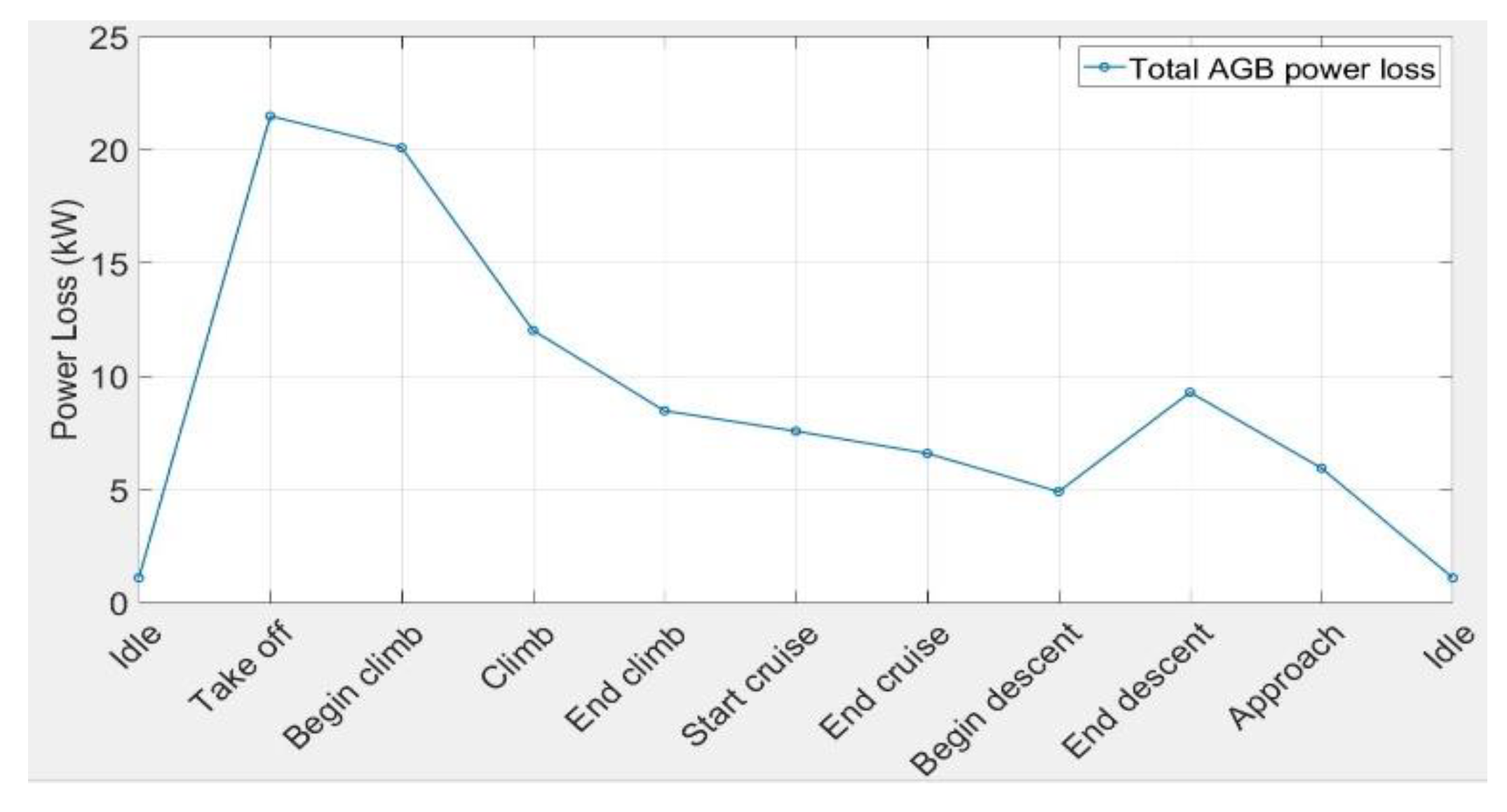

4. Results Analysis

- The gear set connected to the generator creates the highest value of loss in comparison with other elements due to the high power transmitted which causes high friction between the gears as the friction coefficient change with power transmitted.

- The oil and fuel pump gear sets have the next ranks in generating heat loads. The loss in hydraulic pump is less than 2 kW in all flight phases.

- The assumption of neglecting other elements (e.g., de-oiler and heat transfer from the engine components) is valid, as the generated heat loads would be very small (in the order of 1 kW and less).

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Directorate-General for Research and Innovation; Directorate-General for Mobility and Transport. Flightpath 2050, Europe’s Vision for Aviation Maintaining Global Leadership & Serving Society’s Needs; Report of the High-Level Group on Aviation Research; Publication office of the EU: Brussels, Belgium, 2011. [Google Scholar]

- Jafari, S.; Nikolaidis, T. Turbojet engine industrial min-max controller performance improvement using fuzzy norms. Electronics 2018, 7, 314. [Google Scholar] [CrossRef]

- Jafari, S.; Nikolaidis, T. Thermal management systems for civil aircraft engines: Review, challenges and exploring the future. Appl. Sci. 2018, 8, 2044. [Google Scholar] [CrossRef]

- Rolls Royce Deutschland Ltd. & Co KG. Heat Exchange System for A Power Gearbox, A Power Gearbox and A Turbo Engine with A Power Gear Box. Patent No. EP3244039 A1, 22 June 2017.

- Nutakor, C.; Kłodowski, A.; Sopanen, J.; Mikkola, A.; Pedrero, J.I. Planetary gear sets power loss modeling: Application to wind turbines. Tribol. Int. 2017, 105, 42–54. [Google Scholar] [CrossRef]

- Magalhães, L.; Martins, R.; Locateli, C.; Seabra, J. Influence of tooth profile and oil formulation on gear power loss. Tribol. Int. 2010, 43, 1861–1871. [Google Scholar] [CrossRef]

- Martins, R.C.; Cardoso, N.F.R.; Bock, H.; Igartua, A.; Seabra, J.H.O. Power loss performance of high pressure nitrided steel gears. Tribol. Int. 2009, 42, 1807–1815. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, Y.; Luo, C.; Feng, L.; Dai, Y. Churning power losses of a gearbox with spiral bevel geared transmission. Tribol. Int. 2019, 129, 398–406. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part I: Losses in rolling bearings. Tribol. Int. 2015, 88, 298–308. [Google Scholar] [CrossRef]

- Boness, R.J. Churning Losses of Discs and Gears Running Partially Submerged in Oil. In Proceedings of the ASME International Power Transmission and Gearing Conference, Chicago, IL, USA, 7–9 April 1989; Volume 1, pp. 355–359. [Google Scholar]

- Terekhov, A.S. Hydraulic losses in gearboxes with oil immersion. Russ. Eng. J. 1975, 55, 7–11. [Google Scholar]

- Höhn, B.R.; Michaelis, K.; Vollmer, T. Thermal Rating of Gear Drives: Balance between Power Loss and Heat Dissipation; American Gear Manufacturers Association: Alexandria, VA, USA, 1996. [Google Scholar]

- Changenet, C.; Leprince, G.; Ville, F.; Velex, P. A note on flow regimes and churning loss modeling. J. Mech. Des. 2011, 133, 121009. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Martins, R.C.; Seabra, J.H. Torque loss of type C40 FZG gears lubricated with wind turbine gear oils. Tribol. Int. 2014, 70, 83–93. [Google Scholar] [CrossRef]

- Concli, F. Low-loss gears precision planetary gearboxes: Reduction of the load dependent power losses and efficiency estimation through a hybrid analytical-numerical optimization tool. Forschung im Ingenieurwesen 2017, 81, 395–407. [Google Scholar] [CrossRef]

- Wimmer, J.A. Lastverluste von Stirnradverzahnungen: Konstruktive Einflüsse, Wirkungsgradmaximierung, Tribologie. Doctoral Dissertation, Technische Universität München, München, Germany, 2006. [Google Scholar]

- Ohlendorf, H. Verlustleistung und Erwärmung von Stirnrädern. Doctoral Dissertation, Technische Universität München, München, Germany, 1958. [Google Scholar]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part III: Application to a parallel axis and a planetary gearbox. Tribol. Int. 2015, 88, 317–326. [Google Scholar] [CrossRef]

- Feehally, T. Electro-Mechanical Interaction in Gas Turbine-Generator Systems for More-Electric Aircraft. Doctoral Dissertation, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- The Jet Engine; 7 Accessory drives; Rolls-Royce: Birmingham, UK, 1986; pp. 65–71. ISBN 0-902121-04-9.

- The Aircraft Gas Turbine Engine and Its Operation, Part No. PWA 182408 PWA Oper. Instr. 200, Installation Engineering; Pratt & Whitney: East Hartford, CT, USA, 1988; pp. 3-45–3-47.

- Niemann, G.; Winter, H. Maschinenelemente. II: Getriebe allgemein, Zahnradgetriebe-Grundlagen, Stirnradgetriebe; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Streifinger, H. Fuel/oil system thermal management in aircraft turbine engines. In Proceedings of the RTO Meeting Proceedings, Symposium, Design Principles and Methods for Aircraft Gas Turbine Engines, Toulouse, France, 11–12 July 1998; pp. 12–24. [Google Scholar]

| Component | Speed Ratio to HP Spool |

|---|---|

| Oil Pump | 0.62 |

| Generator | 1.79 |

| Fuel Pump | 0.9 |

| Hydraulic Pump | 0.5 |

| Conditions | Idle | Take Off | Begin Climb | Climb | End Climb | Start Cruise | End Cruise | Begin Descent | End Descent | Approach |

|---|---|---|---|---|---|---|---|---|---|---|

| HP Power (kW) | 825 | 24700 | 23200 | 14100 | 9700 | 8570 | 7260 | 5080 | 1090 | 6870 |

| Speed (%) | 0.28 | 0.88 | 0.88 | 0.92 | 0.91 | 0.88 | 0.88 | 0.80 | 0.69 | 058 |

| Parameter | Index | Unites | Value |

|---|---|---|---|

| Base helix angle | 10 | ||

| Bearing mean diameter | 0.20 | ||

| Pitch diameter | 0.35 | ||

| Immersed area | 1.0996 × 10−6 | ||

| Gear immersion depth | 0.22 | ||

| Shaft diameter | 0.2 | ||

| Oil volume | 0.0012 | ||

| N of teeth (Oil Pump) | z | - | 77 |

| N of teeth (Fuel Pump) | z | - | 75 |

| N of teeth (Generator) | z | - | 20 |

| N of teeth (Hydraulic Pump) | z | - | 67 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Jafari, S.; Bouchareb, A.; Nikolaidis, T. Thermal Performance Evaluation in Gas Turbine Aero Engines Accessory Gearbox. Int. J. Turbomach. Propuls. Power 2020, 5, 21. https://doi.org/10.3390/ijtpp5030021

Jafari S, Bouchareb A, Nikolaidis T. Thermal Performance Evaluation in Gas Turbine Aero Engines Accessory Gearbox. International Journal of Turbomachinery, Propulsion and Power. 2020; 5(3):21. https://doi.org/10.3390/ijtpp5030021

Chicago/Turabian StyleJafari, Soheil, Ahmed Bouchareb, and Theoklis Nikolaidis. 2020. "Thermal Performance Evaluation in Gas Turbine Aero Engines Accessory Gearbox" International Journal of Turbomachinery, Propulsion and Power 5, no. 3: 21. https://doi.org/10.3390/ijtpp5030021

APA StyleJafari, S., Bouchareb, A., & Nikolaidis, T. (2020). Thermal Performance Evaluation in Gas Turbine Aero Engines Accessory Gearbox. International Journal of Turbomachinery, Propulsion and Power, 5(3), 21. https://doi.org/10.3390/ijtpp5030021