TGSim Plus™—Real-Time Dynamic Simulation Suite of Gas Turbine Systems for the MATLAB®/Simulink® Environment

Abstract

:1. Introduction

1.1. The Need for a Simulator

1.2. TGSim Plus™ Features

- Gas Turbine Main Model: gas turbine machine and electric motor–generator system.

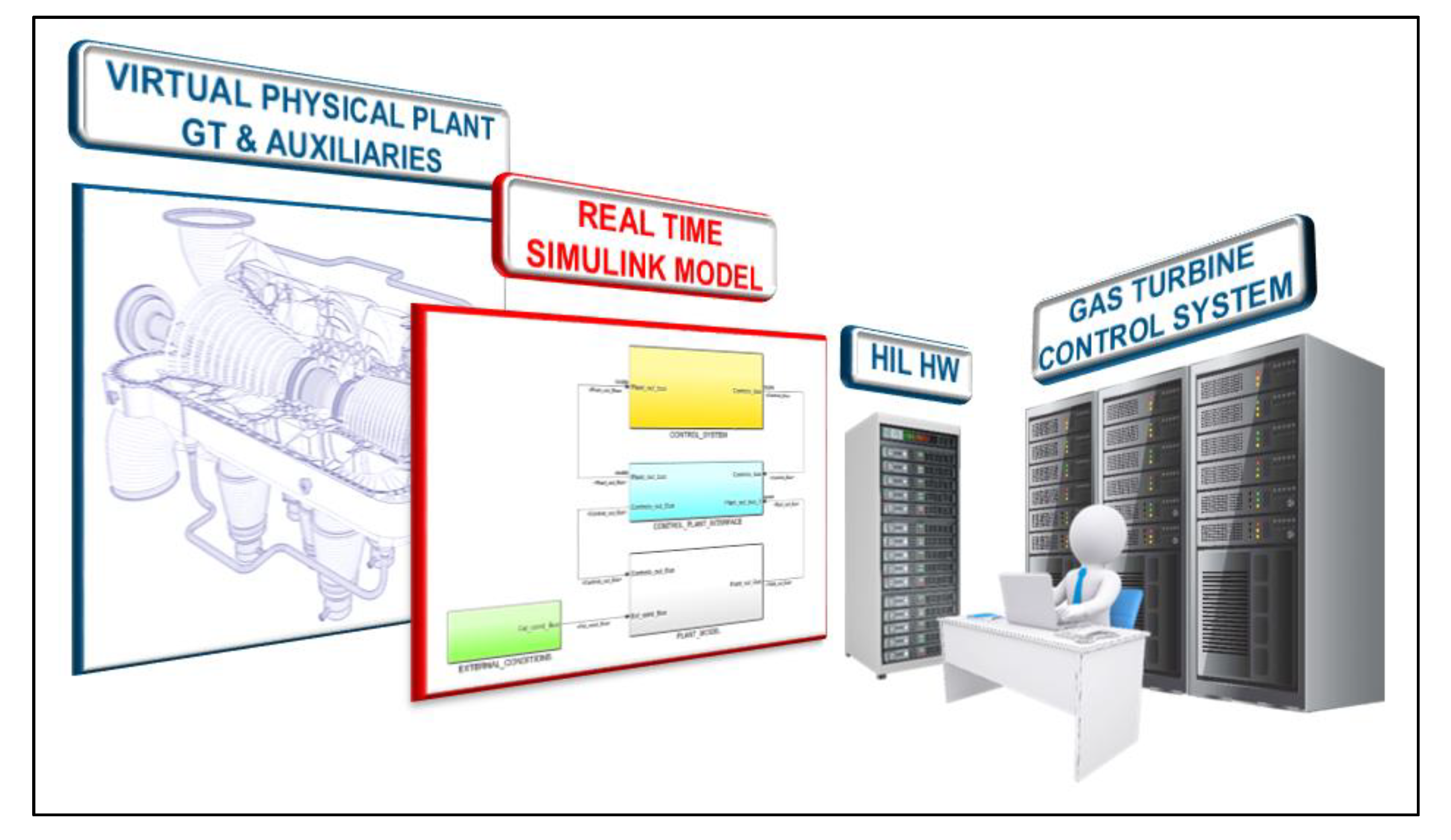

- Gas Turbine Control System (GTCS): real (online model) or simulated version (offline model) of the control system. The former includes the interface with the real control rack through the HIL platform, the other includes the essential controllers and logics in the Simulink® environment needed for the GT and auxiliary systems management in validation or study simulations. The extension of this latter and the level of complexity depends on the level of accuracy and use of the offline model and on the type of validation tests to be performed before starting the HIL tests.In any case the simulated version of the GTCS, used in the offline model, consists of open-loop, feedforward controls and feedback closed-loop controllers, either stand alone or in cascade architectures, depending on the variable to be controlled (i.e., pressures, temperatures, flow rates, liquid levels, shaft speed and GT power controllers). The Simulink® environment and the TGSim Plus™ controllers libraries allow a wide and flexible set of solutions that can be fully customized according to the Customer GT specifications or project phase needs. Controllers extend well over the basic PID (proportional–integral–derivative) controllers as any kind of conditional behaviour is implemented in the library blocks, e.g., up/lowclamp, uprate/downrate limits, hold-up/hold-down conditions, etc.The simulated offline version of the GTCS uses discrete-time controllers at the real system sampling time (that is normally longer than the solver sampling time) interfaced with the continuous-time dynamic model of the physical system.

- Gaseous Auxiliaries Model: auxiliary systems with gaseous fluids, i.e., fuel gas, purge air, cooling, sealing, and compressed air, and GT casing cooling systems.

- Liquid Auxiliaries Model: auxiliary systems with liquid fluids, i.e., lube and hydraulic oil systems, fuel oil, and water injection systems.

2. TGSim Plus™ Modelling

2.1. Accumulating and Flow Rate Generating Blocks

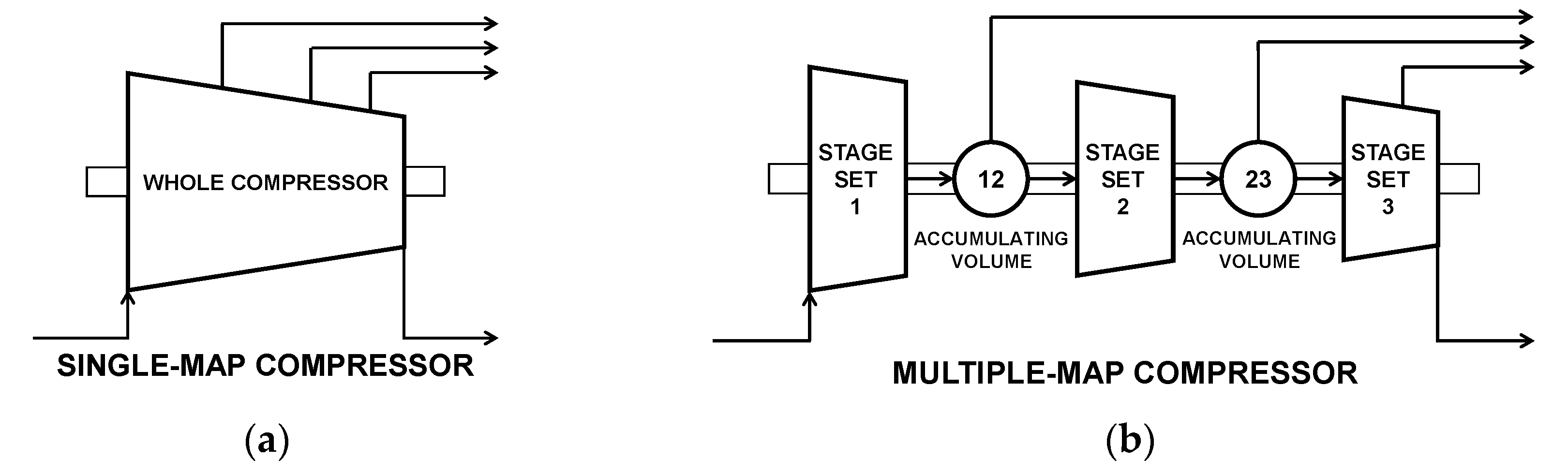

2.2. Compressor Modelling

- Instantaneous shaft speed,

- Actual inlet and discharge stream conditions,

- Inlet guide vane (IGV) angle,

- Actual performance maps.

- the inlet volume flow rate, Q, as function of the shaft speed, Nc, the polytropic head faced by and withstood by the stages set, PH, and IGV angle, or Q = Q(PH, Nc, IGV),

- the polytropic efficiency of the stage set, PE, as function of the shaft speed, the volume flow rate, and the IGV angle, or PE = PE(Q, Nc, IGV).

2.3. Combustor Modelling

- Stoichiometric combustion of fuel, gas or liquid or both, with dry air, assumed adiabatic and isobaric.

- Mixing process of the stoichiometric combustion products with the inert air and water vapour, occurring in a lumped volume, where the mass and energy balances account for the thermal exchange with the burner walls and determine the combustion pressure.

- Fuel mass flow rate, checking the actual presence of fuel flow in the combustor.

- Air mass flow rate, checking the actual presence of air flow in the combustor.

- Stoichiometric air mass flow rate, checking that the stoichiometric air flow required to burn the whole fuel flow is lower than the air flow rate from the compressor, i.e., that the air flow is sufficient to burn all the fuel being injected in the combustion chamber.

- Ignition command, checking that the ignition command signal is ON.

2.4. Expander Modelling

- Instantaneous shaft speed,

- Actual inlet and discharge stream conditions,

- Actual performance maps.

2.5. Electric Motor and Generator

3. Typical Results

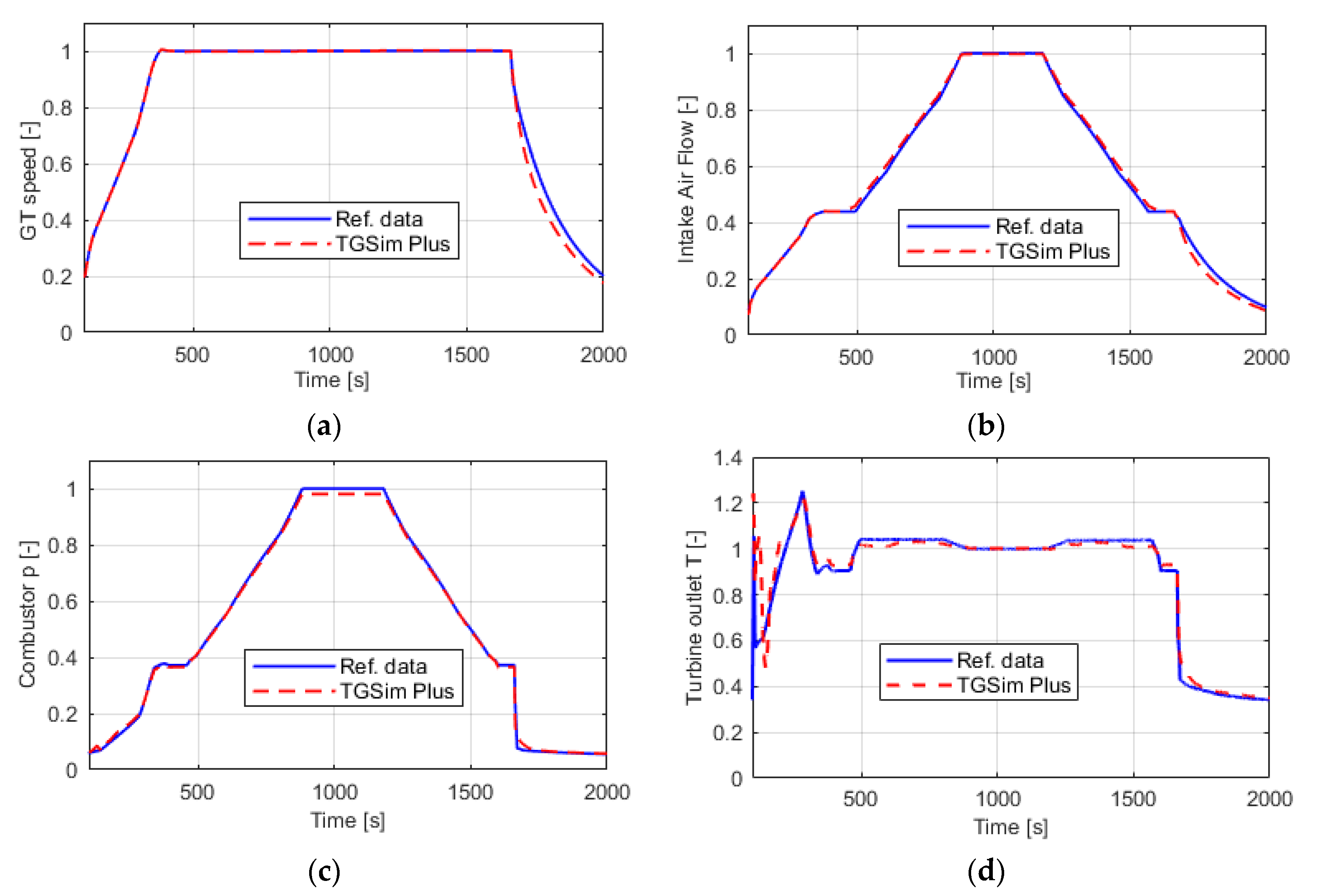

3.1. Comparison Start-Up Simulation, from Purge Speed to FSFL and Shut Down

3.2. Analysis of the GT Start-Up, from Rest to FSNL

- (a)

- Start and warm-up phase at low speed (20% of nominal), from 0 s to 1200 s, in EM-SFC mode under speed control, switching on fuel gas between 1000 s and 1200 s;

- (b)

- Initial ramp-up phase, from 1200 s to 1300 s, driven both by the EM-SFC and by the GT under fuel gas speed controller, acting concurrently up to the EM-SFC switch-off speed;

- (c)

- Final ramp-up phase to Full-Speed No-Load conditions (FSNL), in continuity with the former, from 1300 s to 1600 s, driven only by the GT under fuel gas speed controller;

- (d)

- Synchronization and connection to grid and power increase up to Full-Speed Full-Load (FSFL) or a partial demanded load in EG mode by the fuel gas power controller.

- (1)

- reducing the acceleration demand (Case 1), or

- (2)

- increasing the power rating of the EM-SFC (Case 2).

- In Case 0 the acceleration ramp from ignition speed to synchronization speed is performed quite fast, but is characterised by a high acceleration peak along with excessive temperatures in the combustion chamber.

- In Case 1, by implementing a lower slope acceleration ramp, the full speed is reached in a longer time, with a lower acceleration peak and acceptable temperature values in the combustor.

- In Case 2, with a higher SFC torque limit, the GT system maintains the acceleration ramp of Case 0, but with lower acceleration and temperature peaks with respect to both Case 0 and Case 1.

4. Discussion

4.1. Comparison Start-Up Simulation, from Purge Speed to FSFL and Shut Down

4.2. Analysis of the GT Start-Up, from Rest to FSNL

4.3. Comparison with Other Commercial Software

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Disclosure Restrictions

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbols | Description | Unit |

| a0 | Speed of sound | m/s |

| γ | Heat capacity ratio | – |

| dω/dt | Angular speed derivative | rad/s2 |

| h | Specific enthalpy | kJ/kg |

| Jdr | GT and EMG inertia | kg m2 |

| kh | Dimensionless tunable parameter, range [0,1] | – |

| ṁ | Mass flow rate | kg/s |

| ṁh | Enthalpy rate | kW |

| Nc | Compressor shaft speed | rpm |

| Nt | Expander shaft speed | rpm |

| nc | Instantaneous polytropic exponent | – |

| ηt,is | Expander isentropic efficiency | – |

| nst | Expander cooling bleed port stage | – |

| nst,tot | Total number of stages of the expander | – |

| p | Pressure | Pa |

| pb | Cooling pressure at the intermediate stages | Pa |

| PH | Polytropic head of the stage set | kJ/kg |

| PE | Polytropic efficiency of the stage set | – |

| πt | Expansion ratio | – |

| Q | Volume flow rate | m3/s |

| ηb,t,is | Isentropic efficiency for cooling bleed flows expansion | – |

| ρ | Density | kg/m3 |

| T | Temperature | K |

| Tb,c | Temperature at the bleed port | K |

| Tb,t | Inlet stream temperature at expander cooling bleed port | K |

| Tq,EMG | Mechanical torque applied to the GT driveline shaft | N m |

| Tq,dr | Net GT torque | N m |

| Xm | Molar gas composition | – |

| Subscripts | ||

| corr | Corrected | |

| corr,r | Corrected relative to FSFL values | |

| is | Isentropic | |

| ref | Reference | |

| Abbreviations | ||

| DHIC | Doosan Heavy Industries and Construction | |

| EG | Electrical Synchronous Generator | |

| EM | Electric Starter Motor | |

| EMG | Electric Motor and Generator | |

| FSFL | Full-Speed Full-Load | |

| FSNL | Full-Speed No-Load | |

| GT | Gas Turbine | |

| GTCS | Gas Turbine Control System | |

| H/C | Hydrogen/Carbon ratio | |

| HIL | Hardware in the Loop | |

| IGV | Inlet Guide Vane | |

| MMC | Multiple-Map Compressor | |

| MPHILP | Multi-Processor HIL Platform | |

| NPSS | Numerical Propulsion System Simulation | |

| SFC | Static Frequency Converter | |

| SMC | Single-Map Compressor | |

References

- Brighenti, A.; Duranti, D.; Quintabà, D. Dynamic Simulation; Hydrocarbon Engineering, Palladian Pubblications: Farnham, Surrey, UK, 2019; Volume 24, pp. 65–68. Available online: https://www.hydrocarbonengineering.com/ (accessed on 2 June 2020).

- Brighenti, A.; Duranti, D.; Quintabà, D. Real-Time simulation of Gas Turbine systems. In Proceedings of the 35th International CAE Conference, Vicenza, Italy, 28–29 October 2019; Available online: http://meeting2019.enginsoft.it/ (accessed on 25 June 2019).

- Numerical Propulsion System Simulation (NPSS). Available online: https://www.swri.org/consortia/numerical-propulsion-system-simulation-npss (accessed on 25 June 2019).

- Power Plant Equipment—Gas Turbines. Available online: http://www.doosanheavy.com/en/products/energy/tools/ (accessed on 2 June 2020).

- Doosan Heavy Industries Deploying First Large-Class Gas Turbine for Korean Demonstration Project. Available online: https://www.power-eng.com/2020/01/03/doosan-heavy-industries-deploying-first-large-class-gas-turbine-for-korean-demonstration-project/#gref (accessed on 2 June 2020).

- Doosan Heavy Industries Vying to Join Large Gas Turbine Producers. Available online: https://www.power-eng.com/2019/09/20/doosan-heavy-industries-vying-to-join-large-gas-turbine-producers/ (accessed on 2 June 2020).

- McBride, B.J.; Zehe, M.J.; Gordon, S. NASA Glenn Coefficients for Calculating Thermodynamic Properties of Individual Species; NASA/TP—2002-211556; National Aeronautics and Space Administration: Washington, DC, USA, 2002. [Google Scholar]

- Reid, R.C.; Prausnitz, J.M.; Poling, B.E. The Properties of Gases & Liquids, 4th ed.; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Atherton, D.P.; Borne, P. Concise Encyclopedia of Modelling and Simulation, 1st ed.; Pergamon: Oxford, UK, 1991. [Google Scholar]

- Luyben, W.L. Process Modeling, Simulation and Control for Chemical Engineers, 2nd ed.; McGraw-Hill: New York, NY, USA, 1989. [Google Scholar]

- Mattingly, J.D. Elements of Gas Turbine Propulsion; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Brighenti, A.; Bernocchi, A.; Martini, F.; Eierle, C.N.; Stockmann, R. Simulating Snøhvit Compressors: Part One; LNG industry, Palladian Pubblications: Farnham, Surrey, UK, 2007; pp. 47–52. [Google Scholar]

- Brighenti, A.; Bernocchi, A.; Martini, F.; Eierle, C.N.; Stockmann, R. Simulating Snøhvit Compressors: Part Two; LNG industry, Palladian Pubblications: Farnham, Surrey, UK, 2008; pp. 89–94. [Google Scholar]

- Brighenti, A.; Panikulam, J.V.; Bondi, S.; Fioravanti, L.; Amidei, S.; Gennari, G. Simulator of the Oregen™ system for Waste Heat Recovery from Gas Turbines. In Proceedings of the 32nd CAE Conference, Parma, Italy, 17–18 October 2016. [Google Scholar]

- Schobeiri, M.T. Gas Turbine Design, Components and System Design Integration; Springer: Berlin, Germany, 2017. [Google Scholar]

- Alobaid, F.; Mertens, N.; Starkloff, R.; Lanz, T.; Heinze, C.; Epple, B. Progress in dynamic simulation of thermal power plants. Prog. Energy Combust. Sci. 2017, 59, 79–162. [Google Scholar] [CrossRef]

| Description | Deviation |

|---|---|

| Compressor intake mass flow rate | –0.28% |

| Combustor discharge temperature | –1.13% |

| Combustor discharge pressure | –1.96% |

| Expander discharge temperature | +0.20% |

| Simulation | Ramp-Up Time | Max. Acceleration | Max. C.C. Temperature | C.C. Temperature Exceedance Duration |

|---|---|---|---|---|

| CASE 0 | 258 | 0.69 | 1.297 | 26 |

| CASE 1 | 316 | 0.52 | 1.041 | 2 |

| CASE 2 | 258 | 0.50 | 1.037 | 12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Brighenti, A.; Duranti, D.; Quintabà, D. TGSim Plus™—Real-Time Dynamic Simulation Suite of Gas Turbine Systems for the MATLAB®/Simulink® Environment. Int. J. Turbomach. Propuls. Power 2020, 5, 24. https://doi.org/10.3390/ijtpp5030024

Brighenti A, Duranti D, Quintabà D. TGSim Plus™—Real-Time Dynamic Simulation Suite of Gas Turbine Systems for the MATLAB®/Simulink® Environment. International Journal of Turbomachinery, Propulsion and Power. 2020; 5(3):24. https://doi.org/10.3390/ijtpp5030024

Chicago/Turabian StyleBrighenti, Attilio, Davide Duranti, and Debora Quintabà. 2020. "TGSim Plus™—Real-Time Dynamic Simulation Suite of Gas Turbine Systems for the MATLAB®/Simulink® Environment" International Journal of Turbomachinery, Propulsion and Power 5, no. 3: 24. https://doi.org/10.3390/ijtpp5030024

APA StyleBrighenti, A., Duranti, D., & Quintabà, D. (2020). TGSim Plus™—Real-Time Dynamic Simulation Suite of Gas Turbine Systems for the MATLAB®/Simulink® Environment. International Journal of Turbomachinery, Propulsion and Power, 5(3), 24. https://doi.org/10.3390/ijtpp5030024