ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed †

Abstract

1. Introduction

- 1.

- To enhance the understanding of relevant phenomena at high subsonic and transonic conditions.

- 2.

- To quantify disturbance characteristics at different rotation speeds to provide a benchmark for numerical simulations.

2. Open-Test-Case ECL5

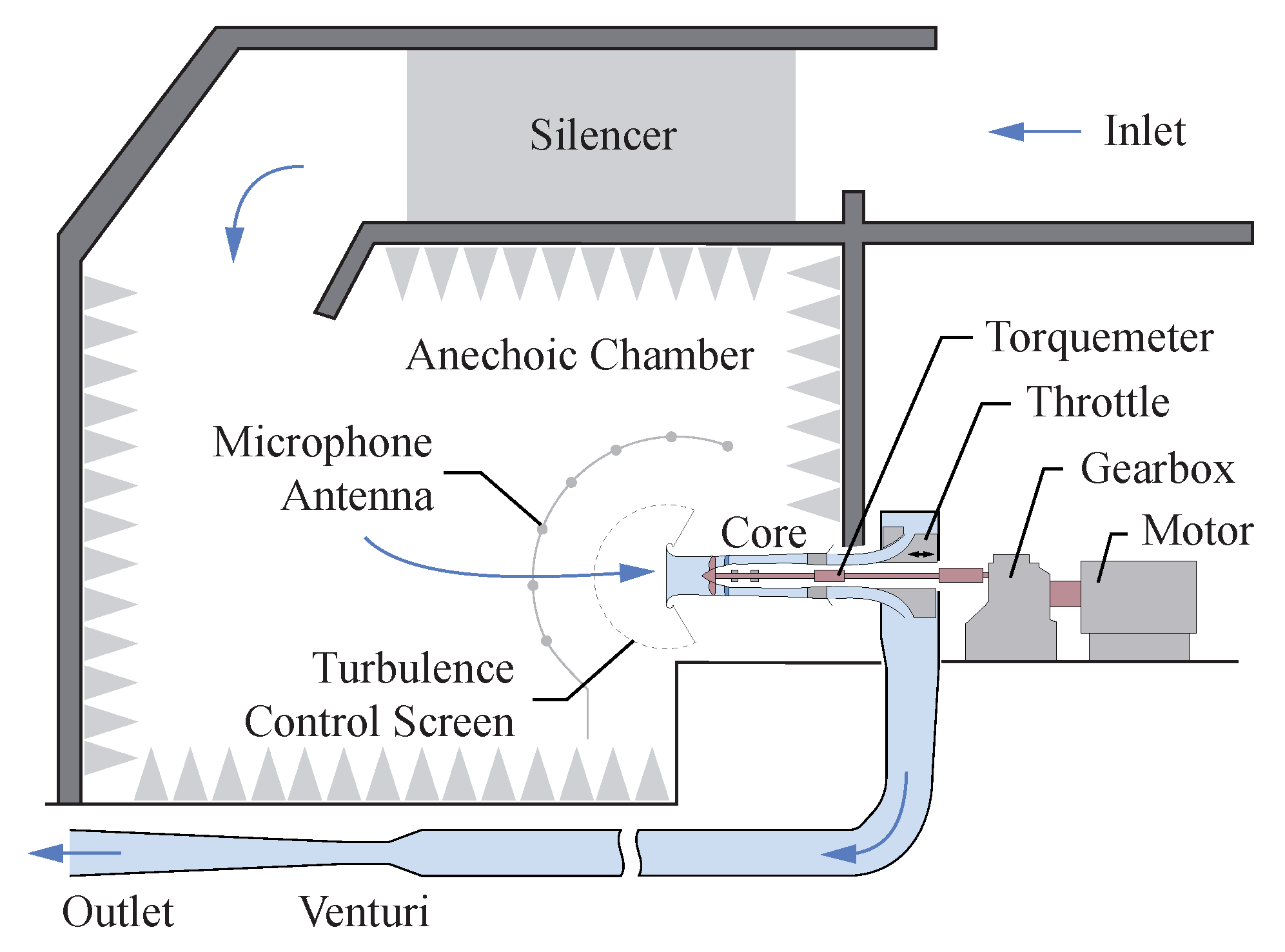

2.1. Test Facility and Instrumentation

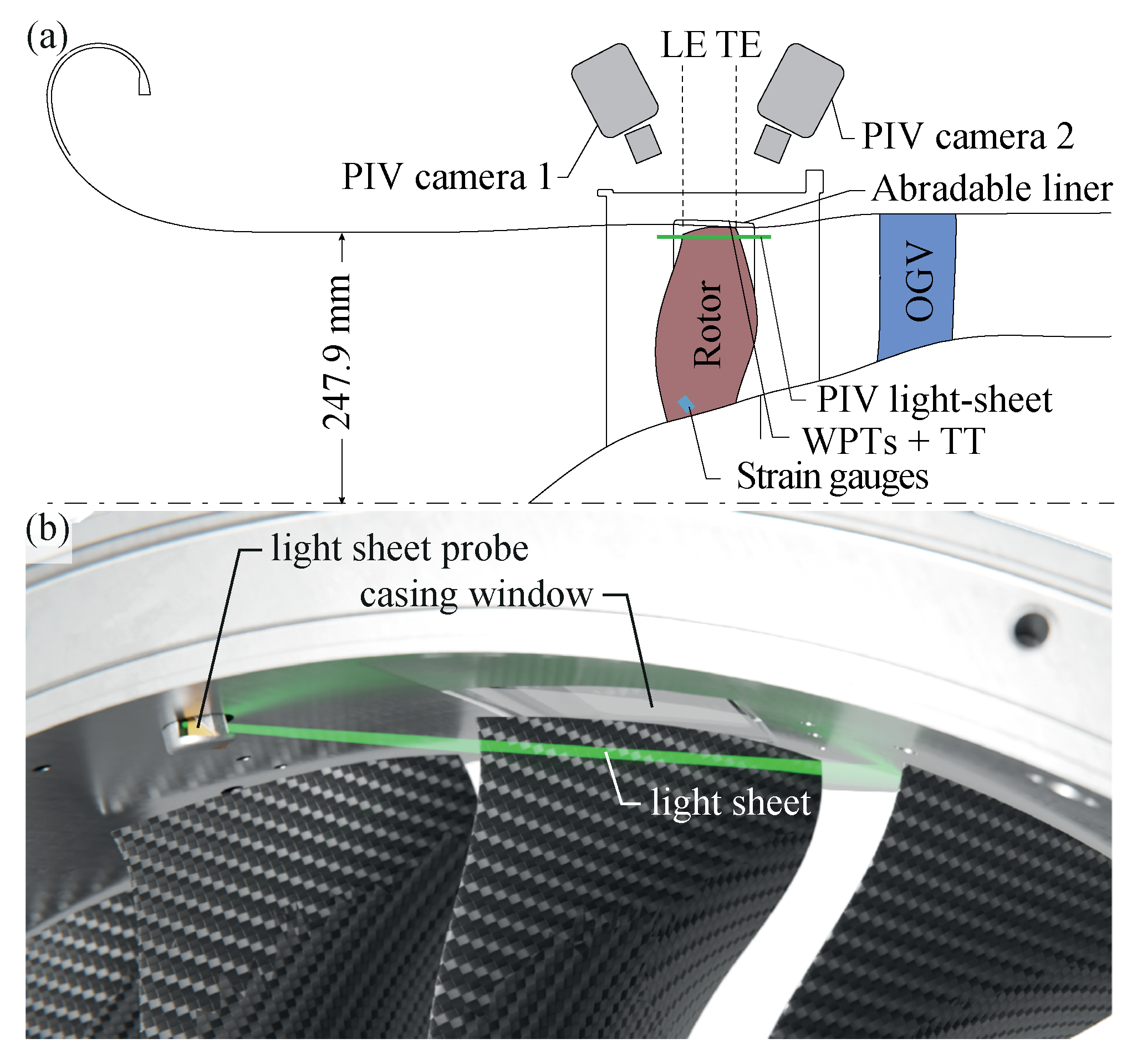

2.2. Stereo-PIV Setup

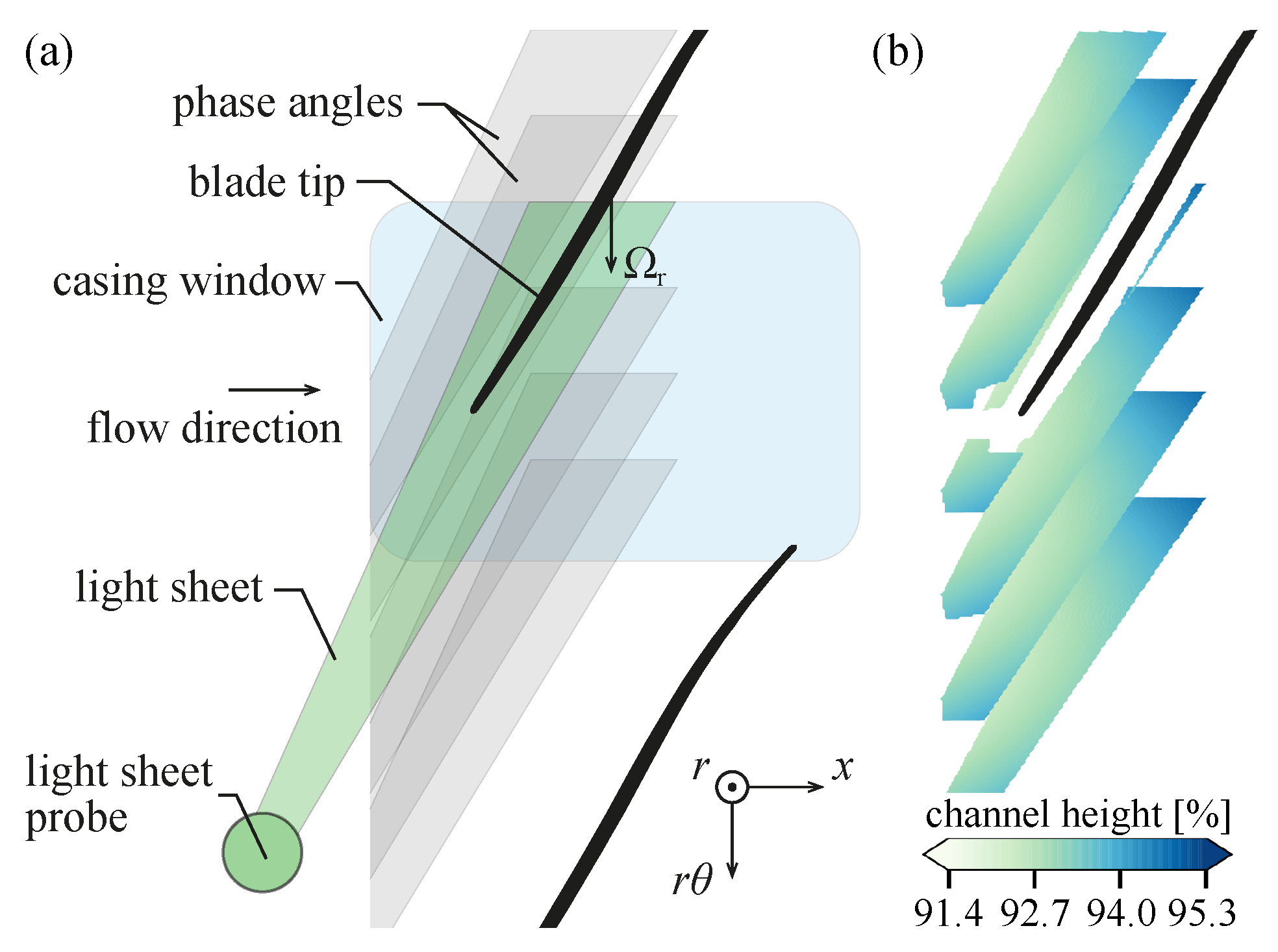

2.3. Stereo-PIV Measurement Procedure and Post-Processing

2.3.1. Image Pre-Processing, Cross-Correlation, and Post-Processing of Velocity Fields

2.3.2. Phase Angle Superposition

2.3.3. Measurement Uncertainty

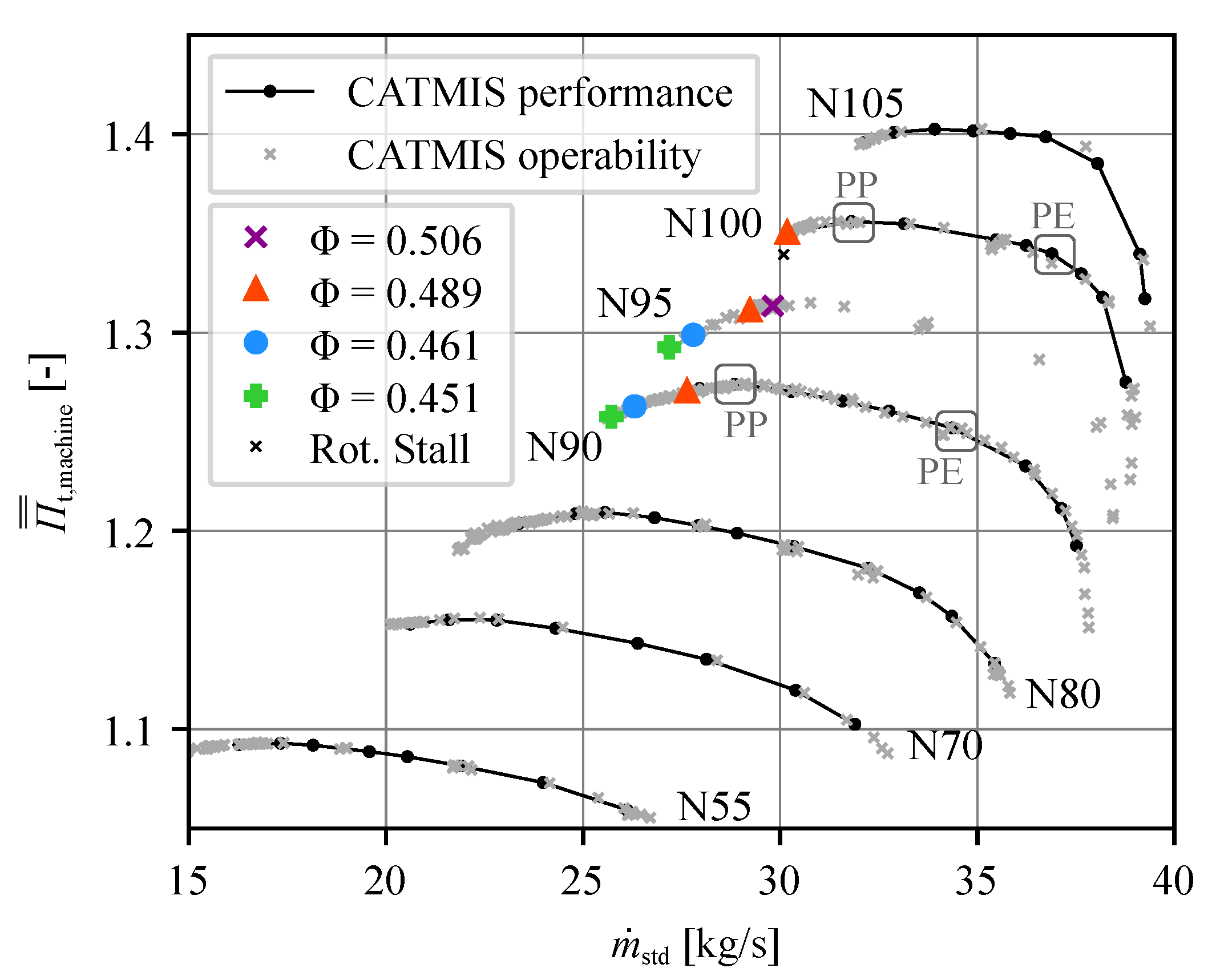

2.4. Machine Performance

3. Results

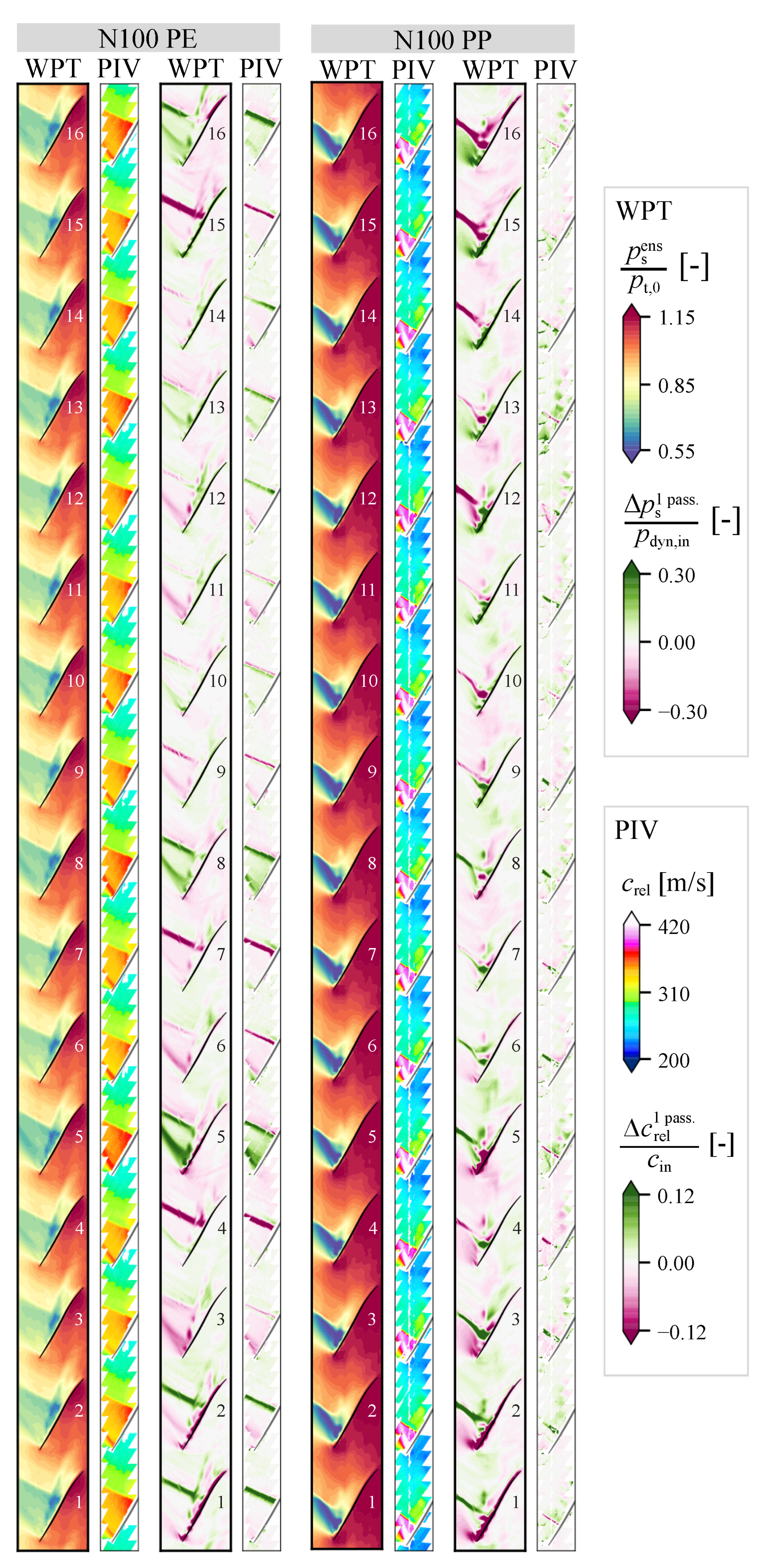

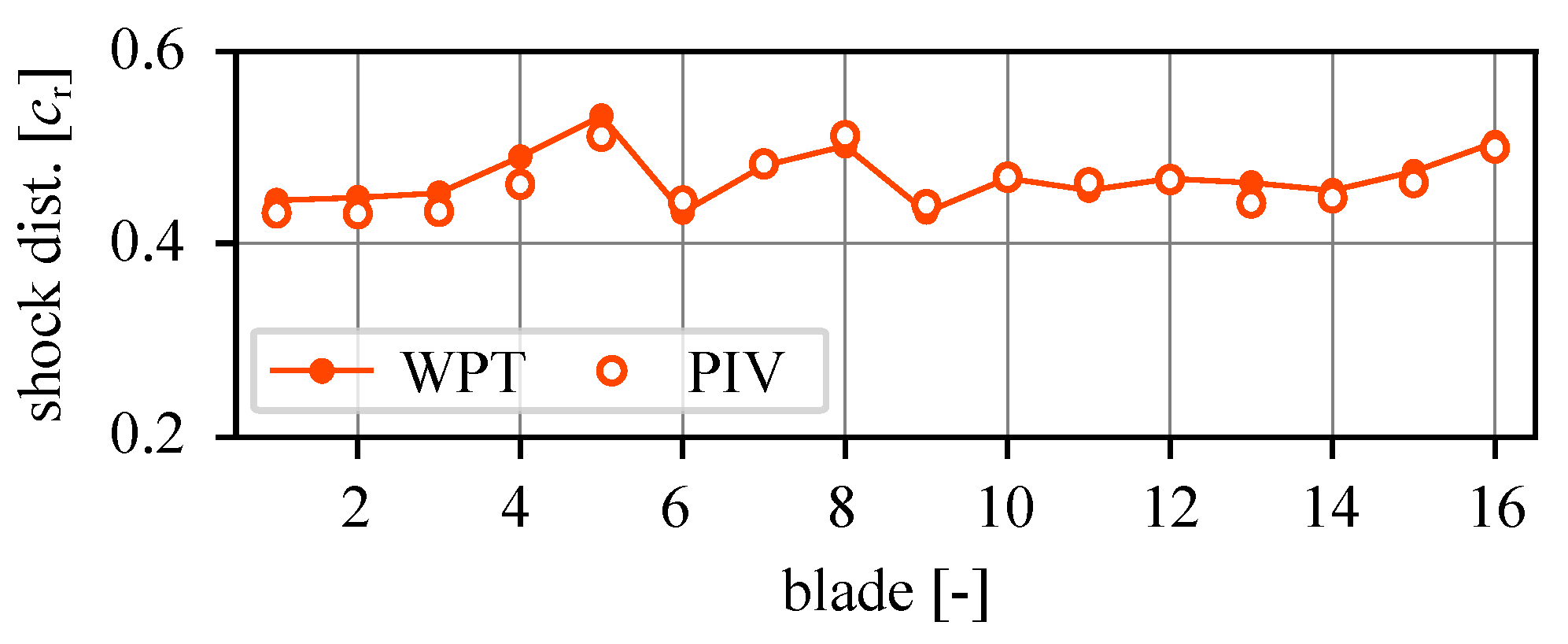

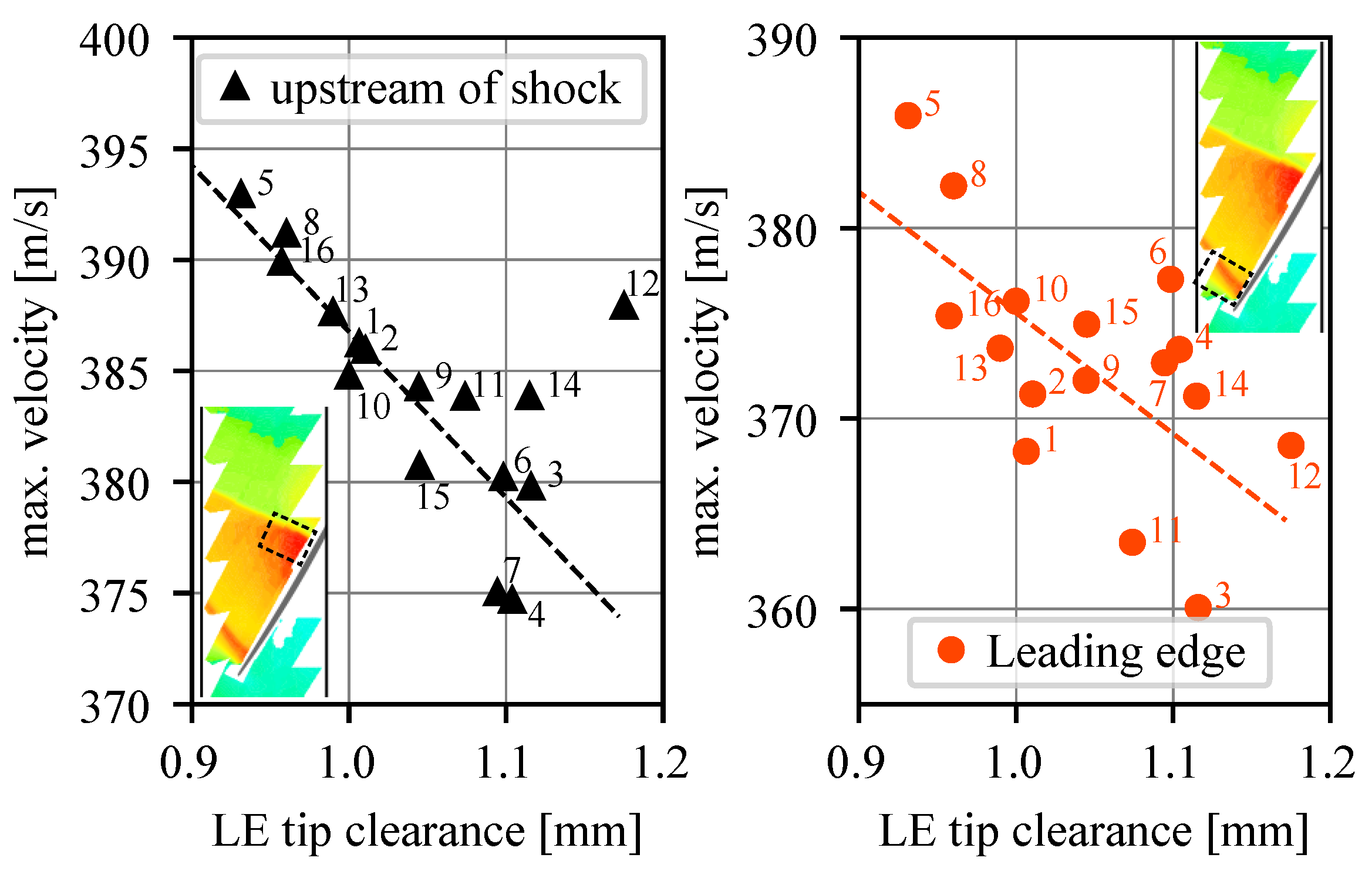

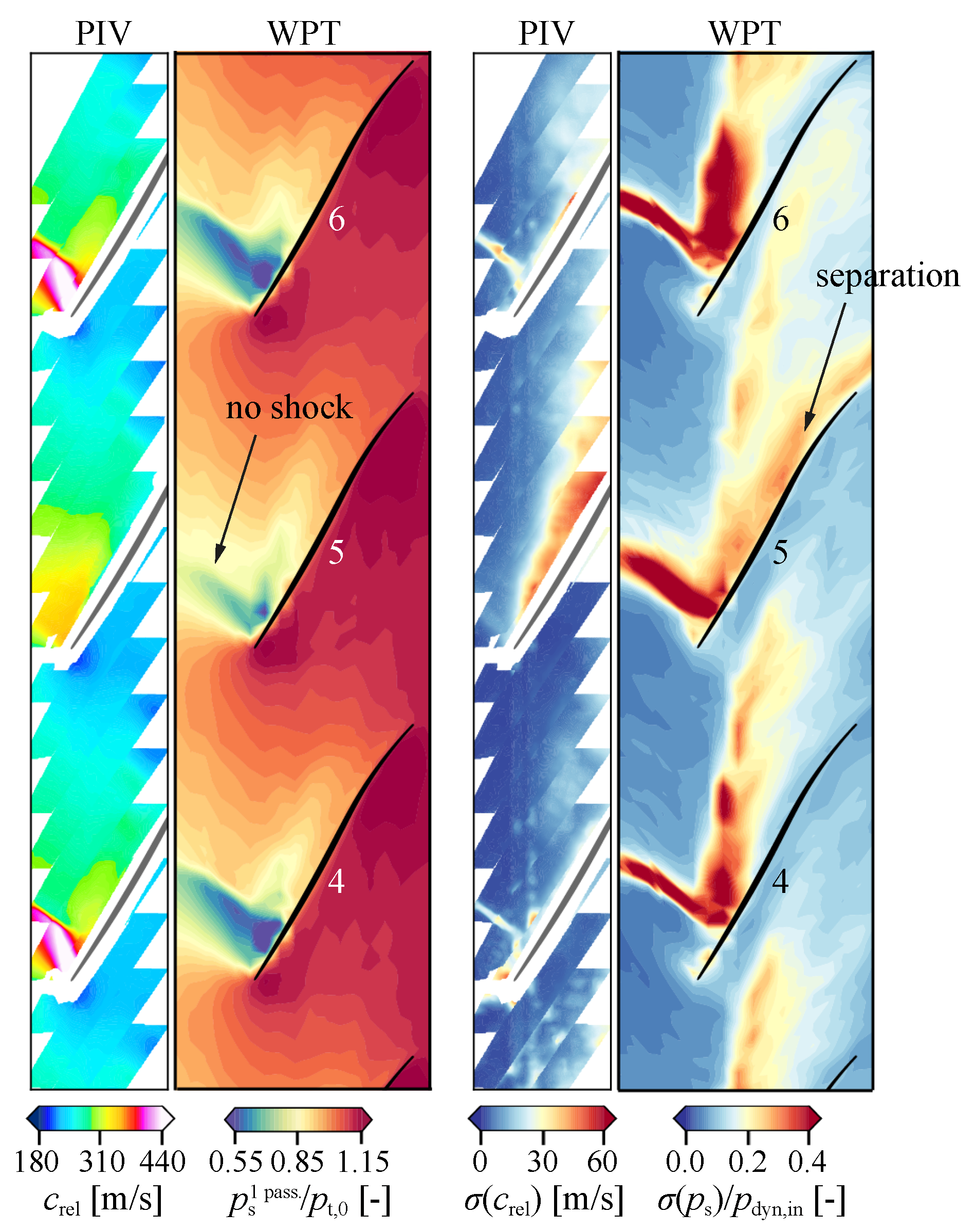

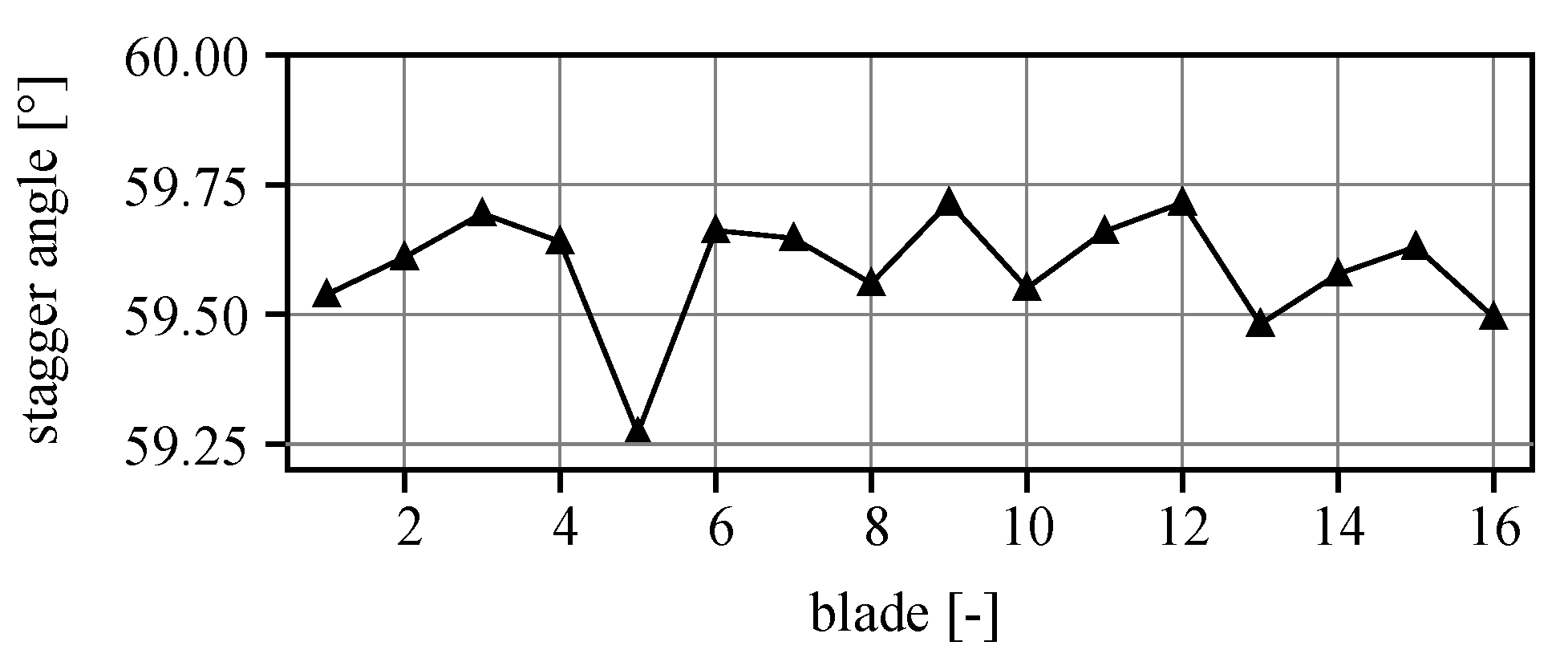

3.1. Cross-Validation of Measurement Systems

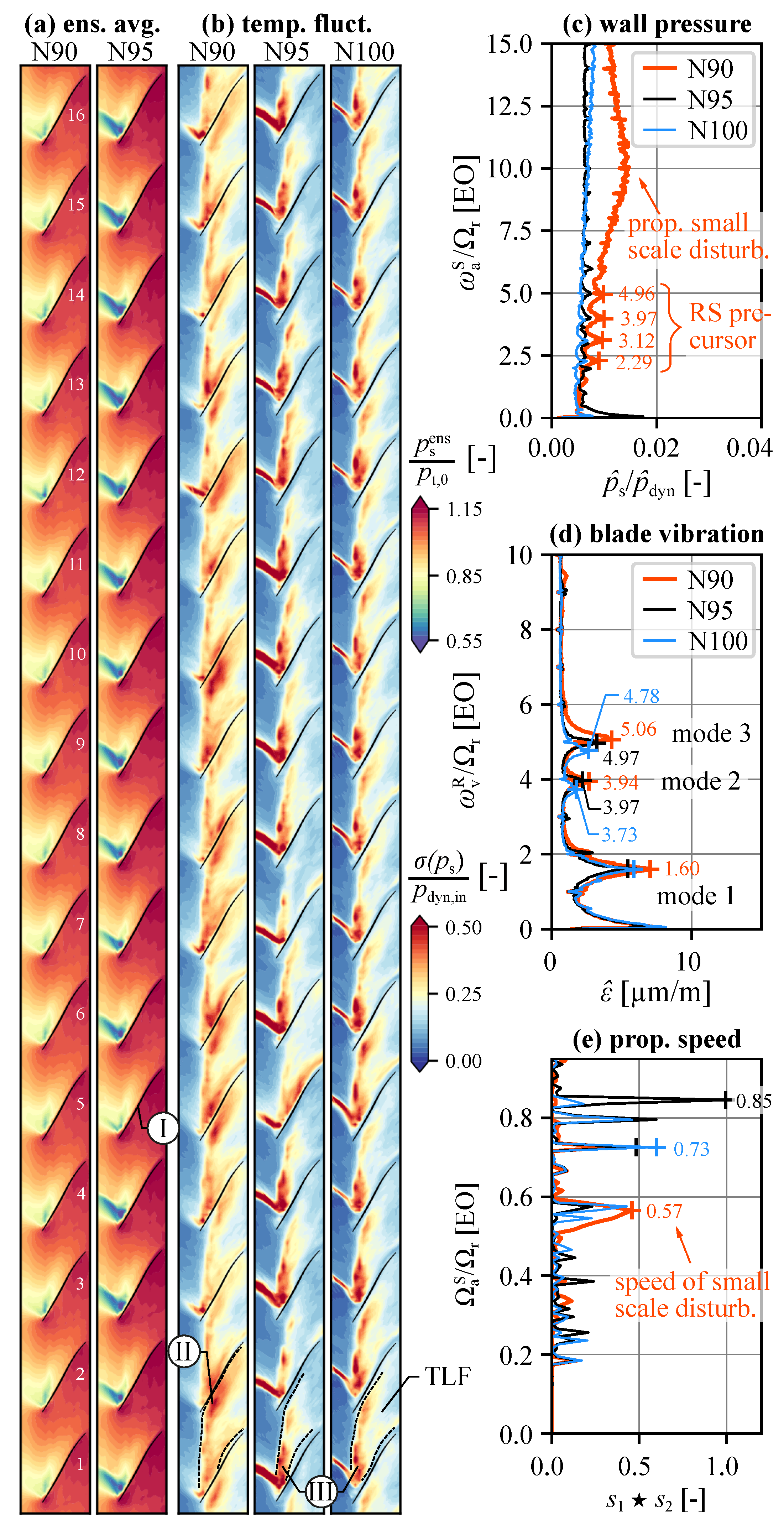

3.2. Investigation of Throttled Operating Points

3.2.1.

3.2.2.

3.2.3.

3.2.4.

4. Discussion and Conclusions

- 1.

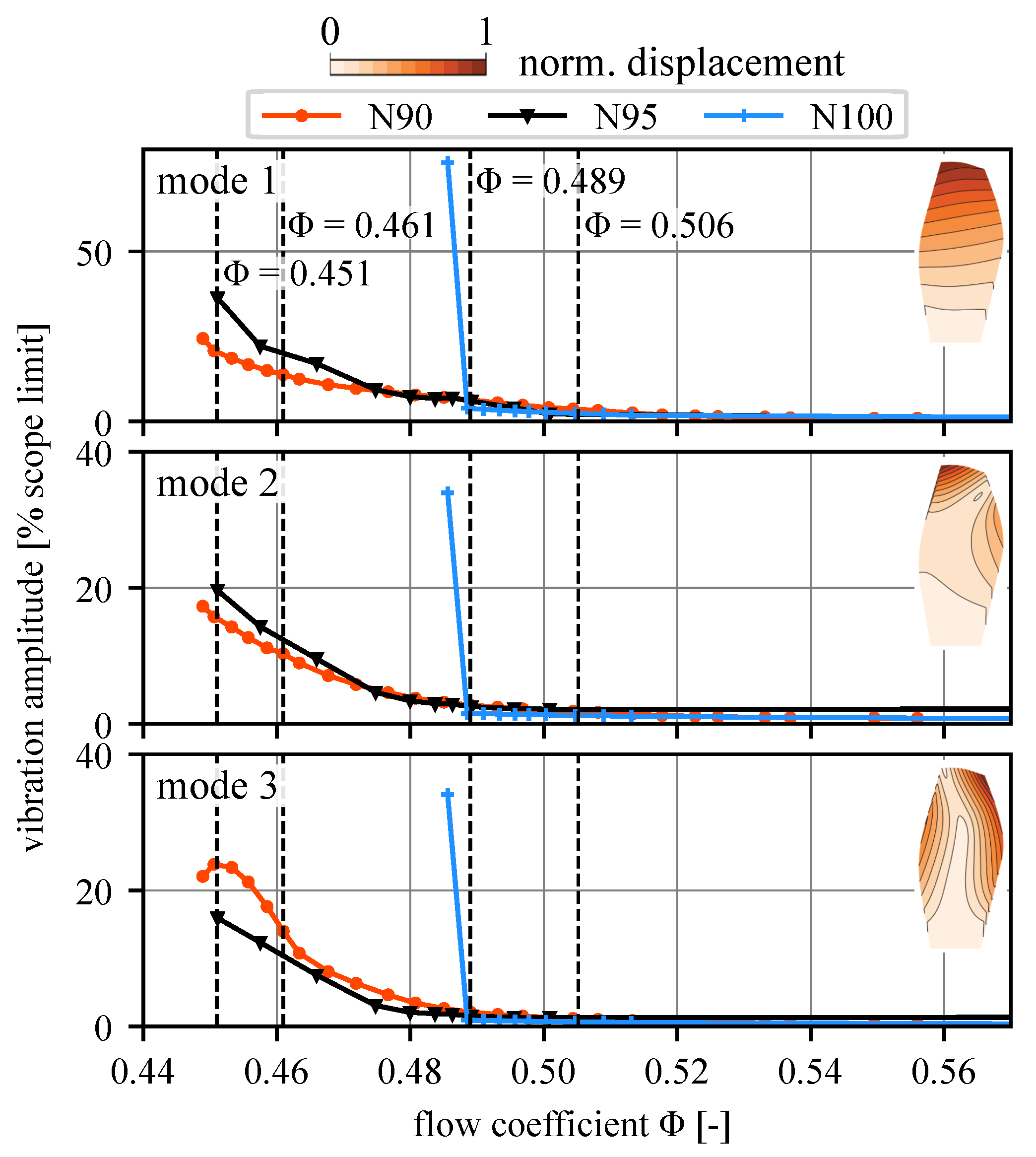

- At 100% speed, the rotor experiences rotating stall with one to two cells and spike-type inception. The onset of rotating stall is accompanied by a strong performance drop and safety-critical vibration amplitudes that necessitate immediate measurement abortion.

- 2.

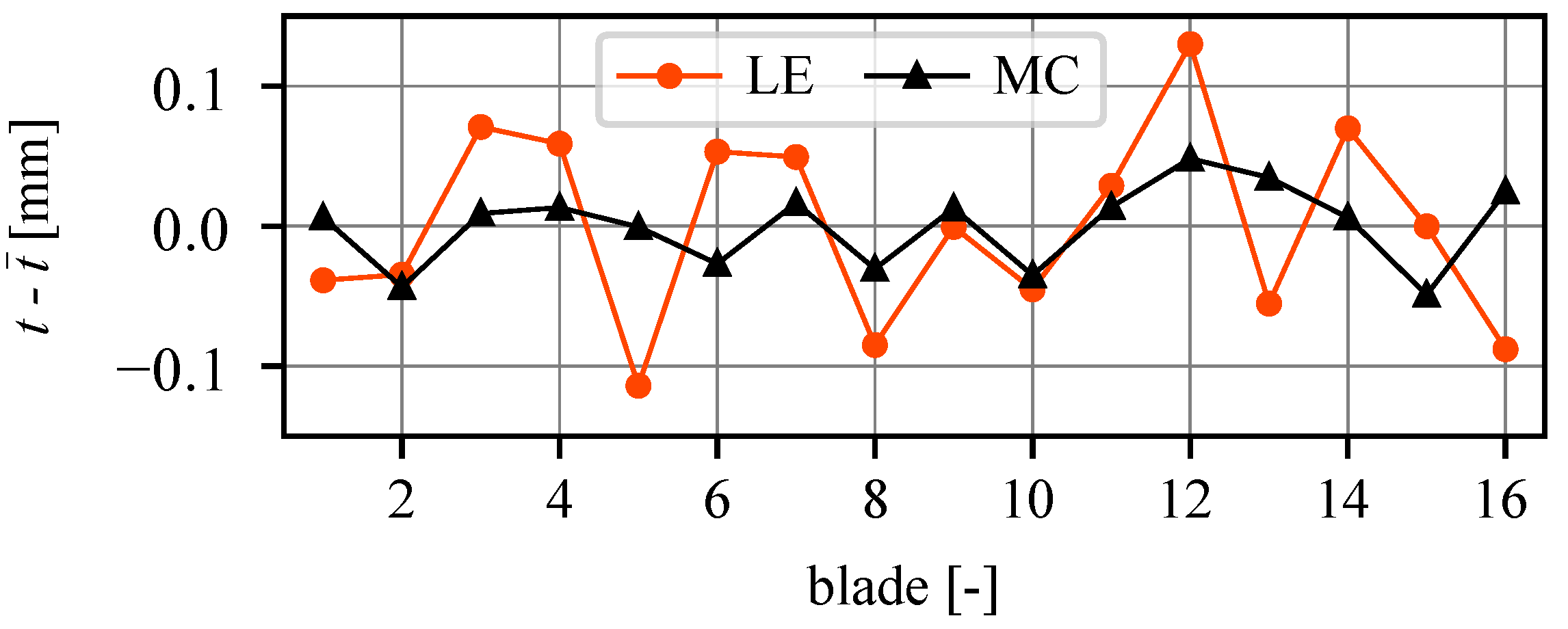

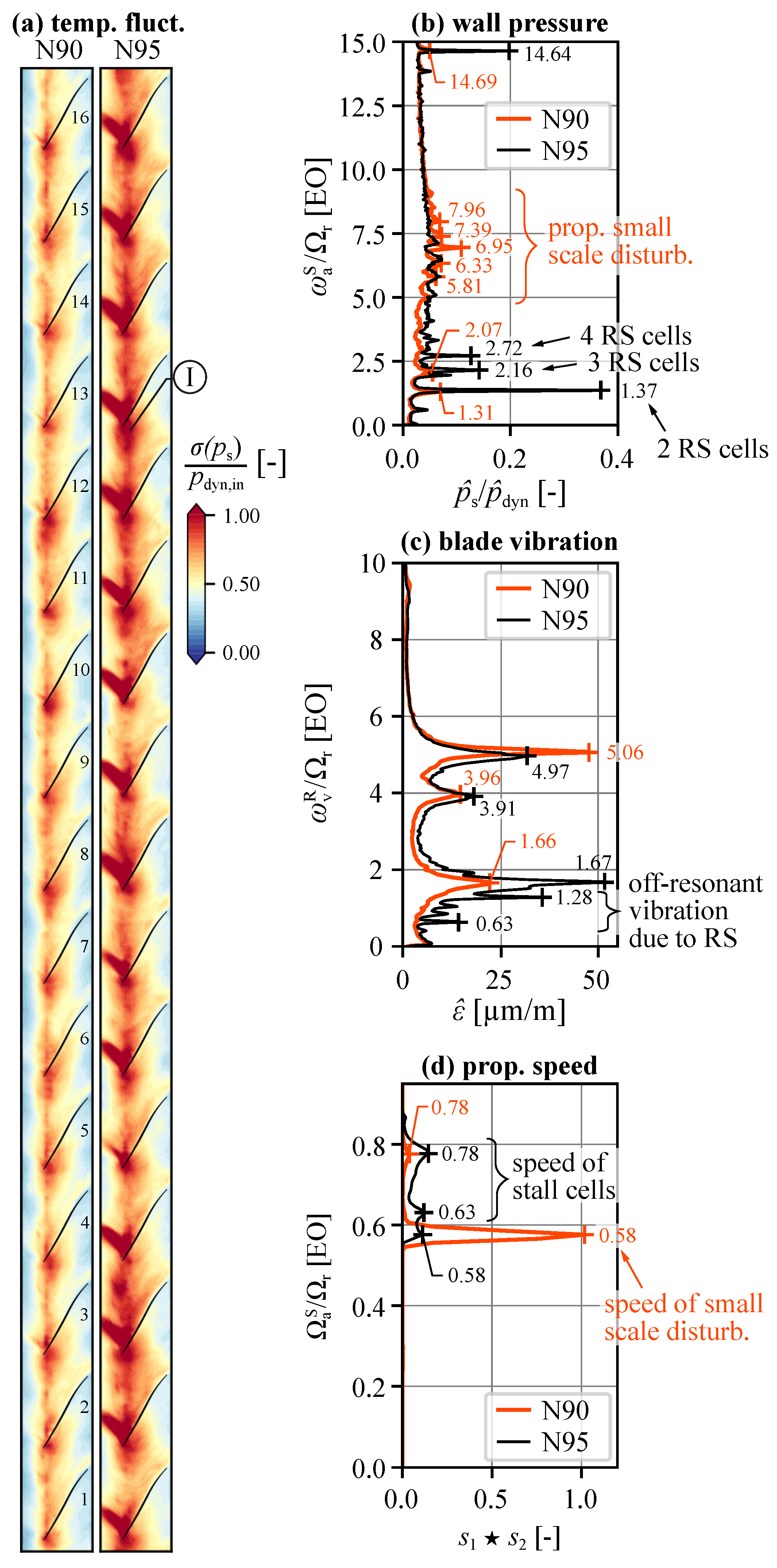

- At 95% speed, significant aerodynamic asymmetry in the form of a single separated blade is observed, long before rotating stall or NSV occurs. This blade-boundary layer separation is attributed to an unintentional misstagger of 0.3° and does not propagate in the rotor system.At lower flow coefficients, a multi-cell (2–4 cells) rotating stall is established that leads to moderate vibration amplitudes. The associated performance degradation is negligible. Further reducing the flow coefficient causes continuously increasing vibration amplitudes until safety limits are reached and the emergency bleed is opened. These vibrations are off-resonant with blade-eigenmodes and considered as non-synchronous forced-response.

- 3.

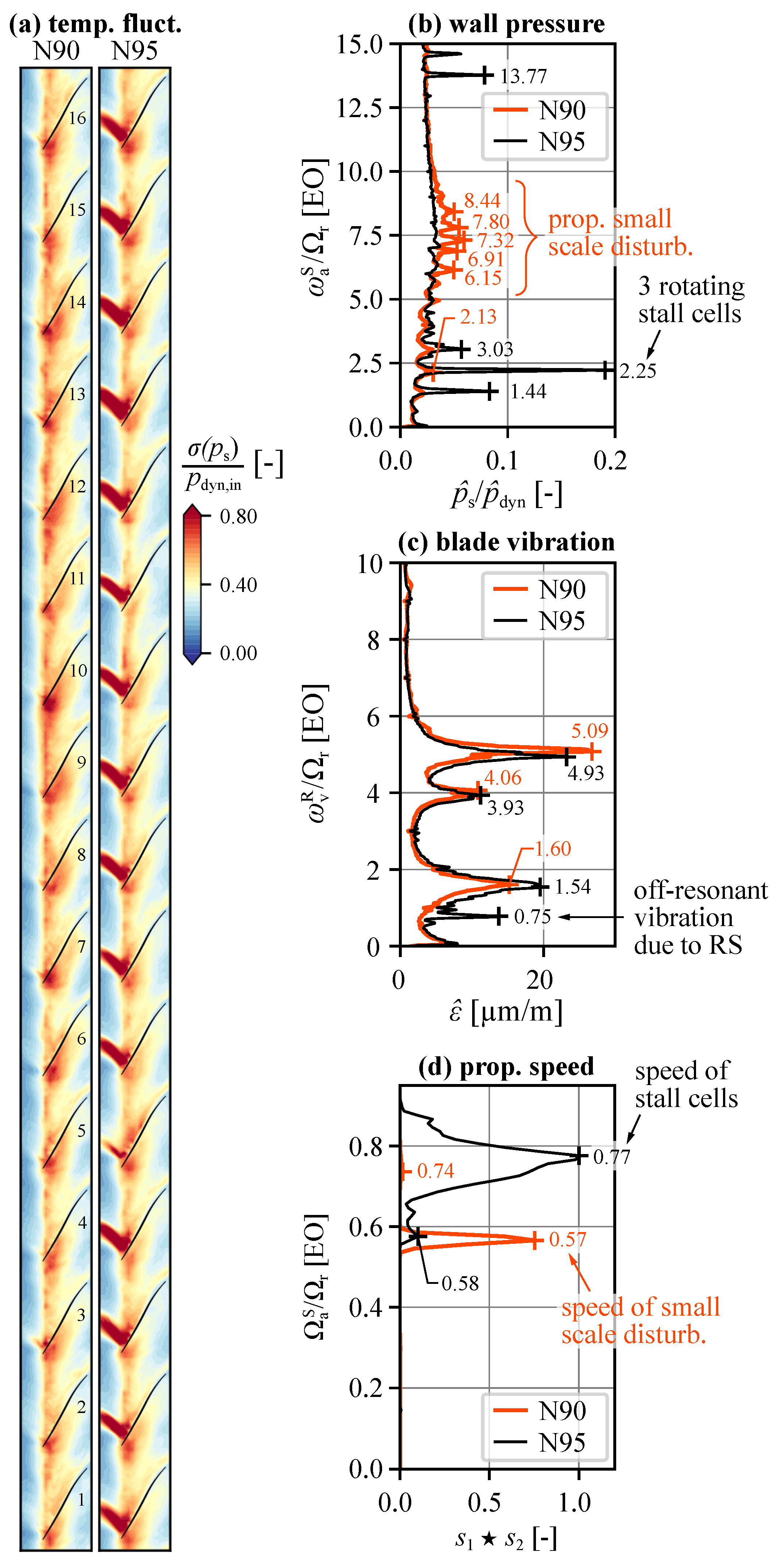

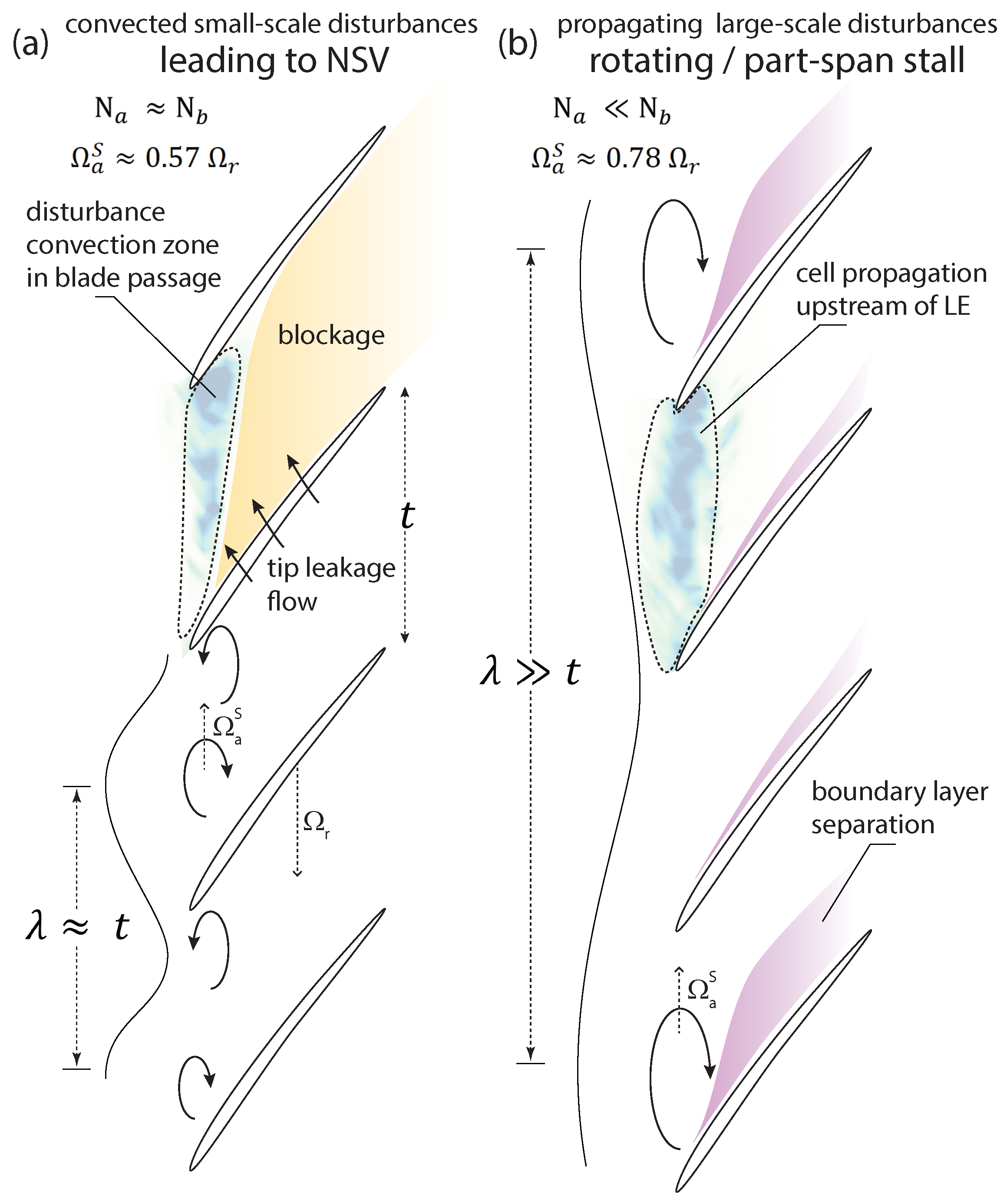

- At 90% speed, small-scale convective disturbances form coherent aerodynamic waves, one of which locks in with the third blade eigenmode, resulting in non-synchronous vibration amplitudes that continuously increase with throttle degree until measurements are stopped at a comparably low flow coefficient.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, K.B.; Wilson, M.; Vahdati, M. Numerical study on aeroelastic instability for a low-speed fan. J. Turbomach. 2016, 139, 071004. [Google Scholar] [CrossRef]

- Vahdati, M.; Cumpsty, N.A. Aeroelastic instability in transonic fans. J. Turbomach. 2016, 138, 022604. [Google Scholar] [CrossRef]

- Kielb, R.E.; Barter, J.W.; Thomas, J.P.; Hall, K.C. Blade Excitation by Aerodynamic Instabilities: A Compressor Blade Study. In Proceedings of the ASME Turbo Expo 2003, Atlanta, GA, USA, 16–19 June 2003. [Google Scholar]

- Stapelfeldt, S.; Brandstetter, C. Non-synchronous vibration in axial compressors: Lock-in mechanism and semi-analytical model. J. Sound Vib. 2020, 488, 115649. [Google Scholar] [CrossRef]

- Inoue, M.; Kuroumaru, M.; Tanino, T.; Furukawa, M. Propagation of multiple short-length-scale stall cells in an axial compressor rotor. J. Turbomach. 2000, 122, 45–54. [Google Scholar] [CrossRef]

- Young, A.; Day, I.; Pullan, G. Stall warning by blade pressure signature analysis. J. Turbomach. 2013, 135, 011033. [Google Scholar] [CrossRef]

- Pullan, G.; Young, A.; Day, I.J.; Greitzer, E.M.; Spakovsky, Z.S. Origins and structure of spike-type rotating stall. J. Turbomach. 2015, 137, 51007. [Google Scholar] [CrossRef]

- Camp, T.R.; Day, I.J. A study of spike and modal stall phenomena in a low-speed axial compressor. In Proceedings of the ASME Turbo Expo 1997, Orlando, FL, USA, 2–5 June 1997. [Google Scholar]

- Moore, F.K. A theory of rotating stall of multistage axial compressors: Part II - Finite disturbances. J. Eng. Gas Turbines Power 1984, 106, 321–326. [Google Scholar] [CrossRef]

- Greitzer, E.M. Review: Axial compressor stall phenomena. J. Fluids Eng. 1980, 102, 134–151. [Google Scholar] [CrossRef]

- Inoue, M.; Kuroumaru, M.; Yoshida, S.; Minami, T.; Yamada, K.; Furukawa, M. Effect of tip clearance on stall evolution process in a low-speed axial compressor stage. In Proceedings of the ASME Turbo Expo 2004, Vienna, Austria, 14–17 June 2004. [Google Scholar] [CrossRef]

- Day, I.J. Stall, surge, and 75 years of research. J. Turbomach. 2016, 138, 011001. [Google Scholar] [CrossRef]

- Baumgartner, M.; Kameier, F.; Hourmouziadis, J. Non-engine order blade vibration in a high pressure compressor. In Proceedings of the 12th International Symposium on Airbreathing Engines, Melbourne, Australia, 10–15 September 1995; Available online: https://hal.science/hal-01353829 (accessed on 12 June 2025).

- Thomassin, J.; Vo, H.D.; Mureithi, N.W. The tip clearance flow resonance behind axial compressor nonsynchronous vibration. J. Turbomach. 2011, 133, 041030. [Google Scholar] [CrossRef]

- Vo, H.D. Role of tip clearance flow in rotating instabilities and nonsynchronous vibration. J. Propuls. Power 2010, 26, 556–561. [Google Scholar] [CrossRef]

- Brandstetter, C.; Juengst, M.; Schiffer, H.P. Measurements of Radial Vortices, Spill Forward, and Vortex Breakdown in a Transonic Compressor. J. Turbomach. 2018, 140, 061004. [Google Scholar] [CrossRef]

- Brandstetter, C.; Ottavy, X.; Paoletti, B.; Stapelfeldt, S. Interpretation of stall precursor signatures. J. Turbomach. 2021, 143, 13. [Google Scholar] [CrossRef]

- Holzinger, F.; Wartzek, F.; Jüngst, M.; Schiffer, H.P.; Leichtfuss, S. Self-excited blade vibration experimentally investigated in transonic compressors: Rotating Instabilties and flutter. J. Turbomach. 2016, 138, 041006. [Google Scholar] [CrossRef]

- Franke, D.; Jüngst, M.; Möller, D.; Schiffer, H.P.; Giersch, T. Influence of pre-swirl, rotor speed and blade count on aeroelastic coupling mechanisms during stall inception of a transonic compressor. In Proceedings of the ASME Turbo Expo 2020, Virtual, 21–25 September 2020. [Google Scholar] [CrossRef]

- de Almeida, V.B.C.; Tüzüner, E.; Eck, M.; Peitsch, D. Numerical characterization of prestall disturbances in a compressor stage. J. Turbomach. 2024, 146, 081009. [Google Scholar] [CrossRef]

- Hernley, V.; Jemcov, A.; Kang, J.; Montgomery, M.; Morris, S.C. Relationship between casing pressure and non-synchronous vibration in an axial compressor. Int. J. Turbomach. Propuls. Power 2024, 9, 14. [Google Scholar] [CrossRef]

- März, J.; Hah, C.; Neise, W. An experimental and numerical investigation into the mechanisms of rotating instability. J. Turbomach. 2002, 124, 367–374. [Google Scholar] [CrossRef]

- Kameier, F.; Neise, W. Rotating blade flow instability as a source of noise in axial turbomachines. J. Sound Vib. 1997, 203, 833–853. [Google Scholar] [CrossRef]

- Mailach, R.; Lehmann, I.; Vogeler, K. Rotating instabilities in an axial compressor originating from the fluctuating blade tip vortex. J. Turbomach. 2001, 123, 453–460. [Google Scholar] [CrossRef]

- Schneider, A.; Fiquet, A.L.; Paoletti, B.; Ottavy, X.; Brandstetter, C. Experiments on tuned UHBR open-test-case fan ECL5/CATANA: Performance and aerodynamics. J. Turbomach. 2024, 146, 081001. [Google Scholar] [CrossRef]

- Fiquet, A.L.; Schneider, A.; Paoletti, B.; Ottavy, X.; Brandstetter, C. Experiments on Tuned UHBR Open-Test-Case Fan ECL5/CATANA: Stability Limit. J. Eng. Gas Turbines Power 2023, 146, 051011. [Google Scholar] [CrossRef]

- Brandstetter, C.; Schneider, A.P.; Fiquet, A.L.; Paoletti, B.; Ottavy, X. Experiments on structurally mistuned UHBR open-test-case fan ECL5/CATANA. J. Eng. Gas Turbines Power 2024, 147, 081010. [Google Scholar] [CrossRef]

- Schneider, A.P. Aerodynamic and Aeroelastic Investigation of a Composite Fan for Ultra-High-Bypass-Ratio Aircraft Engines. Ph.D. Thesis, Ecole Centrale de Lyon, Lyon, France, 2024. Available online: https://theses.fr/2024ECDL0018 (accessed on 12 June 2025).

- Schneider, A.; Paoletti, B.; Ottavy, X.; Brandstetter, C. Influence of a turbulence control screen on the aerodynamic and aeroelastic behavior of a UHBR fan. In Proceedings of the ASME Turbo Expo 2022, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar] [CrossRef]

- Zielinski, M.; Ziller, G. Noncontact Vibration Measurements on Compressor Rotor Blades. Meas. Sci. Technol. 2000, 11, 847–856. [Google Scholar] [CrossRef]

- Raffel, M.; Willert, C.E.; Scarano, F.; Kähler, C.J.; Wereley, S.T.; Kompenhans, J. Particle Image Velocimetry: A Pratical Guide; Spinger: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Wieneke, B. Stereo-PIV using self-calibration on particle images. J. Exp. Fluids 2005, 39, 267–280. [Google Scholar] [CrossRef]

- Voges, M.; Willert, C.; Mönig, R.; Schiffer, H.P. The effect of a bend-slot casing treatment on the blade tip flow flield of a transonic compressor rotor. In Proceedings of the ASME Turbo Expo 2013, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar] [CrossRef]

- Brandstetter, C. Aerodynamische Stabilisierung Transsonischer Axialverdichter: Eine Experimentelle Untersuchung der Blattspitzenströmung Unter dem Einfluss von Gehäusestrukturierungen. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2015. [Google Scholar]

- Brandstetter, C.; Schneider, A.P.; Fiquet, A.L.; Paoletti, B.; Billon, K.; Ottavy, X. ECL5/CATANA: Comparative analysis of advanced blade vibration measurement techniques. In Proceedings of the ETC16, Hannover, Germany, 24–28 March 2025. [Google Scholar]

- Schneider, A.; Paoletti, B.; Ottavy, X.; Brandstetter, C. Quantification of blade vibration amplitude in turbomachinery. Int. J. Turbomach., Propuls. Power 2024, 9, 10. [Google Scholar] [CrossRef]

- Tharreau, P.; Hardy-Falch, M.; Stapelfeldt, S.; Brandstetter, C. Non-synchronous vibration: Characterisation of the aerodynamic disturbance and its dependency on local tip clearance. J. Eng. Gas Turbines Power 2024, 147, 051029. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| frequency | ≈14 | Hz |

| time delay | 2–2.5 | μs |

| image scale | ≈24 | px/mm |

| laser pulse energy | 40–60 | mJ |

| max. repetition rate | 14 | Hz |

| particle image diameter | 3–6 | px |

| camera opening | F4–F5.6 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the EUROTURBO. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Schneider, A.P.; Fiquet, A.-L.; Grosjean, N.; Paoletti, B.; Ottavy, X.; Brandstetter, C. ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed. Int. J. Turbomach. Propuls. Power 2025, 10, 22. https://doi.org/10.3390/ijtpp10030022

Schneider AP, Fiquet A-L, Grosjean N, Paoletti B, Ottavy X, Brandstetter C. ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed. International Journal of Turbomachinery, Propulsion and Power. 2025; 10(3):22. https://doi.org/10.3390/ijtpp10030022

Chicago/Turabian StyleSchneider, Alexandra P., Anne-Lise Fiquet, Nathalie Grosjean, Benoit Paoletti, Xavier Ottavy, and Christoph Brandstetter. 2025. "ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed" International Journal of Turbomachinery, Propulsion and Power 10, no. 3: 22. https://doi.org/10.3390/ijtpp10030022

APA StyleSchneider, A. P., Fiquet, A.-L., Grosjean, N., Paoletti, B., Ottavy, X., & Brandstetter, C. (2025). ECL5/CATANA: Transition from Non-Synchronous Vibration to Rotating Stall at Transonic Speed. International Journal of Turbomachinery, Propulsion and Power, 10(3), 22. https://doi.org/10.3390/ijtpp10030022