1. Introduction

Pulsed power, including pulsed electron, ion, and laser beams, as well as plasma flows, is widely applied for surface modification. To date, great progress has been made in understanding the mechanisms of interaction between pulsed power and matter. In particular, this is illustrated by the widespread use of pulsed lasers in science and various industries [

1,

2,

3,

4,

5,

6,

7]. Additionally, pulsed electron beams (PEBs) are of significant interest due to, among other things, the possibility of controlling the thicknesses of heat-affected zones over a wide range by changing the electron energy. As a rule, energy is delivered to the surface layer of a target, the thickness of which can vary from fractions to hundreds of micrometers. It is for this reason that huge efforts on the part of numerous researchers are being directed toward PEBs as a tool for energy delivery to initiate desirable physicochemical processes in irradiated targets. One of the main challenges associated with PEBs is the lack of a generally accepted approach for solving the problem of the interaction of PEBs with a substance from the point of view of thermal processes. Various groups of scientists work with different PEBs, the operating parameters of which often possess disjunct windows. Accordingly, local patterns that are inherent to a particular PEB source are determined. However, on other PEB sources with different parameters, the patterns may differ significantly. Even a trivial assessment of the fusibility of materials is debatable, because their ranking depends on the implemented PEB source. As illustrated in this paper, well-known fusible materials can be refractory in some cases, while conversely, the most refractory ones can melt relatively easily if the parameters of the PEBs are changed. The reason for this is the phenomenon whereby pulsed heating can be implemented in two ways (surface and volume), depending on the parameters of the PEBs and the target material. These nuances determine which thermophysical properties of the target and parameters of the PEBs will a play key role in each particular case. Thus, a material that is refractory under pulsed surface heating is not necessarily so upon volumetric processing. This study attempts to take the first step towards understanding the general relationships among the PEB parameters, the target materials, and the thermal processes induced in them that would be true for a wide class of PEBs.

According to the reported data, a fairly wide variety of PEB sources have been designed for various purposes, e.g., generating microwave or X-ray radiation, sterilizing medical materials, processing plant seeds, synthesis of dielectric coatings [

8], etc. It should be noted that PEBs are widely used for surface modification: (1) for cleaning surfaces of inclusions, and their homogenization and smoothing; and (2) as a tool for the formation of highly adhesive coatings (surface alloys) by mixing of both molten preliminary deposited films and the surface layers of substrates.

In this paper, the main focus is on those PEB sources that are among the most promising for industrial applications (in the author’s opinion). In particular, the ‘RITM’ PEB source is considered, which was developed at the Institute of High Current Electronics of the Siberian Branch of the Russian Academy of Sciences [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]. Back in the early 2000s, the license for its industrial production was sold to the Japanese ‘SODICK’ company, which produced the ‘PIKA PF32A Finish Machine’ industrial analogue. This equipment is used all over the world for both scientific and industrial purposes [

23,

24]. In Russia, the ‘RITM-SP’ machine (manufactured by the OOO ‘Microsplav’ company) is available for experiments at the Tomsk Regional Center for Collective Use of the Tomsk Scientific Center of the Siberian Branch of the Russian Academy of Sciences (

https://ckp-rf.ru/catalog/ckp/3058/, accessed on 3 August 2023). In Europe, such a machine is installed in the Laboratory of Surface Engineering and Applied Electrochemistry ‘Roberto Piontelli’ of the Politecnico di Milano University (

https://www.cmic.polimi.it/en/ricerca/elenco-gruppi-di-ricerca/surfacelab/, accessed on 3 August 2023). Designed by the Efremov Institute of Electrophysical Apparatus (St. Petersburg, Russia) in collaboration with the Karlsruhe Institute of Technology (Germany), the ‘GESA’ PEB source is available in both Russia and Germany [

25,

26,

27]. One of the potential applications of the ‘GESA’ machine is the processing of gas turbine engine blades. The ‘SOLO’ PEB source has also been widely used for scientific purposes [

28,

29,

30,

31,

32]. It is an integral part of the ‘UNIKUUM’ complex of unique electrophysical equipment in Russia [

33] (

https://ckp-rf.ru/catalog/usu/434216/, accessed on 3 August 2023). The ‘TEU-500’ PEB source, developed at Tomsk Polytechnic University [

34,

35,

36], the ‘DUET’ one, developed by the Institute of High-Current Electronics [

37,

38,

39], and the ‘SINUS-7’ machine [

40,

41,

42,

43] are also of great interest for several scientific and technological applications.

As for the operating parameters of the PEBs described above, they are quite wide: the accelerating voltage U varies from 5 to 1000 kV, i.e., the minimum and maximum values differ by a factor of 200 times, while the pulse durations τ range from 0.05 to 300 µs, i.e., by a factor of 6000. As noted above, such PEB sources initiate thermal processes in targets that differ in parameters and dynamics; therefore, the classification of both PEBs and the initiated thermal processes is necessary. For this purpose, simple criteria are generally used: beams can be classified as continuous or pulsed, relativistic or non-relativistic, high or low current. All these criteria depend exclusively on the beam parameters and are independent of the target material type. It is interesting to consider more complex benchmarks that would make it possible to understand the nature of processes occurring under irradiation of a particular target and the possibility of using a beam for certain applications. Naturally, such criteria should depend not only on the beam parameters, but also on the target materials. The first aim of this research was to classify PEBs and briefly analyze the thermophysical processes occurring in a target based on one of these thermophysical criterion, which is called the heating type criterion. It depends on the parameters of both the beam and the target, and its definition is given below in the Theoretical background section.

In processing metallic materials with PEBs, the initial melting mode is well known, and has been widely applied in several practical purposes, such as surface smoothing or the detection of contaminants on the irradiated surface [

19,

23]. In this case, the first portions of the melt appear on the target surface. The mode of initial melting for a particular material is determined by the PEB parameters. However, the specific energy (power) absorbed by the target in the mode of initial melting, called the material melting threshold (MMT), is already a characteristic of the substance. Among other things, the MMT can be used as a kind of reference point for performing a comparative analysis of the effects of different PEBs on the same material. In turn, the second research aim was to analyze the temperature modes induced by PEBs in a wide range of their parameters, judging by the MMT level achieved.

3. Theoretical Background

Assuming that the surface layer of an irradiated target consists of a set of successively arranged parallel microscopic plates, the overall target area can be heated during a pulse duration τ in two ways: sequentially (1) or simultaneously (2). Sequential (plate-by-plate) heating (1) is caused by thermal conduction, when the heating front propagates at a certain speed from the surface into the target. Simultaneous heating (2) of many microscopic plates occurs as a result of the instantaneous input of energy into their integral area. According to solid-state physics, any such a plate is a local subsystem of nuclei located in an electron gas. Respectively, it can receive energy (be heated) either from nuclear subsystems of neighboring plates, which corresponds to sequential heating or through the excited electron shell of an atom upon instantaneous heating. It should be noted that neither heating mode is associated with mass transfer.

As mentioned above, mathematically, the difference between the two heating modes lies in the fact that energy (heat) propagates with a certain finite speed, sequentially heating layer by layer, in the first case, while a target is heated almost instantly throughout its entire volume in the second case, i.e., the energy propagation speed can be considered to be infinite. Therefore, the beam energy is completely released on the surface in the first case, and the thickness of the energy release layer

r is zero. In the second case, it is above zero, corresponding to the extrapolated particle range in the target. Therefore, it is heated with a surface source in the first case, but with a volume one in the second. It is clear that surface heating, when the extrapolated particle range in the target

r is zero, is a mathematical approximation, but in reality, energy is always released in a layer of finite thickness. However, if the thickness of the layer heated during a pulse via thermal conduction

is much greater than the extrapolated particle range

r in the target, then the heating source can be considered a surface one. Conversely, if it is much thinner, then the heating source is a volume one. Let’s introduce the

γ heating type criterion as follows:

The γ heating type criterion makes it possible to understand the nature of thermal processes occurring in a target of a particular material under irradiation with PEBs.

Obviously, the following three options are possible:

For the general notation of the heat equation, two auxiliary parameters and are added, which are equal to 0 for both γ ≫ 1 and γ ≪ 1 conditions, but are equal to 1 in all other cases.

It is known that a one-dimensional problem should be solved in order to calculate the

T(

,t) temperature at a point in a sample with a

radius vector at a

t time if the following condition is fulfilled:

where

D is the cross-sectional dimension of the homogeneous energy release region of an electron beam.

For most PEBs, the

D parameter can be considered as the diameter. Condition (6) means that the beam radius should be much larger than the thickness of the heated near-surface region during the observation of the process. If the beam diameter is greater than the size of the irradiated target, then this condition is satisfied for any

t values. In this case, the temperature fields

T(x, t) in targets irradiated with PEBs up to the initial melting modes can be calculated by solving the one-dimensional non-stationary heat equation:

with both initial and boundary conditions, the left of which has the form

where

is the heat source function or the volume heat source,

(t) is the surface heat source, and

l is the thickness of the target.

In the heat equation, the use of the auxiliary parameters and makes it possible to simplify calculations when considering edge cases. If γ≫ 1, i.e., heating is performed by a volume heat source, then , and the first term on the right side of Equation (7), as well as the right side of the Boundary Condition (8), are equal to zero. If γ ≪ 1 due to the application of a surface heat source, then and the second term on the right side of Equation (7) vanishes. In all other cases, the surface is heated with both and (t) heat sources during a pulse duration.

It should be clarified that the power density is understood to be that already absorbed by a target, but not emitted by an electron beam. It is clear that only part of the electron beam energy is absorbed under real conditions, while the rest is reflected. For elements with a low nuclear charge, the reflected part of the electron beam energy is low, but it may reach up to 40% for those characterized by high nuclear charge values [

47].

3.1. Heating with a Volume Heat Source

Let us consider the

γ ≫ 1 case in more detail, when Equation (7) is transformed into the following:

which is integrated easy

where

In this case, is the electron energy loss function normalized by its extrapolated range r (depth of penetration).

Substituting the

in Expression (11), it can be written as

and by combining Expressions (13) and (10), finally it corresponds to

Taking accelerating voltage

and the material specific heat capacity

in Expression (14), it has been rewritten as

It can be concluded from Expression (15) that the temperature is proportional to the area under the

j current density profile, and does not depend on its shape. Assuming

and considering the surface temperature by the end of a pulse (

, it can be stated that

As follows from Expressions (15) and (16), temperature variations in the surface layer are directly proportional to j current density, and inversely proportional to the square root of accelerating voltages U. Additionally, temperature is inversely proportional to the specific heat capacity of the target material and does not depend on its thermal conductivity. The surprise in these expressions is that temperature does not depend on material density, although the thickness of the energy release layer varies for different densities of the target material. The reason for this is the fact that the number of nuclei of a substance, to which the beam energy is transferred, remains unchanged when varying its density. On the one hand, the specific density of nuclei increases in direct proportion to the substance density, and temperature should decrease. On the other hand, the energy release volume decreases due to the inverse relationship between the electron range and the substance density. Thus, these two opposite tendencies compensate each other, and the temperature does not change, while the heated surface layer thickness varies in proportion to the substance density.

Equating

in Expression (16) and making some transformations, the following is obtained:

Formula (17) determines the threshold of the absorbed electron beam power density at which the melting temperature is reached on the target surface; in other words, this formula specifies the MMT in the volume heating case (at γ ≫ 1).

3.2. Heating with a Surface Heat Source

In the

γ≪1 case, Equation (7) is transformed into (18) with the left side of Boundary Condition (19):

If

(t) = const, then the solution of Equation (18) with Boundary Condition (19) has the following form [

48]:

Describing the thermal diffusivity

a in accordance with its definition and considering the temperature on the target surface by the end of a pulse, the following dependence can be written:

Equating

in Expression (21) and making some transformations, the following is obtained:

Formula (22) determines the threshold of the absorbed electron beam power density at which the melting temperature is reached on the target surface; in other words, this formula specifies the MMT in the surface heating case (at γ ≪ 1).

It can be concluded from Formula (22) that values depend, as a power function with a degree of 1/2, not only on thermal conductivity, but also on the other thermophysical properties of the target material, such as density and heat capacity. In addition, the melting temperature has the greatest influence on the MMT, according to the directly proportional relationship. On the basis of these general considerations, it is clear that the PPM should decrease with increasing pulse duration. It can be seen from the formula that this is the case, with the PPM falling with the root of the pulse duration. Therefore, an increase by a factor of 100 times lowers MMT by 10 times.

4. Results

Let us find a formula for the

γ heating type criterion in the case of target irradiation with PEBs. Firstly, a thickness

should be assessed for the layer heated via thermal conduction during a

τ pulse duration. It can be written based on the

condition and taking into account the temperature field Expression (20):

Then, substituting Formulas (23) and (12) into (4), the following dependence of the

γ heating type criterion can be obtained:

It follows from Formula (24) that γ values are the same if the condition is met. Thus, the pulse duration τ has to be increased by 8 times when the accelerating voltage U is doubled.

It should be noted that the dividend on the right side of Formula (24) depends solely on the PEB parameters, while the divisor only depends on the material properties. Thereby, the numerator and the denominator of Formula (24) are the abovementioned BF and MF, respectively. The calculated BF ranges for PEB sources are given in the fourth column of

Table 1, and the MF values for the studied metals are presented in the last column of

Table 2. If BF is numerically equal to MF, then

γ = 1, which means that the contributions from the volume and surface sources are equal, i.e., the heating type is volume–surface, or mixed. Accordingly, if the dividend is much larger or smaller than the divisor, then the heating type is volume or surface, respectively.

Thereby, in accordance with Condition (5) and Formula (24), the ‘BF–MF’ phase space can be divided into three regions Z1–Z3, which correspond to the volume, mixed and surface heating types, respectively. All of them are highlighted in different colors in

Figure 1. In the Z2 central region, there is a dotted line corresponding to the

γ heating type criterion of 1. In addition, dashed lines are plotted in

Figure 1, limiting the range of BF changes for each of the PEB sources given in

Table 1. The dashed lines should extend over the entire MF range, but they are limited to small segments in order not to clutter the drawing. Between the dashed lines limiting each BF range, the corresponding PEB source name is given.

It follows from

Figure 1 that the PEB sources fall into different Z1–Z3 phase space regions, while, depending on its parameters and the type of target, the same PEB can be located in several areas. Therefore, the ‘RITM’ and ‘SOLO’ PEB sources are in the Z3 region, i.e., their heating sources are of the surface type for almost all target materials. However, part of the dotted line of the upper ‘RITM’ PEB source range is in the mixed heating region. This means that the heating source is of the mixed type for the Ti, Mg and Al targets at accelerating voltages

U in the upper parts of the range. The ‘GESA’ and ‘DUET’ PEB sources are in the Z2 mixed heating region. Nevertheless, both the ‘GESA-1’ and ‘DUET’ PEB sources can be considered to be of the surface type in the lower energy range at high pulse durations

τ for most target materials, except for Ti and Mg. The ‘TEU-500’ and ‘SINUS-7’ ones fall into the Z1 volume heating region, but ‘TEU-500’ PEB source is in the region of mixed heating when irradiating W.

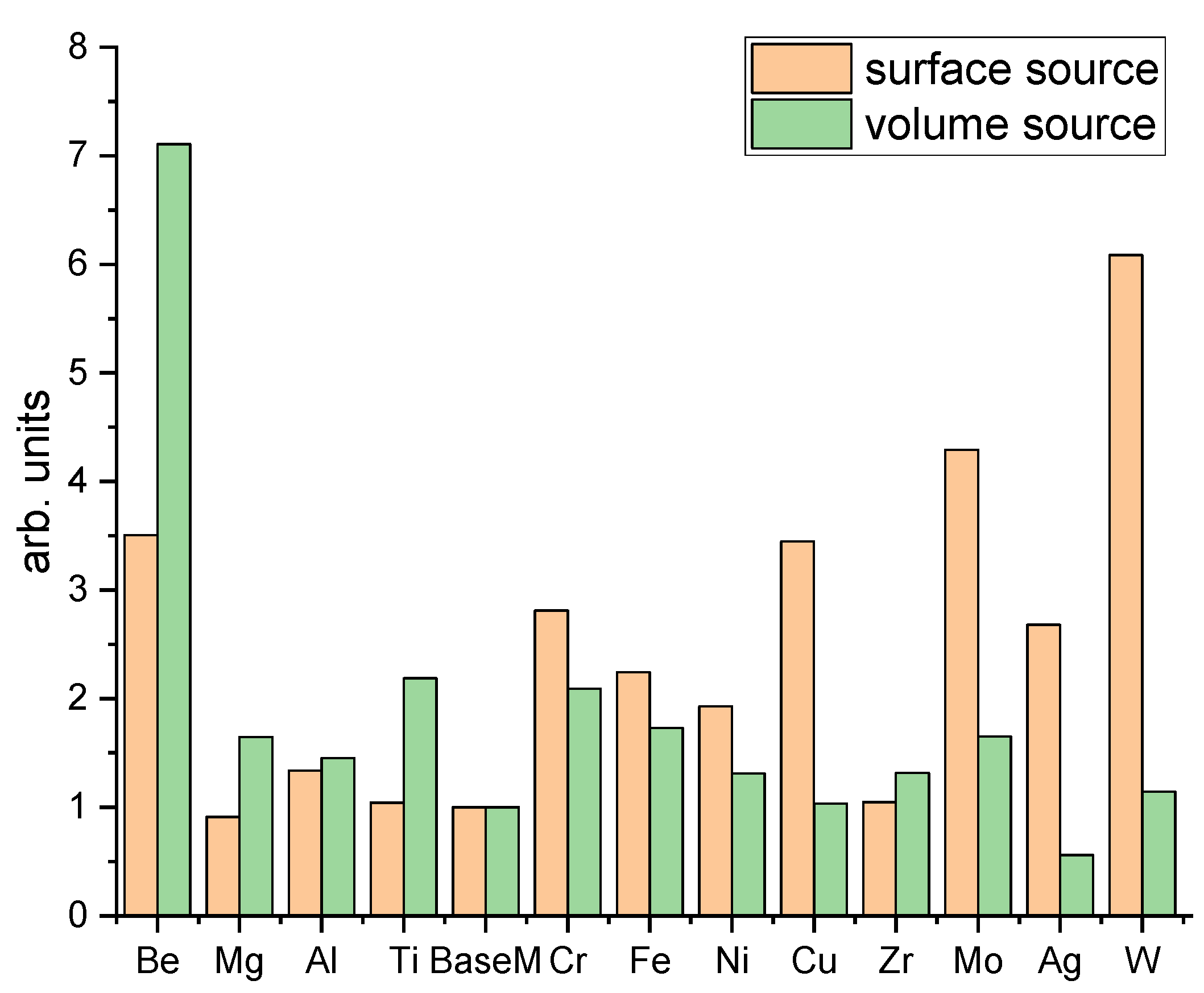

The

and

values, given by Formulas (17) and (22) for the

γ ≫ 1 and

γ ≪ 1 cases, respectively, depend both on the material thermophysical properties and on the PEB parameters. It has been of interest to calculate the contribution of the material thermophysical properties to MMT, i.e., the parts of the formulas in square brackets. The obtained results are shown in

Figure 2. The left (yellow) columns refer to the pulsed surface heating, while the right (green) columns reflect the pulsed volume one. The data are given in relative units, normalized to the contributions to the MMT values for the BaseM material, which are numerically equal to 1.13 × 10

7 and 3.92 × 10

5 for the

γ ≪ 1 and

γ ≫ 1 cases, respectively.

The contributions of the material thermophysical properties to the MMT values for the surface heating case have a wide range: from 0.9 for the most fusible Mg in this series of materials up to 6.1 for the most refractory W. In the volume heating case, this spread is noticeably lower: from 0.6 for Ag up to 2.2 for Ti, with the exception of Be, which contribution is 7.1.

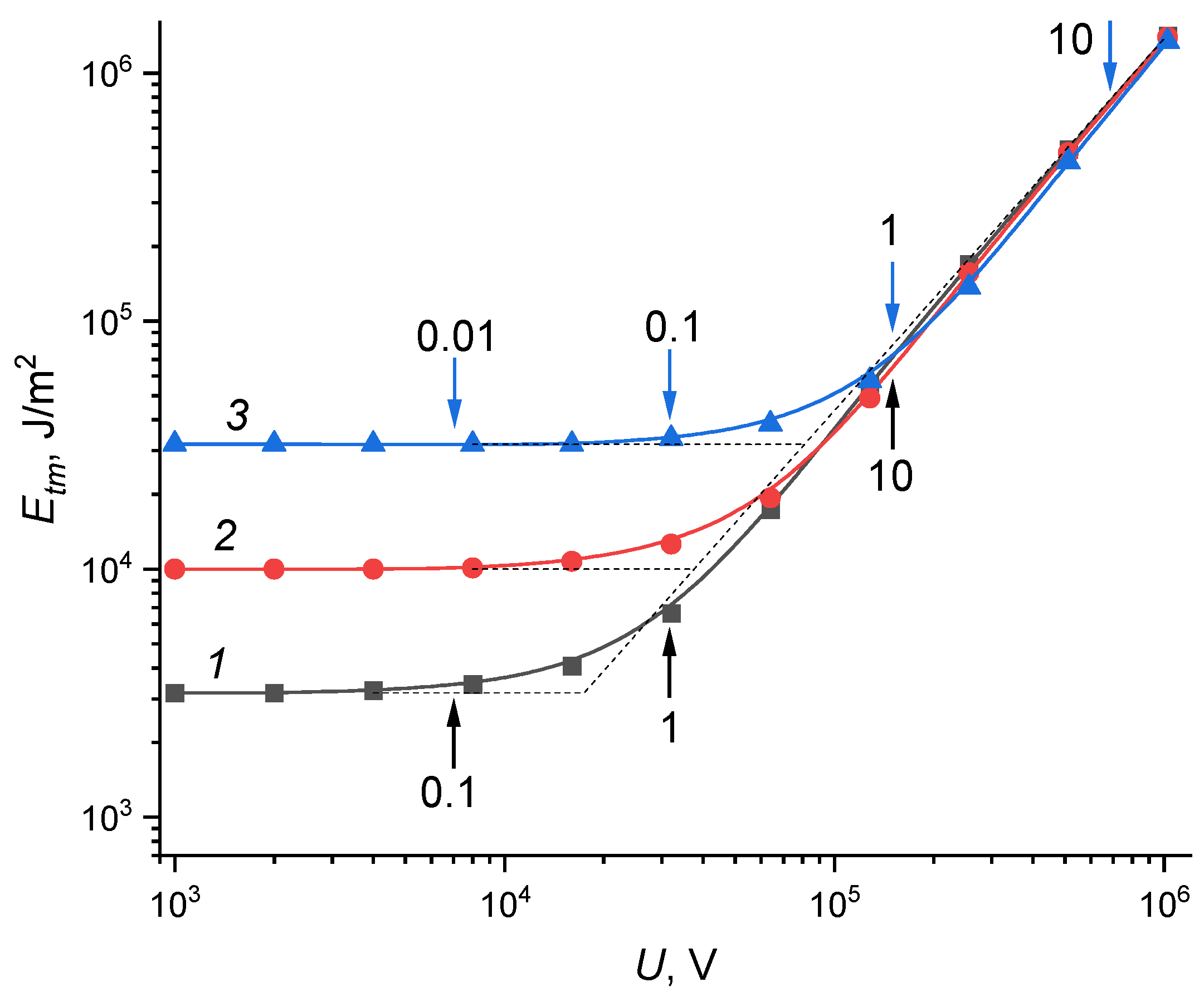

Since MMT depends on the

U accelerating voltage as the

power function for the

γ ≫ 1 case according to Formula (17), it has been interesting to follow the change in both EMMT and MMT over the entire

U range of the studied PEB sources.

Figure 3 shows the calculated EMMT curves obtained using the ‘HEATPACK-1.0’ software package for the BaseM material at three different pulse durations

τ. Additionally, dashed lines indicate curves calculated using Analytical Formulas (17) and (22) for the

γ ≫ 1 and

γ ≪ 1 cases, respectively. In addition, arrows indicate the points on the curves corresponding to certain

γ values. It can be concluded that the agreement between the calculated and analytical curves is satisfactory.

It follows from

Figure 3 that the EMMT changes by an order of magnitude with increasing pulse duration

τ, from 3.2·10

3 J/cm

2 at

τ = 0.1 µs to 3.2·10

4 J/cm

2 at

τ = 10 µs, at low

U values. However, the difference between the EMMT levels decreases with increasing

U accelerating voltage, and they cease to depend on the

τ pulse duration starting from a certain

U value.

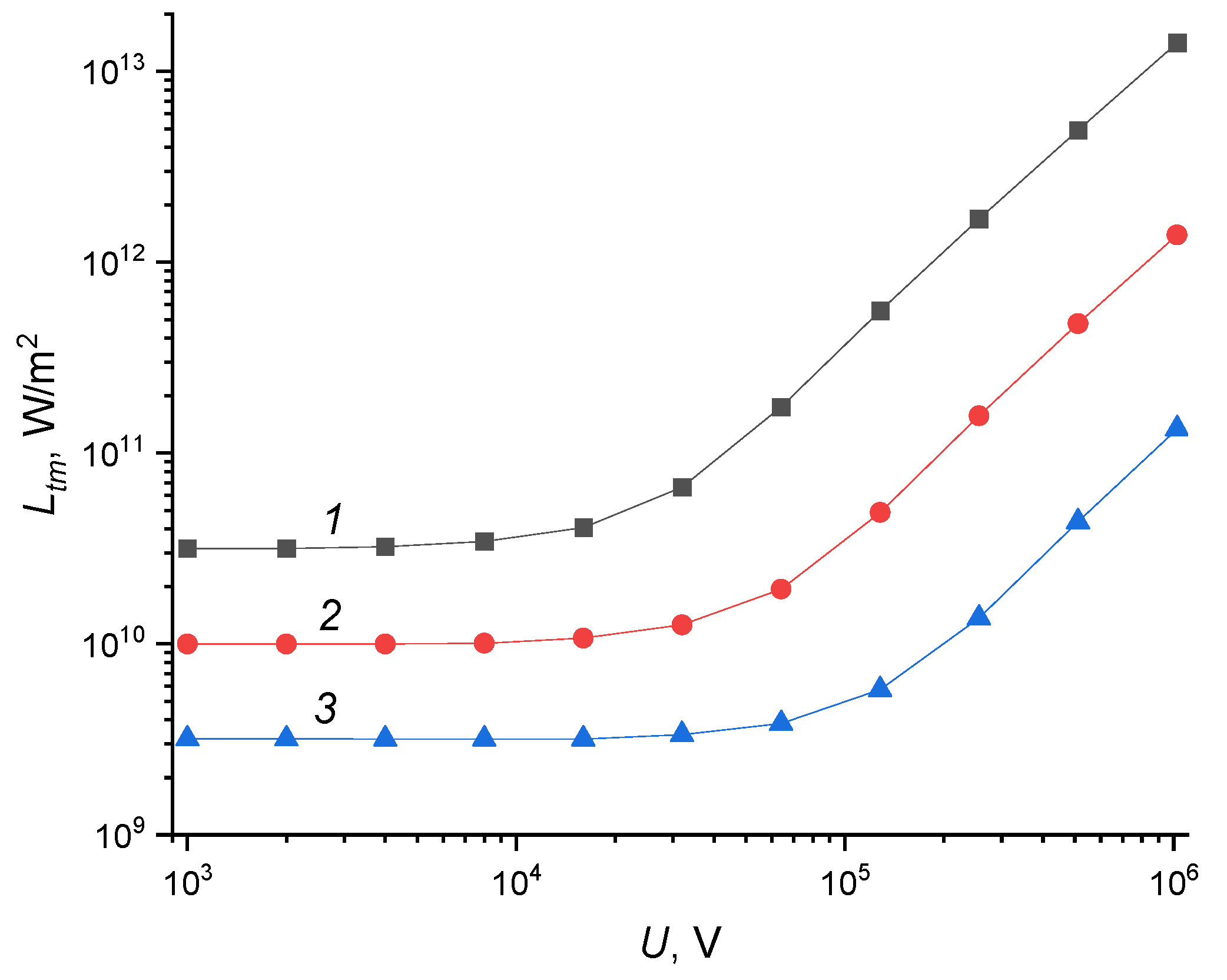

Figure 4 shows the calculated MMT curves for the same pulse durations

τ as in

Figure 3. It can be concluded from these data that the MMT behavior is completely different: the variations between its levels do not decrease, but increases when increasing the accelerating voltage

U. In contrast to EMMT, MMT reduces when increasing the pulse duration

τ.

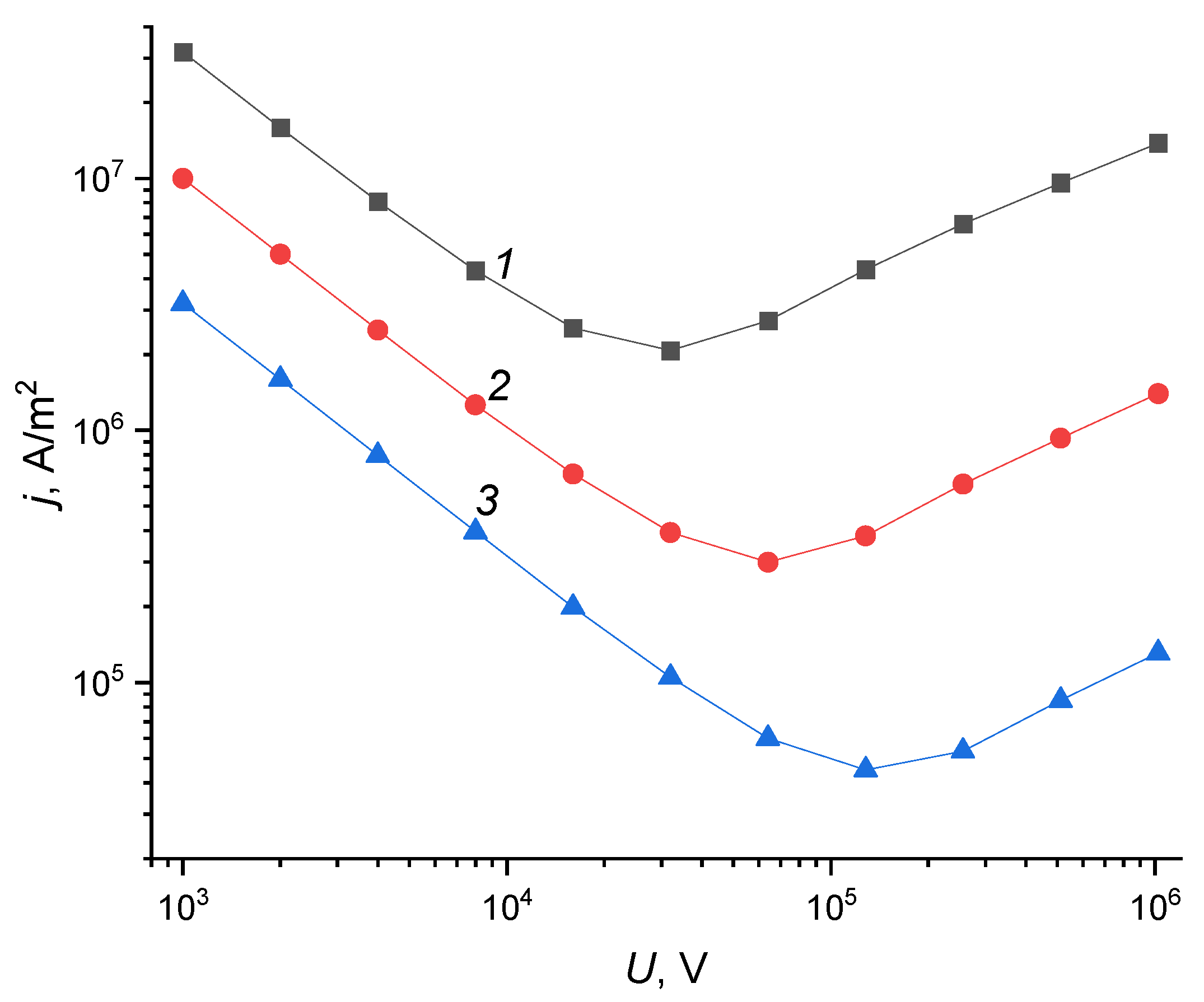

At a given accelerating voltage

U, the MMT can only be achieved by adjusting the current density

j. Such

U(

j) relationships, called current–voltage dependences (CVDs), are shown in

Figure 5. They were calculated for the same cases as presented in

Figure 3 and

Figure 4. The left branch of the CVDs is decreasing, i.e., to increase the

U accelerating voltage, we should reduce the current density

j. The reason for this is that at

γ ≪ 1, the

values do not depend on the

U accelerating voltage. In turn, the temperature field is only determined by the energy density of the surface source. To keep the energy input constant as the

U accelerating voltage is increased (

Figure 4), the

j current density should be proportionally reduced. The right branch of the CVDs is increasing, i.e., when enhancing the

U accelerating voltage, the

j current density should also be risen. This is explained by the fact that an increase in the

U accelerating voltage enhances the electron range and the heated layer thickness at

. It follows from Formula (17) that the

j current density should increase as

with increasing accelerating voltage

U. Therefore, the inclination angle of the left branch of the CVDs is greater than that of the right one. Tracing the relationship between the CVD behavior and the

γ values, it turns out that

for

γ = 1.

5. Discussion

In this section, the author discusses in more detail some of the interesting results presented above. For example, Formula (22) was obtained from the solution of the heat equation, which determines the MMT for the surface heating case (

γ ≪ 1). This formula can be written without solving differential equations, but from a simple energy balance condition. For this purpose, the amount of heat

Q necessary for melting a layer with the thickness

x should be assessed:

where

s < D is the heated area of the sample face.

Dividing the left and right parts by

sτ and substituting in (25) the estimate for the heated layer thickness

x = 0.5

, where

is determined using Formula (23), the MMT dependence can be written as:

Since the assumption made that the entire layer of the thickness x is heated to the melting temperature, Formula (26) gives the upper MMT estimation. Meanwhile, Formula (22) reflects real MMT values, considering that a temperature distribution inside the heated layer of the thickness x is non-uniform. The heated surface actually reaches the melting point; however, temperature decreases with increasing depth, and is lower at the x coordinate. The difference between the exact and approximate formulas, as can be concluded from their comparison, does not depend on either the PEB parameters or the material properties. Approximate Formula (26) always overestimates by ≈11%. This fact indicates that the layer of the thickness x is actually heated up to high temperatures close to the melting point by the end of a pulse. In addition, thermal heating turns out to be strongly localized near the surface, since the temperature drops sharply with increasing depth, and is already an order of magnitude lower than the melting point at a depth of 2x.

Discussing

Figure 1 in more detail, it should be noted that the ‘BF–MF’ phase space regions can be used for a simplified classification of PEBs. Indeed, PEBs falling into one or another region of the phase space makes it possible to draw conclusions not only about the possibility of using certain approaches to calculate temperature fields in targets, but also about their potential applications. Thus, PEBs that fall into the surface heating region are mainly applied to modify metallic surfaces and form surface alloys. Accordingly, they are not suitable for sterilizing medical materials. Conversely, PEBs from the volume heating region cannot be used for surface modification, since they are factually suitable for the sterilization of liquids, the fracture of solids, or microwave generation. Those from the mixed heating region, depending on another parameter, namely the current density

j, can be used in a large number of applications, such as surface modification, initiation of radiation–chemical transformations, and disinfection of biological materials.

Therefore, the ‘BF–MF’ phase space regions, drawn on the basis of the γ heating type criterion, made it possible to understand not only the nature of the thermal processes occurring under the irradiation of a particular target, but also the possibility of using PEBs for certain applications. The γ heating type criterion is referred to as complex because it depends not only on the PEB parameters, but also on the target material.

The contributions of the material thermophysical properties to MMT were considered above (

Figure 2), but this parameter is more interesting as a whole, when also taking into account the PEB parameters. In the surface heating case (

γ ≪ 1), MMT is described using Formula (22). This formula, in addition to the term in square brackets, which reflects the contribution from the material thermophysical properties, includes the

constant and the contribution from the PEB parameters, which is defined as the pulse duration

τ with a power of −1/2. Assuming

τ = 10

–6 s, it can be seen that MMT is equal to the contribution of the material thermophysical properties in relative units (according to

Figure 2), multiplied by 10

10 W/m

2. For Mg and W,

and

W/m

2, respectively. Considering Formula (1), EMMT can also easily be assessed for each metal. In the surface heating case at

γ ≪ 1 and a pulse duration

τ of 10

–6 s, EMMT appears to be equal to the contribution of the material thermophysical properties, i.e., the height of the left (yellow) columns in

Figure 2. Therefore, from the diagram, it can easily be seen, for instance, that

and

J/cm

2 for Mg and W, respectively.

For the

γ ≫ 1 case, the contribution to MMT of the PEB parameters is determined not only by the pulse duration

τ, but also by the accelerating voltage

U, according to Formula (17). Therefore, it is easier to consider a formula for EMMT, since, taking Formula (1) into account, Formula (17) can be rewritten in a convenient way without the dependence on the pulse duration

τ:

In Formula (27),

f(0) = 0.9 [

34]. The contribution of the PEB parameters is defined by the accelerating voltage

U, with a power of 3/2. At

U = 10

6 V, the contribution of the PEB parameters to EMMT, multiplied by the

−17/2 constant, is 3.5, and EMMT is 1.372·10

6 J/m

2 for the BaseM material. To assess EMMT for another metal, this value should be multiplied by the contribution from the material’s thermophysical properties, i.e., the height of the corresponding right (green) column in

Figure 2. At

U = 10

6 V, EMMT values lie in the range (0.77–9.74)·10

6 J/m

2 for all metals, i.e., they vary by an order of magnitude. When the accelerating voltage

U changes by 10 times, EMMT varies proportionally by

≈ 31.6 times.

Therefore, EMMT values can be considered for different materials as a function of the accelerating voltage U. To calculate MMT, Formula (1) should be used, and the obtained EMMT values should be divided by the pulse duration τ.

Figure 2 is useful in that it demonstrates the different behavior of MMT between surface and volume heating types. For surface heating, the most refractory of the considered materials are W, Mo, and Be, while in the volume heating case these are Be, Ti, and Mg. The latter two are simultaneously the most fusible ones in surface heating.

The behaviors of the most refractory, W, and the most fusible, Mg, are especially impressive. Indeed, a 6.8 times higher energy density is needed to melt W when using surface heating. However, the situation changes radically when considering volume heating. The PPM of Mg is almost 1.5 times higher than that of W. This is explained by the fact that the specific heat capacity of the former is almost 5.5 times higher than that of the latter, but during volume heating, it is the specific heat capacity that makes the key contribution to the MMT among the material thermophysical properties.

Figure 2 also shows that

Be is the key material for the pulsed power technologies, which ranks third and first in terms of refractoriness for the surface and volume heating types, respectively. In pulsed volume heating, the MMT for Be is 3.2 times higher than that for Ti, which occupies the second place.

To facilitate the selection of materials for the design of one or another component of the operating electron-beam equipment, which are simultaneously subjected to both surface and volume heating, it can be proposed that a general series of refractoriness of metals in pulsed heating can be formed by multiplying EMMT (for both

γ ≪ 1 and

γ ≫ 1 cases). The obtained results are shown in

Figure 6. The series classifies the metals not only with respect to the complexity of the heating of the surface layer up to the melting point, but also in terms of their ability to accumulate heat upon processing. Therefore, Be can absorb a relatively large amount of heat while remaining at a rather low temperature. Its closest competitors are Mo, W, and Cr, which are significantly (by 3.5–4.2 times) inferior in this respect.

Figure 3 shows the changes in the EMMT behavior for different pulse duration

τ with increasing accelerating voltage

U. Based on Formulas (1) and (22), EMMT can be written as follows for the surface heating case:

At low

U values, EMMT is described by Formula (28), but it is described by Formula (27) at high

U levels. The reason for which, at low voltages, i.e., at

γ ≪ 1, the EMMT increases with increasing pulse duration is clear. The longer the pulse, the more energy is able to propagate deep into the bulk, and the more it needs to be delivered to the near-surface layer to compensate for heat removal. At high

U, when the

γ ≫ 1 condition is satisfied, heat conduction is excluded from the energy propagation mechanisms; therefore, all of the energy released into the surface layer remains there, and heat removal into the bulk does not occur. Accordingly, only the fact of the energy accumulation becomes important, regardless of the pulse duration

τ. It is possible to input either a large amount of energy within a short period of time, or a small amount of energy over a long period of time (see

Figure 4).

Moreover,

Figure 3 presents a good algorithm for satisfactorily estimating EMMT for any materials and any PEBs. It suffices, using Analytical Formulas (27) and (28), to draw two straight lines, which, as can be seen, describe EMMT well in all ranges, except for the interval

γ ∊ [0.1;1]. Regarding this interval, EMMT can be predicted using any known interpolation method.

Returning again to the current–voltage dependences shown in

Figure 5, the following should be noted. It is surprising that some conclusions can be drawn regarding the nature of the thermal processes occurring only by changing the PEB parameters and observing the target surface, with no data available on the thermophysical properties. Namely, when the left side of the CVDs deviates from direct proportionality, the heat source ceases to be surface and becomes mixed. However, the heat source should be considered volume when CVD passes through the point

, in accordance with

Figure 3. In essence, CVDs can be seen as a practical guideline for operators of various PEB sources to determine

j current densities that provide MMT at a given accelerating voltage

U.

In this study, all of the above results concerning surface heat sources are true not only for PEBs, but also for other pulsed beams (laser, ion and plasma), if their parameters satisfy the

γ ≪ 1 condition [

49,

50,

51]. However, Formula (24) is not applicable in such cases, since the particle range is expressed not by Formula (12), but by another one corresponding to their type.

It should be noted that this paper is devoted not so much to the development of any theoretical model for calculating temperature fields and melting thresholds of materials, since the implemented one is based on the well-known one-dimensional non-stationary heat Equation (17). Rather, it focuses on a methodological approach to the use of a specific PEB source for certain industrial applications. The presented list of PEB sources can be expanded. Accordingly, the range of BFs for additional ones should be calculated using Formula (1). Then, the calculated BF lines should be plotted on

Figure 1 in the ‘BF–MF’ phase space. This makes it possible to understand which of the Z1–Z3 regions, corresponding to the mixed volume or surface heating source, correspond to these PEBs. In other words, a range is determined for the

γ type of heating criterion for certain PEB sources. As discussed above, firstly, this makes it possible to draw conclusions about the possibility of using PEBs for the required applications. Secondly, the relative MMT and EMMT values for these PEB sources can be directly estimated (without calculations) using the data shown in

Figure 2. Moreover, through multiplication of the coefficients presented in Formulas (17), (22), (27), and (28), real (not relative) values of MMT (for γ ≫ 1 and γ ≪ 1 cases) and EMMT (for cases γ ≫ 1 and γ ≪ 1), respectively, can be determined.

Experimental verification of the presented analytical model and the calculated results is an important component of this study. However, it should be stated that such examinations are a separate and very difficult task. Nevertheless, it is possible to test the accuracy of the presented model using previously published data. For example, in [

52], the experimentally determined EMMT values for bulk Cu and 316 stainless steel were 5.0–5.5 and 2.0–2.5 J/cm

2, respectively. In this case, irradiation was carried out with a PEB source with parameters close to those for the ‘RITM’ PEB source, at a pulse duration

τ of ≈ 2.5 µs. It follows from

Figure 1 that this case corresponds to the

γ ≪ 1 range.

Figure 2 shows that the EMMT value for Cu (yellow column) is 3.45 J/cm

2 at

τ~1.0 µs. In accordance with Formula (28), and taking into account that the experimental value of

τ is 2.5 times greater, it is necessary to multiply the EMMT value by

. As a result, we get EMMT ≈ 5.45 J/cm

2 for Cu, which correlates well with the experimental data.

For the 316 stainless steel, the EMMT value is more difficult to determine because this material is not represented in

Figure 2. Nevertheless, an estimation can be determined, given that all properties of this steel are close to those of pure iron (except for thermal conductivity, which is approximately four times lower). It follows from

Figure 2 that the EMMT value of Fe (yellow column) is 2.24 J/cm

2 at

τ~1.0 µs. As in the previous case, it is necessary to multiply this value by

, in accordance with Formula (28). Considering that the thermal conductivity is four times lower, it should be also divided by two. As a result, EMMT ≈ 1.77 for the 316 stainless steel, which is in satisfactory agreement with the experimental data.